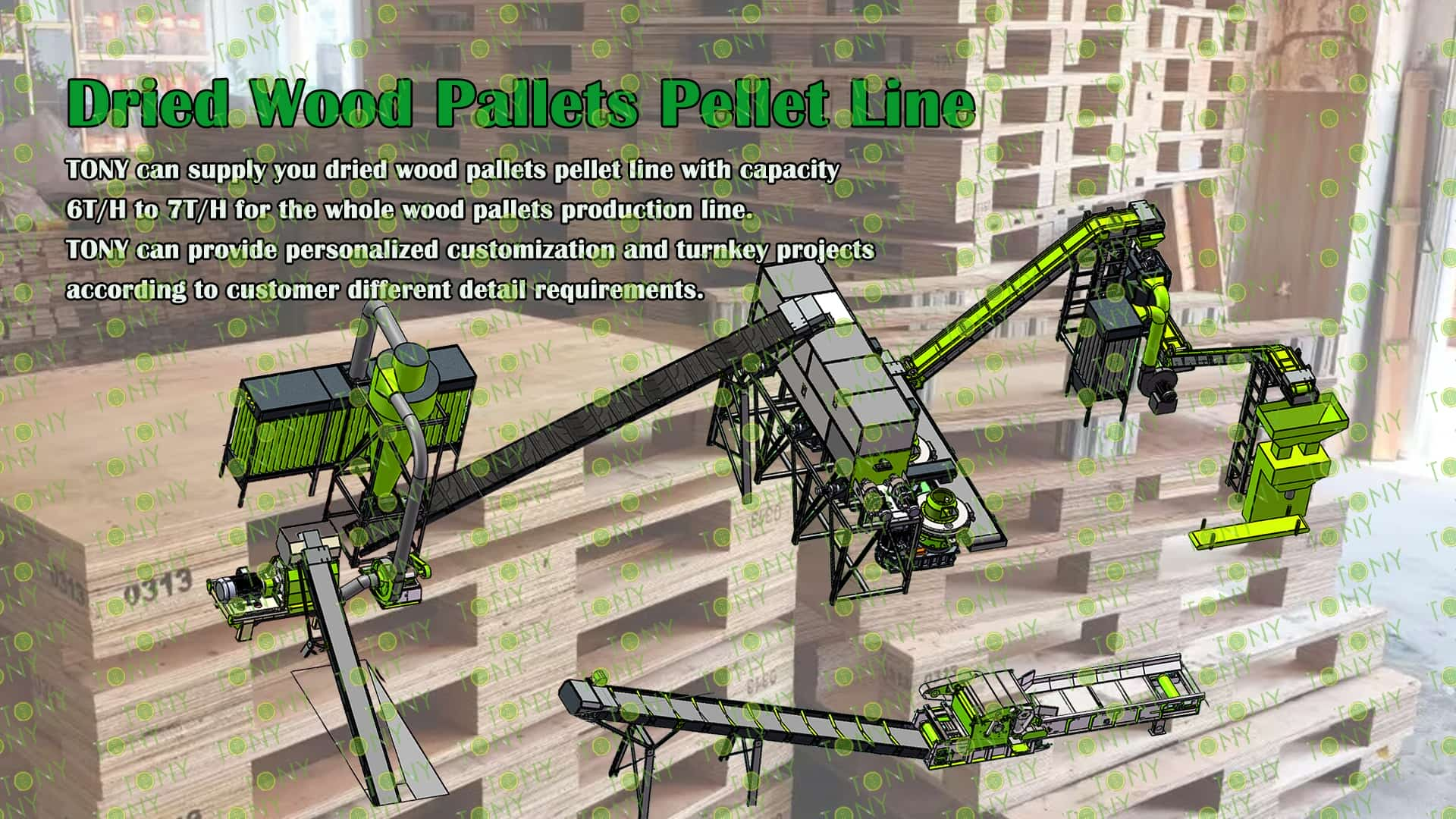

Project Brief Introduction:

1.Product:Dried Wood Pallets Pellet Line

2.Capacity: 6-7T/Hour

3.TONY Brand 6-7Ton /Hour Dried Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, TONY Pellet Machine TYJ551-Ⅲ-132KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 925KW

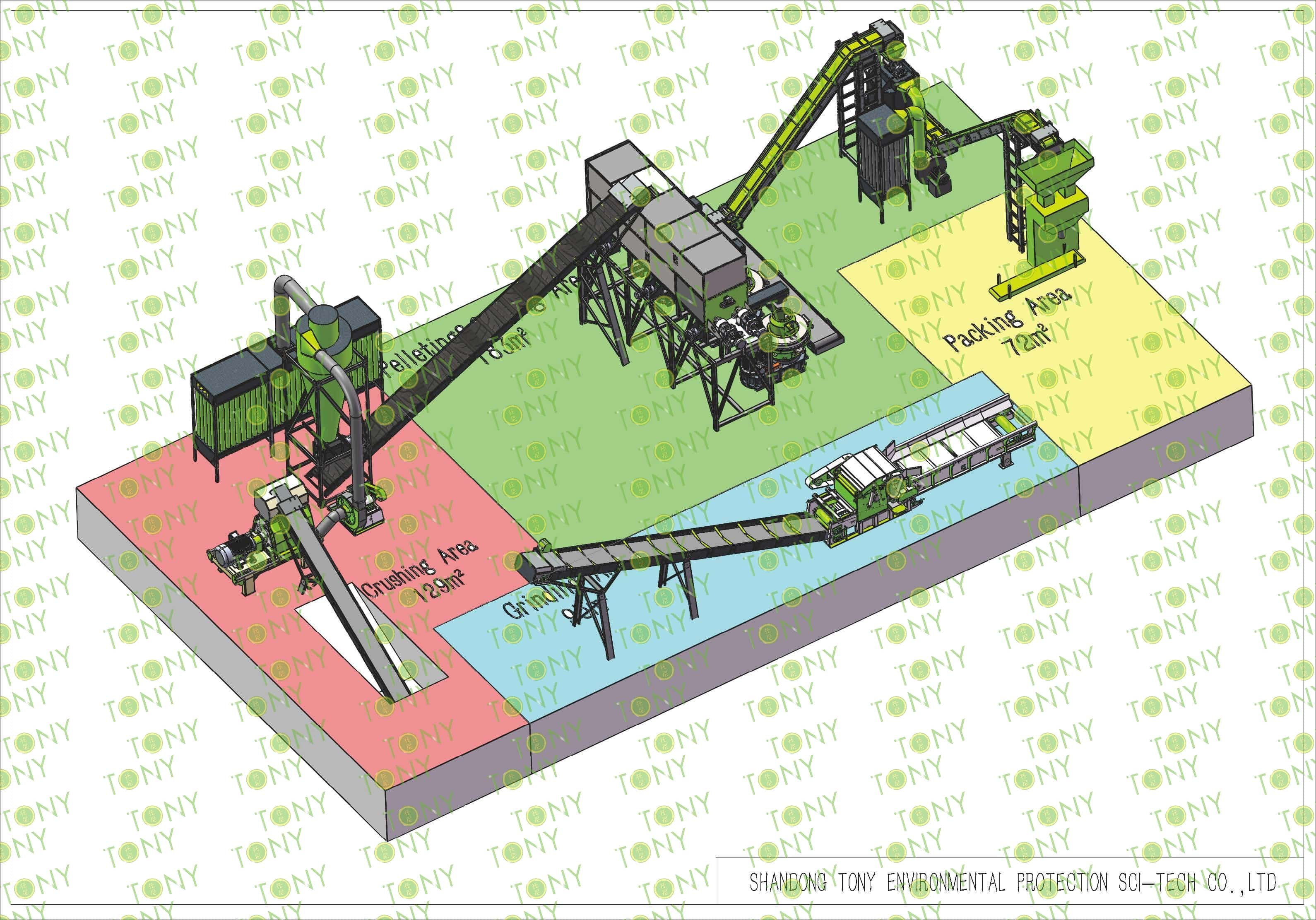

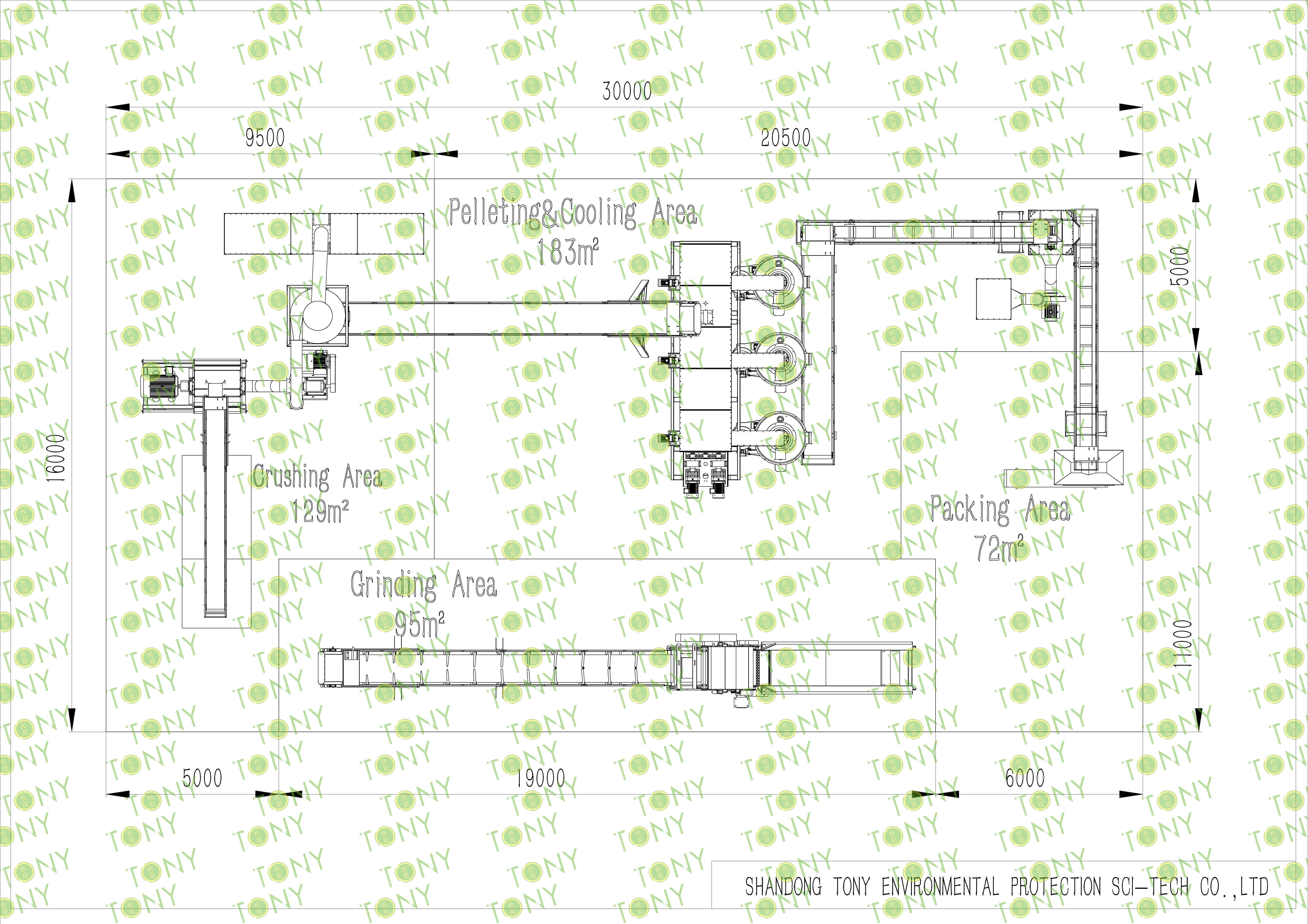

