Project Brief Introduction:

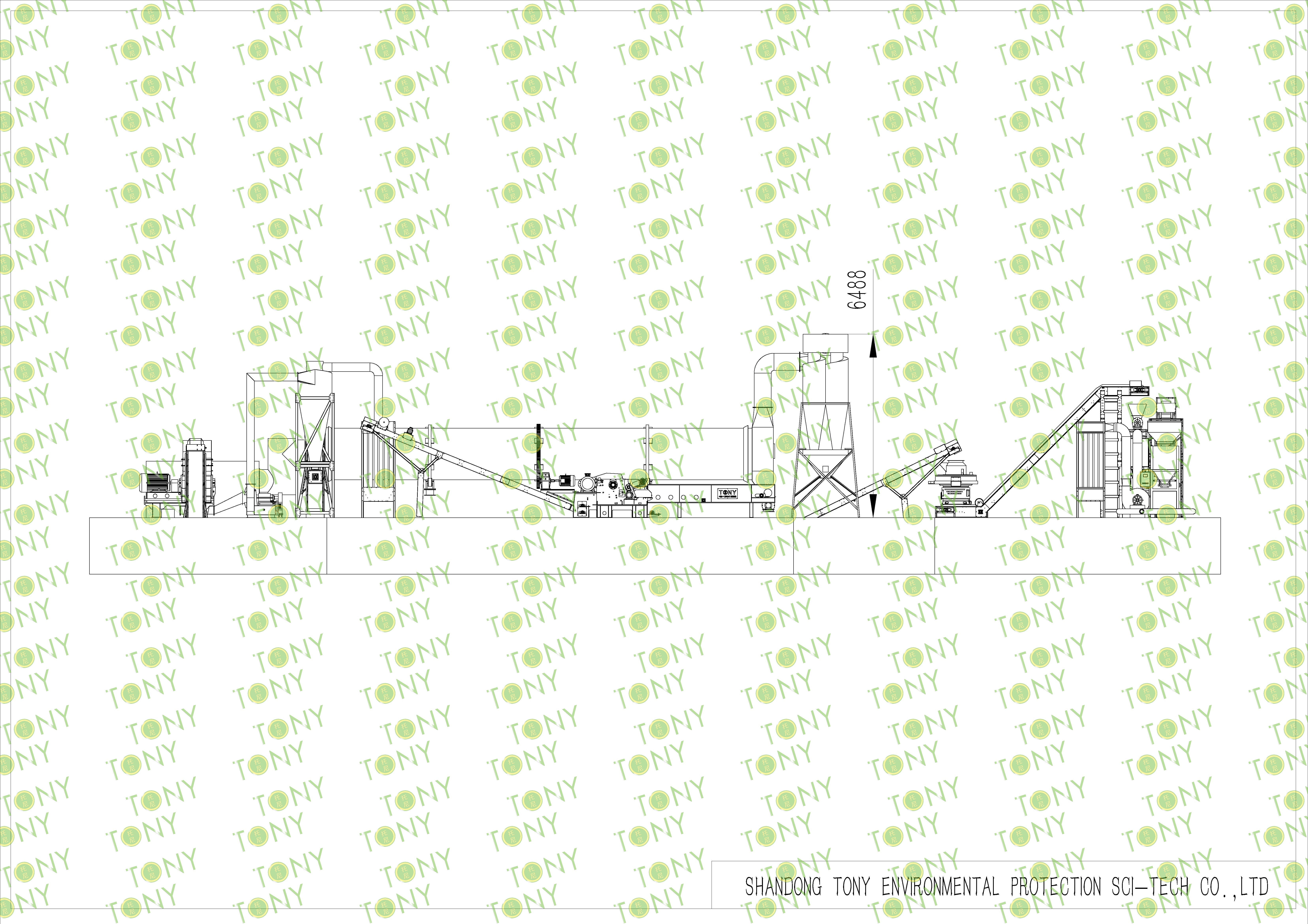

1.Product:Wet Wood Log Pellet Line

2.Capacity:3T/Hour

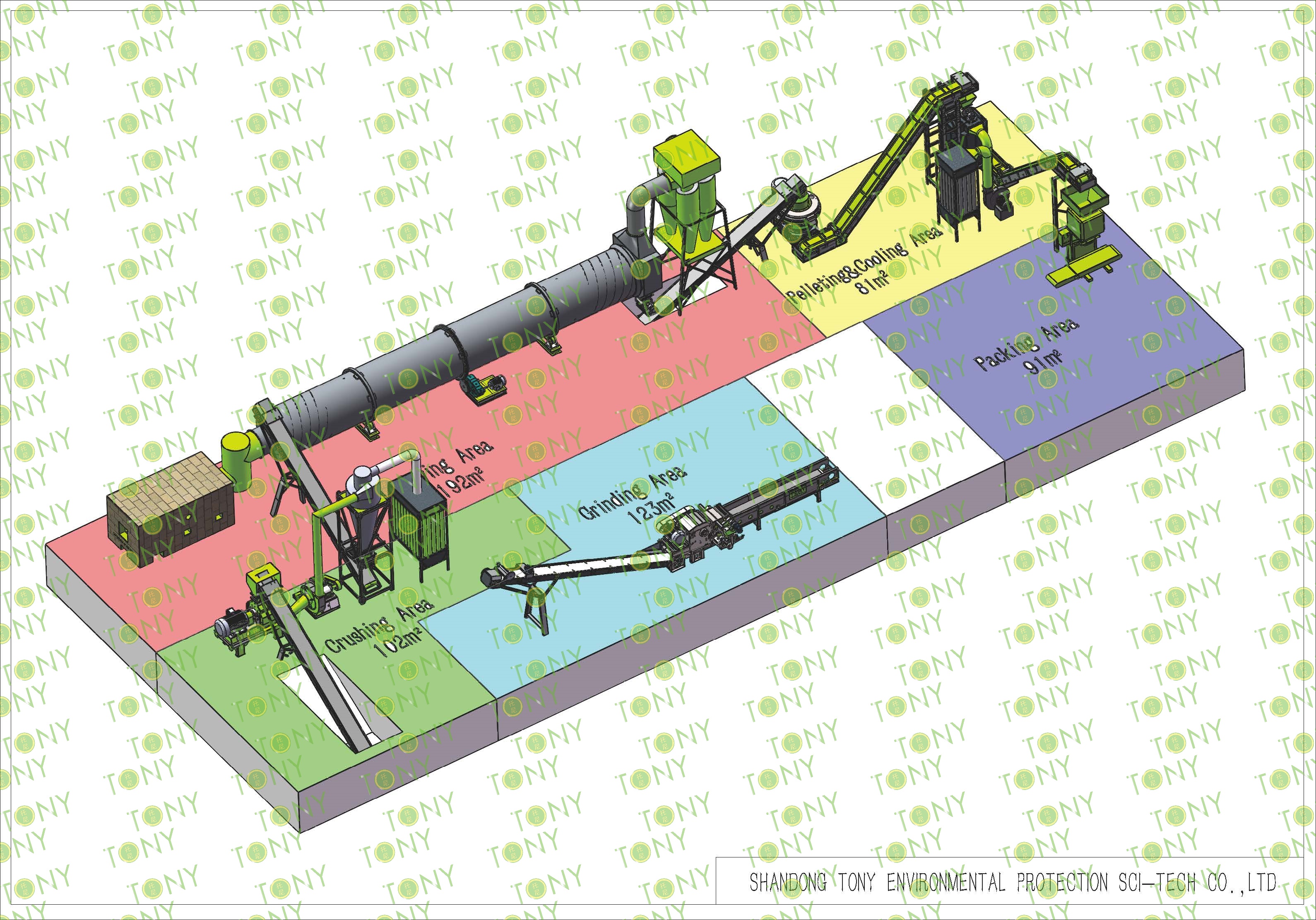

3.TONY Brand 3Ton/Hour Wet Wood Log Pellet Line Project Process

4.Main Machine: Wood Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet MachineTYJ450-II-55KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 440KW

