Project Brief Introduction:

1.Product:Wet Wood Log Pellet Line

2.Capacity:2.8-3.2T/Hour

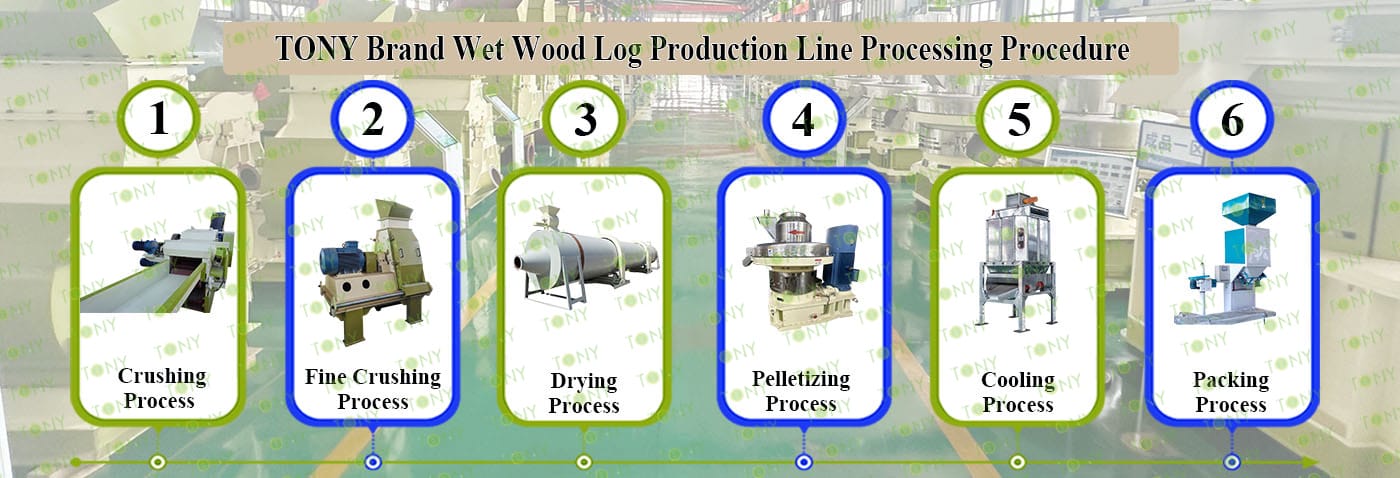

3.TONY Brand 2.8-3.2Ton/Hour Wet Wood Log Pellet Line Project Process

4:Main Machine: Wood Chipper , Hammer Mill, Rotary Drum Dryer, TONY Pellet Machine TYJ760-Ⅲ-185KW, Pellet Cooler, Packaging Machine And Belt Conveyors

