1.图片

Project Brief Introduction:

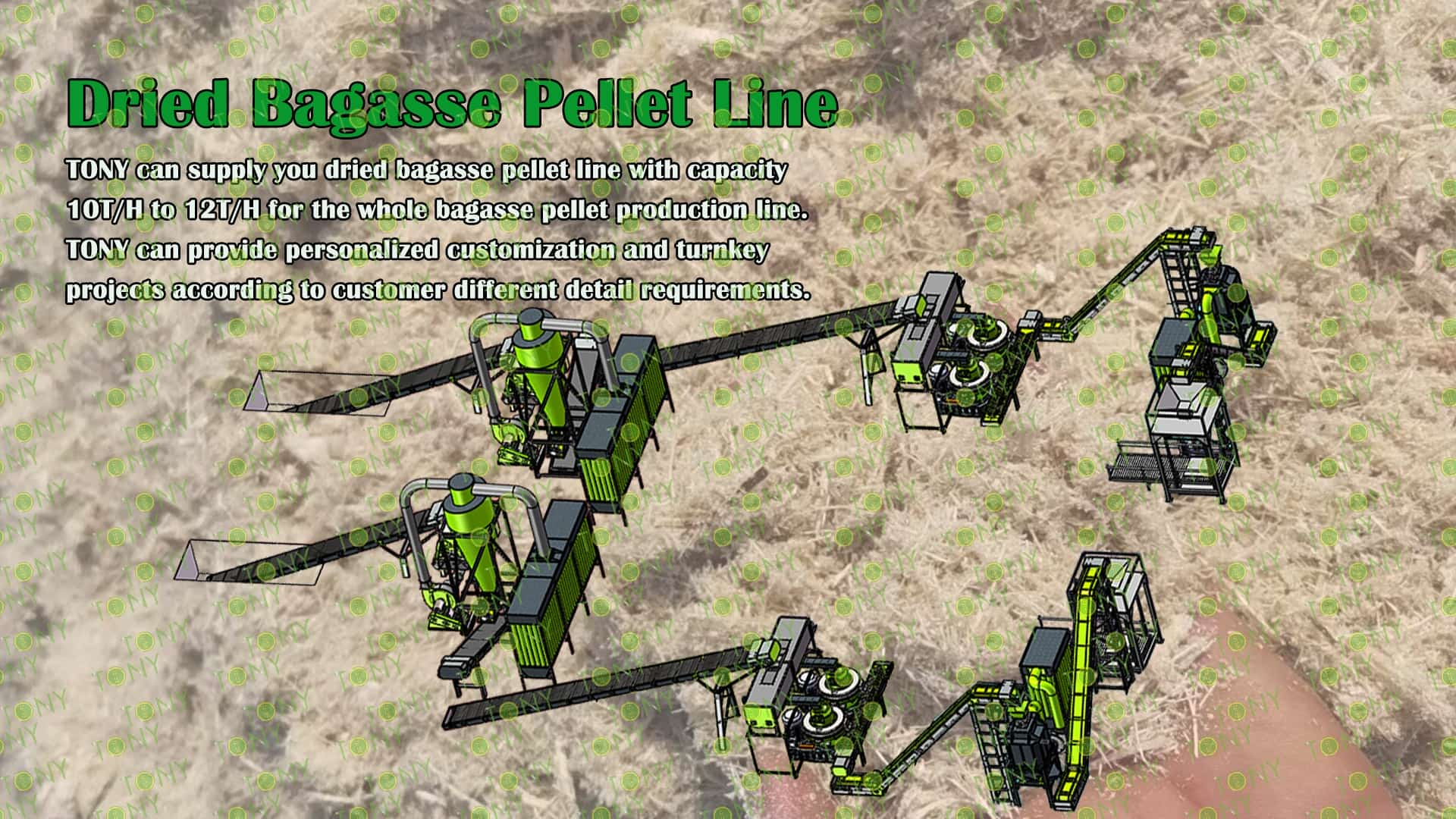

1.Product:Dried Bagasse Pellet Line

2.Capacity: 10-12T/Hour

3.TONY Brand 10-12Ton /Hour Dried Bagasse Pellet Line Project Process

4.Main Machine:Hammer Mill,TONY Pellet Machine TYJ760-Ⅲ-160kw,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

原材料图+颗粒机图片

1. The working principle of dried bagasse biomass pellet processing equipment

The principle behind the dry bagasse biomass pellet processing equipment is the coupling of mechanical forces (extrusion and shearing) and thermal energy (frictional heat and external heating). Mechanical force narrows interfiber gaps and shapes the pellets, while thermal energy softens the fibers and activates natural binders, ultimately transforming the loose bagasse into high-density, highly stable biomass pellets. This entire process eliminates the need for chemical binders, ensuring the pellets' environmental friendliness while fully utilizing the fiber properties of bagasse, effectively repurposing agricultural and forestry waste.