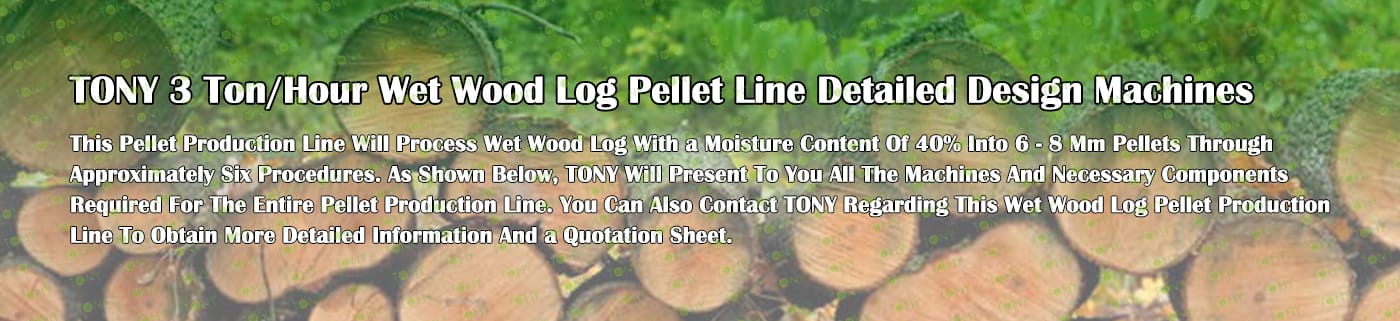

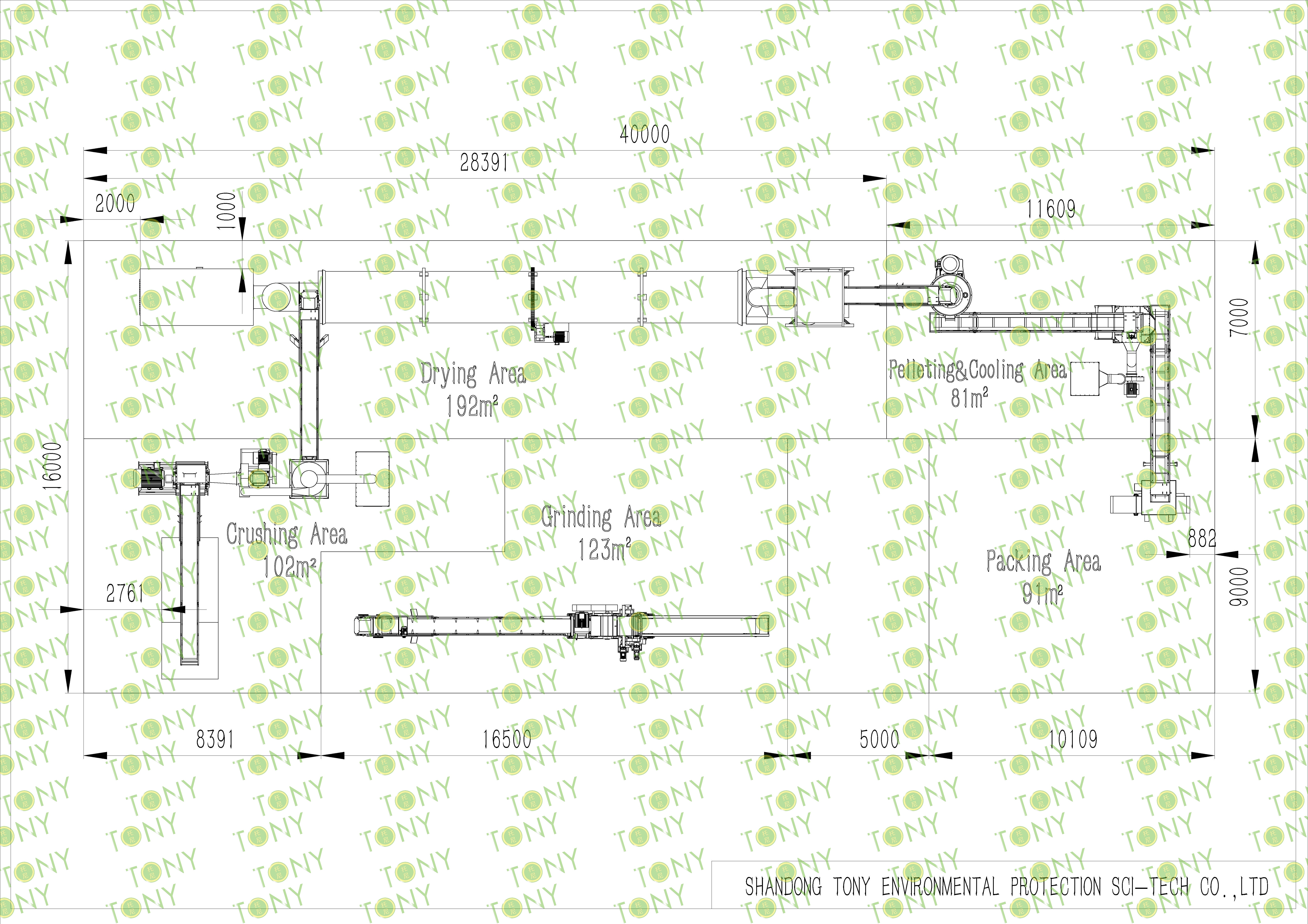

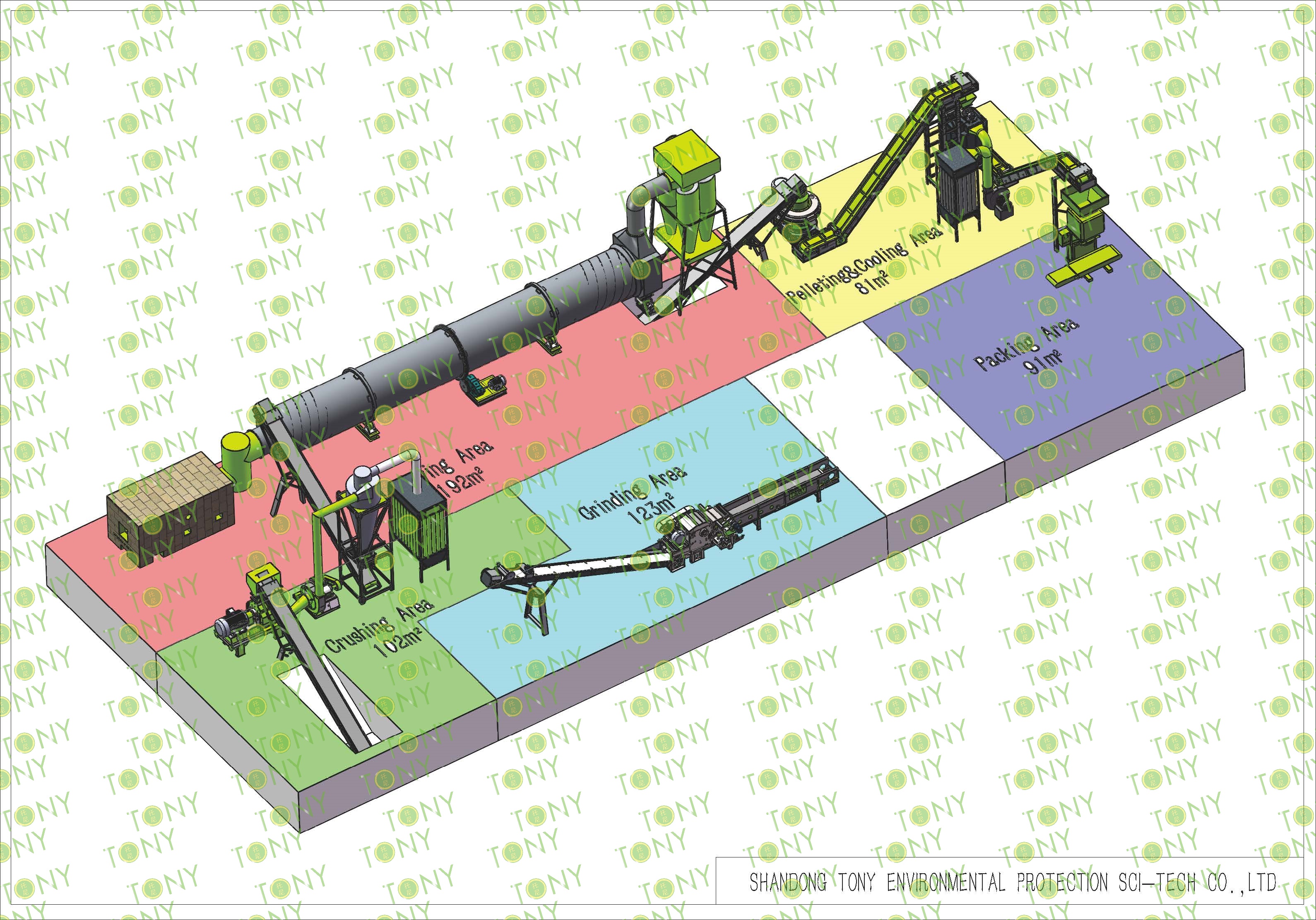

6.Need Area: About 640㎡ L:40M W: 16M H:6.488M

Project Layout For Customer:

1.The working principle of wet wood log biomass pellet processing equipment

Due to its high moisture content and soft texture, wet wood needs to be directly processed into biomass pellets to solve two core problems: "dehydration" and "forming". The process of processing wet wood into biomass pellets should focus on "reducing moisture to the forming requirement (usually 10%-15%)" and "compression molding through mechanical force". The core equipment includes pretreatment equipment, drying equipment, pelletizing equipment and post-processing equipment.

2.Characteristics of wet wood biomass pellet processing equipment

(1)Strong adaptability to high-moisture raw materials

Equipped with an efficient drying system, it can directly process wet wood with a moisture content of 30%-60% without relying on external pre-treatment and dehydration. It is particularly suitable for scenarios where "wet materials are concentrated" such as wood processing plants and forestry bases.

(2)High degree of integration

The "crushing - drying - pelletizing - cooling" integrated production line is often used to reduce the secondary absorption of moisture during the material transportation process (wet wood is easily absorbed and moisturized when exposed to the air), thereby improving overall processing efficiency.

(3)Balance between energy consumption and molding efficiency

The drying process is the main energy consumption point (accounting for about 50%-70% of the total energy consumption). Advanced equipment reduces costs through "biomass pellet combustion and heating" (self-sufficiency); the pelletizing process optimizes the ring die compression ratio (wet wood usually requires a higher compression ratio) to ensure the pellet molding rate (>90%) and hardness (crushing strength >85%).

(4)Anti-clogging and corrosion-resistant design

Wet wood contains more sap and fiber. The equipment's feed screw, ring die and other components are made of wear-resistant alloy materials (such as high-chromium cast iron), and cleaning devices (such as automatic scrapers) are added to prevent material adhesion and clogging. The motor, bearings and other components in humid environments are sealed and moisture-proof to extend their service life.

3.Application scenarios of wet wood log biomass pellet processing equipment

(1)Wood processing enterprises

Furniture factories and board factories produce a large amount of wet sawdust and scraps (moisture content 40%-50%). They are processed into pellets through supporting processing equipment and directly used as fuel for the factory's boilers (for heating and drying boards), realizing "waste resource utilization" and reducing the cost of purchasing energy.