5.Total Power: About 420KW

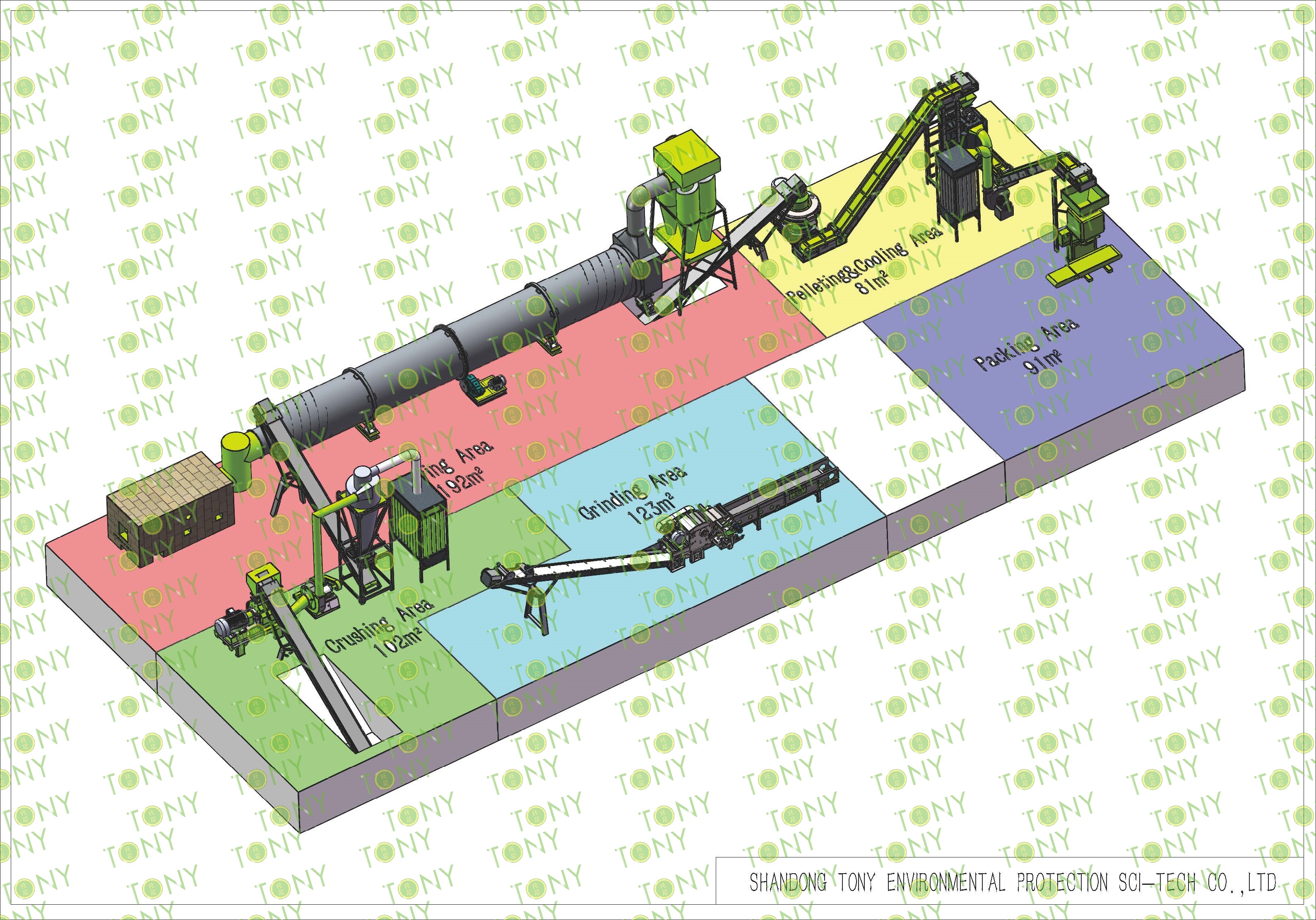

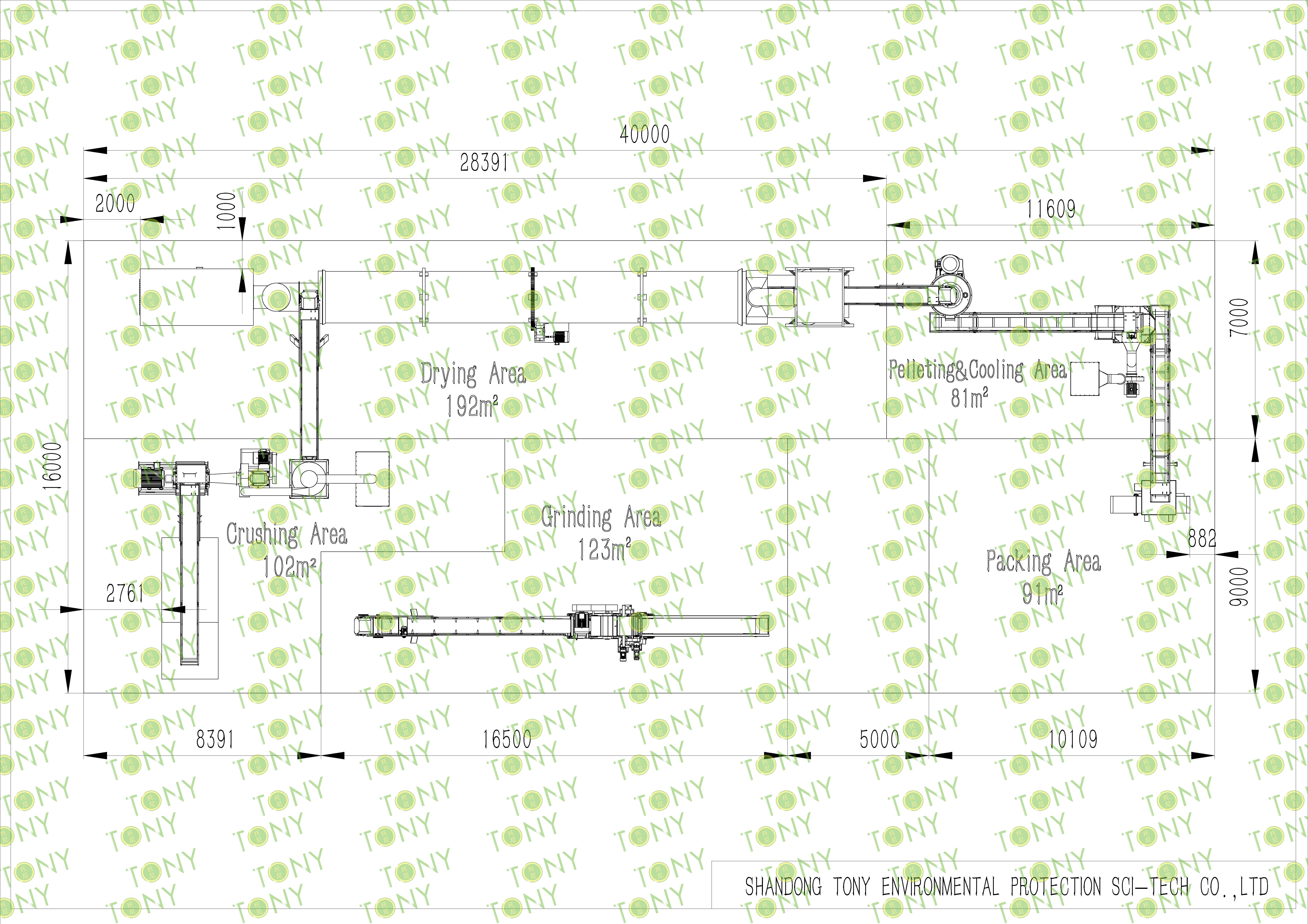

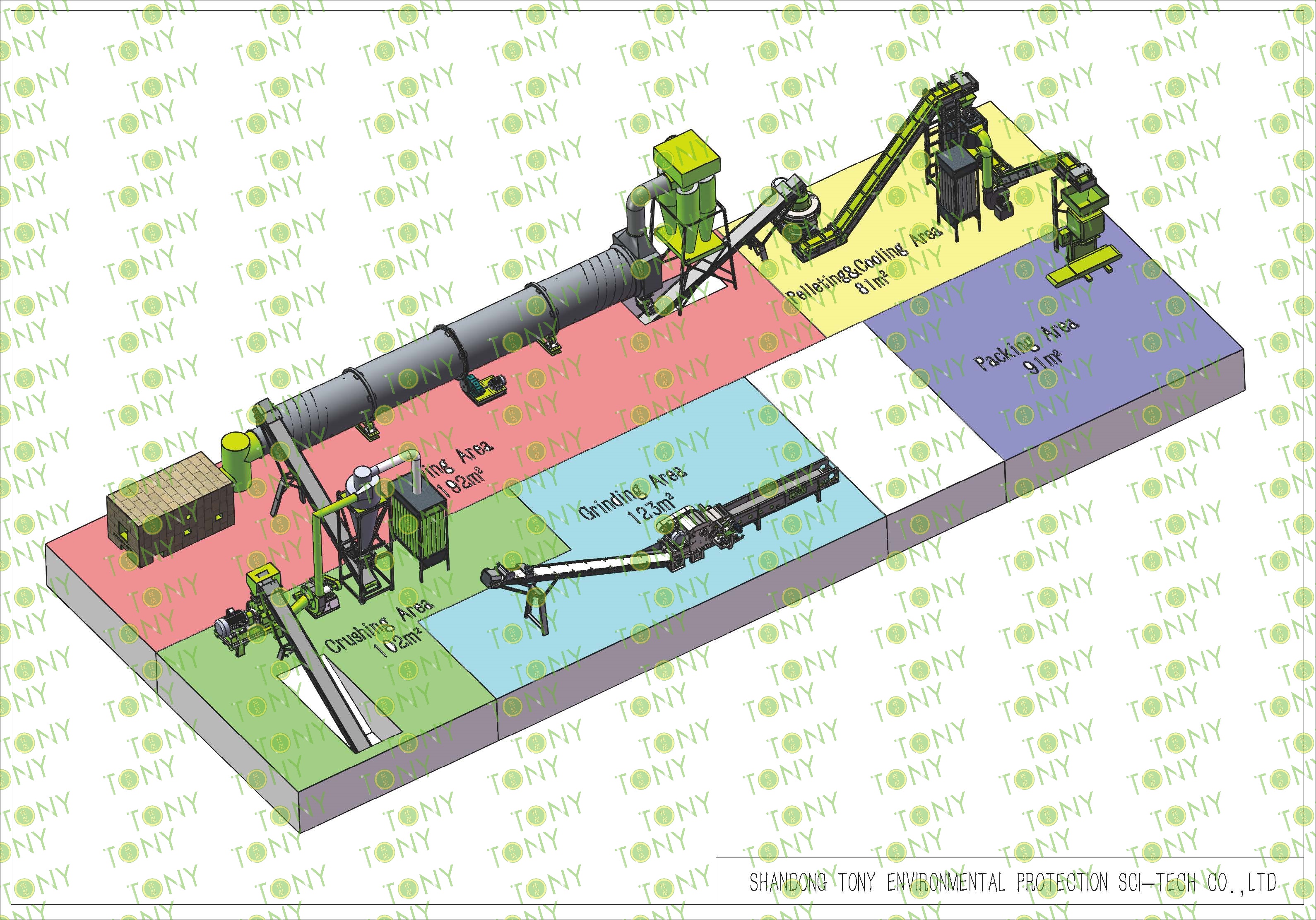

6.Need Area: About 640㎡ L:40M W: 16M H:6.488M

Project Layout For Customer:

1.The working principle of wet wood log biomass pellet processing equipment

The production principle of wood processing pellets (i.e. wood chip pellets) is based on *"physical compression molding*. By pre-treating the wood raw materials (wood chips, sawdust, etc.) and mechanically extruding them, the wood fibers are recombined to form high-density pellets. The core process does not rely on chemical additives, but mainly utilizes the fiber properties of the wood itself and trace amounts of natural resin to achieve bonding.

2.Characteristics of wet wood log biomass pellet processing equipment

High Formation Rate: The core pelletizer utilizes a ring die structure, compressing and bonding wood fibers through high temperature and high pressure, achieving a formation rate exceeding 95%. The pellets typically have a density of 0.8-1.2 g/cm³, are hard, and resistant to breakage.

High Continuous Operation Capability: The equipment utilizes wear-resistant alloy dies and rollers, optimizing the life of wear parts for the high fiber content of wood raw materials. This allows for 12-24 hour continuous production and reduces downtime for maintenance.

Controllable Pellet Size: By replacing dies with different apertures (commonly 6-12 mm), wood pellets of varying sizes can be produced to meet the needs of diverse applications, such as industrial boilers and home heating.

3.Application scenarios of wet wood log biomass pellet processing equipment

Industrial Energy:Processing equipment provides fuel (replacing coal and oil) for factory boilers and kilns, such as steam boilers in textile and food factories, and heating kilns in the ceramic and building materials industries. This stable production of pellets ensures energy supply.

