Project Brief Introduction:

1.Product:Wet Wood Log Pellet Line

2.Capacity:18T/Hour

3.TONY Brand 18Ton/Hour Wet Wood Log Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Large Hydraulic Storage Silo, Rotary Drum Dryer,TONY Pellet MachineTYJ860-III-280KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 2500KW

6.Need Area: About 608㎡ L:38M W: 16M H:5.489M

Project Layout For Customer:

3D图

1.The working principle of wet wood log biomass pellet processing equipment

Equipment for processing wet wood biomass pellets (i.e., pellet forming equipment for high-moisture wood feedstock) must address the molding difficulties caused by excessive moisture content. Its principles and characteristics differ significantly from those used for processing dry wood. The key to processing wet wood biomass pellets (typically with a moisture content exceeding 30%, and even reaching 50%-60%) is the synergistic effect of drying and mechanical compression to overcome the molding barrier caused by high moisture content, ultimately producing dense pellets.

2.Characteristics of wet wood log biomass pellet processing equipment

(1)High degree of automation, reducing manual intervention

The PLC control system is used to link the crushing, tempering, molding, cooling and other links, and automatically adjust the feed amount, pressure wheel speed and other parameters according to the moisture and hardness of the raw materials, reducing production interruptions caused by fluctuations in the characteristics of wet materials.

Equipped with an automatic mold cleaning device, when the mold is detected to be blocked, it can automatically reverse the pressure wheel or spray a release agent to reduce the frequency of shutdowns for cleaning.

(2)Balance between energy consumption and adaptability, taking into account both efficiency and cost

Compared with equipment that processes dry materials, wet material processing equipment consumes slightly more energy (because it needs to overcome the viscosity and moisture resistance of the wet material), but it eliminates the need for a separate drying step (or significantly reduces drying energy consumption), and the overall energy consumption may be lower (especially when the moisture content of the raw materials is extremely high).

It has strong adaptability to raw materials and can not only process wet wood, but also mix and process other high-moisture biomass (such as straw, sugarcane bagasse, etc.), making it suitable for small and medium-sized processing plants with complex raw materials.

3.Application scenarios of wet wood log biomass pellet processing equipment

(1)Energy and fuel fields

This is the main application scenario. The processed pellets (called "biomass pellet fuel") can replace coal and natural gas and be used in industrial boilers (such as heating in food factories and chemical plants), civil fireplaces (home heating), and biomass power plants (power generation and grid connection).

Advantages: High combustion efficiency (calorific value of about 4000-4800kcal/kg, close to medium-quality coal), low pollutant emissions (SO₂ emissions are only 1/10 of coal).

(2)Agriculture and animal husbandry

Aquaculture bedding: The pellets have strong water and moisture absorption (each kg can absorb 2-3kg of water) and are soft in texture. They are often used as bedding in chicken houses, pig houses, and pet cages. They can reduce ammonia emissions and improve the breeding environment.

Organic fertilizer raw materials: After being crushed, the pellets can be mixed with livestock and poultry manure for fermentation to make organic pellet fertilizer, which can be used in farmland and orchards to improve soil fertility.

TONY Brand 18Ton/Hour Wet Wood Log Pellet Manufacturing Plant can take wet wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity:18Ton/Hour

2. Raw materials: Wet wood log , branches, small - diameter logs, twigs, etc.

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1.Project Name: Wet Wood Log Pellet Production Line