(2)Forestry bases

Wet branches and trunks (moisture content 50%-60%) produced after forestry felling are crushed, dried and pelletized nearby in the forest area through mobile processing equipment, avoiding long-distance transportation of wet materials (high transportation costs and easy to rot). The pellets can be exported to biomass power plants or heating companies.

(3)Biomass pellet plants

In order to expand the source of raw materials (reduce dependence on dry materials), professional pellet plants are equipped with wet wood processing equipment to process the purchased wet wood waste and produce pellets that meet industrial standards (calorific value 18-22 MJ/kg) for supply to customers such as industrial boilers and distributed power stations.

(4)Agricultural and forestry circular economy projects

In the “Agricultural and forestry waste resource utilization” project, wet wood (such as fruit tree pruning branches, straw and wood mixed waste) is processed into pellets for use in rural central heating, home heating, or as an auxiliary fuel for organic fertilizer production (replacing coal and reducing pollution).

TONY Brand 3Ton/Hour Wet Wood Log Pellet Manufacturing Plant can take wet wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood log as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity:3Ton/Hour

2. Raw materials: Wet wood log, branches, small - diameter logs, twigs, etc.

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Log Pellet Production Line

2. Raw Material: All kinds of wet wood Log

3. Moisture Content of Raw Material: 40%

4. Capacity: 3 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Wood Chipper TPQ216 - 55KW, Effective Hammer Mill-TFD75*100-90KW, Rotary Drum Dryer-1.8*15m, TONY Pellet Machine TYJ760-Ⅲ-200KW, Pellet Cooler, Small Packaging Machine and Belt Conveyors

