1.Principle of wet wood pellet processing equipment

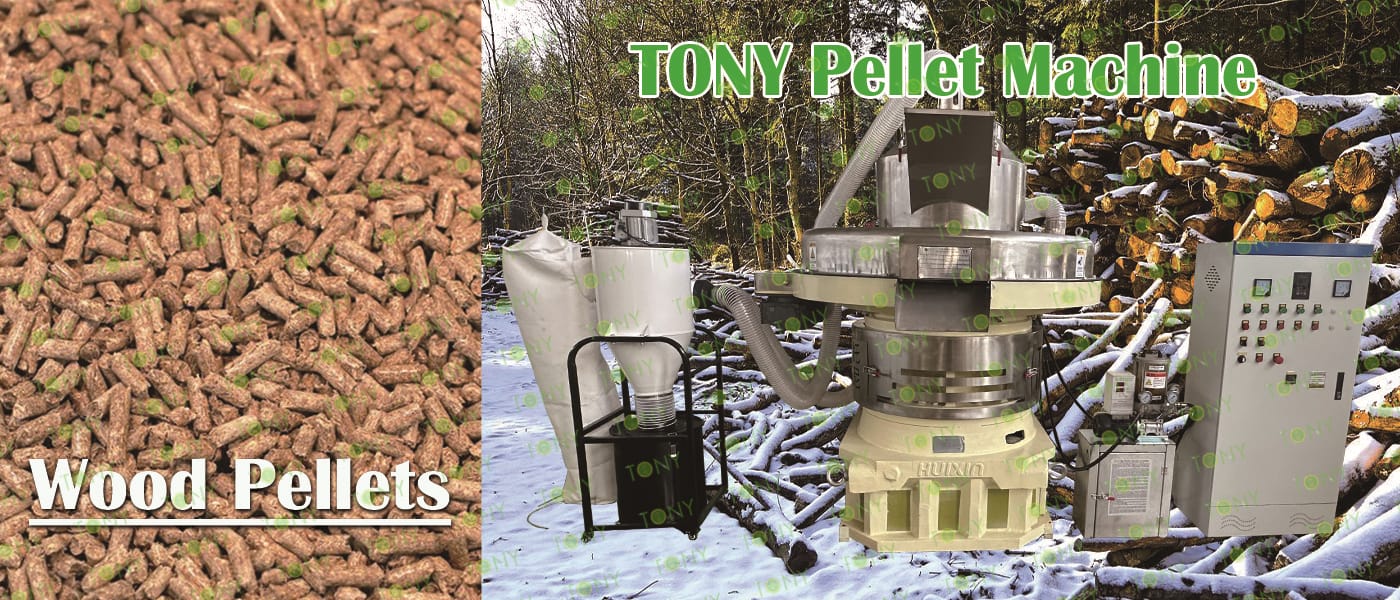

The core principle of wood pellet processing equipment (such as wood chip pellet machines) is to convert biomass feedstock into high-density pellet fuel through mechanical extrusion. The basic process includes three steps: feedstock pretreatment (crushing, drying, and screening), mechanical pressing, and finished product processing (cooling and packaging). For example, in a ring die pellet machine, a motor connected to a reducer via a coupling drives the ring die to rotate. Gravity forces the feedstock into the pressing zone, where the pressing rollers squeeze the material into the ring die holes. After being formed in the die, the pellets are cut into pellets of a fixed length by a cutter.

2.Characteristics of wet wood pellet processing equipment

(1) Wet wood biomass pellet processing equipment features high efficiency and low energy consumption. It can rapidly process biomass raw materials into fuel pellets, significantly improving production efficiency.

(2) The biomass pellet machine has strong material adaptability and is suitable for the molding of various biomass raw materials. The pellet machine is equipped with molds of various specifications. According to different biomass raw materials, the corresponding mold can be selected for processing, enhancing the adaptability of processing.

(3) The design of wet - wood biomass pellet processing equipment is mature. The finished pellets have stable molding, stable output, and high quality.