2. Characteristics of dried bagasse biomass pellet processing equipment

(1) Strong adaptability of raw materials and cost reduction No need for complex pre-treatment: The equipment can directly process sugarcane bagasse without additional drying, reducing the pre-processing steps. Extremely low raw material cost: Sugarcane bagasse is an agricultural waste with a wide range of access channels, low prices, and can even be recycled for free, which greatly reduces the raw material cost of biomass pellets.

(2) Significant energy consumption and environmental protection advantages Low energy consumption: Some equipment (such as ring die pellet machines) can use the fiber friction of sugarcane bagasse to generate heat during the pressing process to assist in material molding and reduce external heating energy consumption. Comply with environmental protection standards: There are no pollutant emissions during the processing process, and the carbon emissions of the biomass pellets produced are much lower than those of coal when burned. They can replace fossil fuels and help enterprises or regions achieve the "dual carbon" goals.

(3) High molding efficiency and stable product quality High molding rate: The equipment's pressing pressure is adjustable, and the parameters can be optimized according to the fiber characteristics of sugarcane bagasse. The pellet molding rate can reach more than 90%, reducing raw material waste. Stable product performance: The biomass pellets produced have high density (typically 1.1-1.3g/cm³), stable calorific value (approximately 16-18MJ/kg), are easy to store and transport, and have strong market applicability.

3. Application scenarios of dried bagasse biomass pellet processing equipment

(1) Industrial sector: It can replace coal for boiler heating in sugar mills, paper mills, and food processing plants, or as fuel for biomass power plants (a cycle of "sugarcane - sugar production - sugarcane bagasse pellets - power generation/heating");

(2) Civilian sector: It can be used for household heating stoves, biomass cookers, or as heating fuel for small and medium-sized farms and greenhouses;

(3) Environmental protection sector: It can be incinerated in conjunction with sludge, landfill leachate, etc., using its calorific value to assist in the treatment of solid waste and reduce treatment costs.

(4) Livestock sector: When fresh grass is scarce in winter, small and medium-sized farmers can purchase sugarcane bagasse pellets as reserve feed.

2.图片

TONY Brand 10-12 Ton/Hour Dried Bagasse Pellet Manufacturing Plant can take dried bagasse as the main raw material. After pretreatment and processing, it is solidified into high - density Bagasse pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bagasse resources.

1. Capacity: 10-12 Ton/Hour

2. Raw materials: Dried bagasse

3. Moisture: dried type, about 10-15%.

4. Application: All kinds of bagasse materials suitable for pellet production.

Suitable customers: Sugarcane processing factories are the direct output of bagasse, such as sugar mills, sugarcane ethanol factories, sugarcane pulping factories, etc.; centralized storage and transit places, such as sugar mills, ethanol factories, agricultural product processing parks, where multiple sugarcane processing factories often gather to form a park. The storage and transit areas of bagasse are uniformly planned within the park, and the resource concentration is extremely high.and other places where bagasse raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3.图片

图片

原材料--成品图

1. Project Name: Dried Bagasse Pellet Production Line

2. Raw Material: All kinds of dried bagasse

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 10-12 tons per hour

5. Process: Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD75*160-160kw, TONY Pellet Machine- TYJ760-Ⅲ-160kw, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

4.图片

|

How to use the TONY pellet production line to make pellets from dried bagasse? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the slightly larger bagasse into 8-14 mm bagasse.If customer has enough Investment budget,he can also chose TONY Special Cutting Machine for bagasse which will be more expensive than the hammer mill. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

流程图1

流程图2

5.图片

原材料+颗粒图

颗粒+机器图

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

| Effective Hammer Mill | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

| 1.To Crush Larger Bagasse Into 8-14mm Baggase. 2.Model: TFD75*160-160KW*2sets 3.Capacity: 5-6 Ton/Hour/Set |

