1.图片

Project Brief Introduction:

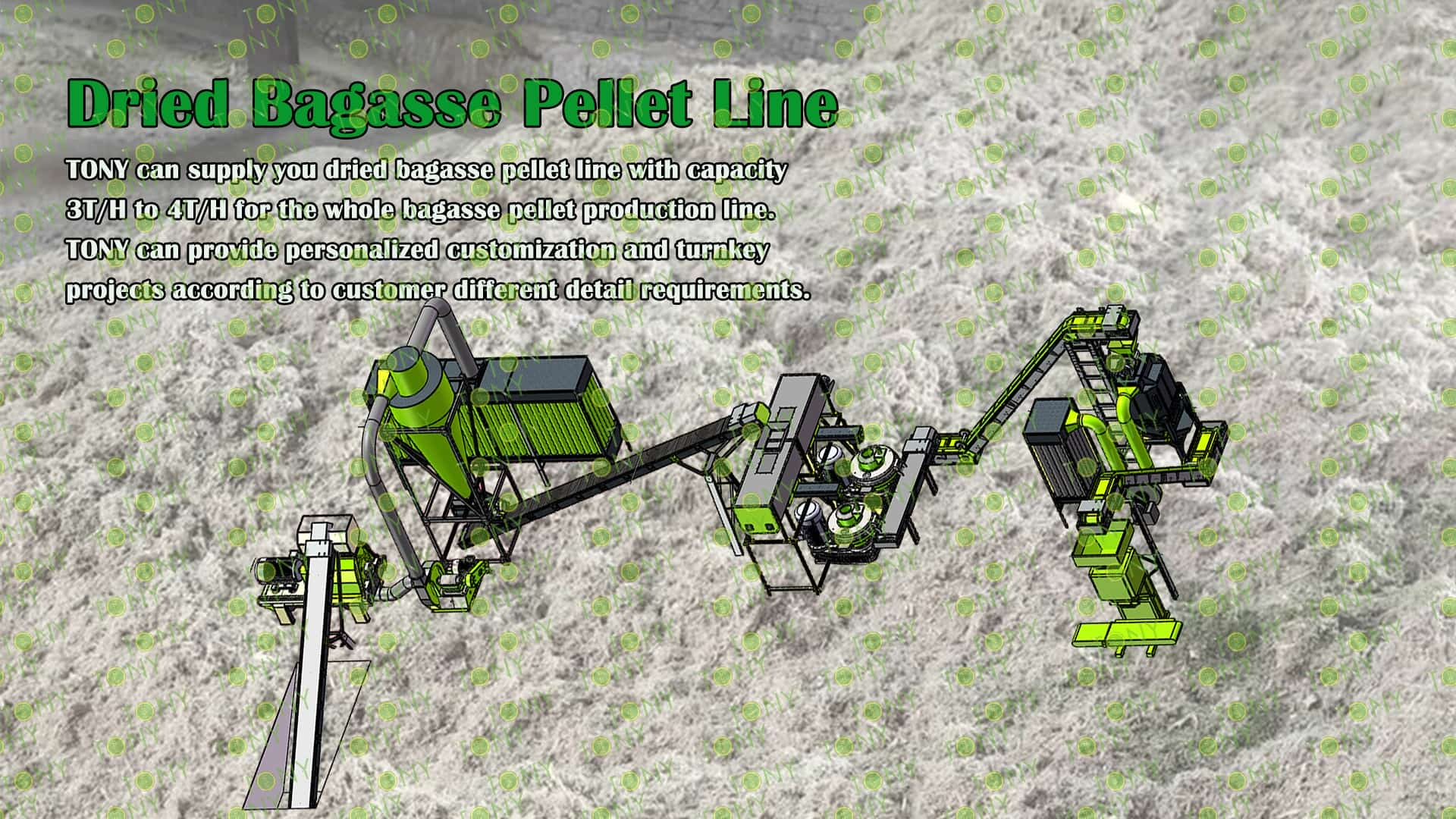

1.Product:Dried Bagasse Pellet Line

2.Capacity: 3-4 T/Hour

3.TONY Brand 3-4 Ton /Hour Dried Bagasse Pellet Line Project Process

4.Main Machine:Hammer Mill,TONY Pellet Machine TYJ551-Ⅲ-110KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 380 kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D图

原材料图+颗粒机图片

1. The working principle of dried bagasse biomass pellet processing equipment

The pre-treated dry bagasse enters the core of the equipment - the extrusion molding system. This is the key step in pellet molding, which is mainly achieved by the mechanical structure of "screw feeding + die extrusion":

(1) Screw feeding: continuous pressure pushing The material enters the spiral extrusion chamber from the hopper. The spiral shaft in the chamber (usually with a variable diameter and variable pitch design) rotates at high speed under the drive of the motor. As the spiral shaft advances, the pitch gradually decreases and the cavity space gradually compresses. The extrusion pressure on the material increases rapidly from the initial several MPa to 50-100 MPa. The strong extrusion pressure greatly reduces the gaps between the bamboo fibers, providing a basis for subsequent shaping.