2. Raw Material: All kinds of wet wood Log

3. Moisture Content of Raw Material: 40%

4. Capacity: 18 tons per hour

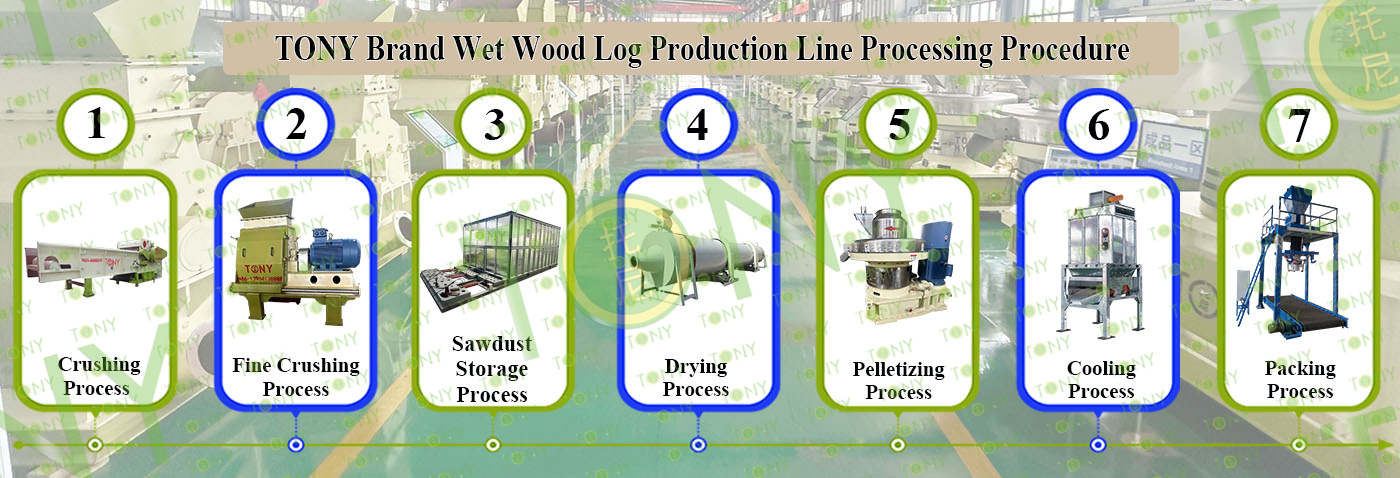

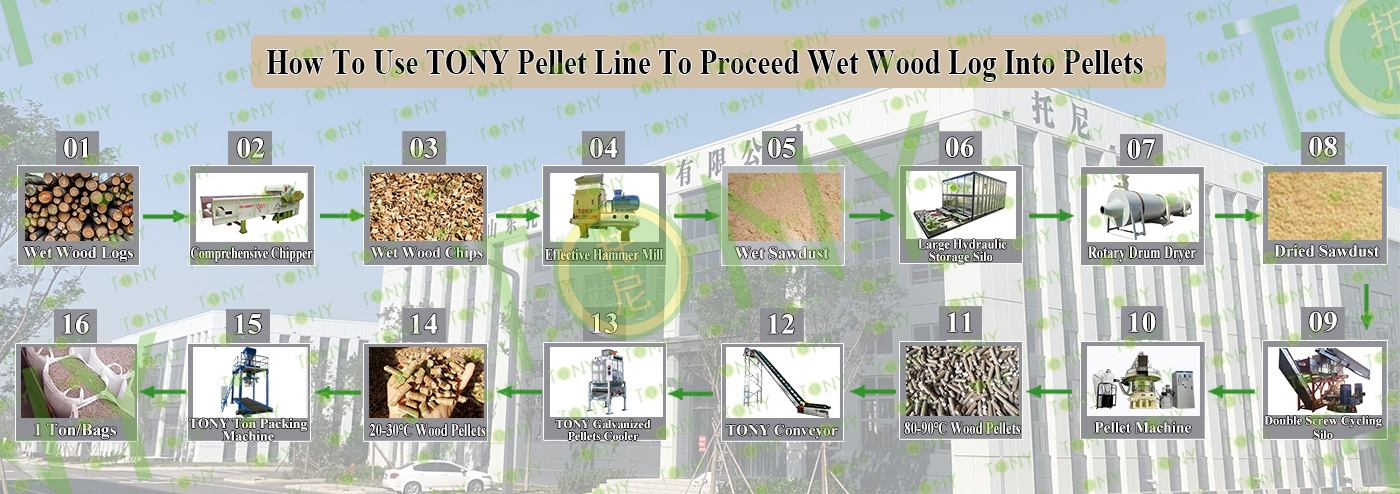

5. Process: Crushing Process - Fine Crushing Process -Sawdust Storage Process- Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1300-600-132KW, Effective Hammer Mill-TFD75*132-132KW, TONY Large Hydraulic Storage Silo,Rotary Drum Dryer-2.8*24m, TONY Pellet Machine TYJ760-Ⅲ-200kw, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet wood Log? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut wet wood log with a diameter of less than 30 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 4. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 5. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 6. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 7. Use TONY ton packing machineto pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. |

|||

|

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Large Hydraulic Storage Silo | Rotary Drum Dryer |

| 1.To Grind Wood Logs φ ≤30cm Into25-55mm Wood Chips. 2.Model: TPC1300-600-132KW With 6 Blades*2sets 3.Capacity:20-30Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*132-132KW*4sets 3.Capacity: 4.5Ton/Hour/Set |

1.To Storage Sawdust Before Dryer Control Sawdust Flow Entering The Dryer Model: TCY-25*2sets 2.TONY Uses Galvanized Material |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2.8*24*2sets 3.Capacity: 9Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*6sets 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*2sets 3.Capacity:18Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags. 2.Model: TBD* 2sets 3.Capacity: 18 Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*20sets 3.Capacity:Designed With The Whole Line |

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 30cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand comprehensive chipper TPC1300-600-132KW model with 6 flying blades type:

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:18Ton/Hour.