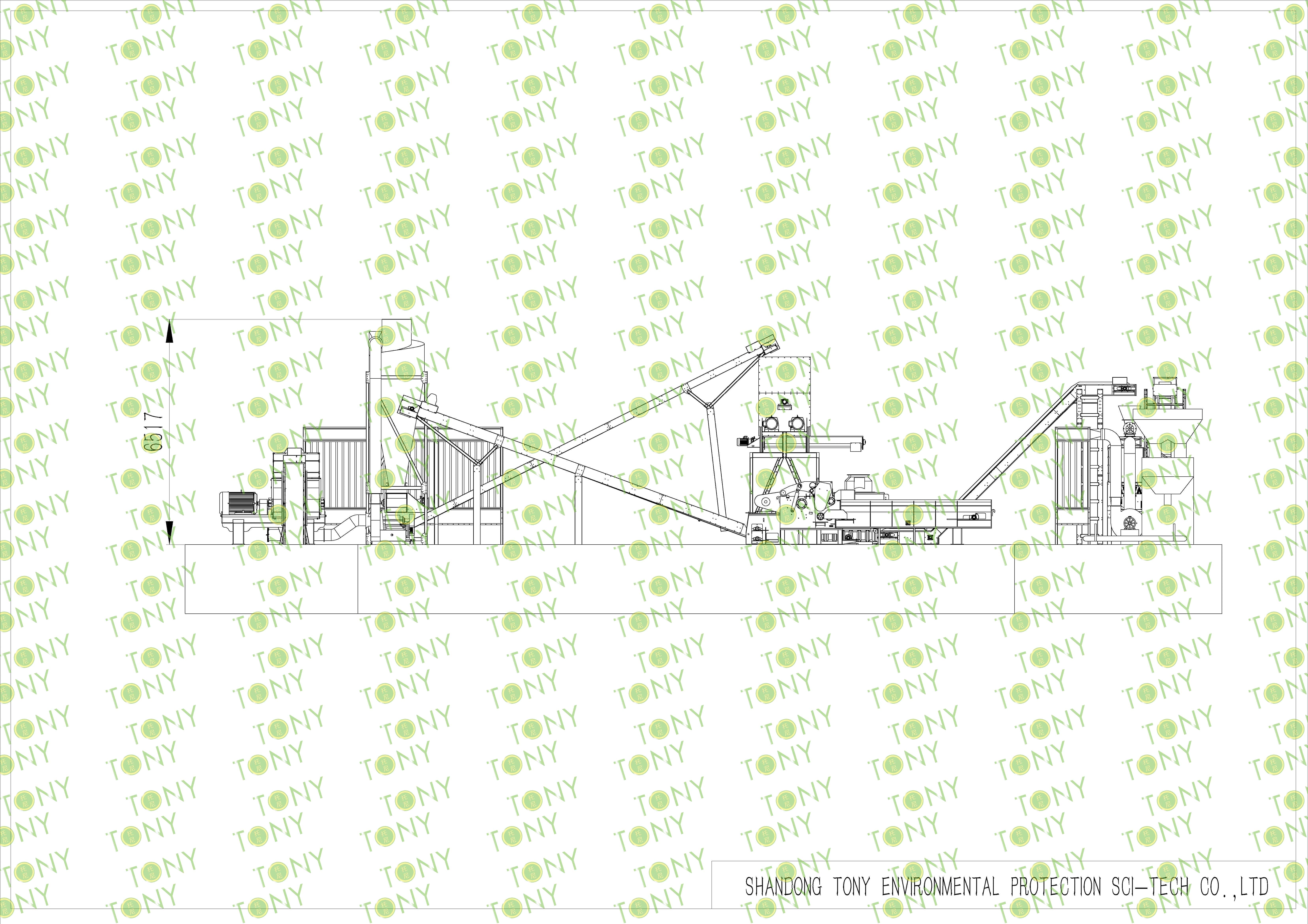

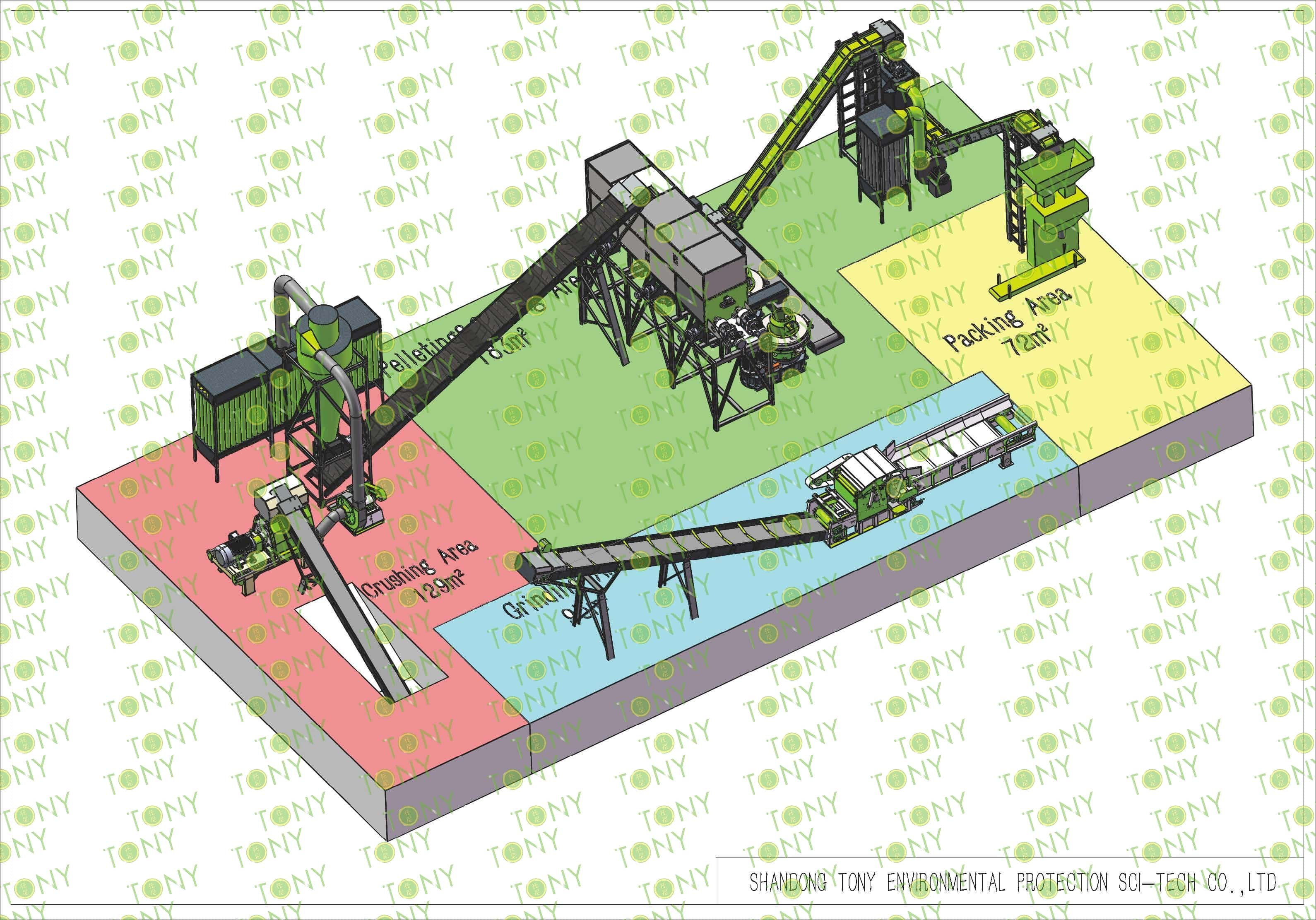

6.Need Area: About 480㎡ L: 30 M W: 16 M H: 6.517 M

Project Layout For Customer:

1.The working principle of dried wood pallets biomass pellet processing equipment

The essence of dry tray pellet processing lies in the continuous process of "physical pretreatment (removal of impurities and pulverization) → high-pressure extrusion molding (leveraging the natural bonding of lignin) → cooling and stabilization." This process transforms low-density, difficult-to-store wood raw materials into high-density, highly efficient, and easily transportable and storable pellets. The high-pressure extrusion of the ring die pelletizer and the softening and bonding of lignin are the core elements of pellet formation, while the coordinated operation of each process ensures both finished product quality and production efficiency.

