Project Brief Introduction:

1.Product:Dried Wood Pallets Pellet Line

2.Capacity: 3T/Hour

3.TONY Brand 3Ton /Hour Dried Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, TONY Pellet Machine TYJ760-III-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 420KW

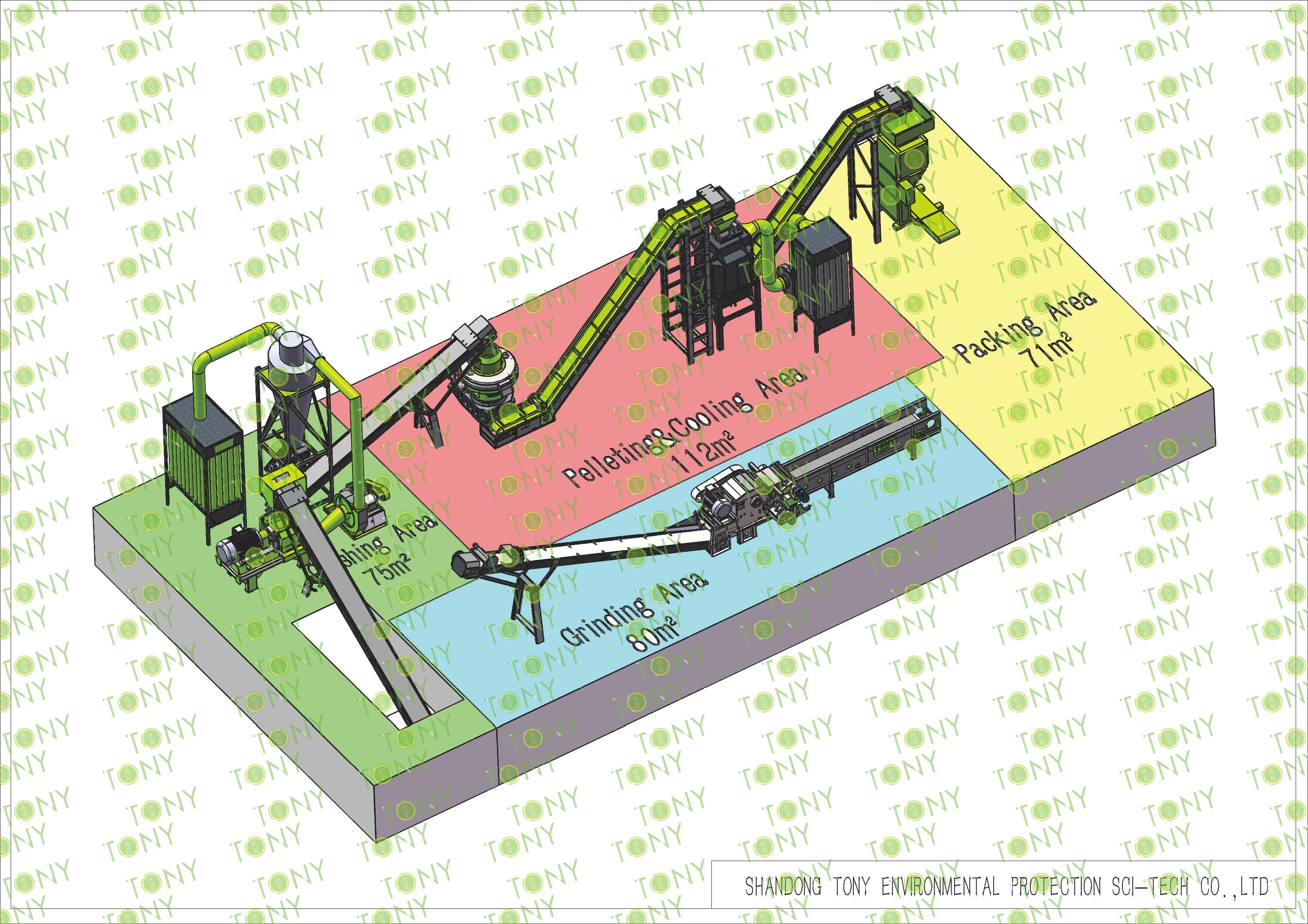

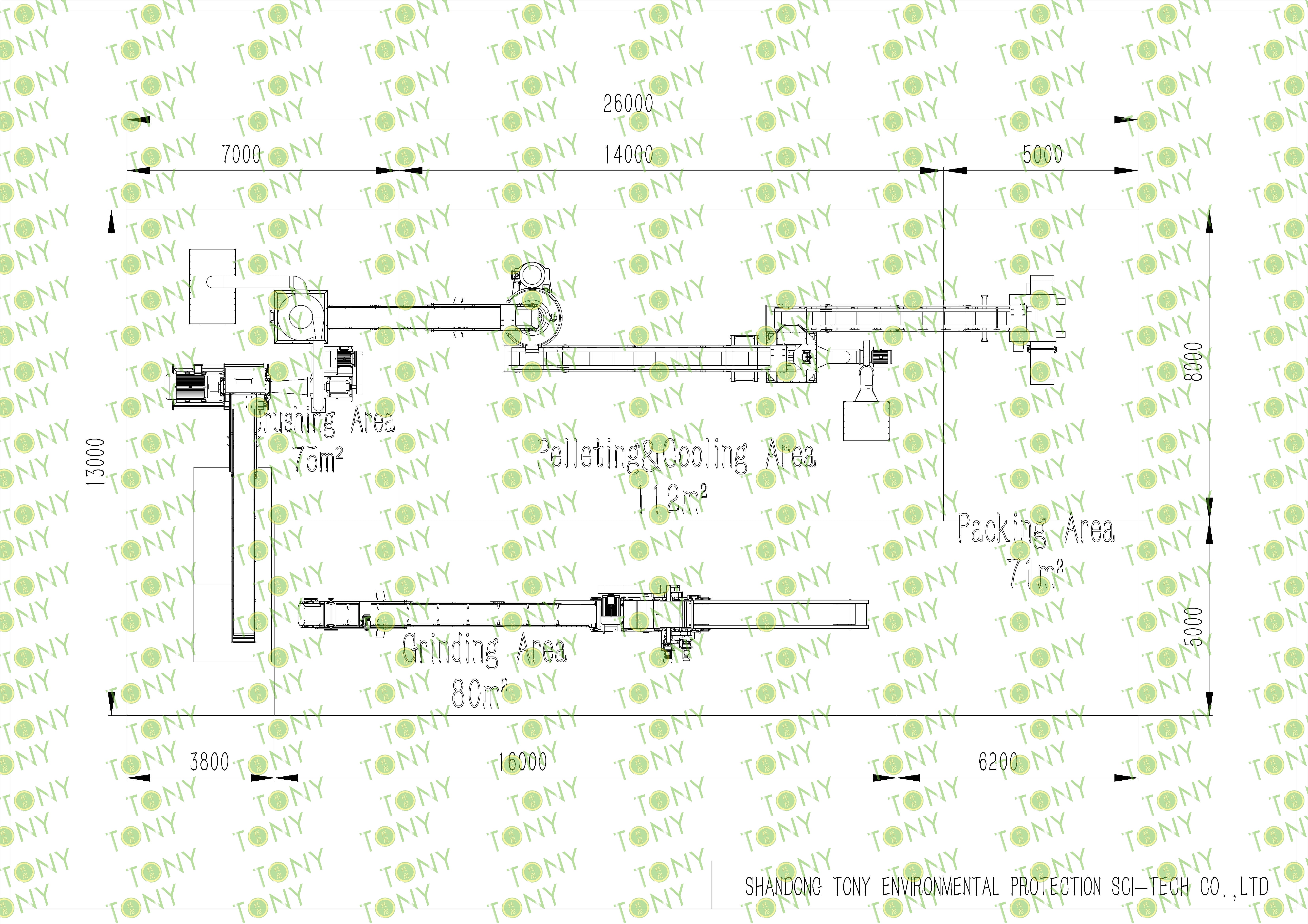

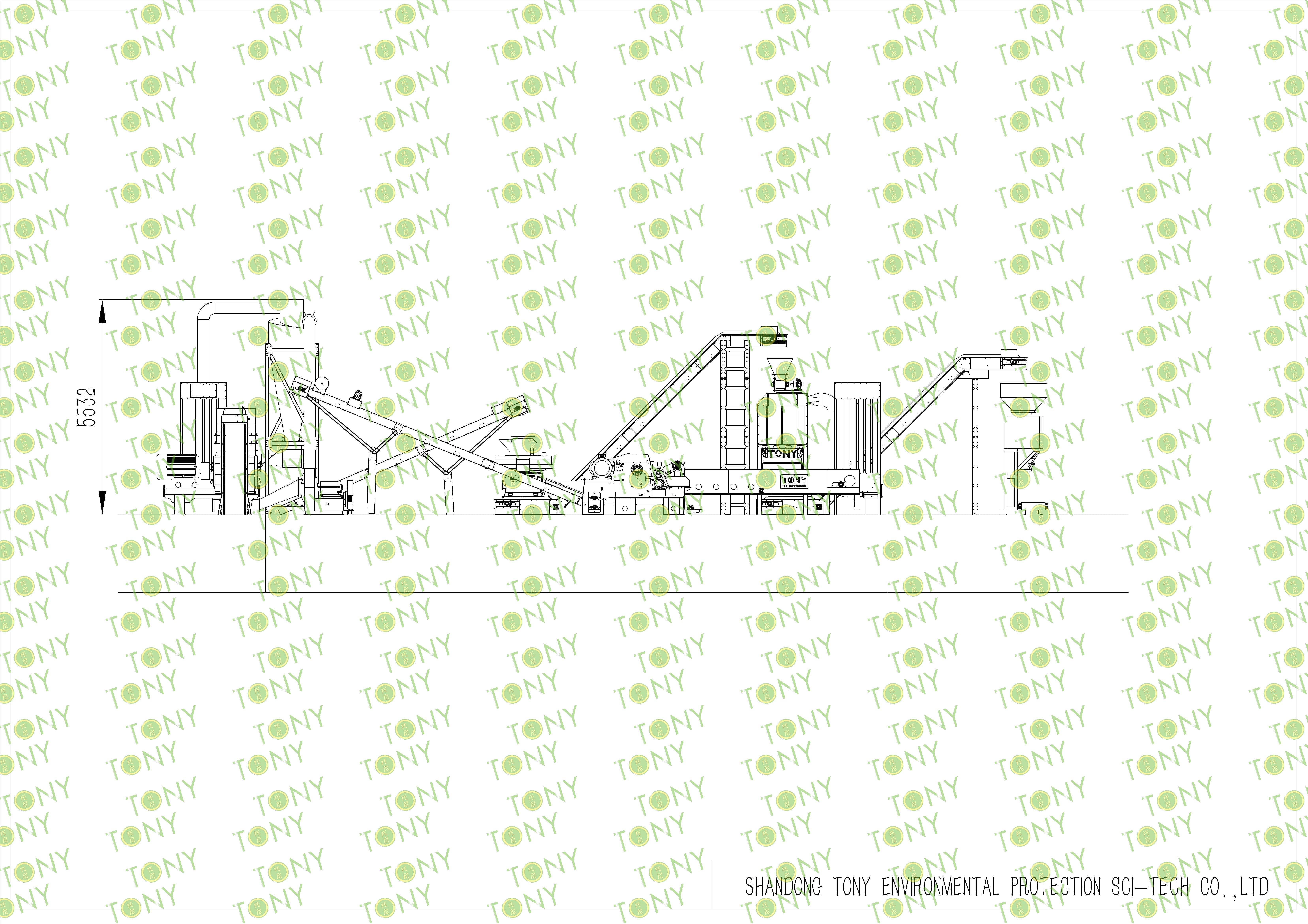