|

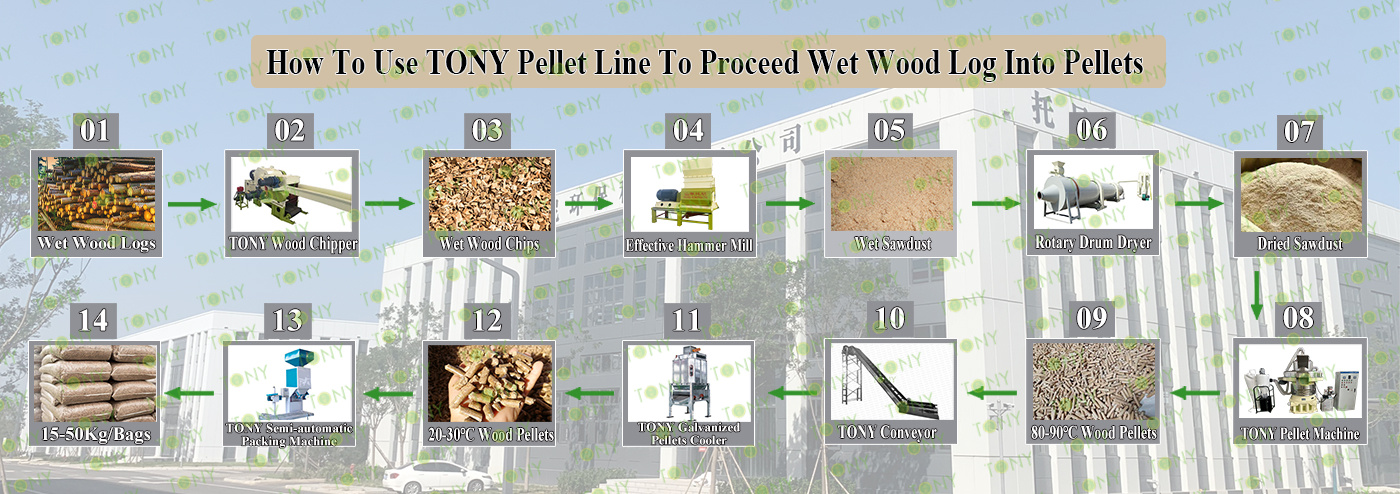

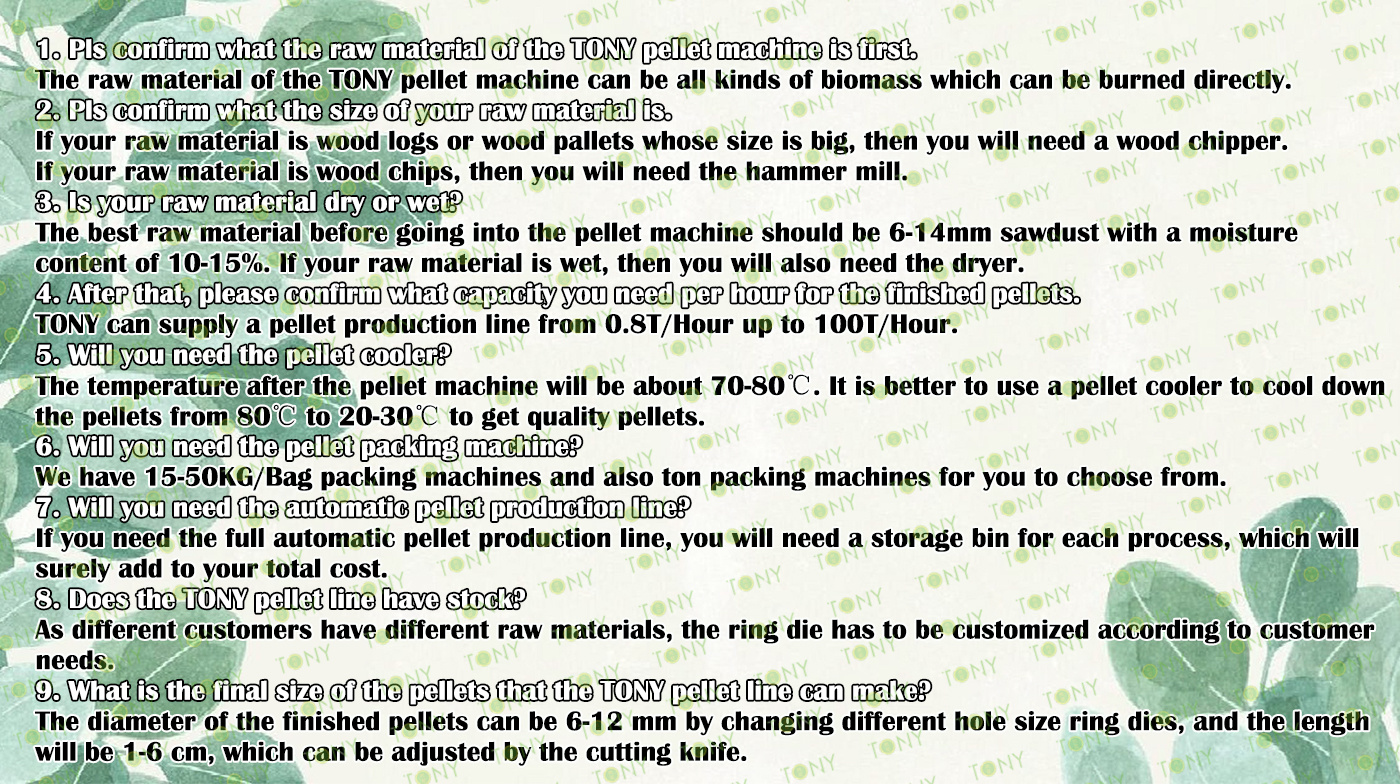

How to use the TONY pellet production line to make pellets from wet wood Log? The process mainly includes the following steps and equipment: 1. Use TONY wood chipper to cut wet wood Log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 5. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 6. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 7. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout.

|

|

|

