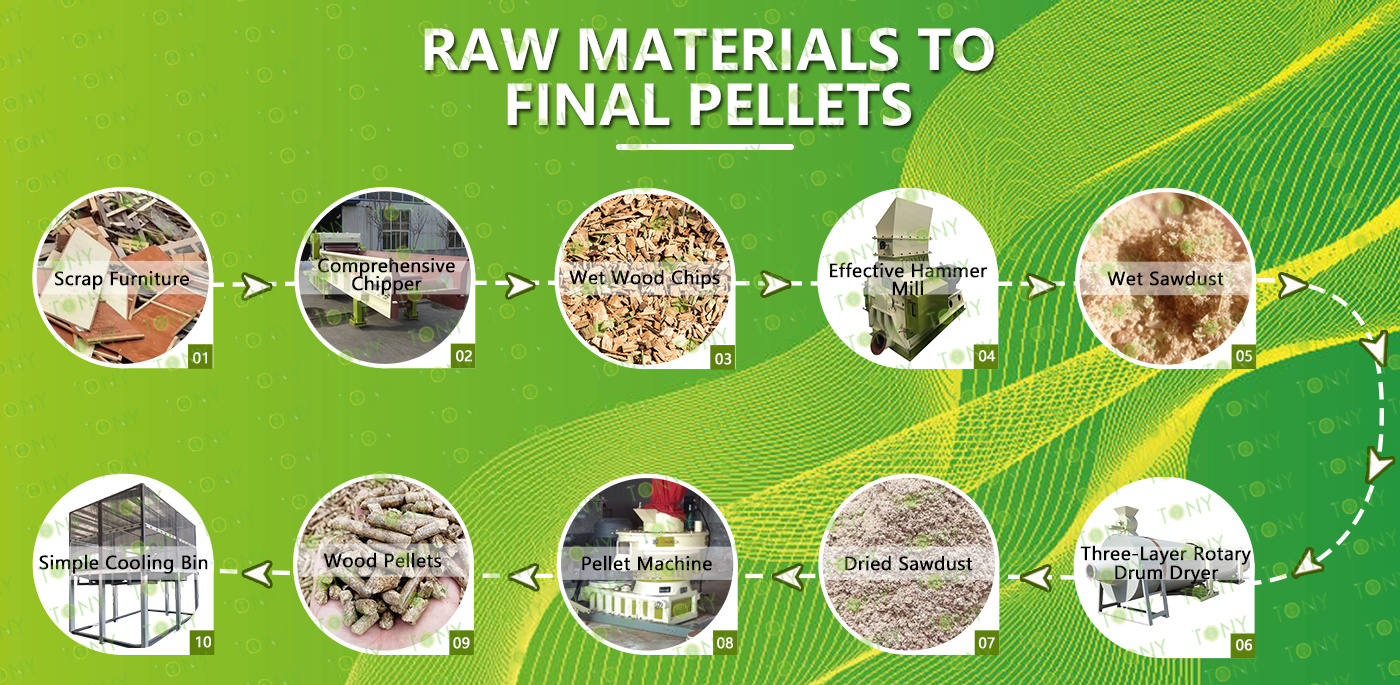

Hello, everyone. Today, we introduce a complete 7.5-9 tons of Scrap Furniture pellet production line installed by TONY for the customer.

The customer's raw material is furniture waste, the moisture is about 40%, the customer ordered our 3 sets of TYJ-760 pellet machine, the power of a single pellet machine is 160kw, the main processing process: crushing, fine crushing, drying, pelleting, cooling and packaging process

|

1. Crushing Process: The buyer uses our TPC1300 comprehensive wood chipper to grind the furniture waste into 35mm-45mm wet wood chips 2. Fine Crushing Process: Through the effective hammer Mill -TFS75*160 model, the wet wood chips of 35mm ~ 45mm are crushed into wet sawdust of 10mm ~ 14mm 3.Drying Process: Through the Three-Layer Rotary Drum Dryer, the wet sawdust with a water content of about 40% is dried into 10-15% dry sawdust to meet the requirements of granulation 4. Pelleting Process: Dry sawdust is physically extruded into 6-8mm rod-like pellets by TONY Pellet machine TYJ-760-model 5. Cooling Process: The finished particles are transported to a simple cooling bin of 100m³, which is built and welded by the buyer locally to store and cool the particles. Packaging equipment can be connected to the bottom of the simple cooling bin |

2025 Tony Machinery - All Rights Reserved. Map