Power Generation:Biomass power plants require large quantities of standardized pellets as fuel. Large-scale processing equipment can meet the power plants' stringent requirements for pellet calorific value and density, ensuring combustion efficiency and stable power generation.

Agriculture and Animal Husbandry:Some processing equipment can produce pellets for livestock bedding (such as straw pellets) or raw material pellets for organic fertilizer production. The equipment can be adapted to different agricultural needs by adjusting the process.

Residential Heating:For pellets used in home fireplaces and small heating appliances, processing equipment must control pellet size and hardness to accommodate residential combustion equipment. The equipment's refined production capacity directly impacts the user experience of these pellets.

Environmental Protection and Waste Management: In garbage and sewage treatment plants, processing equipment can convert organic waste (such as sludge and food waste) into fuel pellets for resource utilization. Corrosion- and clogging-resistant designs are key.

TONY Brand 2.8-3.2Ton/Hour Wet Wood Log Pellet Manufacturing Plant can take wet wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity:2.8-3.2Ton/Hour

2. Raw materials: Wet wood Log, branches, small - diameter logs, twigs, etc.

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Log Pellet Production Line

2. Raw Material: All kinds of wet wood Log

3. Moisture Content of Raw Material: 40%

4. Capacity: 2.8-3.2 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Wood Chipper TPQ216 - 55KW, Effective Hammer Mill-TFD75*100-90KW, Rotary Drum Dryer-1.8*15m, TONY Pellet Machine TYJ760-Ⅲ-185KW, Pellet Cooler, Small Packaging Machine and Belt Conveyors

|

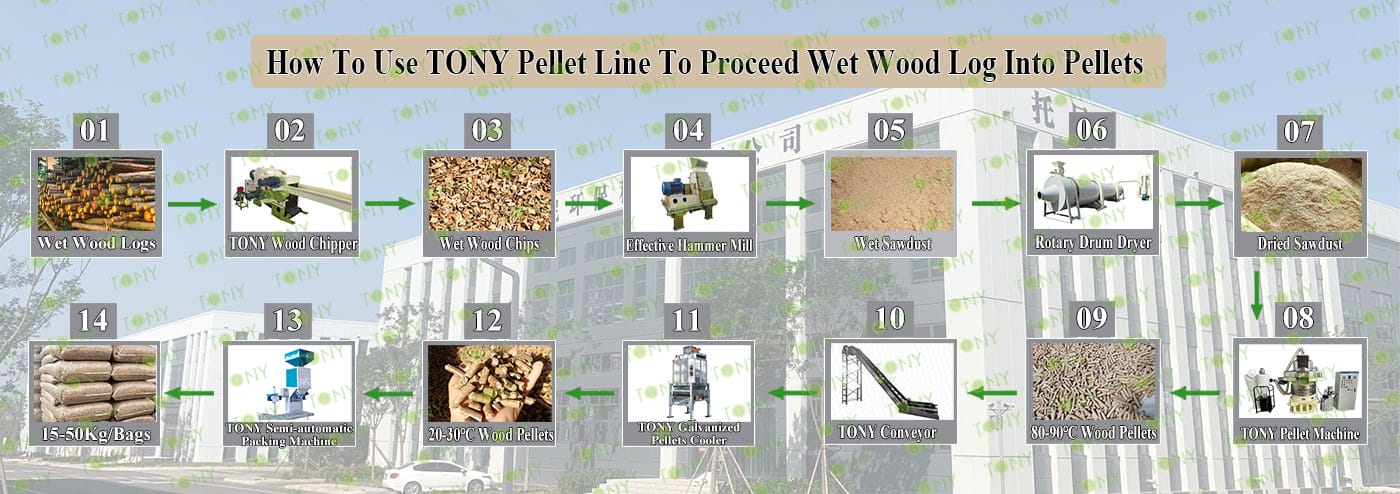

How to use the TONY pellet production line to make pellets from wet wood log? The process mainly includes the following steps and equipment: 1. Use TONY wood chipper to cut wet wood log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 5. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 6. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 7. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Wood Chipper | Effective Hammer Mill | Rotary Drum Dryer |

| 1.To Grind Wood Logs φ ≤20cm Into25-55mm Wood Chips. 2.Model: TPQ216-55KW With 2 Blades*1set 3.Capacity: 4-7Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*100-90KW*1set 3.Capacity: 2.8-3.2Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD1.8*15*1set 3.Capacity:2.8-3.2Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-185KW*1set 3.Capacity:2.8-3.2Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:2.8-3.2Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity: 2.8-3.2Ton/Hour |