1.To Stroage Bagasse Before Pellet Machine; Adjust The Speed Of Bagasse Entering The Pellet Machine 2.Model: TLC-6*2sets 3.Capacity:5-6 Ton/Hour/Set |

1.To Press Dry Bagasse Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-160KW*4sets 3.Capacity:2.5-3 Ton/Hour/Set 4.New 304SS Type |

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*2sets 3.Capacity:10-12 Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags 2.Model: TBD*2 sets 3.Capacity: 10-12 Ton/Hour |

1.Transport Bagasse,Pellets. 2.Width: 80cm*12 Sets 3.Capacity:Designed With The Whole Line |

三维图

5.1图片

高效粉碎机

带锯末图

1.Bagasse Fine Crushing Process:

A.This process is mainly used to crush larger bagasse into 8-14mm bagasse.

B.Capacity:10-12 Ton/Hour.

C.TONY brand effective hammer mill TFD75*160-160kw*2sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.2图片

颗粒机四件套带 原材料,颗粒图

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:10-12Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-160kw*4 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

5.3图片

镀锌冷却仓加颗粒图

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:10-12 Ton/Hour.

C.TONY brand galvanized pellets cooler *2 sets

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.4图片

吨包机

4.Packing Process:

A.This process is mainly used to pack pellets into 1 Ton/Bags.

B.Capacity:10-12 Ton/Hour.

C.TONY brand ton packing machine*2 sets

Main Parts:

(1)TONY Ton Packing Machine

(2) Electronic Platform Scale Metering System

(3) Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

6.图片

客户生产线案例图

7.图片

图 干甘蔗渣+颗粒 颗粒机

Raw Material Security: The Key to Project Feasibility

Dry sugarcane bagasse raw material is the lifeblood of the project and must meet three key requirements: stable source, manageable costs, and satisfactory quality.

1. Raw Material Type: Primarily waste from sugarcane processing, dry sugarcane branches pruned from sugarcane plantations, and sugarcane roots. The raw material must maintain a moisture content of 10%-18% (overdrying can cause dust, while overwetness can clog equipment. Excessively wet raw material requires drying equipment) and be free of hard impurities (such as nails and metal parts to prevent damage).

2. Raw Material Cost: Proximity to sugarcane product clusters offers lower raw material purchase prices (some small sugarcane processing plants can obtain it free of charge, requiring only transportation costs).

3. Transportation Radius: To control costs, the recommended raw material transportation radius should not exceed 50 kilometers (exceeding this radius increases transportation costs).

8.图片

干甘蔗渣图 颗粒图

Bagasse pellets offer nutritional and feeding advantages as feed—they meet the needs of ruminants and improve breeding efficiency.

Through optimized processing, bagasse pellets can better meet the physiological needs of ruminants such as cattle and sheep, resolving the issues of bagasse's poor palatability and difficulty in digestion.

1. High Fiber Suitable for Ruminant Digestion: Bagasse contains 40%-50% crude fiber and is rich in lignin and hemicellulose, perfectly matching the rumen digestive needs of ruminants such as cattle and sheep. It can serve as a high-quality roughage, promoting rumen motility, reducing indigestion and rumen indigestion, and improving livestock and poultry health.

2. Improved Palatability and Digestibility: During processing, crushing (to a particle size of 2-3mm) and conditioning (adding molasses and urea) softens crude fiber and improves taste. This results in a 20%-30% increase in feed intake for cattle and sheep compared to feeding raw bagasse directly. Furthermore, the high-pressure extrusion process partially destroys the fiber structure, making it easier for rumen microorganisms to break it down, increasing crude fiber digestibility by 15%-20% and minimizing feed waste.

3. Customizable Nutrition: The formula can be adjusted based on the type of animal (e.g., calves, fattening cattle, dairy cows). For example, soybean meal can be added to increase protein content (from 2%-4% to 8%-10%), and minerals can be added to meet the needs of different growth stages. This addresses the nutritional limitations of raw bagasse, often characterized by its monotonous nutrition, and meets diverse farming needs.

9.图片

绿色地球+原材料+颗粒图

10.图片

11.图片

公司展会图

2025 Tony Machinery - All Rights Reserved. Map