1标题

Project Brief Introduction:

1.Product:Dried Hay/Grass/Alfalfa Pellet Line

2.Capacity:6-7Ton /Hour

3.TONY Brand 6-7Ton /Hour Dried Hay/Grass/Alfalfa Pellet Line Project Process

4.Main Machine: Straw Cutter,Hammer Mill,TONY Pellet Machine TYJ551-III-132KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 825kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D图

原材料图+颗粒机图片

原材料--成品图

1. The working principle of dried bagasse biomass pellet processing equipment

The pellet mill's main unit is the core equipment, operating based on the compression mechanism between rollers and a die. When material is fed into the pellet mill, an electric motor drives the main shaft through a gearbox or reducer, which in turn rotates the rollers. As the rollers rotate, they squeeze the material into the pores of the die. Under the influence of high temperature and pressure, the lignin in the sawdust softens, causing the cellulose molecules to dislocate, deform, and expand, allowing adjacent biomass particles to mesh with each other, automatically forming the pellets without any adhesive.

2. Characteristics of dried bagasse biomass pellet processing equipment

(1) High centrifugal rate and high pressure: Suitable for pressing materials that are difficult to bond and difficult to form, such as rice husks, sunflower seed shells, peanut shells and other fruit shells; various wood scraps such as pine, birch, poplar, and fruit wood; various crop straws;

(2) Low wear rate and long life of the pressing wheel die: The die is made of alloy steel with a special processing technology, with a hard and wear-resistant surface and a tough core, and has high low-temperature impact toughness.

(3) The pressing roller adopts a vertical structure: direct feeding, high efficiency, and conducive to heat dissipation: The die adopts a vertical mechanism, direct feeding, high efficiency, and conducive to heat dissipation.

(4) Reasonable design and reliable manufacturing quality: It has the characteristics of simple structure, easy operation, small size, small footprint, labor saving and power saving.

3. Application scenarios of dried bagasse biomass pellet processing equipment

Large-scale production lines can achieve efficient conversion of dry residue, reducing unit processing costs and improving resource utilization. The pellet volume is reduced by 6-10 times, reducing transportation costs. The pellets are supplied to surrounding food factories, paper mills, chemical plants, and other industrial enterprises that require steam or heat energy. Biomass heating stations are built in towns or industrial parks, using sugarcane bagasse pellets to heat residents and commercial facilities. The ashes from the combustion are tested for heavy metals and applied to sugarcane fields as silicon-potassium fertilizer. The pellet heat is used for grain drying, reducing pollution from field burning. This realizes the "waste-to-treasure" transformation of sugarcane bagasse.