2.Characteristics of dried wood pallets biomass pellet processing equipment

(1)Material compatibility:The core crushing and pelletizing equipment (such as hammer mills and ring die pelletizers) can process all types of wooden pallets (including solid wood pallets, plywood pallets, and compressed wood pallets). There is no need to strictly classify the raw materials, and only pre-treatment is required to remove metal impurities.

(2)Durability of vulnerable parts:The hammers of the crushing equipment and the ring die/roller of the pelletizer are made of high-hardness alloy materials (such as 65Mn steel and Cr12MoV steel). After heat treatment, the wear resistance is improved. The service life of the hammer can reach 100-200 hours, and the service life of the ring die can reach 500-1000 hours, which reduces the frequency of equipment shutdown and part replacement and ensures production continuity.

(3)No secondary pollution:During the production process, the dust in the drying stage is recovered (re-pelletized) through the cyclone separator, and the crushed powder in the screening stage is recycled, without any waste of raw materials; when the equipment is in operation, no wastewater is discharged.

(4)Easy to operate:The production line is equipped with a touch screen control system. Key parameters can be set through the interface with one click. Workers can operate independently after 1-2 weeks of training without professional technical background.

(5)Low maintenance cost:The equipment structure is modular (for example, the crushing chamber of the crusher and the granulating chamber of the granulator can be disassembled separately). Daily maintenance (cleaning the screen, replacing the hammer, lubricating the bearing) can be completed by only 2-3 people, without the need for a professional maintenance team. Consumable parts (hammers, screens, cutters) are inexpensive and can be purchased in bulk from the manufacturer, further reducing maintenance costs.

(6)Flexible site requirements:A small production line only requires a few hundred square meters of space (including raw material storage area, equipment area, and finished product area). There is no need for complex factory renovation, which reduces site costs.

3.Application scenarios of dried wood pallets biomass pellet processing equipment

(1)Small and medium-sized pellet plants (regional):After introducing dry pallet pellet processing equipment, they can supplement raw materials by recycling discarded pallets from surrounding logistics companies, broaden raw material channels, reduce dependence on a single wood chip supplier, and ensure full-load operation of the production line.

(2)Large-scale pellet plants (industrial grade):For example, large-scale pellet plants serving power plants and chemical plants require a large amount of wood raw materials to support production. Pellets processed from discarded dry pallets (high density and stable wood fiber) have "higher combustion value and lower ash content" (better than ordinary wood chip pellets) and can be used as raw materials for "high-end pellets" (such as pellets for industrial boilers), increasing the selling price of finished products (10%-20% higher than ordinary pellets).

(3)Professional wood solid waste treatment companies: For example, environmental protection companies that process discarded furniture and construction wood waste. Discarded dry pallets are compatible with this type of wood waste (both are solid wood/artificial wood). The equipment can be "integrated for processing" without the need for separate classification, improving processing efficiency; the processed pellet fuel can be used as the company's "core product for export", expanding from "single processing service" to a complex business of "processing + product sales", thereby improving profitability.

(4)Regional new energy entrepreneurs:By recycling waste dry pallets from surrounding enterprises and processing pellets, the raw material acquisition cost is low (even free), and the finished products can be sold to local factories and heating companies (within a sales radius of 50 kilometers, and transportation costs are controllable). The investment is small and the return is fast, which is suitable for small and medium-sized entrepreneurs.

(5)Environmental protection investment companies:This type of enterprise focuses on "green and low-carbon projects". Dry pallet pellet processing projects combine "solid waste treatment (environmental protection attributes)" and "biomass energy (new energy attributes)". After investment, stable returns are obtained, while improving the company's ESG rating.