(4) Biomass pellet processing equipment is simple to operate, easy to use, has a high degree of automation, requires less labor, effectively reduces labor intensity, and improves production.

3.Application scenarios of wet wood pellet processing equipment

(1) Biomass energy field: Wet wood pellets can be used as biomass fuel for power generation, heating, etc., replacing traditional fossil fuels and reducing environmental pollution.

(2) Animal feed: Wet wood pellets can be used as high-quality feed to improve the production efficiency of poultry and livestock

(3)Environmentally friendly processing: wet wood pellet processing equipment can effectively process wood waste, convert it into useful pellet fuel, and reduce environmental pollution

(4) Energy savings: Since wet wood pellets are a renewable energy source, using them saves energy and reduces dependence on finite fossil fuels

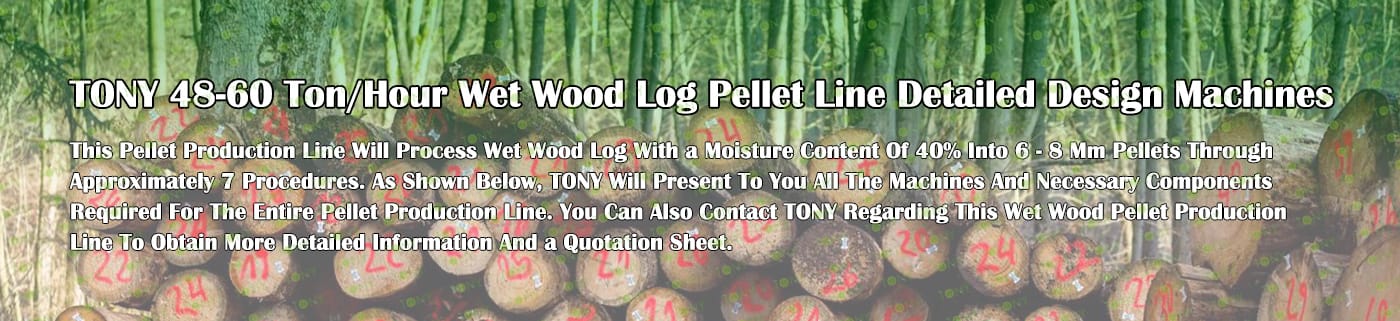

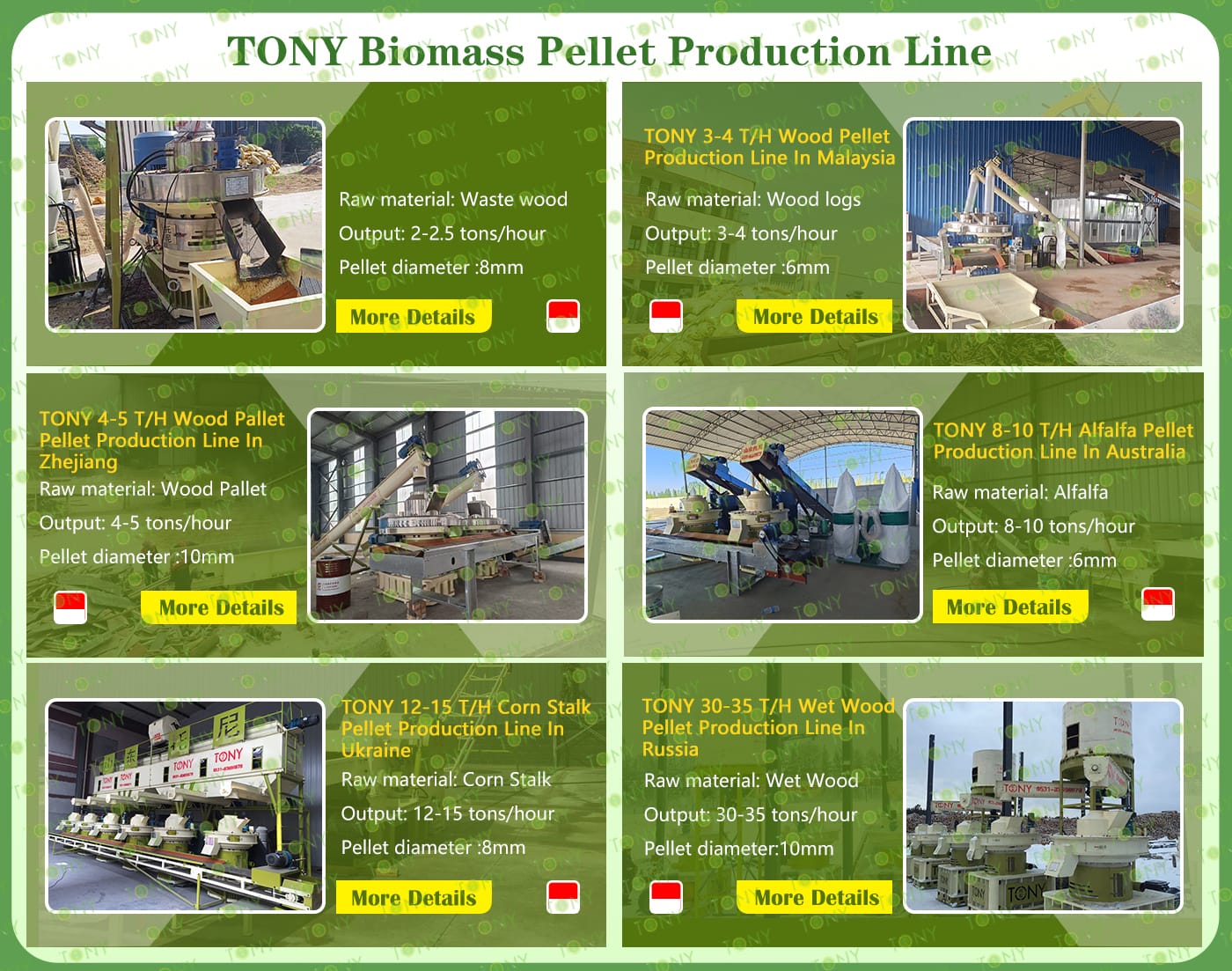

TONY Brand 48-60Ton/Hour Wet Wood Log Pellet Manufacturing Plant can take wet wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

