1.图片

Project Brief Introduction:

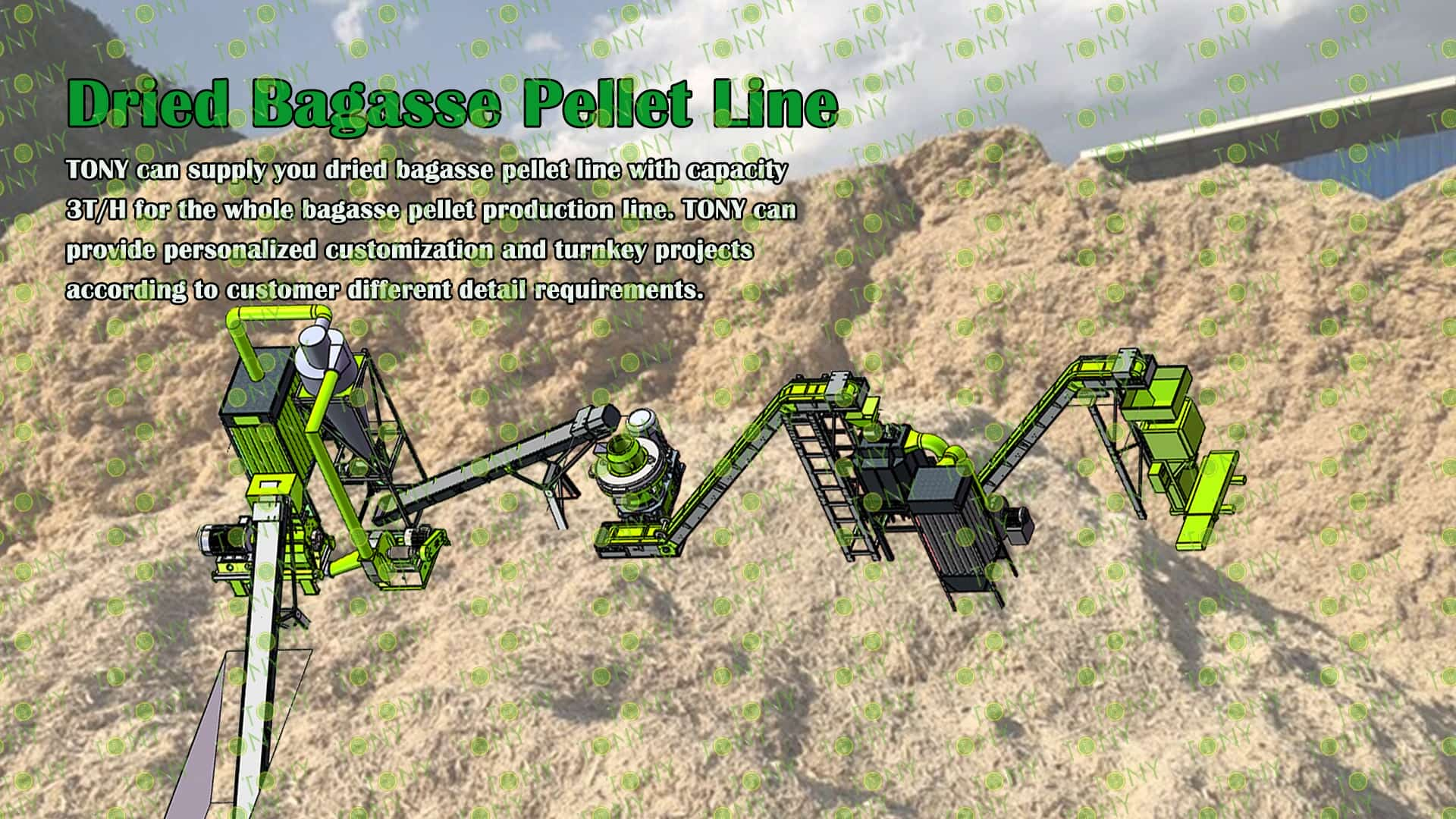

1.Product:Dried Bagasse Pellet Line

2.Capacity: 3 T/Hour

3.TONY Brand 3 Ton /Hour Dried Bagasse Pellet Line Project Process

4.Main Machine:Hammer Mill,TONY Pellet Machine TYJ760-Ⅲ-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 320 kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D图

原材料图+颗粒机图片

1. The working principle of dried bagasse biomass pellet processing equipment

The essence of dry bagasse pellet processing equipment is to transform low-value agricultural waste (dry bagasse) into high-density fuel pellets through a process that involves "fine grinding in a crusher → high-pressure extrusion in a pelletizer → frictional heating → cooling and screening." Its core advantage lies in the fact that it eliminates the need for chemical binders and instead relies solely on the softening and bonding properties of the raw material's fibers under high temperature and high pressure to form pellets. This ensures the pellets are environmentally friendly (no harmful gases are emitted during combustion) while reducing production costs, perfectly meeting the demand for "resource-based and clean" biomass energy.

2. Characteristics of dried bagasse biomass pellet processing equipment

Modern dry bagasse pellet processing equipment is increasingly adopting automated and intelligent control technologies to reduce manual labor and improve production efficiency. These equipment are equipped with advanced control systems, allowing operators to set operating parameters, monitor operating status, and remotely control the equipment through a user interface. For example, a PLC control system enables precise control of equipment start-up, shutdown, and speed adjustment. It also collects real-time operational data, such as temperature, pressure, and output, for analysis and processing, providing a basis for production decision-making.