2标题

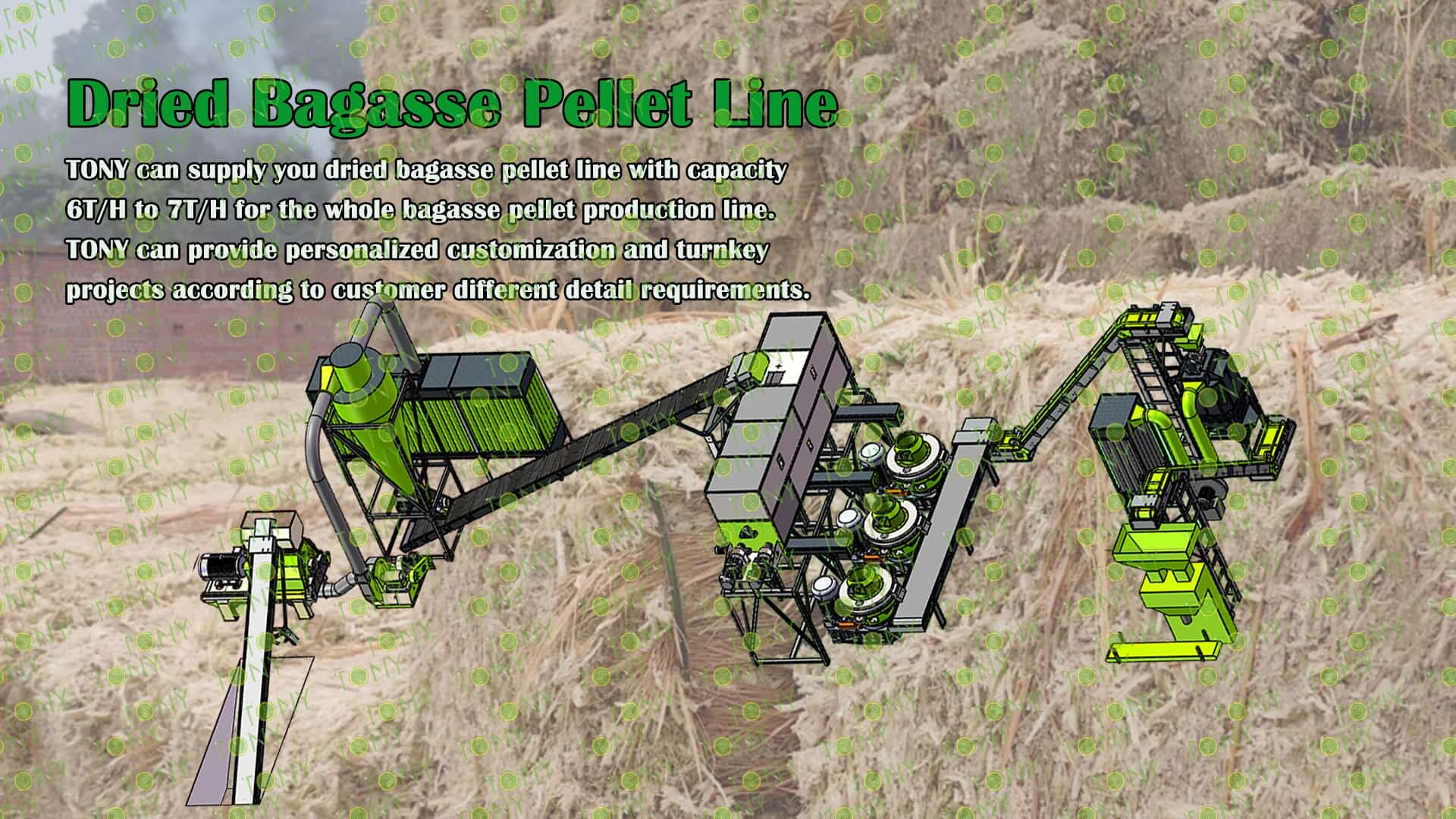

TONY Brand 6-7 Ton/Hour Dried Bagasse Pellet Manufacturing Plant can take dried bagasse as the main raw material. After pretreatment and processing, it is solidified into high - density Bagasse pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bagasse resources.

1. Capacity: 6-7 Ton/Hour

2. Raw materials: Dried bagasse

3. Moisture: dried type, about 10-15%.

4. Application: All kinds of bagasse materials suitable for pellet production.

Suitable customers: Sugarcane processing factories are the direct output of bagasse, such as sugar mills, sugarcane ethanol factories, sugarcane pulping factories, etc.; centralized storage and transit places, such as sugar mills, ethanol factories, agricultural product processing parks, where multiple sugarcane processing factories often gather to form a park. The storage and transit areas of bagasse are uniformly planned within the park, and the resource concentration is extremely high.and other places where bagasse raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3标题

图片

原材料--成品图

1. Project Name: Dried Bagasse Pellet Production Line

2. Raw Material: All kinds of dried bagasse

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 6-7 tons per hour

5. Process: Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD85*250-250kw, TONY Pellet Machine- TYJ551-Ⅲ-132kw, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

4标题

|

How to use the TONY pellet production line to make pellets from dried bagasse? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the slightly larger bagasse into 8-14 mm bagasse.If customer has enough Investment budget,he can also chose TONY Special Cutting Machine for bagasse which will be more expensive than the hammer mill. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY Double Packing Machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

