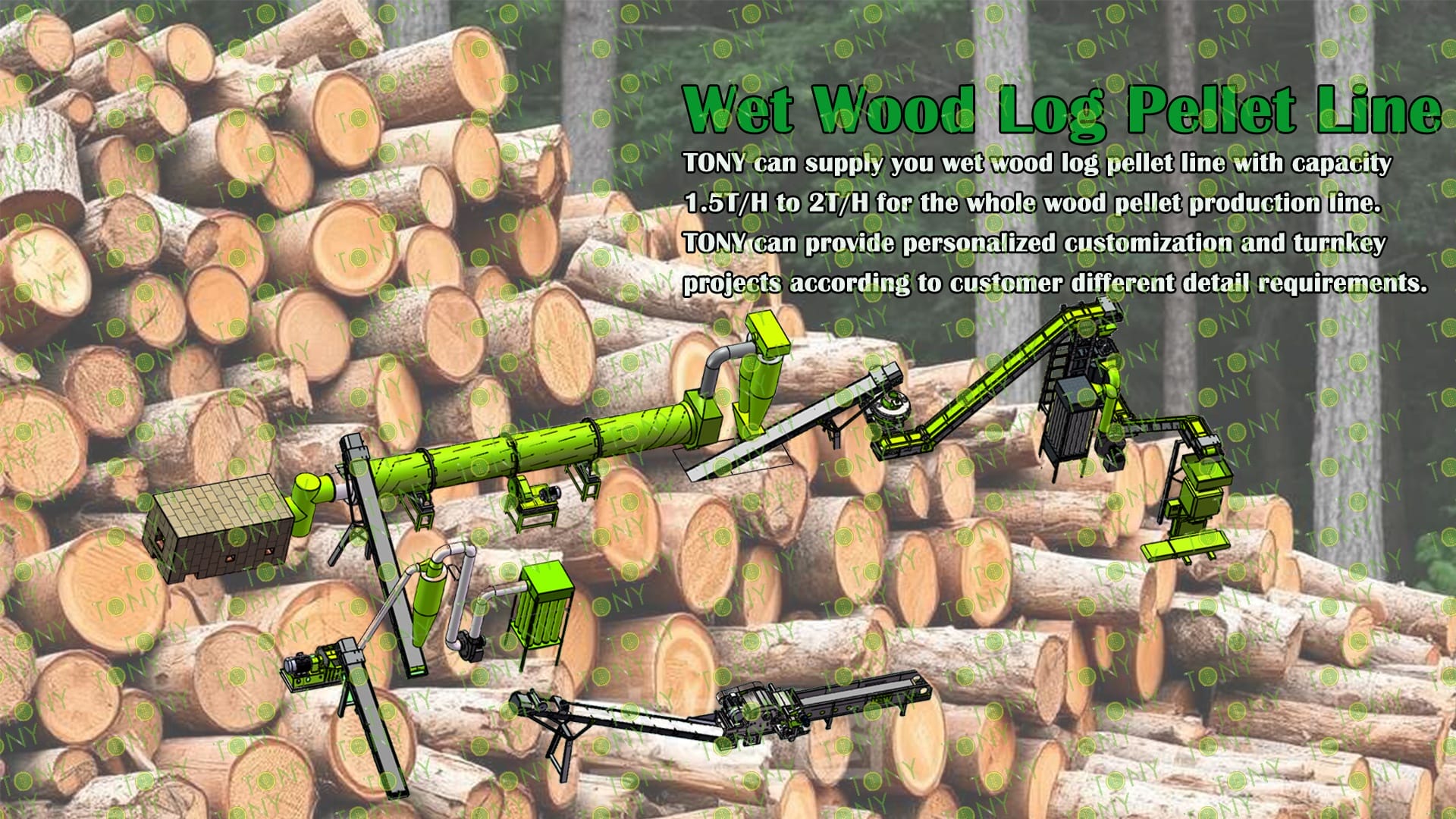

Project Brief Introduction:

1.Product:Wet Wood Log Pellet Line

2.Capacity:1.5-2T/Hour

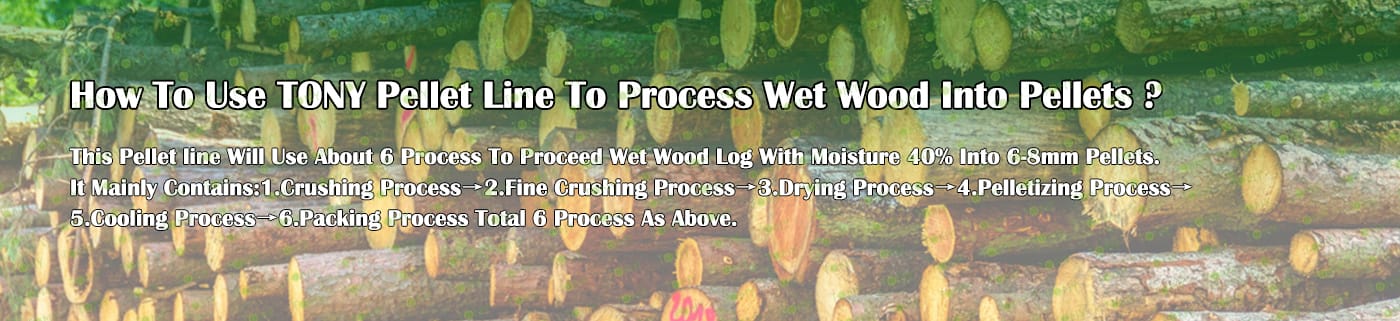

3.TONY Brand 1.5-2Ton/Hour Wet Wood Log Pellet Line Project Process

4:Main Machine: Wood Chipper ,Hammer Mill, Rotary Drum Dryer, TONY Pellet Machine TYJ551-Ⅲ-110KW, Pellet Cooler, Packaging Machine And Belt Conveyors