C.TONY effective hammer mill TFD75*132-132KW*4sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B. TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's New Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

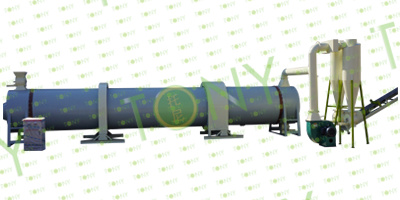

4.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:18Ton/Hour.

C.TONY use 2 sets of 2.8*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:18Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-200KW*6sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

6.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.2 sets of TONY galvanized cooler separator

Main Parts:

(1)TONY's New Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

7.Packing Process:

A.This process is mainly used to pack pellets into 1ton/bags.

B.2 sets of TONY ton packing machine

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Project Site Selection and Construction Plan

1.Project Site Selection

(1)Resource Advantages: The project site is surrounded by numerous wood processing plants, furniture factories, and other businesses, providing a rich source of wood processing residues, ensuring a stable supply of raw materials. Furthermore, the abundant local forestry resources provide a solid foundation for the project's long-term development.

(2)Convenient Transportation: The site is located near major transportation arteries and boasts a well-developed road and rail network, facilitating the import and export of raw materials and products, effectively reducing transportation costs.

(3)Well-Developed Infrastructure: The area has comprehensive infrastructure, including water, electricity, and communications, to meet the needs of project construction and production operations. Furthermore, the local government has provided a series of preferential policies and a favorable business environment to attract investment, facilitating the smooth implementation of the project.

2.Construction Plan

(1)Production Workshop: The modern production workshop features a steel structure with wide spans and high ceilings, facilitating equipment installation and production operations. The workshop is rationally laid out according to the production process flow, with functional areas such as raw material storage, pretreatment, crushing, drying, pelletizing, cooling, screening, and packaging to ensure a smooth production process. Raw Material Warehouse and Finished Product Warehouse: Separate warehouses will be built to store raw materials and finished products. These enclosed warehouses feature excellent ventilation, moisture-proofing, and fire-proofing to ensure the quality and safety of raw materials and products.

(2)Office and Living Area: A comprehensive office building will be used for daily office work and management.

(3)Environmental Protection Facilities: To minimize the environmental impact of the project's production processes, comprehensive environmental protection facilities will be constructed. These include the installation of efficient dust removal equipment to collect and treat dust generated during production, ensuring that exhaust emissions meet emission standards; sewage treatment facilities to treat wastewater generated during production to meet national emission standards; and dedicated solid waste storage areas to collect and properly dispose of solid waste, including slag, generated during production.

Wood pellets are standardized biomass fuels made from wood processing waste (such as wood chips, sawdust, shavings, and branches) that are crushed, dried, and compressed.

1.They have stable physical properties.

They have a regular shape: most pellets are cylindrical, 6-12mm in diameter and 20-50mm in length, with a density of 0.8-1.2g/cm³. They are hard and resistant to breakage, making them easy to store and transport.

They have a low moisture content: They undergo a drying process before molding, typically keeping the moisture content at 10%-15%. This reduces charring during combustion and ensures stable thermal efficiency.

2.Their composition and combustion characteristics are tailored to energy needs.

They are primarily composed of lignocellulose, which contains approximately 45%-50% carbon. They have a high calorific value (typically 4200-4800 kcal/kg, similar to medium-quality coal) and burn efficiently.

They have an extremely low sulfur content (typically <0.05%) and low nitrogen content. Pollutants such as SO₂ and NOₓ produced during combustion are far lower than those produced by coal, meeting environmental standards.

3.The raw materials are widely available and renewable.

The raw materials are wood processing waste (such as scraps from furniture and panel mills) and forestry waste (such as pruned branches and fallen leaves). This represents a "waste-to-treasure" resource recycling effort, without requiring additional arable land or forest resources.

2025 Tony Machinery - All Rights Reserved. Map