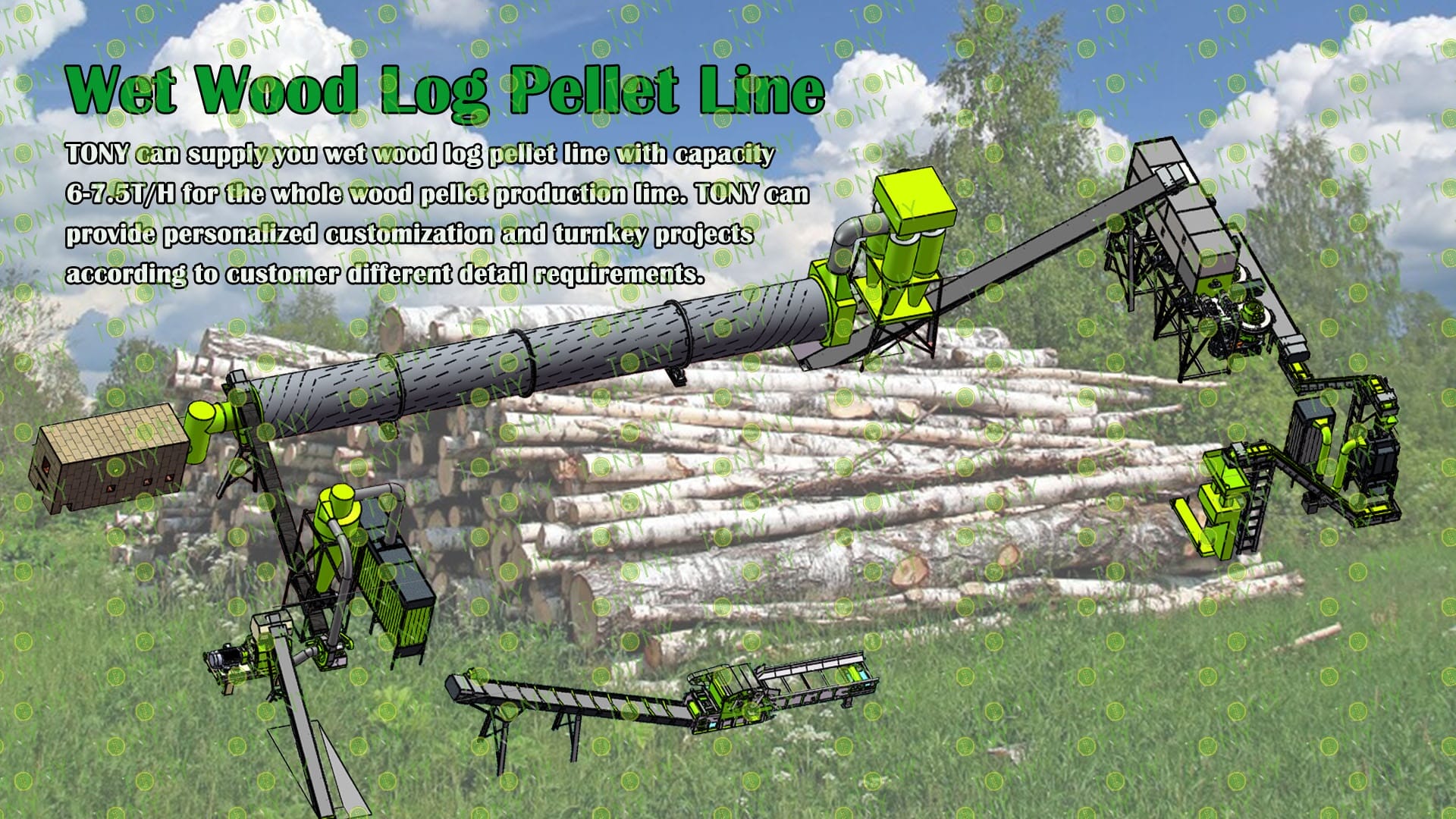

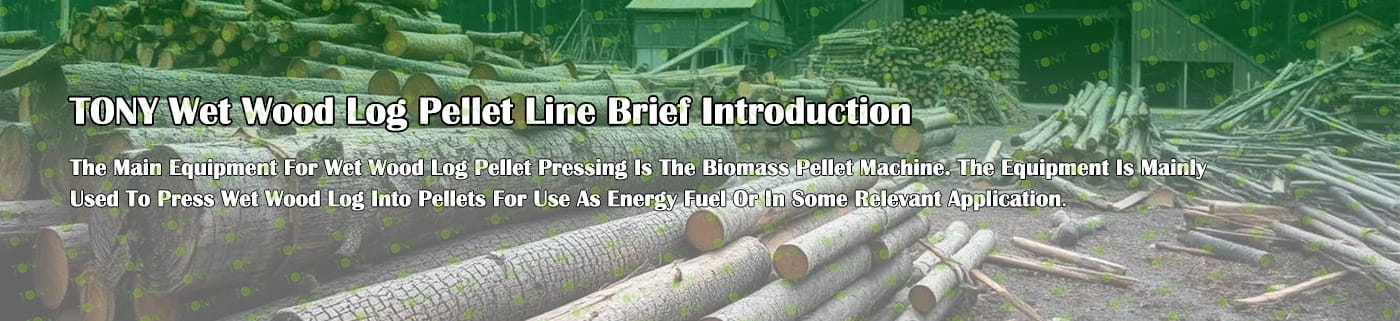

Project Brief Introduction:

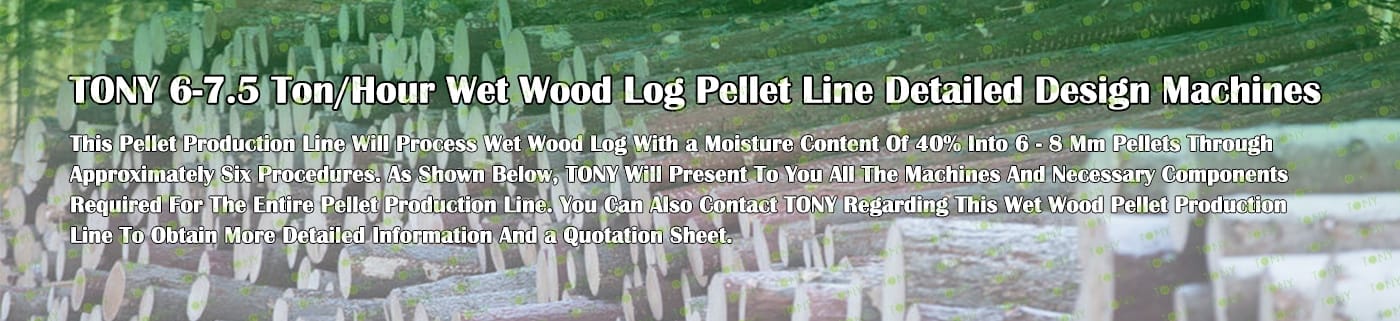

1.Product:Wet Wood Log Pellet Line

2.Capacity:6-7.5T/Hour

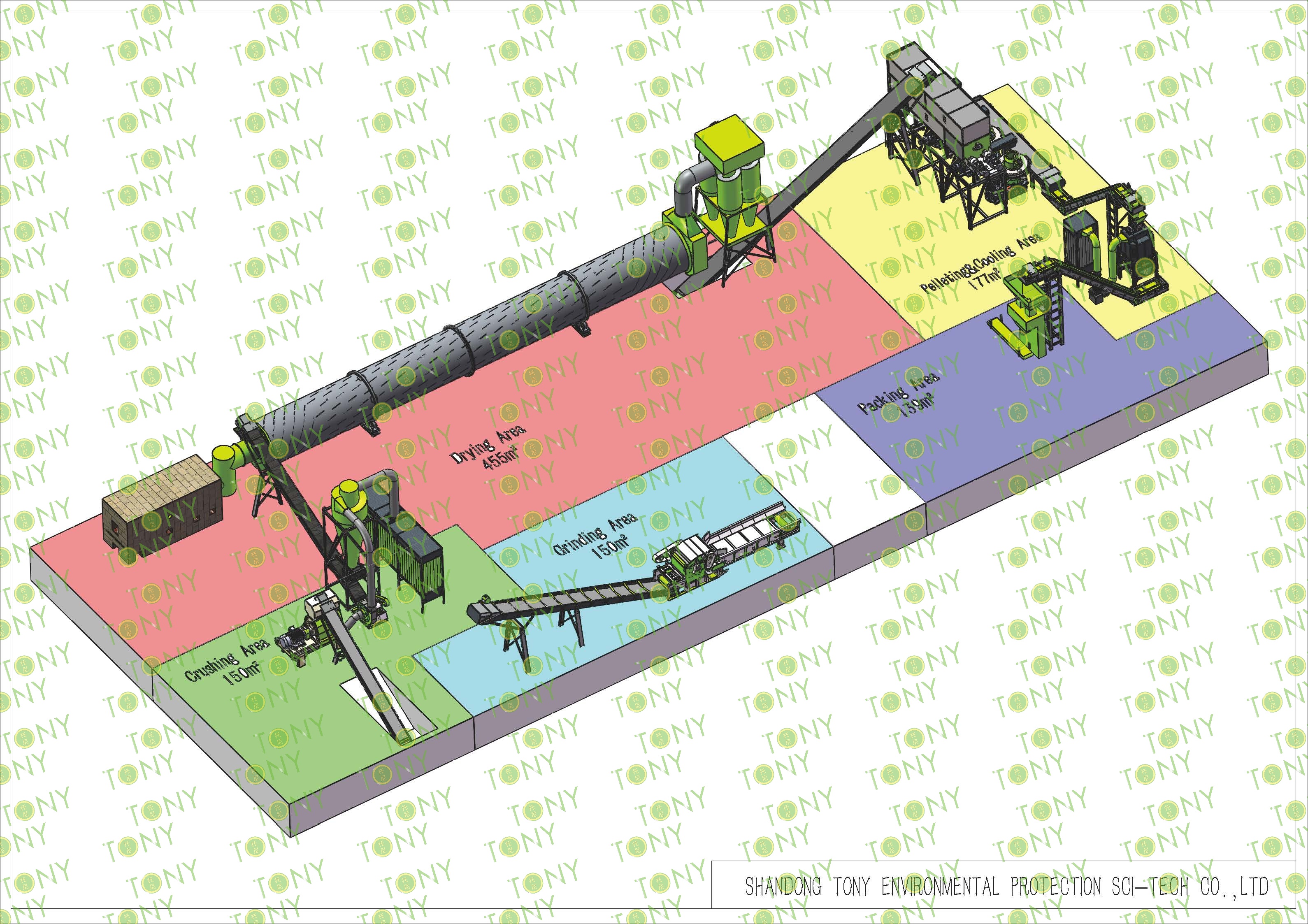

3.TONY Brand 6-7.5Ton /Hour Wet Wood Log Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet MachineTYJ551-Ⅲ-132KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1000KW