5.Total Power: About 250KW

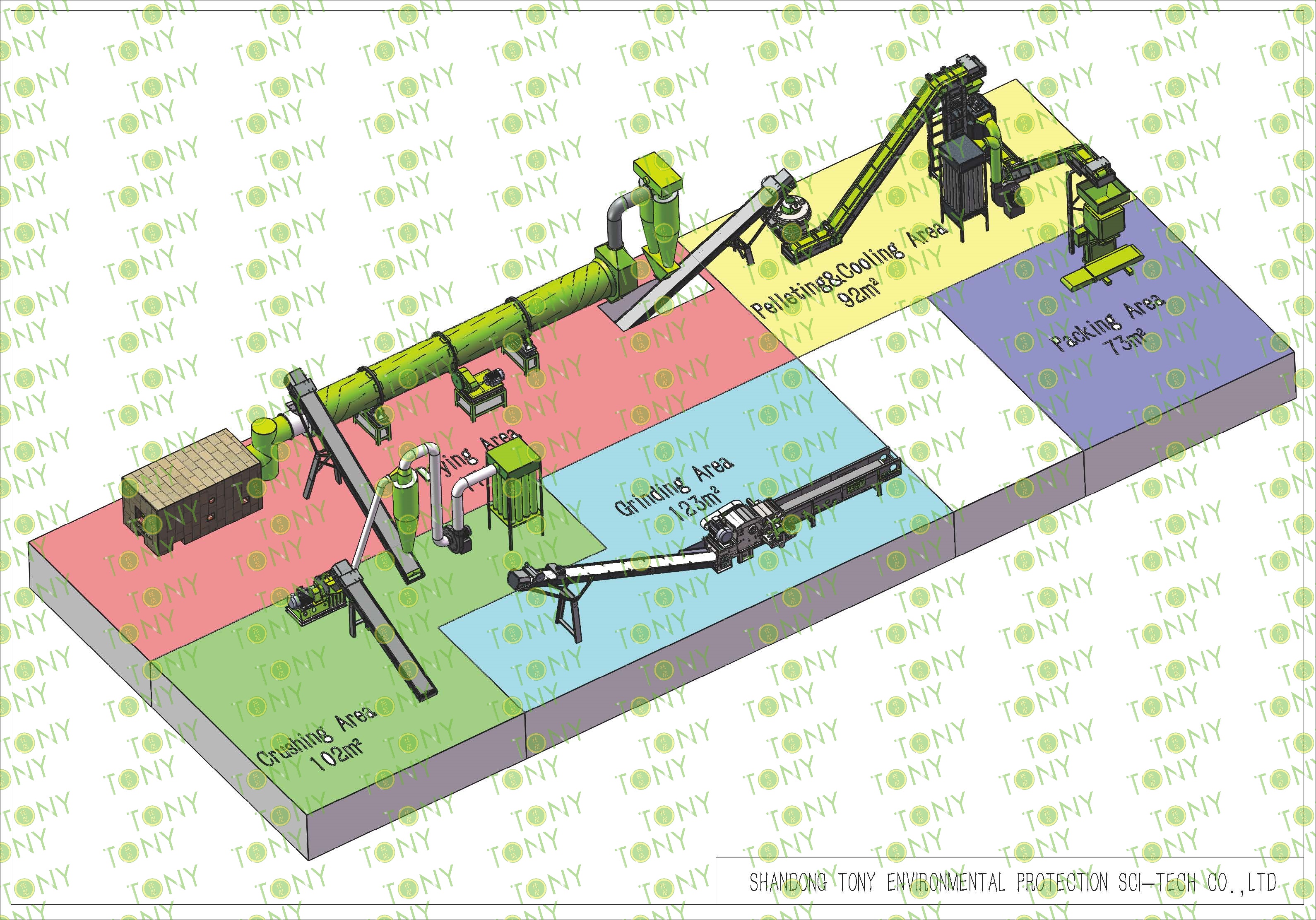

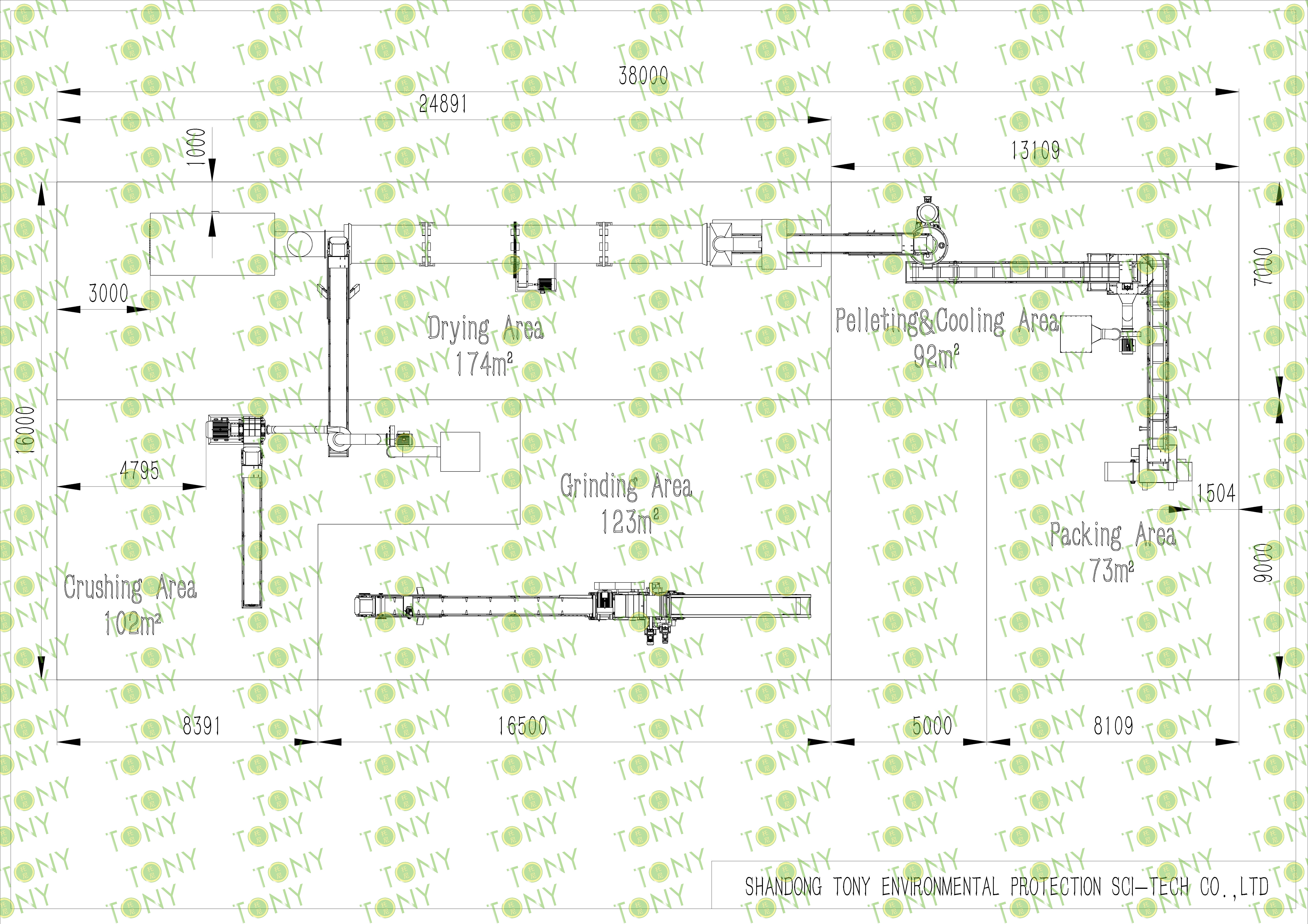

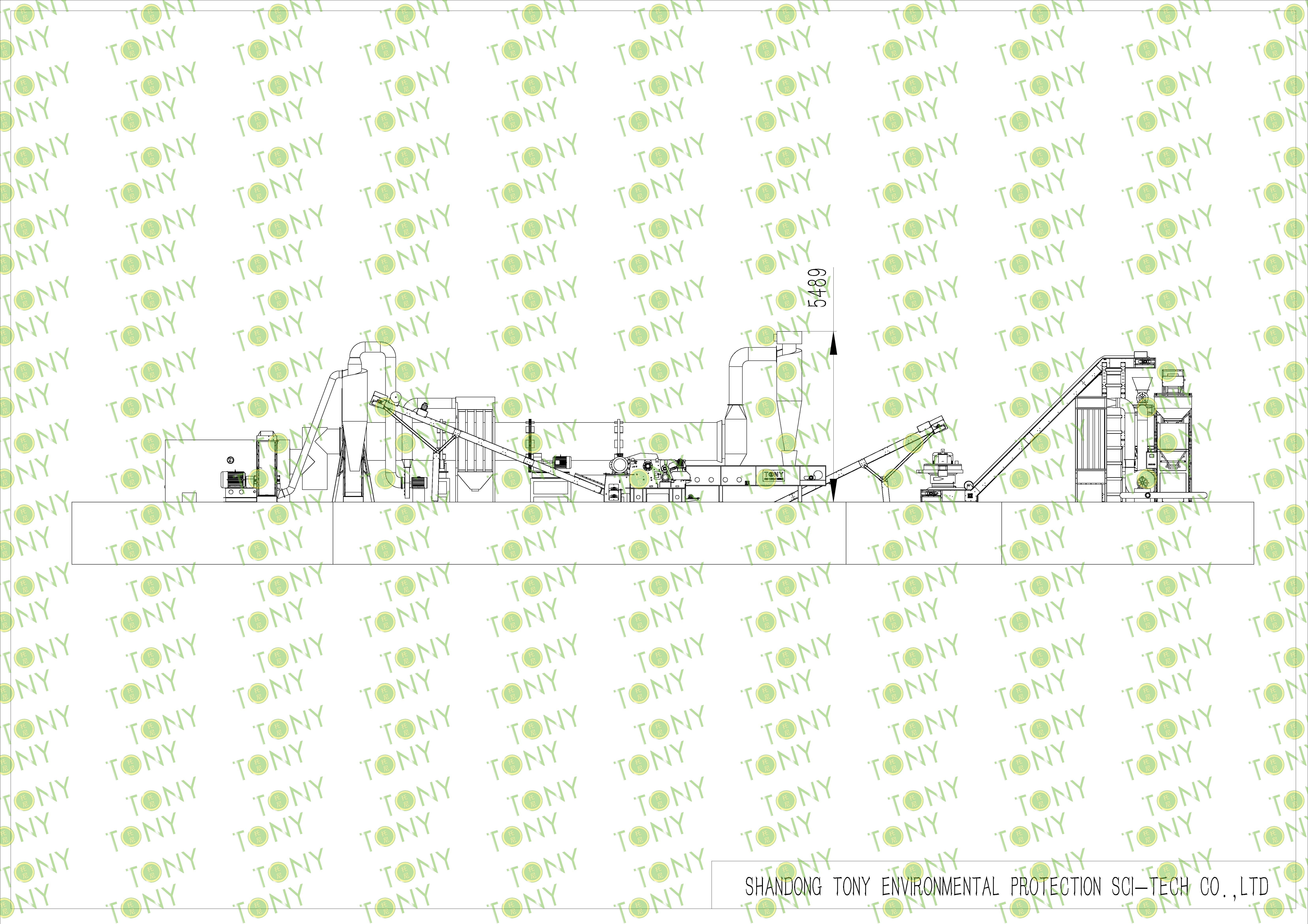

6.Need Area: About 608㎡ L:38M W: 16M H:5.489M

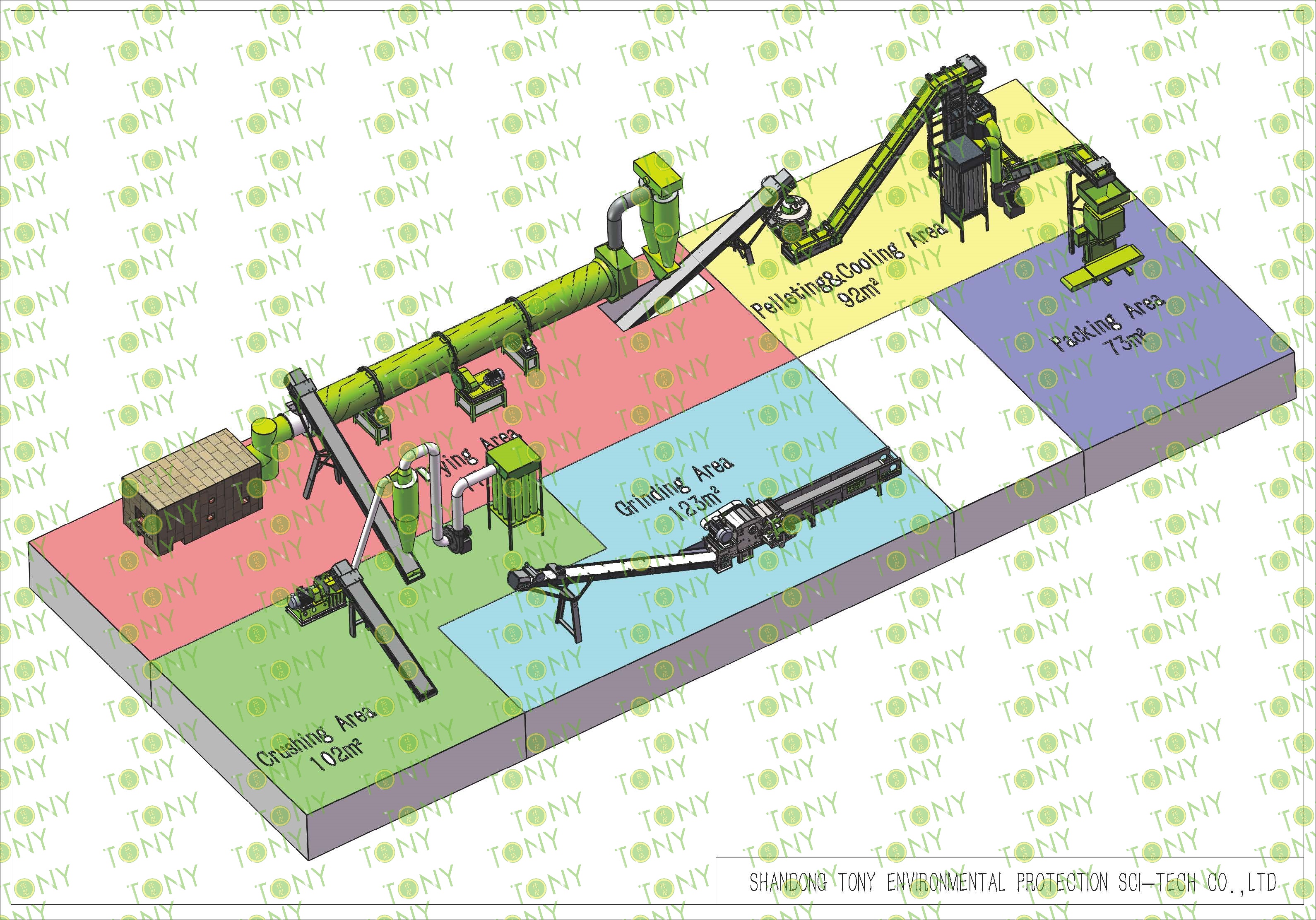

Project Layout For Customer:

1.The working principle of wet wood log biomass pellet processing equipment

The working principle of wood pellet processing is to utilize mechanical power, through the friction between the rollers and the die, to extrude the powdered material through the die under high pressure.

No additives or binders are required during the processing. Wood chips, straw, and other materials contain a certain amount of cellulose and lignin. Lignin is a structural monomer in the material, a phenylpropane-type polymer that strengthens cell walls and binds cellulose. Lignin is an amorphous substance that is primarily insoluble in all solvents at room temperature and has no melting point, but it does have a softening point. When the temperature reaches a certain level, the lignin softens and its binding force increases. Under a certain pressure, the cellulose molecules are dislocated, deformed, and stretched, and adjacent biomass particles intermesh and recombine to form the pressed pellets.