(2) Die extrusion: forming the prototype of the pellets The end of the extrusion chamber is connected to a ring die (the die has evenly distributed forming holes with a diameter of 6-12 mm, and the hole diameter can be adjusted according to needs). When the material reaches the die under the push of the spiral shaft, it will be forcibly "pressed" into the forming hole under the action of high pressure. In the process of passing through the forming hole, the material is subjected to the friction resistance and extrusion of the hole wall, gradually forming a cylindrical "material strip" with the same diameter as the forming hole, completing the shaping of the particle prototype.

2. Characteristics of dried bagasse biomass pellet processing equipment

(1) Raw material pretreatment module: Adapt to the physical properties of sugarcane bagasse to ensure feed stability

Although dry sugarcane bagasse has a low moisture content (usually below 15%), its fiber structure is loose and easy to agglomerate. A hammer crusher is equipped to solve the feeding problem

(2) Core pelletizing module: High-pressure molding + wear-resistant design to meet the challenges of fiber raw materials

The core pelletizer must have two key features: one is an ultra-high compression ratio mold, and the other is a dual-pressure wheel synchronous drive structure with a high molding rate

(3) Energy-saving design: Adapt to the low calorific value of sugarcane bagasse to reduce energy consumption costs

The comprehensive energy consumption of TTONY pelletizer is 15%-20% lower than that of ordinary pelletizers

(4) Environmental protection and safety configuration: Comply with agricultural waste processing standards and reduce secondary pollution

Equipped with a multi-stage dust removal system and safety protection devices,

(5) Automation and adaptability: Meet the needs of large-scale production and compatible with multi-raw material processing

For the large-scale needs of sugarcane bagasse processing, the equipment usually has a high degree of automation. A single production line only requires 1-2 people to monitor, reducing labor costs. At the same time, the equipment has the flexibility to adapt to raw materials. In addition to dry sugarcane bagasse, it is also compatible with agricultural waste such as sugarcane leaves, straw, and peanut shells (just replace the mold with the corresponding compression ratio)

3. Application scenarios of dried bagasse biomass pellet processing equipment

(1) Industrial sector: It can replace coal for boiler heating and steam production in sugar mills, paper mills, food factories and other enterprises, realizing the "slag-to-energy" cycle model;

(2) Civil sector: It can be used as a clean fuel for home heating and cooking, replacing liquefied gas and loose coal;

(3) Power generation sector: It can be used as fuel for biomass power plants and participate in grid-connected power generation;

(4) Animal husbandry sector: It can be used as feed for animal husbandry, taking advantage of its "high crude fiber" characteristics, as a roughage supplement for ruminants such as cattle and sheep.

2.图片

TONY Brand 3-4 Ton/Hour Dried Bagasse Pellet Manufacturing Plant can take dried bagasse as the main raw material. After pretreatment and processing, it is solidified into high - density Bagasse pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bagasse resources.

1. Capacity: 3-4 Ton/Hour

2. Raw materials: Dried bagasse

3. Moisture: dried type, about 10-15%.

4. Application: All kinds of bagasse materials suitable for pellet production.

Suitable customers: Sugarcane processing factories are the direct output of bagasse, such as sugar mills, sugarcane ethanol factories, sugarcane pulping factories, etc.; centralized storage and transit places, such as sugar mills, ethanol factories, agricultural product processing parks, where multiple sugarcane processing factories often gather to form a park. The storage and transit areas of bagasse are uniformly planned within the park, and the resource concentration is extremely high.and other places where bagasse raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3.图片

图片

原材料--成品图

1. Project Name: Dried Bagasse Pellet Production Line

2. Raw Material: All kinds of dried bagasse

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 3-4 tons per hour

5. Process: Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD75*100-110kw, TONY Pellet Machine- TYJ551-Ⅲ-110kw, Galvanized Pellets Cooler, Semi-automatic Packing Machine and Belt Conveyors

4.图片

|

How to use the TONY pellet production line to make pellets from dried bagasse? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the slightly larger bagasse into 8-14 mm bagasse.If customer has enough Investment budget,he can also chose TONY Special Cutting Machine for bagasse which will be more expensive than the hammer mill. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