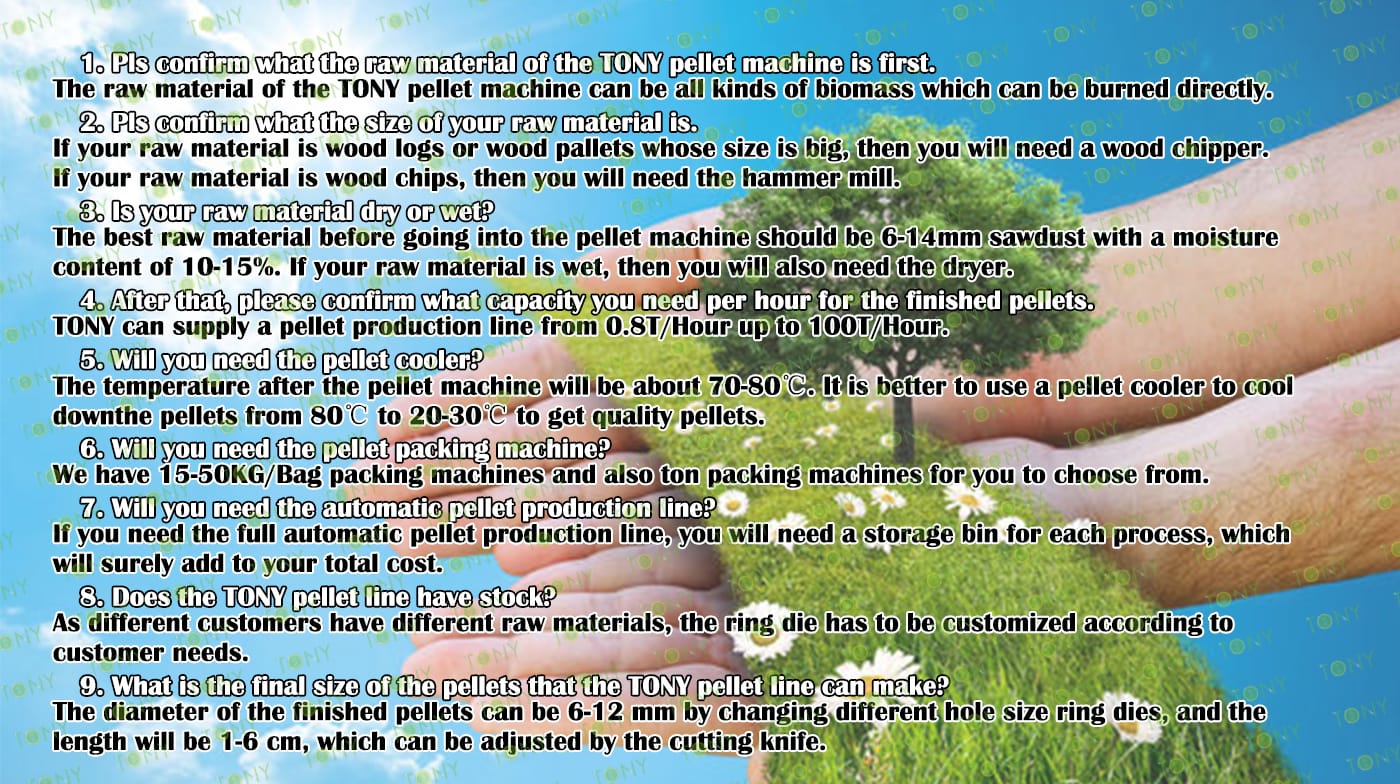

1. Capacity:48-60Ton/Hour

2. Raw materials: Wet wood log , branches, small - diameter logs, twigs, etc.

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Log Pellet Production Line

2. Raw Material: All kinds of wet wood Log

3. Moisture Content of Raw Material: 40%

4. Capacity: 48-60 tons per hour

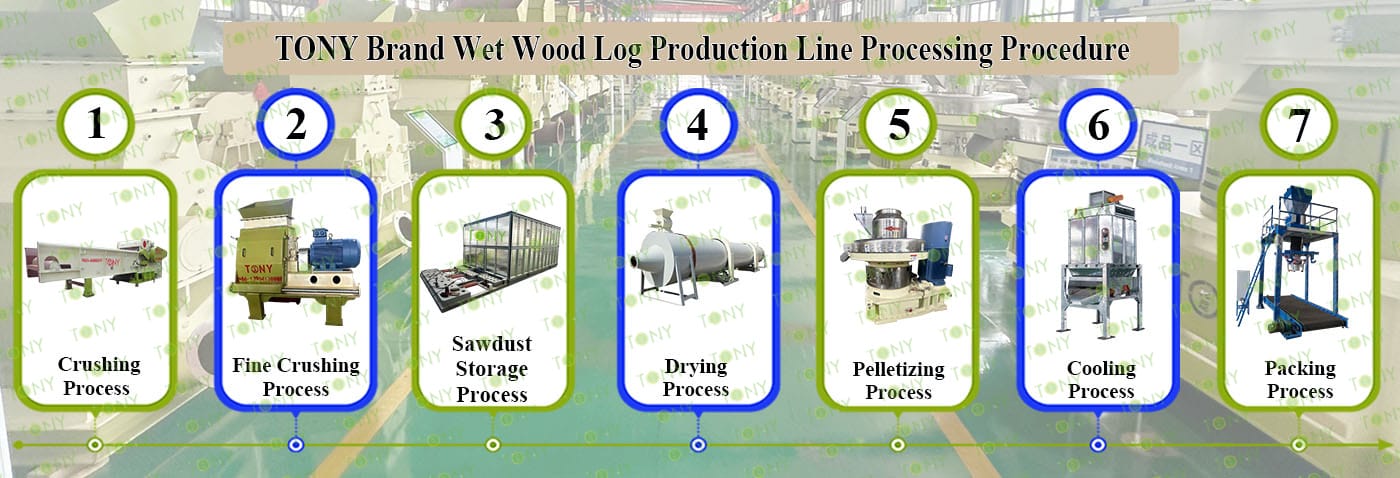

5. Process: Crushing Process - Fine Crushing Process -Sawdust Storage Process- Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1600-1000-315KW, Effective Hammer Mill-TFD120*200-355KW, TONY Large Hydraulic Storage Silo,Rotary Drum Dryer-3.2*28m, TONY Pellet Machine TYJ860 - Ⅲ - 280kw, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

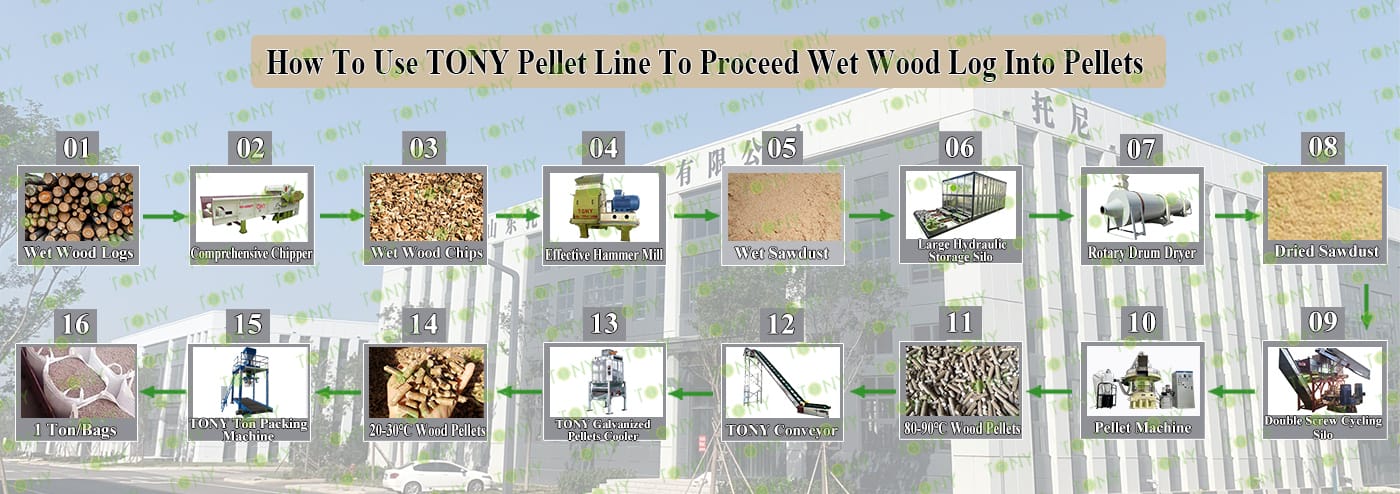

How to use the TONY pellet production line to make pellets from wet wood Log? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut wet wood log with a diameter of less than 40 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 4. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 5. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 6. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 7. Use TONY ton packing machine to pack the pellets into bags, each weighing 1ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Large Hydraulic Storage Silo | Rotary Drum Dryer |

| 1.To Grind Wood Logs φ ≤40cm Into25-55mm Wood Chips. 2.Model: TPC1600-1000-315KW With 6 Blades*3sets 3.Capacity:48-60Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD120*200-355KW*5sets 3.Capacity: 10-12Ton/Hour/Set |

1.To Storage Sawdust Before Dryer Control Sawdust Flow Entering The Dryer Model: TCY-30*5sets 2.TONY Uses Galvanized Material |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD3.2*28*5sets 3.Capacity:10-12Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*12sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*5sets 3.Capacity:48-60/Hour |

1.To Pack Pellets Into 1Ton/Bags 2.Model: TBD* 5sets 3.Capacity: 48-60Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*35sets 3.Capacity:Designed With The Whole Line |

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 40cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand comprehensive chipper TPC1600-1000 model with 6 flying blades type:

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:48-60Ton/Hour.