2.Characteristics of wet wood log biomass pellet processing equipment

(1)TONY Automatic Self -lubrication system

A.TONY Spindle Automatic lubrication system

B.Rollers automatic lubrication system :It can keep TONY pellet machine in maintenance for 24 hours.

(2)Output of TONY pellet machine: It can reach the expected output in our technical parameter.

(3)Working Life of spare parts: Working life of our dies is 3000-4000 hours, much longer than others'

(4)Number of Ring Die holes: TONY ring die has 5 rows of holes, which is much more than other supply

(5)Driving Method of TONY pellet machine: Our machine is drived by gear,not reduction box; Gear drives helpful to increase the usage life of gear, so the maintenance rate of gear is much lower.

(6)Forged Main Shaft: TONY main shaft is forged, not casted. As well known, there is no air bubble in forging process, so it is hard to be broken.

3.Application scenarios of wet wood log biomass pellet processing equipment

(1)Feed Processing Industry: Used to produce various animal feed pellets, such as those for poultry, livestock, and aquatic products. Different feed ingredients, such as grains, soybean meal, fish meal, oils, and additives, can be evenly mixed and processed into pellets, making them easier for animals to consume and digest, thereby improving feed utilization.

(2)Biomass Energy Industry: Processing biomass raw materials, such as agricultural and forestry waste, into biomass fuel pellets can replace traditional fossil fuels for heating, household stoves, hot water boilers, industrial boilers, and biomass power plants, achieving efficient utilization of biomass energy and reducing environmental pollution.

(3)Other Industries: It can also be used in the production of pet bedding, cat litter, and other products, processing the relevant raw materials into pellets to meet pet care and cleaning needs.

TONY Brand 1.5-2Ton/Hour Wet Wood Log Pellet Manufacturing Plant can take wet wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 1.5-2Ton/Hour

2. Raw materials: Wet wood Log, branches, small - diameter logs, twigs, etc.

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Log Pellet Production Line

2. Raw Material: All kinds of wet wood Log

3. Moisture Content of Raw Material: 40%

4. Capacity: 1.5-2 tons per hour

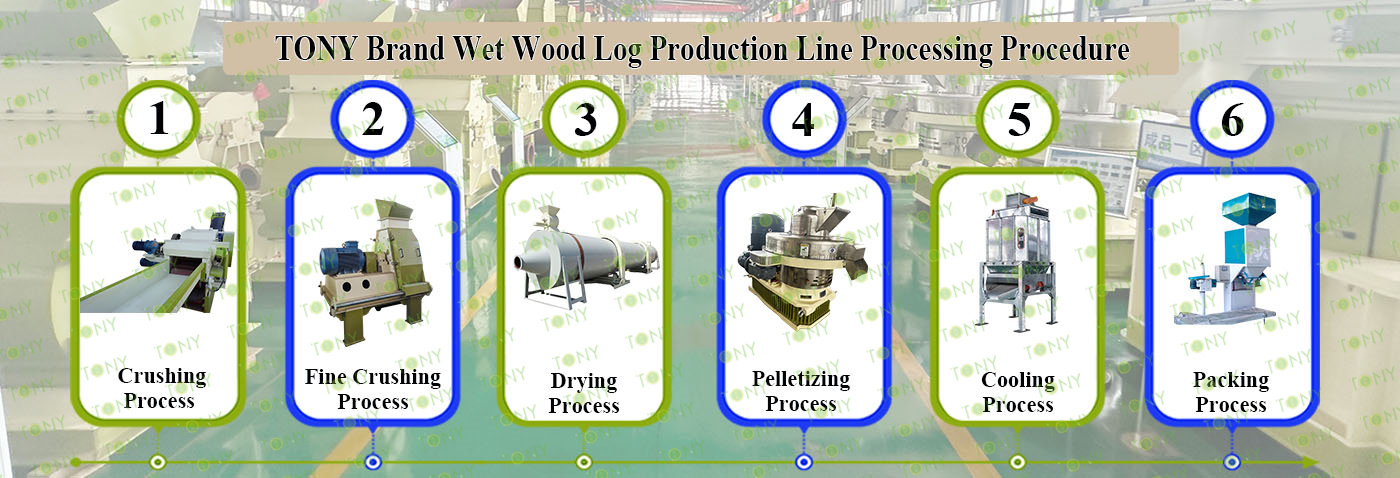

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Wood Chipper TPQ216 - 55KW,Effective Hammer Mill-TFD65*55-55KW, Rotary Drum Dryer-1.6*12m, TONY Pellet Machine TYJ551-Ⅲ-110KW, Pellet Cooler, Small Packaging Machine and Belt Conveyors