流程图1

流程图2

5.图片

原材料+颗粒图

颗粒+机器图

3D图

3D图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

| 图1 | 图2 | 图3 |

| Effective Hammer Mill | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

|

1.To Crush Larger Bagasse Into 8-14mm Baggase. 2.Model: TFD75*100-110KW*1set 3.Capacity: 3-4 Ton/Hour/Set |

1.To Stroage Bagasse Before Pellet Machine; Adjust The Speed Of Bagasse Entering The Pellet Machine 2.Model: TLC-4*1set 3.Capacity:3-4 Ton/Hour/Set |

1.To Press Dry Bagasse Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-110KW*2sets 3.Capacity:1.5-2 Ton/Hour/Set 4.New 304SS Type |

| 图4 | 图5 | 图6 |

| Galvanized Pellets Cooler | Semi-automatic Packing Machine | Belt Conveyor |

|

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3-4 Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TBF-50*1set 3.Capacity: 3-4 Ton/Hour |

1.Transport Bagasse,Pellets. 2.Width: 50cm*5 Sets 3.Capacity:Designed With The Whole Line |

三维图

5.1图片

高效粉碎机

带锯末图

1.Bagasse Fine Crushing Process:

A.This process is mainly used to crush larger bagasse into 8-14mm bagasse.

B.Capacity:3-4 Ton/Hour.

C.TONY brand effective hammer mill TFD75*100-110kw*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.2图片

颗粒机四件套带 原材料,颗粒图

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:3-4Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-110kw*2 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

5.3图片

镀锌冷却仓加颗粒图

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:3-4 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.4图片

包装机

4.Packing Process:

A.This process is mainly used to pack pellets into 15-50KG/Bags.

B.Capacity:3-4 Ton/Hour.

C.TONY brand semi-automatic packing machine*1 set

Main Parts:

(1)TONY Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

6.图片

客户生产线案例图

7.图片

图 干甘蔗渣+颗粒 颗粒机

Key Risks and Responses for Processing Dry Bagasse into Biomass Pellets

1. Raw Material Risk: Reduced raw material supply or rising raw material prices during the sugarcane product industry's off-season ;

Response: Sign long-term supply agreements with 3-5 sugarcane product mills (locking in pricing and supply), and stockpile 1-2 months' worth of raw material in advance during the off-season.

2. Market Risk: Intensified competition in the biomass pellet market (such as the impact of low prices for wood chip pellets and straw pellets), or declining downstream demand (such as industrial enterprises switching to natural gas);

Response: Develop differentiated competition (highlighting the advantages of sugarcane pellets' low ash content and high calorific value), expand into multi-purpose markets (such as feed carriers and organic fertilizer carriers), and avoid dependence on a single customer.

3. Technical Risk: Equipment failure leading to downtime (such as roller wear or die blockage) or substandard pellet quality (such as low density or excessive broken pellets);

Response: Select a reputable equipment manufacturer, such as TONY (which offers after-sales service), and provide regular operator training to master equipment commissioning and maintenance skills.

8.图片

干甘蔗渣图 颗粒图

1. Clean Emissions:

Sulfur dioxide and nitrogen oxide emissions during combustion are far lower than those of coal, with less dust pollution, meeting strict environmental emission standards and reducing air pollution.

2. Carbon Neutral Cycle:

The carbon dioxide absorbed during sugarcane growth is essentially offset by the carbon dioxide released during pellet combustion, achieving "zero carbon emissions" and aligning with the dual carbon goals.

3. Waste Resource Utilization:

Using sugarcane processing waste as raw material, this avoids the environmental problems caused by the indiscriminate disposal or incineration of bagasse, and achieves a recycling of agricultural waste.

4. High Combustion Efficiency:

With a stable calorific value of 4,000-4,500 kcal/kg, the pellets burn thoroughly and sustainably, achieving thermal efficiency over 30% higher than loose bagasse.

5. High Adaptability:

The pellets have a regular morphology (6-10 mm in diameter, 10-30 mm in length), making them directly adaptable to existing equipment such as industrial boilers, residential heating stoves, and biomass generators, without the need for major modifications.

6. Simple Post-Processing:

The ash content after combustion is less than 5%, resulting in minimal residue and low cleaning frequency. Furthermore, the ash can be returned to the fields as potash fertilizer, further improving resource utilization.

7. Low Raw Material Cost:

Sugarcane bagasse is a byproduct of sugar and ethanol refineries, making it inexpensive to obtain. In some areas, it can even be recycled at low or no cost, reducing raw material costs.

8. Controllable Cost of Use:

The market price is generally lower than that of coal and natural gas, and the raw material supply is concentrated in major sugarcane-producing areas, resulting in minimal price fluctuations and stable energy costs.

9.图片

绿色地球+原材料+颗粒图

10.图片

图片

11.图片

客户参观图

2025 Tony Machinery - All Rights Reserved. Map