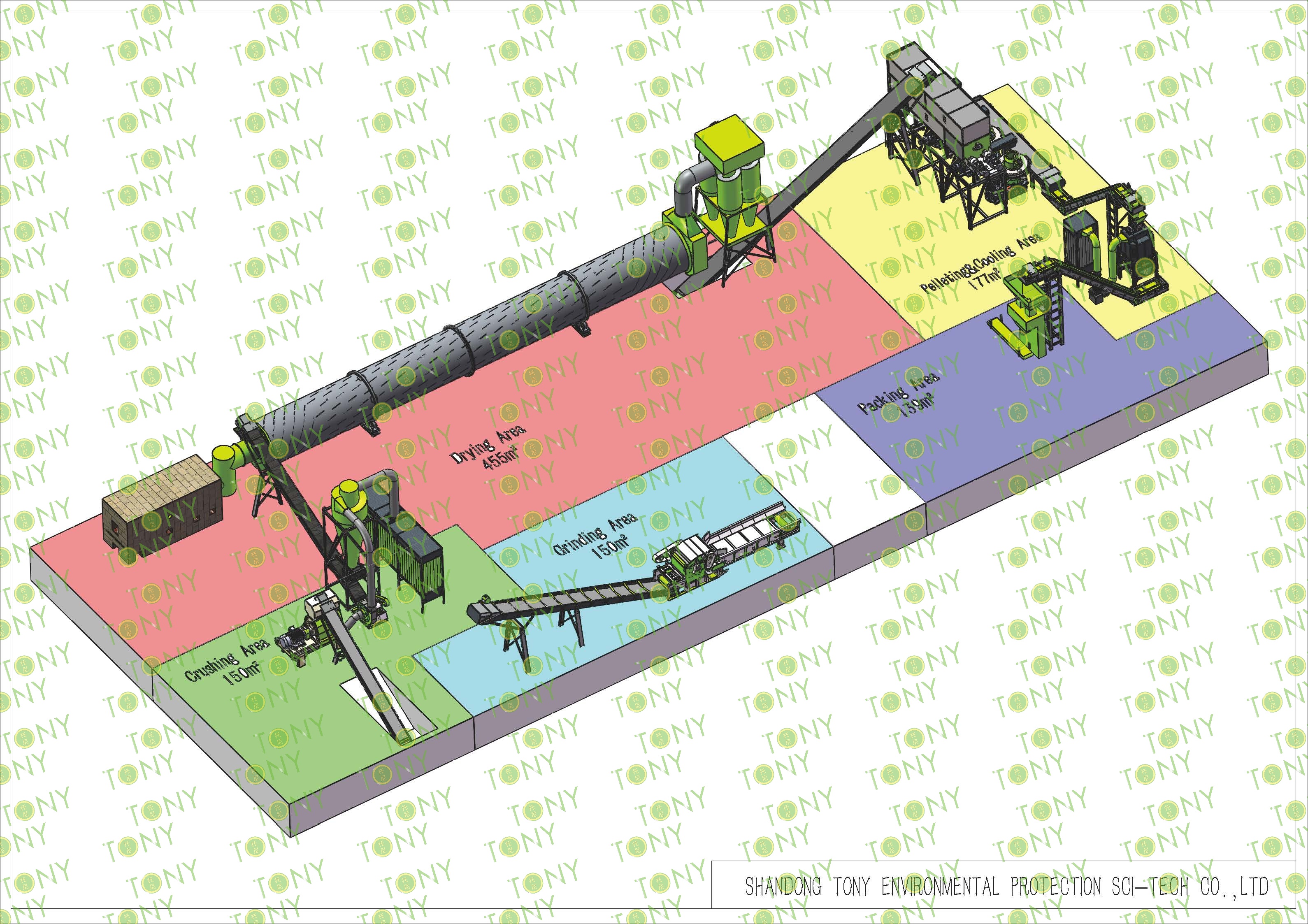

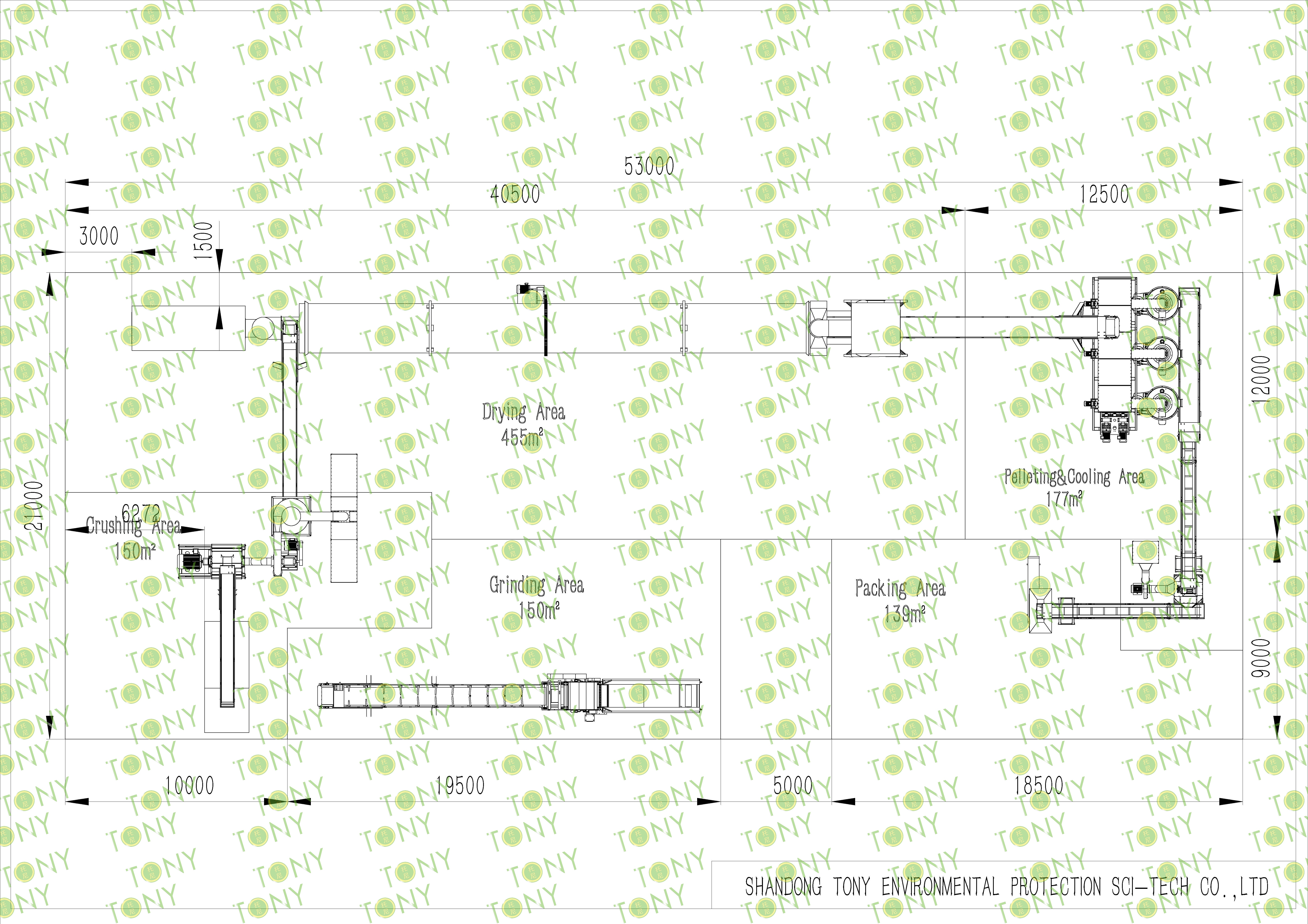

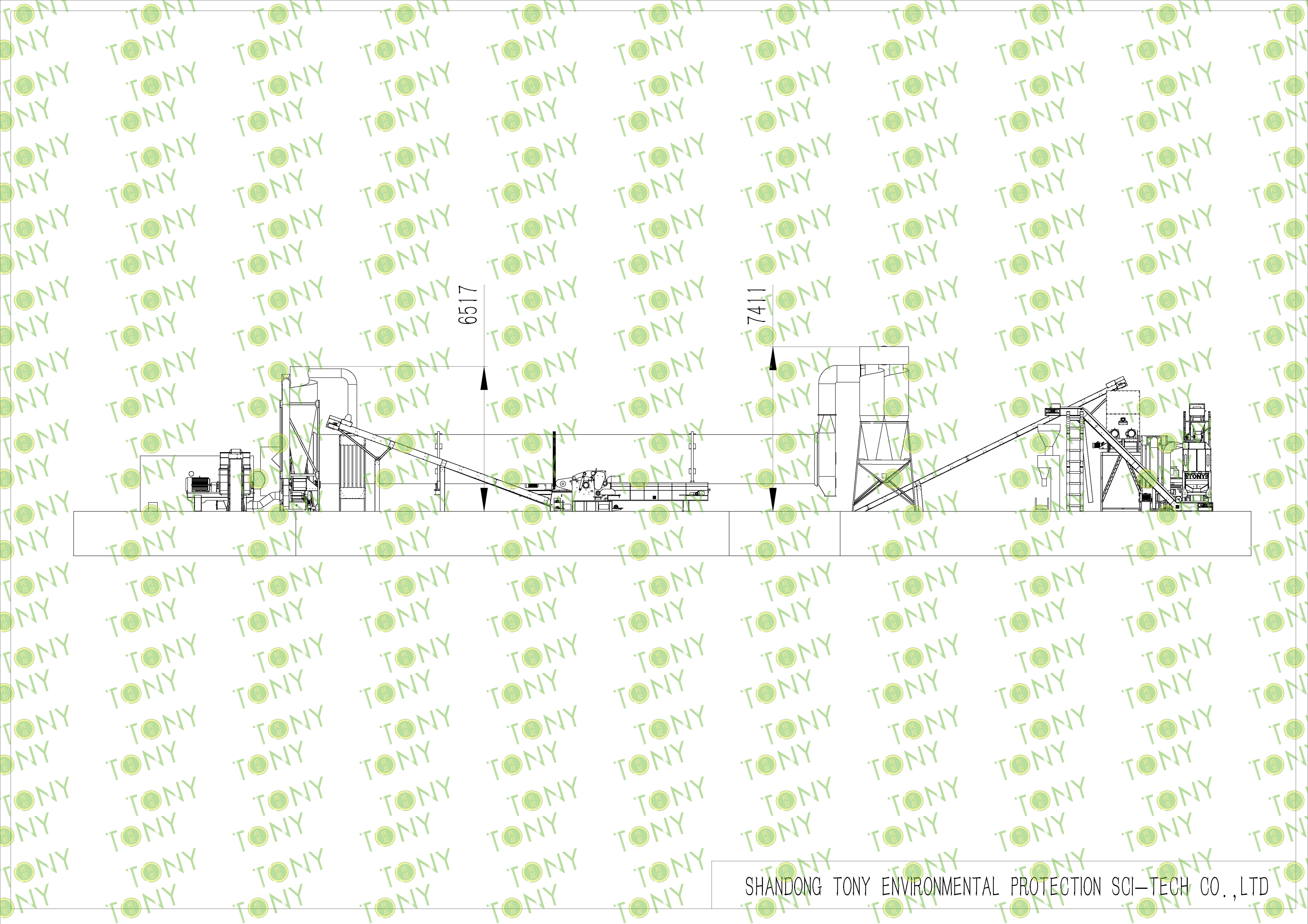

6.Need Area: About 1113㎡ L: 53M W: 21M H: 7.411M

Project Layout For Customer:

1.The working principle of wet wood log biomass pellet processing equipment

(1)Feeding Principle:The die is positioned upward, feeding the material vertically into the pelletizing chamber, ensuring direct delivery.

(2)Material Distribution Principle:The die is stationary, while the rollers rotate. Centrifugal force and the rebound effect of the two-layer high-circumference die naturally and evenly distribute the material across the inner surface of the ring die.

(3)Forming Principle:Taking the TONY wood pellet machine as an example, it utilizes the interaction between the extrusion force between the ring die and roller group and the friction of the die hole to form the material. No additives or binders are required during the processing of the material. Wood pellets have a softening property. When the temperature reaches a certain level, they soften, increasing their bonding strength. Under pressure, the fiber molecules dislocate, deform, and extend, and adjacent biomass particles are reassembled and pressed into shape.