TONY Brand 6-7Ton/Hour Dried Wood Pallets Pellet Manufacturing Plant can take dried wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings. After pretreatment and processing, dried wood pallets is solidified into high - density wood pellet fuel.The content of pollutants such as sulfur dioxide and nitrogen oxides produced by biomass pellets during combustion is extremely low, and the dust emission is also low, which can effectively reduce air pollution. Moreover, the raw material sources of biomass pellets are very wide, and the combustion efficiency is high. Compared with traditional fossil energy, it reduces the production and use costs and has higher economic efficiency. It has received a lot of attention and promotion.

1. Capacity: 6-7Ton/Hour

2. Raw materials: Dried wood pallets

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Pallets Pellet Production Line

2. Raw Material: All kinds of dried wood pallets

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 6-7 tons per hour

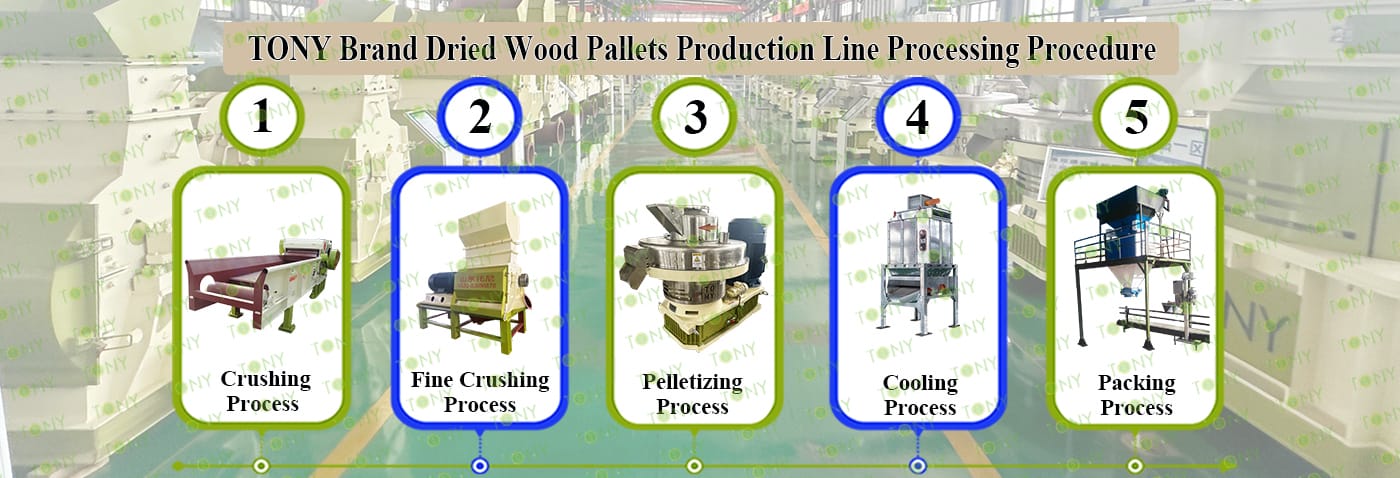

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer Mill-TFD85*250-250KW, TONY Pellet Machine TYJ551-Ⅲ-132KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