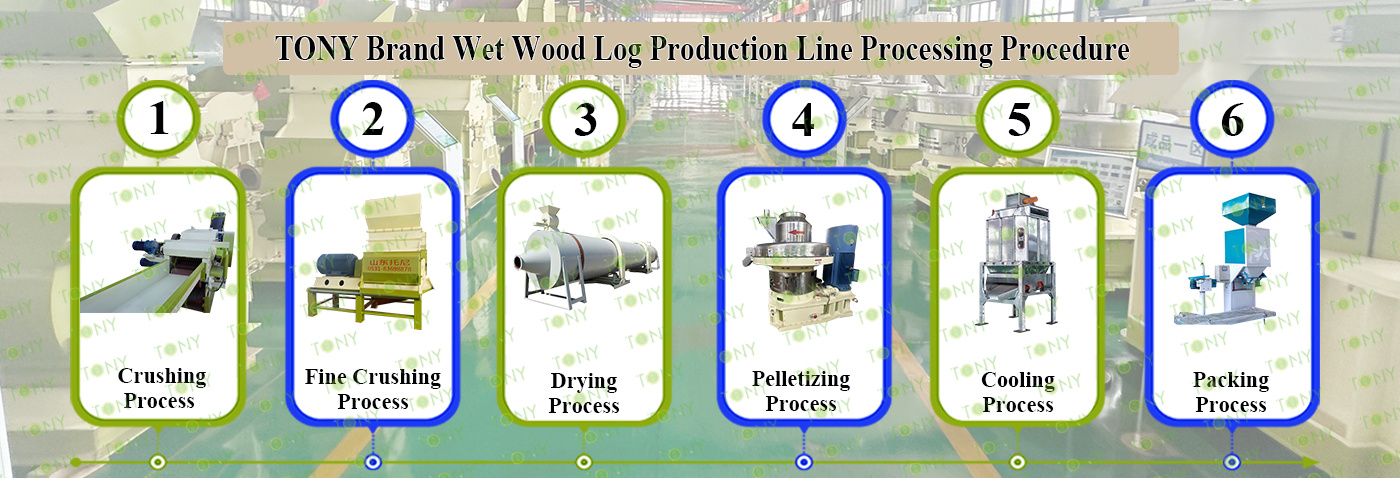

| Wood Chipper | Effective Hammer Mill | Rotary Drum Dryer |

|

1.To Grind Wood Logs φ ≤20cm Into25-55mm Wood Chips. 2.Model: TPQ216-55KW With 2 Blades*1set 3.Capacity: 4-7Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*100-90KW*1set 3.Capacity: 3 Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD1.8*15*1set 3.Capacity:3 Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*1set 3.Capacity:3Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity: 3Ton/Hour |