|

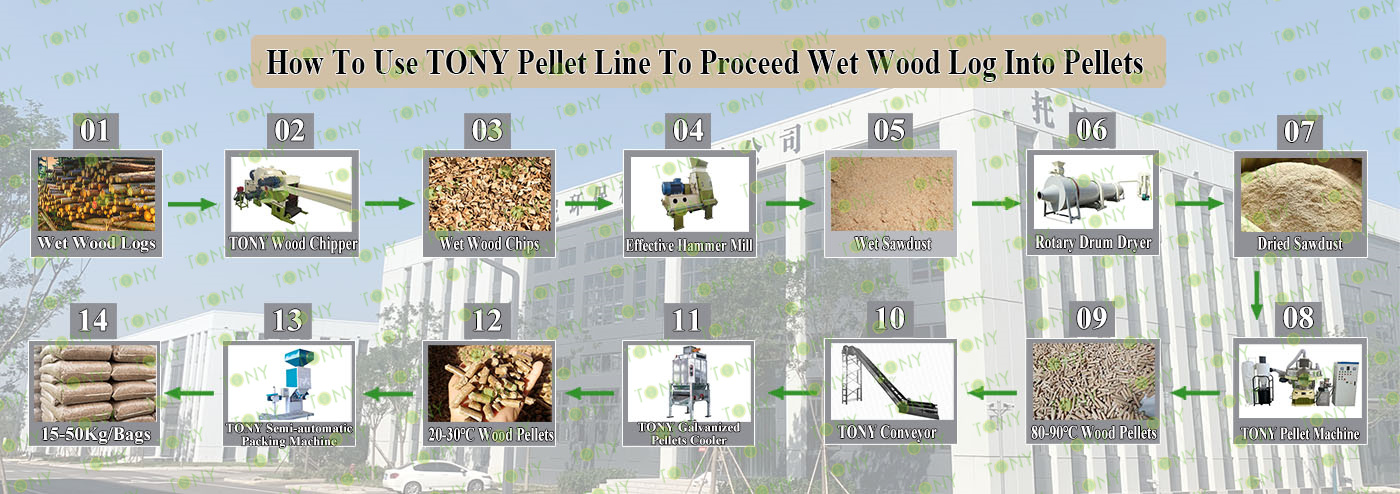

How to use the TONY pellet production line to make pellets from wet wood log? The process mainly includes the following steps and equipment: 1. Use TONY wood chipper to cut wet wood log with a diameter of less than 20 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 5. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 6. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 7. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Wood Chipper | Effective Hammer Mill | Rotary Drum Dryer |

|

1.To Grind Wood Logs φ ≤20cm Into22-55mm Wood Chips. 2.Model: TPQ216-55KW With 2 Baldes*1set 3.Capacity: 4-7Ton/Hour. |

1.To Crush 22-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD65*55-45KW*1set 3.Capacity: 1.5-2Ton/Hour/Set |

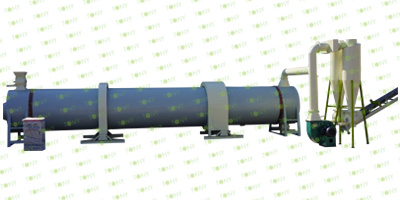

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD1.6*12*1set 3.Capacity:1.5-2Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-110KW*1set 3.Capacity:1.5-2Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-1.5*1set 3.Capacity:1.5-2Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity: 1.5-2Ton/Hour |

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 20cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand TPQ216 model with 2 flying blades type

C.Capacity:4-7Ton/Hour.

Main Parts:

(1)TONY's Wood Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:1.5-2Ton/Hour.