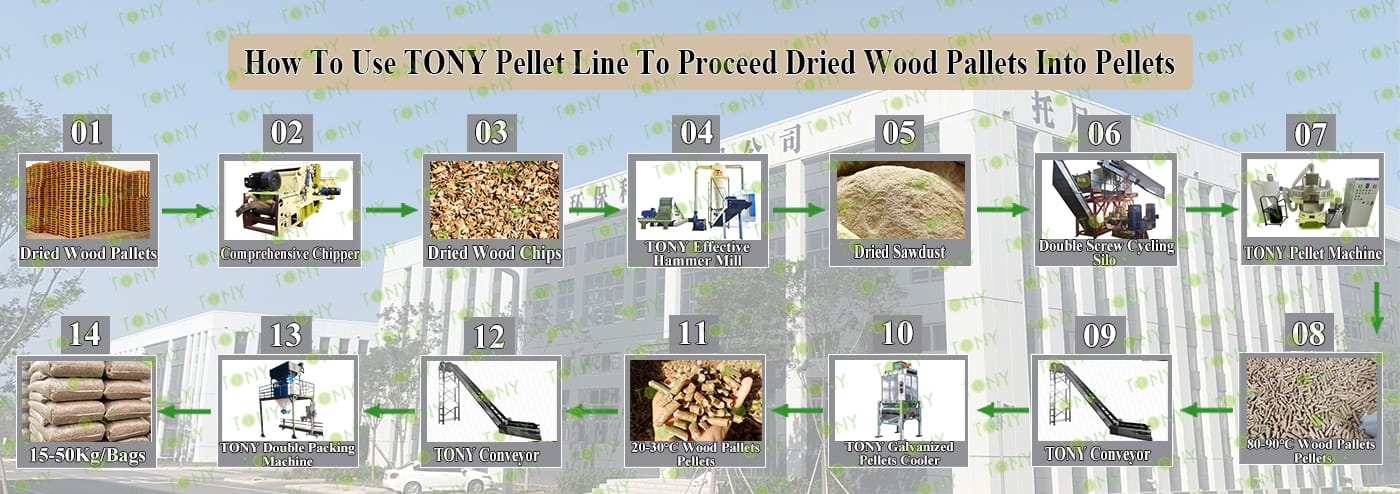

How to use the TONY pellet production line to make pellets from dried wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind dried wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

|

1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 16 Hammer Heads*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*1set 3.Capacity: 6-7Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; 2.Model: TLC-7*1set 3.Capacity:6-7Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-132KW*3sets 3.Capacity:2-2.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:6-7Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6-7Ton/Hour |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY Brand comprehensive chipper TPC1000-90KW model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:6-7Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:6-7Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-132KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:6-7Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:6-7Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

The dry pallet processing of biomass pellet fuel projects has promising development prospects. The following is an analysis from market, technical, economic, and environmental perspectives:

1.Market Demand:

With increasing environmental awareness, the market demand for biomass pellet fuel as a clean fuel continues to grow. The widespread use of biomass pellet fuel as a replacement for coal-fired heating has further expanded market demand.

2.Technical Feasibility:

The technology for dry pallet processing of biomass pellet fuel is relatively mature. Key production equipment, such as crushers, pulverizers, and pelletizers, is readily available. Environmentally friendly treatment technology is also well-established. A "cyclone dust collector + bag filter" system is used to treat dry flue gas, achieving a particle removal efficiency of up to 99%.

3.Economic Benefits:

While the specific costs and profits of dry pallet processing projects vary depending on factors such as region, raw material prices, and equipment selection, they generally offer good economic benefits when raw material supply is stable and market prices are reasonable.

4.Environmental Benefits:

Biomass pellet fuel processed from dry pallets produces less harmful gases such as sulfur oxides and nitrogen oxides, has a low ash content, and has a minimal environmental impact, meeting environmental protection requirements. This helps reduce air pollution and promotes sustainable development.

Core evaluation indicators of wood pallet pellet fuel quality:

1.Calorific value: determines the heat release capacity of combustion.

16-19 MJ/kg (about 4000-4600 kcal/kg) Close to medium-quality coal, far exceeding straw pellets (13-15 MJ/kg), meeting industrial/civilian heating needs.

2.Density and hardness: Anti-crushing, easy to store and transport.

Density 1.1-1.3 g/cm³, hardness ≥60. High density means it is not easy to crush (transportation loss ≤3%), not easy to collapse during combustion, and stable thermal efficiency.

3. Moisture content: affects combustion efficiency and coking risk.

8%-12%. Too low moisture content will easily crack, too high will cause black smoke and reduce thermal efficiency (for every 1% moisture content, thermal efficiency will drop by 0.5%-1%).

4.Ash content: determines the amount of residue after combustion.

0.3%-1.5% (much lower than coal). 10%-20%) Low ash content means low frequency of slag cleaning, which reduces equipment wear, and the residue can be used as raw material for organic fertilizer.

5. Forming rate and appearance: reflects production stability and practicality.

Forming rate ≥95%, smooth surface, no obvious cracks. High forming rate means high raw material utilization rate, and regular appearance facilitates automated feeding (such as boiler and fireplace feeding systems).

2025 Tony Machinery - All Rights Reserved. Map