3. Application scenarios of dried bagasse biomass pellet processing equipment

Large-scale production lines can achieve efficient conversion of dry residue, reducing unit processing costs and improving resource utilization. The pellet volume is reduced by 6-10 times, reducing transportation costs. The pellets are supplied to surrounding food factories, paper mills, chemical plants, and other industrial enterprises that require steam or heat energy. Biomass heating stations are built in towns or industrial parks, using sugarcane bagasse pellets to heat residents and commercial facilities. The ashes from the combustion are tested for heavy metals and applied to sugarcane fields as silicon-potassium fertilizer. The pellet heat is used for grain drying, reducing pollution from field burning. This realizes the "waste-to-treasure" transformation of sugarcane bagasse.

2.图片

TONY Brand 3 Ton/Hour Dried Bagasse Pellet Manufacturing Plant can take dried bagasse as the main raw material. After pretreatment and processing, it is solidified into high - density Bagasse pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bagasse resources.

1. Capacity: 3 Ton/Hour

2. Raw materials: Dried bagasse

3. Moisture: dried type, about 10-15%.

4. Application: All kinds of bagasse materials suitable for pellet production.

Suitable customers: Sugarcane processing factories are the direct output of bagasse, such as sugar mills, sugarcane ethanol factories, sugarcane pulping factories, etc.; centralized storage and transit places, such as sugar mills, ethanol factories, agricultural product processing parks, where multiple sugarcane processing factories often gather to form a park. The storage and transit areas of bagasse are uniformly planned within the park, and the resource concentration is extremely high.and other places where bagasse raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3.图片

图片

原材料--成品图

1. Project Name: Dried Bagasse Pellet Production Line

2. Raw Material: All kinds of dried bagasse

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 3 tons per hour

5. Process: Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD75*100-90kw, TONY Pellet Machine- TYJ760-Ⅲ-200kw, Galvanized Pellets Cooler, Semi-automatic Packing Machine and Belt Conveyors

4.图片

|

How to use the TONY pellet production line to make pellets from dried bagasse? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the slightly larger bagasse into 8-14 mm bagasse.If customer has enough Investment budget,he can also chose TONY Special Cutting Machine for bagasse which will be more expensive than the hammer mill. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

流程图1

流程图2

5.图片

原材料+颗粒图

颗粒+机器图

3D图

3D图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

| 图1 | 图2 | 图3 | 图4 |

| Effective Hammer Mill | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

|

1.To Crush Larger Bagasse Into 8-14mm Baggase. 2.Model: TFD75*100-90KW*1set 3.Capacity: 3-3.5 Ton/Hour/Set |

1.To Press Dry Bagasse Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*1set 3.Capacity:3-3.5 Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3 Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TBF-50*1set 3.Capacity: 3 Ton/Hour |

三维图

5.1图片

高效粉碎机

带锯末图

1.Bagasse Fine Crushing Process:

A.This process is mainly used to crush larger bagasse into 8-14mm bagasse.

B.Capacity:3-3.5 Ton/Hour.

C.TONY brand effective hammer mill TFD75*100-90kw*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.2图片

颗粒机四件套带 原材料,颗粒图

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:3-3.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-200kw*1 set

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

5.3图片

镀锌冷却仓加颗粒图

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:3 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.4图片

包装机

4.Packing Process:

A.This process is mainly used to pack pellets into 15-50KG/Bags.

B.Capacity:3 Ton/Hour.

C.TONY brand semi-automatic packing machine*1 set

Main Parts:

(1)TONY Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

6.图片

客户生产线案例图

7.图片

图 干甘蔗渣+颗粒 颗粒机

This project leverages negative-cost raw materials, policy-driven demand, and carbon finance to create a triple growth engine.

This creates a closed-loop value chain in key sugarcane-producing regions: waste processing fees, pellet sales, carbon sequestration revenue, and product premiums. By 2025, when the global carbon pricing system matures, the project's net profit margin could exceed 60%.

This makes it a high-quality asset in the context of carbon neutrality and provides a dual solution for rural revitalization: green employment and environmental governance. We recommend prioritizing deployment in the core sugarcane producing regions of Guangxi and Yunnan to seize this window of opportunity.

8.图片

干甘蔗渣图 颗粒图

1. Renewable

Unlike fossil fuels like coal and natural gas, which are consumable (and take a long time to produce), sugarcane bagasse pellets are renewable because sugarcane grows annually, providing a continuous supply of raw materials.

2. Turning Waste into Treasure

Against the backdrop of global energy shortages, sugarcane bagasse pellets represent a paradigm shift from waste to wealth, maximizing the utilization of sugarcane and increasing farmers' incomes. They can generate sufficient heat to meet the full needs of a typical sugar refinery or generate profits through pellet production.

3. Excellent Combustion Performance

The resulting fuel contains minimal ash, significantly reducing the amount of ash storage space and slag disposal costs. More importantly, combustion produces no harmful gases, making it a direct replacement for mineral coal. Suitable for industrial wood chip boilers, power plants, residential heating, cooking, and other industries, they mitigate the environmental impact of traditional fossil fuels.

9.图片

绿色地球+原材料+颗粒图

10.图片

图片

11.图片

公司介绍图

2025 Tony Machinery - All Rights Reserved. Map