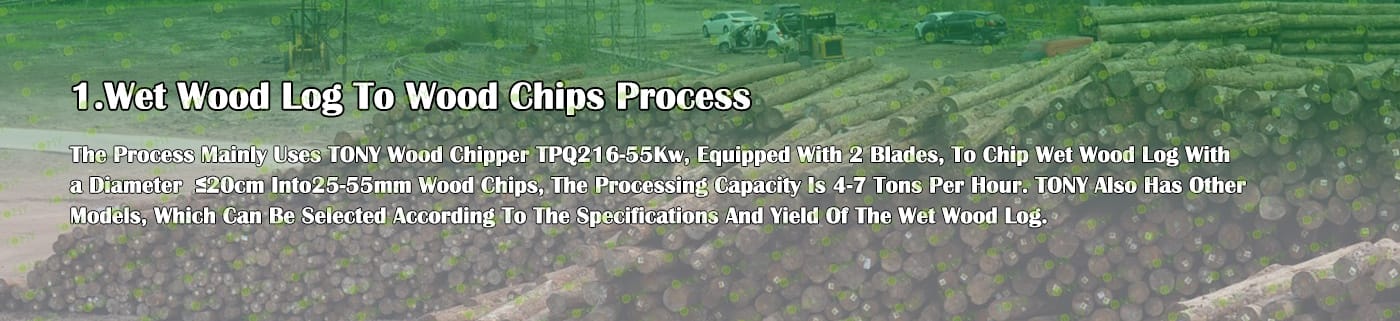

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 20cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPQ216 model with 2 flying blades type:

Main Parts:

(1)TONY's Wood Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:3Ton/Hour.