C.TONY effective hammer mill TFD120*200-355KW*5sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B. TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's New Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

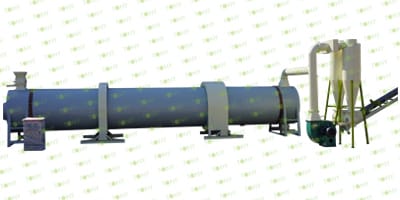

4.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:48-60Ton/Hour.

C.TONY use 5 sets of 3.2*28m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:48-60Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-280KW*12sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

6.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.5 sets of TONY galvanized cooler separator

Main Parts:

(1)TONY's new Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

7.Packing Process:

A.This process is mainly used to pack pellets into 1ton/bags.

B.5 sets of TONY ton packing machine

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

1.With the increasingly severe energy and environmental crisis, biomass energy, as a renewable and clean energy source, has received growing attention. Taking crop straw as an example, its potential for in - depth development is enormous. There are various ways to utilize biomass, and processing biomass into compressed pellet fuel is an advanced approach to biomass utilization. The sulfur content in biomass pellet fuel is less than one - tenth of that in coal. Replacing coal combustion with it can effectively reduce the emission of sulfur dioxide in the atmosphere, and the ash generated after combustion is an excellent natural fertilizer. At present, the gasification combustion of biomass pellets is a clean and environmentally friendly combustion mode, which is of great significance for reducing pollution emissions and protecting the atmospheric environment.

2.Crop straw, as an extremely important resource in agricultural production, is very common in rural areas and exists in huge quantities. For a long time, there has been a lack of good treatment methods for straw. If it is burned on - site, it will cause pollution to the environment. However, choosing straw as the raw material for biomass pellets results in extremely low raw material costs. If there are a large number of straw resources in or around the area, the raw material cost can be almost negligible.

3.Biomass fuel is not only environmentally friendly but also provides an option for the country's energy needs. The market demand for biomass fuel is constantly increasing, and the price of biomass pellet energy made from straw is also rising steadily. For entrepreneurial projects, there is a considerable profit margin. Therefore, using straw to produce biomass pellets has multiple benefits. Besides protecting the environment and helping to solve employment problems, it can also bring considerable economic benefits and ensure the sustainability of energy.