C.TONY effective hammer mill TFD65*55-45KW

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

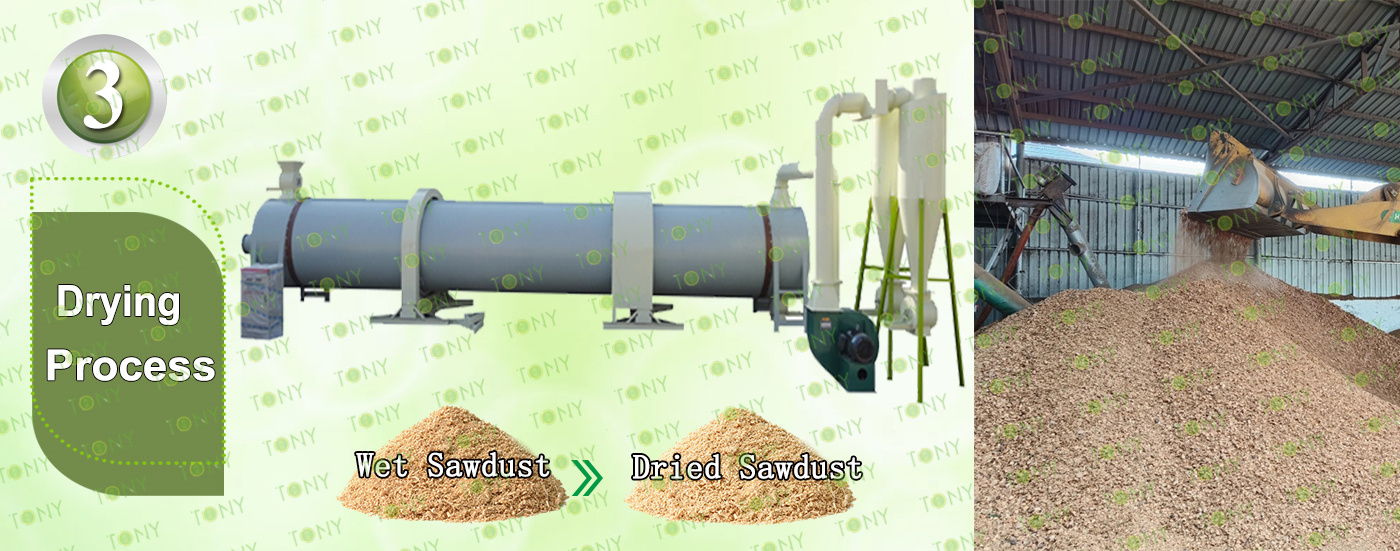

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:1.5-2Ton/Hour.

C.TONY use 1set of 1.6*12m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:1.5-2Ton/Hour.

C.1 set of TONY brand vertical ring die pellet machine TYJ551-III-110KW with capacity 1.5-2ton/hour.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1 set Of TONY galvanized cooler separator with capacity 1.5-2Ton/Hour

Main Parts:

(1)TONY's New Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY semi-automatic packing machine.

Main Parts:

(1)TONY Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

The biomass pellet project uses agricultural and forestry waste as raw materials to produce biomass pellet fuel, offering significant economic and environmental benefits.

1.Significant Environmental Benefits:

Biomass pellets emit zero sulfur and phosphorus when burned, effectively reducing atmospheric pollutant emissions and meeting environmental standards. They demonstrate significant potential as a coal replacement and emission reduction tool.

2.Raw materials are sourced from a wide range of sources:

Agricultural waste such as straw, rice husks, and peanut shells, as well as forestry waste such as sawdust, wood chips, and wood scraps, can all be used as raw materials, achieving resource recycling.

3.Strong Policy Support:

Biomass energy is a key development area for renewable energy, and local governments are supporting project development through subsidies and tax incentives.

Biomass pellet fuel refers to a granular fuel made by using crops (such as straw), wood (such as wood, pine, fir, etc.), sawdust and other agricultural and forestry processing waste (such as rice husks, tree bark, furniture factory foot feed, wood powder, cotton poles, peanut shells, medicinal residue, bamboo chips, sludge, building formwork, wooden pallets, etc.) as raw materials. After being extruded by a biomass pellet machine, the crushed raw materials are made by cold compact molding and processing under normal temperature conditions using a press roller and ring mold.

1.Reduce greenhouse gas and pollutant emissions:

Near-zero carbon dioxide emissions can be achieved. The sulfur content and nitrogen content of biomass particles are extremely low, and the pollutants such as sulfur dioxide and nitrogen oxides generated during combustion are far less than that of traditional fossil fuels

2.Low raw material cost and efficient use of resources:

Raw material sources are wide and low cost, can be agricultural waste (such as crop straw), forestry waste (such as branches, wood chips), urban garden waste, fruit shells, bagasse and other organic waste for effective use.

3.Energy density:

After the compression molding of biomass raw materials, the volume is greatly reduced, the energy density is significantly increased, which is convenient for storage and transportation, and reduces the storage space and transportation costs

4.High combustion efficiency:

It is easier to mix with air in the combustion process, making the combustion more full

5.Comprehensive cost reduction:

The combined cost may be lower than some conventional fossil fuels when generating the same amount of heat

2025 Tony Machinery - All Rights Reserved. Map