C.TONY effective hammer mill TFD75*100-90KW

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

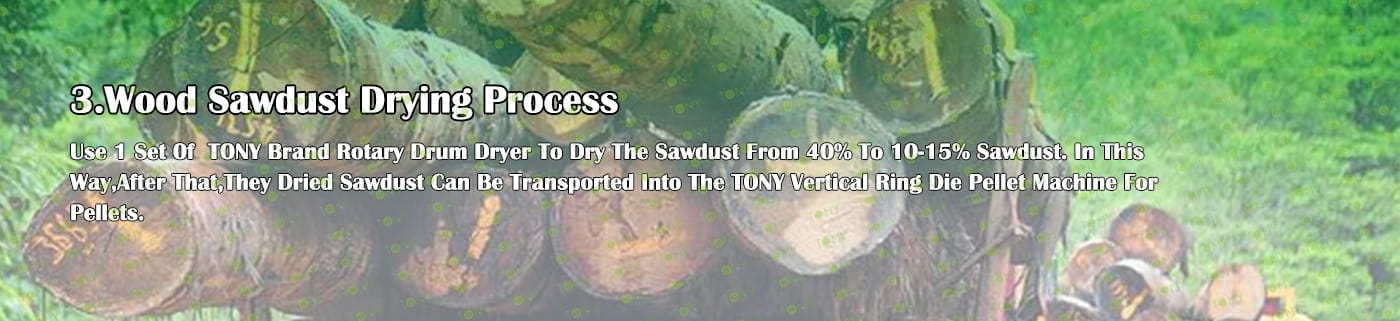

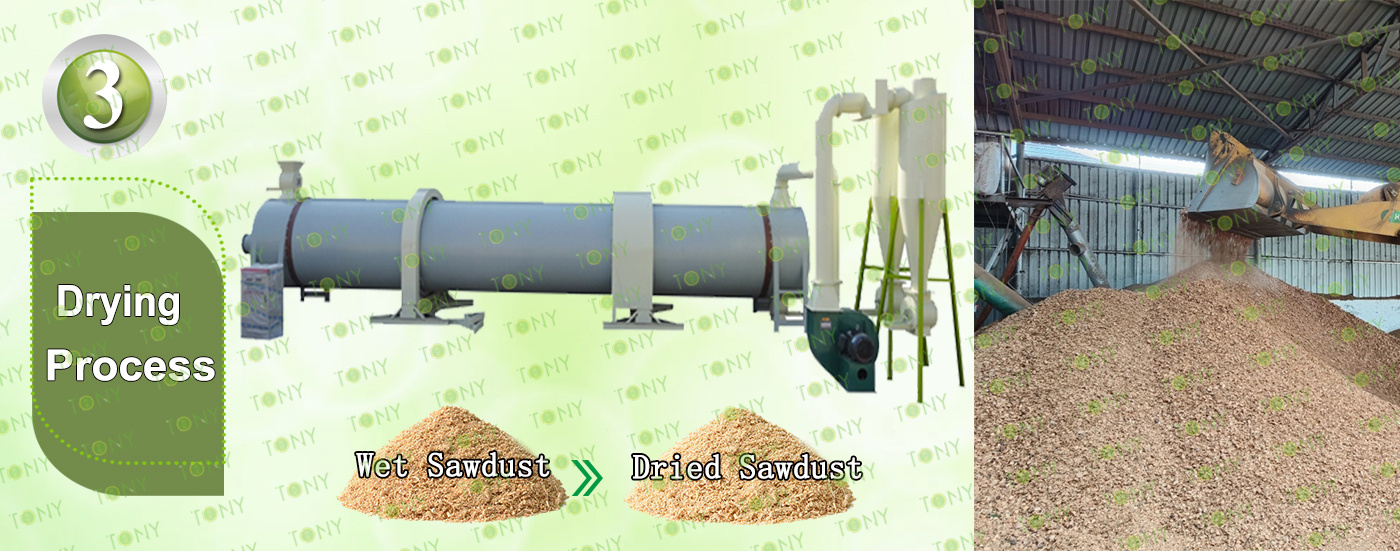

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:3Ton/Hour.

C.TONY use 1set of 1.8*15m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:3Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-200KW

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1set of TONY galvanized cooler separator

Main Parts:

(1)TONY's New Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY semi-automatic packing machine.

Main Parts:

(1)TONY Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Project Advantages: Project Cost and Equipment Technology

1.Wide Source of Raw Materials and Low Cost

The raw materials for biomass pellets are primarily agricultural and forestry waste, such as wood chips, rice husks, straw, and corn cobs. These wastes are abundant in rural areas and agricultural and forestry production areas. In the past, they were often discarded or incinerated, wasting resources and polluting the environment. Today, they have become valuable raw materials for biomass pellet production. If entrepreneurs have their own agricultural and forestry waste resources, the raw material cost can be virtually zero. Even if they need to purchase them from outside, the price remains low year-round, far below the calorific value of traditional fuels like coal. This abundant and affordable source of raw materials provides a solid foundation for the project's low-cost operation.

2.Mature Equipment Technology, Efficient and Stable Production Capacity

After years of development, biomass pellet processing equipment technology has reached considerable maturity. Modern, fully automated biomass pellet production lines cover the entire process, from raw material crushing, drying, pelletizing, cooling, screening, and packaging, automating operations. This significantly reduces manual labor, improves production efficiency, and ensures consistent product quality. For example, the TONY pellet machine, a renowned brand in the industry, boasts an output rate exceeding 98%, high pellet density, excellent appearance, and resistance to brittleness. Core components utilize high-manganese steel and alloy molds, extending wear resistance and lifespan by 300%. Fully automated operation allows a single operator to control the entire line, saving 50% in labor costs. It also supports trial runs with incoming materials and customized compression ratios, seamlessly adapting to a wide range of raw materials. These stable and efficient equipment ensures the project can achieve large-scale production and meet market demand.

Wood pellets are solid fuels made from wood processing waste (such as wood chips, sawdust, and shavings) through crushing, drying, and extrusion. Their main characteristics and advantages are as follows:

1.Stable Physical Form

They are regular cylindrical pellets (typically 6-10 mm in diameter and 20-50 mm in length) with a high density (approximately 1.1-1.3 tons/cubic meter). They are significantly more compact than raw wood chips (which have a density of only 0.1-0.2 tons/cubic meter), making them easier to store, transport, and meter. They are also less prone to moisture absorption and agglomeration.

2.Single Composition and Stable Combustion

Mainly composed of wood cellulose, they contain no impurities such as gangue and sulfur. They produce a stable flame, high thermal efficiency, and low ash content (typically less than 1%) during combustion, minimizing wear and tear on combustion equipment.

3.Easy to ignite and good flame control.

Compared to fuels like coal and biomass briquettes, wood pellets have a lower ignition point (approximately 200-250°C) and ignite quickly. The combustion intensity can be precisely controlled by adjusting the feed rate, making them suitable for automated combustion equipment (such as pellet stoves and boilers).

4.Excellent environmental performance.

A renewable energy source, the carbon dioxide released during combustion is essentially balanced by the carbon dioxide absorbed during the tree's growth, achieving "carbon neutrality." Furthermore, sulfur and nitrogen emissions are extremely low (far lower than coal), meeting environmental emission standards.

2025 Tony Machinery - All Rights Reserved. Map