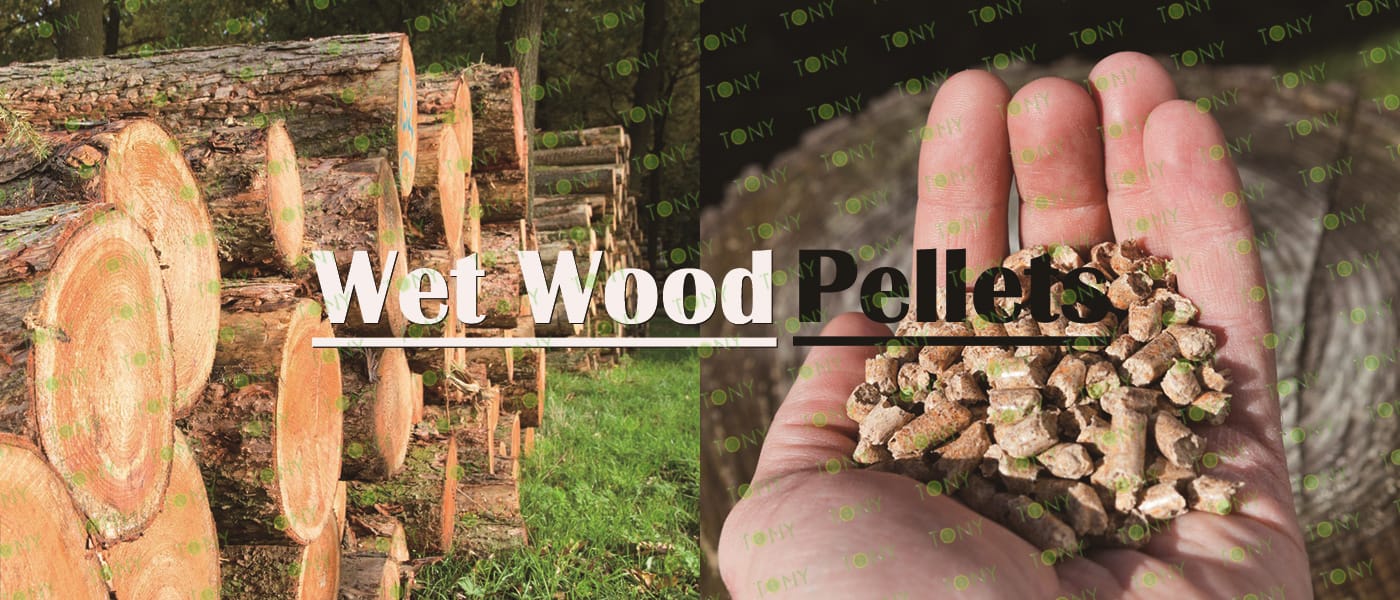

Advantages of Wet Wood as Biomass Pellet Fuel

When wet wood is processed into biomass pellet fuel, it offers numerous advantages, which are not only evident in environmental protection, economic aspects, and contributions to social development and energy structure improvement, but also in its unique combustion performance. The main advantages are as follows:

1.Calorific Value and Combustion Residue

The calorific value of wet wood biomass pellet fuel after combustion, as well as its ash content, is approximately 10% lower than that of medium - grade coal. However, wet wood biomass pellets burn out completely under normal working conditions. In contrast, coal cannot burn out entirely, leaving cinders with a combustible composition accounting for 10% to 15% of the total. As a result, in practical applications, the effective calorific values of the two are comparable.

2.Ignition Ease

Wet wood biomass pellet fuel has a better ignition property compared to coal. It ignites easily, significantly reducing the ignition time required for starting the combustion process.

3.Solid Emissions

The solid emissions of wet wood biomass pellet fuel are much lower than those of coal. This not only cuts down on the cost of slag disposal but also reduces environmental pollution. The solid emissions of wet wood biomass pellet fuel are mainly ash, accounting for about 0.4% - 7.0% of the total weight. In contrast, the solid emissions from coal combustion are a mixture of ash, alkali, and unburned coal, making up about 25% to 40% of the total weight.

4.Air Pollution and Corrosion

The degree of air pollution and boiler corrosion caused by coal is far greater than that of wet wood biomass pellet fuel. Coal soot contains a large amount of particulate carbon and toxic and corrosive gases such as SO₂ and CO. The main component of wet wood biomass pellet fuel is C - H organic matter. There is no particulate carbon and SO₂ gas in its flue gas. Instead, it mainly consists of C - H volatile gases, and its SO₂ and CO emissions are nearly zero. When burned, the smoke color is less than Ringelmann 1 level. This greatly reduces air pollution and carbon dioxide emissions, and wet wood biomass pellet fuel is internationally renowned as a "clean fuel."

5.Cost and Time Savings

Using wet wood biomass pellet fuel for boiler operation incurs less cost and time compared to burning coal. For example, a 0.5t boiler using wet wood biomass pellet fuel costs 11% less than when burning coal and saves 34% of the time. In another case, for a 0.5t boiler, the fuel cost relative to coal is reduced by 10%, and the time saved is 16%.

6.Continuous Combustion

The continuous combustion time of wet wood biomass pellet fuel is generally 8 to 10 times longer than that of soft, bulk materials. It can maintain a stable and continuous combustion state, ensuring a more reliable energy supply.

2025 Tony Machinery - All Rights Reserved. Map