2.Characteristics of wet wood log biomass pellet processing equipment

(1)The motor shaft is directly connected to the gear shaft, which provides stronger power transmission, greater torque resistance, greater stability and lower maintenance rate.

(2)The bearing chamber has been modified, the sealing method has been changed, and the forged and tempered wear-resistant materials have been used to prevent dust from falling into the bearing chamber.

(3)The gearbox body is larger, the gears are larger, the output is higher, and the power consumption is lower.

(4)The bearings are made of genuine heavy-duty Ha shafts, which have a longer bearing life and a lower maintenance rate for the entire machine.

(5)The ring die is vertical and double layered, with dual use of upper and lower layers, improving utilization, reducing costs, and increasing efficiency.

(6)The pressure wheel rotates, the material is centrifuged, and the surrounding material is evenly distributed.

(7)Efficient and energy-saving, automatic timed oil lubrication, ensuring sufficient lubrication of bearings and safer and more reliable operation.

(8)High pressure filtration, clean and smooth independent frequency conversion device, ensuring the yield of pellets.

3.Application scenarios of wet wood log biomass pellet processing equipment

(1)Feed Processing Industry:Used to produce various animal feed pellets, such as those for poultry, livestock, and aquatic products. Different feed ingredients, such as grains, soybean meal, fish meal, oils, and additives, can be evenly mixed and processed into pellets, making them easier for animals to consume and digest, thereby improving feed utilization.

(2)Biomass Energy Industry:Processing biomass raw materials, such as agricultural and forestry waste, into biomass fuel pellets can replace traditional fossil fuels for heating, household stoves, hot water boilers, industrial boilers, and biomass power plants, achieving efficient utilization of biomass energy and reducing environmental pollution.

(3)Other Industries:It can also be used in the production of pet bedding, cat litter, and other products, processing the relevant raw materials into pellets to meet pet care and cleaning needs.

TONY Brand 6-7.5Ton/Hour Wet Wood Log Pellet Manufacturing Plant can take wet wood, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity:6-7.5Ton/Hour

2. Raw materials: Wet wood log , branches, small - diameter logs, twigs, etc.

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood - based biomass materials suitable for pellet production.

Suitable customers: Green energy companies, forestry enterprises, and private wood - processing workshops that have advantages in wood raw materials.

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1.Project Name: Wet Wood Log Pellet Production Line