流程图1

流程图

5标题

原材料+颗粒图

颗粒+机器图

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

| 图1 | 图2 | 图3 |

| Effective Hammer Mill | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

| 1.To Crush Larger Bagasse Into 8-14mm Baggase. 2.Model: TFD85*250-250KW*1set 3.Capacity: 8-10 Ton/Hour/Set |

1.To Stroage Bagasse Before Pellet Machine; Adjust The Speed Of Bagasse Entering The Pellet Machine 2.Model: TLC-7*1set 3.Capacity:6-7 Ton/Hour/Set |

1.To Press Dry Bagasse Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-132KW*3sets 3.Capacity:2-2.5Ton/Hour/Set 4.New 304SS Type |

| 图4 | 图5 | 图6 |

| Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*1set 3.Capacity:6-7 Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TPZ-50*1Set 3.Capacity: 6-7 Ton/Hour |

1.Transport Bagasse,Pellets. 2.Width: 80cm*5 Sets 3.Capacity:Designed With The Whole Line |

三维图

5.1标题

高效粉碎机

带锯末图

1.Bagasse Fine Crushing Process:

A.This process is mainly used to crush larger bagasse into 8-14mm bagasse.

B.Capacity:8-10 Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250kw*1set

Main Parts:

(1). TONY Effective Hammer Mill.

(2). Galvanized Dust Collector.

(3). Sawdust Transportation Fan Blower.

(4). Cyclone With Airlock.

(5). Electrical Cabinets.

5.2标题

颗粒机四件套带 原材料,颗粒图

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:6-8Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-132kw*3 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1). TONY's new Vertical Ring Die Pellet Machine.

(2). Cyclone And Bags Dust Collectors.

(3). Automatic Lubrication System.

(4). Electrical Cabinets.

5.3标题

镀锌冷却仓加颗粒图

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:6-7 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.4标题

4.Packing Process:

A.This process is mainly used to pack pellets into 15-50KG/Bags.

B.Capacity:6-7 Ton/Hour.

C.TONY brand double packing machine*1 set

Main Parts:

(1)TONY Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

6标题

客户生产案例图

7标题

图 干甘蔗渣+颗粒 颗粒机

The technology for converting sugarcane bagasse into biomass pellets is mature and reliable, with a high degree of domestically produced equipment. This technology involves crushing and drying the sugarcane bagasse, then compressing it into pellets under a controlled temperature and pressure. The resulting pellets are dense, easy to store and transport, and highly efficient, making them suitable for use as boiler fuel or household fuel. Sugarcane bagasse biomass pellets have a near-zero sulfur content, produce no black smoke or odor, and emit only 1/51 the nitrogen oxides of coal. The ash residue rate is less than 3%, and the ash is a loose, off-white powder that can be returned directly to the field. They fully comply with the "Boiler Air Pollutant Emission Standards," helping to reduce air pollution and improve the ecological environment.

8标题

干甘蔗渣图 颗粒图

1. Renewable

Unlike fossil fuels like coal and natural gas, which are consumable (and take a long time to produce), sugarcane bagasse pellets are renewable because sugarcane grows annually, providing a continuous supply of raw materials.

2. Turning Waste into Treasure

Against the backdrop of global energy shortages, sugarcane bagasse pellets represent a paradigm shift from waste to wealth, maximizing the utilization of sugarcane and increasing farmers' incomes. They can generate sufficient heat to meet the full needs of a typical sugar refinery or generate profits through pellet production.

3. Excellent Combustion Performance

The resulting fuel contains minimal ash, significantly reducing the amount of ash storage space and slag disposal costs. More importantly, combustion produces no harmful gases, making it a direct replacement for mineral coal. Suitable for industrial wood chip boilers, power plants, residential heating, cooking, and other industries, they mitigate the environmental impact of traditional fossil fuels.

9标题

绿色地球+原材料+颗粒图

10标题

10图

11标题

11图

2025 Tony Machinery - All Rights Reserved. Map