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 20cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPQ216 model with 2 flying blades type:

Main Parts:

(1)TONY's Wood Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:2.8-3.2Ton/Hour.

C.TONY effective hammer mill TFD75*100-90KW

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

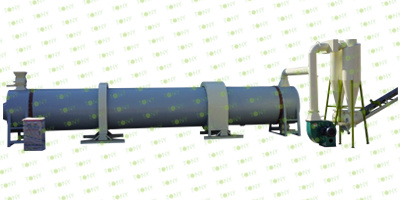

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:2.8-3.2Ton/Hour.

C.TONY use 1set of 1.8*15m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:2.8-3.2Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-185KW

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1set of TONY galvanized cooler separator

Main Parts:

(1)TONY's New Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY semi-automatic packing machine.

Main Parts:

(1)TONY Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

1.Strong Policies

As an important renewable energy source, biomass energy has received strong support from national and local governments. The clear advocacy of "replacing coal and achieving clean combustion" provides a solid policy foundation for the development of the biomass pellet industry. Biomass projects are eligible for numerous preferential policies, including tax exemptions and equipment subsidies, lowering the barrier to entry for entrepreneurs.

2.Strong Market Demand

In recent years, the price of traditional fossil fuels has fluctuated frequently and steadily increased, raising concerns about the stability and cost of energy supply. At the same time, growing environmental awareness has led to explosive growth in demand for clean energy. As a clean and efficient renewable energy source, biomass pellets have a wide range of applications. In the industrial sector, they can replace coal and natural gas, providing a stable heat source for factory boilers and kilns, meeting the production heat needs of industries such as food processing, textiles, papermaking, and chemicals. In the power sector, they are the core fuel for biomass power plants, contributing to clean energy generation. In the residential sector, they are suitable for home fireplaces, heating stoves, and cooking stoves, providing residents with a warm and comfortable living environment. In the agricultural sector, they can be used for drying agricultural and sideline products and heating greenhouses.

Biomass pellet fuel is a type of biomass fuel that uses crop straw, forestry waste (such as wood chips, bark), agricultural and forestry processing residues and other biomass as raw materials.Core features:

1.The raw materials are widely available and renewable.

The raw materials mainly include straw, rice husks, wood chips, branches, peanut shells, sugarcane bagasse and other agricultural and forestry wastes. These resources exist in large quantities in nature and are renewable resources. They are continuously recycled through plant photosynthesis and will not be depleted due to use.

2.Regular shape, easy to store and transport.

Usually compressed into cylindrical pellets with a diameter of 6-10 mm and a length of 20-30 mm, the density can reach 1.1-1.3 tons/cubic meter (much higher than the original biomass of 0.1-0.3 tons/cubic meter), which greatly reduces storage space and is not easy to scatter, making it convenient for mechanized transportation and warehousing.

3.High energy density and stable combustion

After compression molding, its calorific value is generally 16-22 MJ/kg (about 3800-5200 kcal/kg), which is lower than coal (about 29-37 MJ/kg), but much higher than raw biomass (about 10-15 MJ/kg). During combustion, the fire is stable, the furnace temperature is high, and the combustion rate is easy to control.

4.Low sulfur content and low pollutant emissions

Biomass itself has an extremely low sulfur content (usually < 0.05%) and a low nitrogen content (about 0.5-1.5%). When burned, it produces far less sulfur dioxide (SO₂) and nitrogen oxides (NOₓ) than coal, which can significantly reduce the risk of acid rain and air pollution.

2025 Tony Machinery - All Rights Reserved. Map