2. Raw Material: All kinds of wet wood Log

3. Moisture Content of Raw Material: 40%

4. Capacity: 6-7.5 tons per hour

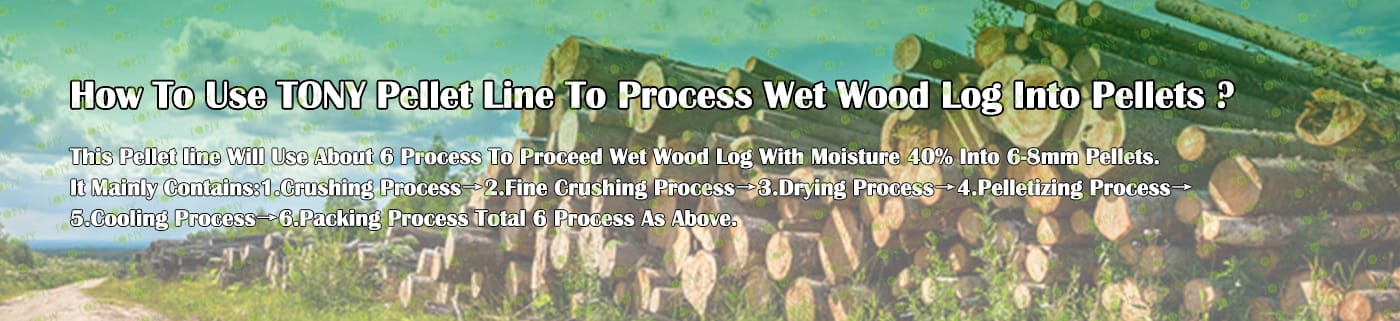

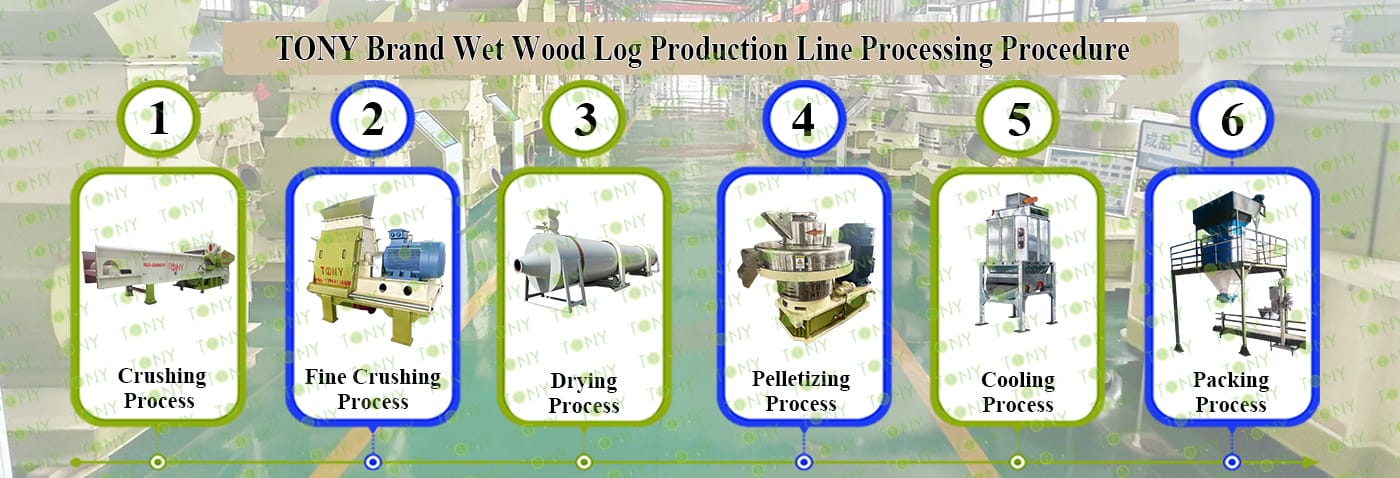

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer Mill-TFD85*250-250KW, Rotary Drum Dryer-2.2*24m, TONY Pellet Machine TYJ551-Ⅲ-132KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

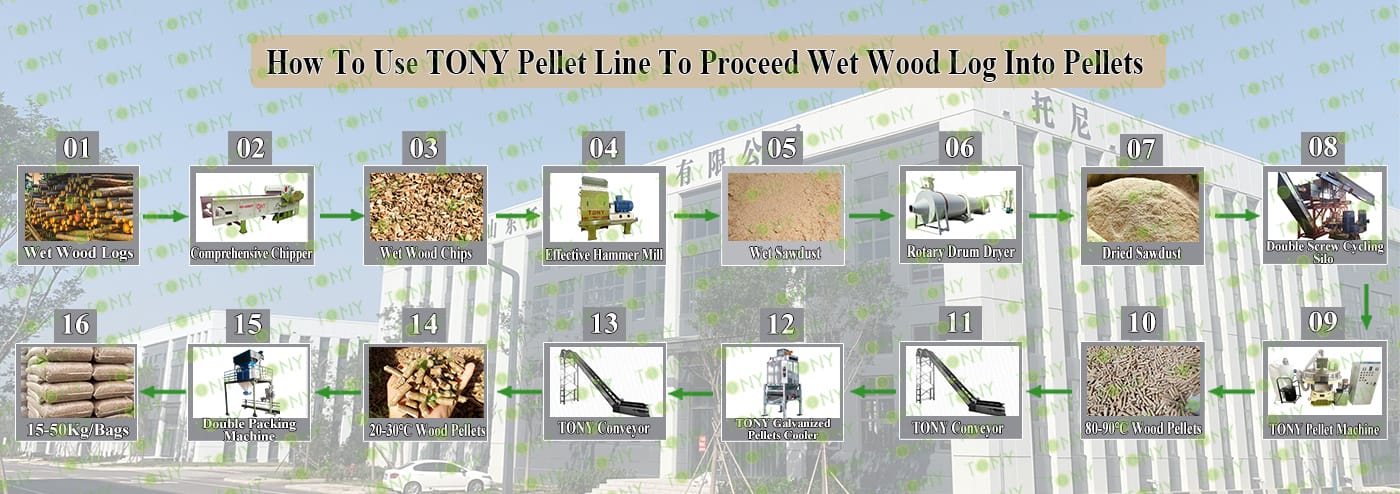

How to use the TONY pellet production line to make pellets from wet wood Log? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut wet wood log with a diameter of less than 30 cm into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Sil |

|

1.To Grind Wood Logs φ ≤30cm Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 6 Blades*1set 3.Capacity:7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*1set 3.Capacity: 6-7.5Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2.5*24*1set 3.Capacity:6-7.5Ton/Hour/Set |

1.To Stroage Sawdust before pellet machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-8*1set 3.Capacity:6-7.5Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-132KW*3 sets 3.Capacity:2-2.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*1set 3.Capacity:6-7.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6-7.5Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*6sets 3.Capacity:Designed With The Whole Line |

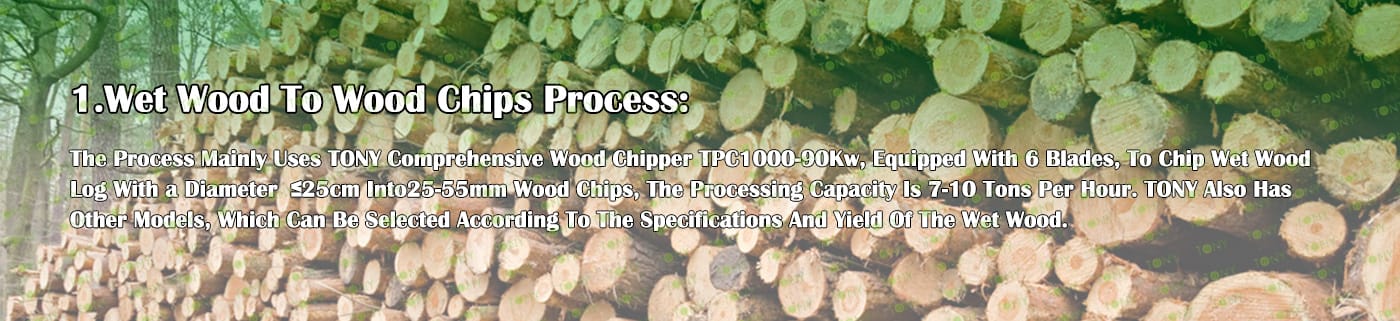

1.Wood Chipping Process:

A.This process is mainly used to grind the wood logs whose diamater is under 30cm into wood chips with size 25-55mm. The finish wood chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand comprehensive chipper TPC1000 model with 6 flying blades type:

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:6-7.5Ton/Hour.

C.TONY effective hammer mill TFD85*250-250KW*1sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

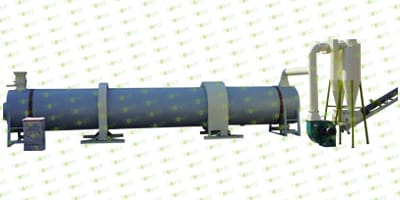

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:6-7.5Ton/Hour.

C.TONY use 1set of 2.2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:6-7.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-132KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.1 set of TONY galvanized cooler seperator

Main Parts:

(1)TONY's New Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.1 set of TONY double packing machine

Main Parts:

(1)TONY Double Packing Machine

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

1.Significant Economic Benefits:

The selling price of biomass pellets is relatively high, but after deducting equipment depreciation, factory rental, transportation costs, and taxes, the monthly net profit is substantial.

2.Mature and Stable Technology:

Biomass pellet production technology is relatively mature. The entire production line adopts a modular design, supporting automated feeding, crushing, drying, pelletizing, cooling, and packaging, reducing manual labor. The core pelletizer can operate continuously for over 12 hours without clogging, achieving a pelletizing rate of over 98%. By optimizing the compression ratio and power matching, power consumption per ton is less than 55 kWh, saving over 15% energy compared to traditional equipment.

3.Outstanding Environmental Advantages:

Biomass pellets produce low carbon dioxide emissions during combustion, essentially achieving zero emissions. They also contain very low levels of sulfur oxides, nitrogen oxides, and dust, helping to mitigate the greenhouse effect, improve air quality, reduce environmental pollution, and meet environmental requirements.

4.Easy Storage and Transportation:

After compression molding, biomass pellets have a higher density and a more regular shape, making them easier to store and transport. This reduces storage and transportation costs, improves the efficiency of biomass energy, and enables their application in a wider range of regions.

Wood pellets are standardized biomass fuels made from wood processing waste (such as wood chips, sawdust, shavings, and branches) that are crushed, dried, and compressed.

1.They have stable physical properties.

They have a regular shape: most pellets are cylindrical, 6-12mm in diameter and 20-50mm in length, with a density of 0.8-1.2g/cm³. They are hard and resistant to breakage, making them easy to store and transport.

They have a low moisture content: They undergo a drying process before molding, typically keeping the moisture content at 10%-15%. This reduces charring during combustion and ensures stable thermal efficiency.

2.Their composition and combustion characteristics are tailored to energy needs.

They are primarily composed of lignocellulose, which contains approximately 45%-50% carbon. They have a high calorific value (typically 4200-4800 kcal/kg, similar to medium-quality coal) and burn efficiently.

They have an extremely low sulfur content (typically <0.05%) and low nitrogen content. Pollutants such as SO₂ and NOₓ produced during combustion are far lower than those produced by coal, meeting environmental standards.

3.The raw materials are widely available and renewable.

The raw materials are wood processing waste (such as scraps from furniture and panel mills) and forestry waste (such as pruned branches and fallen leaves). This represents a ""waste-to-treasure"" resource recycling effort, without requiring additional arable land or forest resources.

2025 Tony Machinery - All Rights Reserved. Map