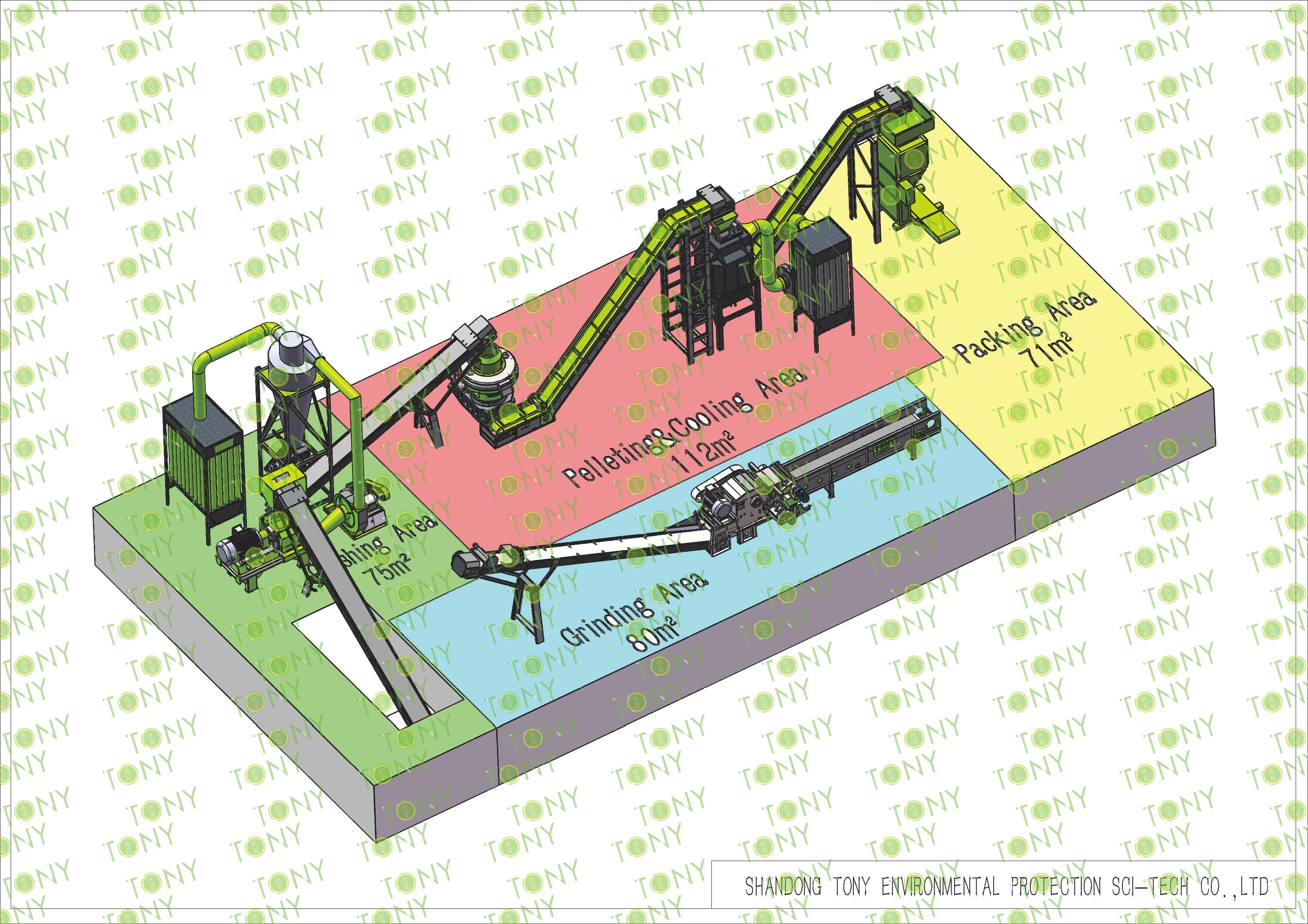

6.Need Area: About 338㎡ L: 26 M W: 13 M H: 5.532 M

Project Layout For Customer:

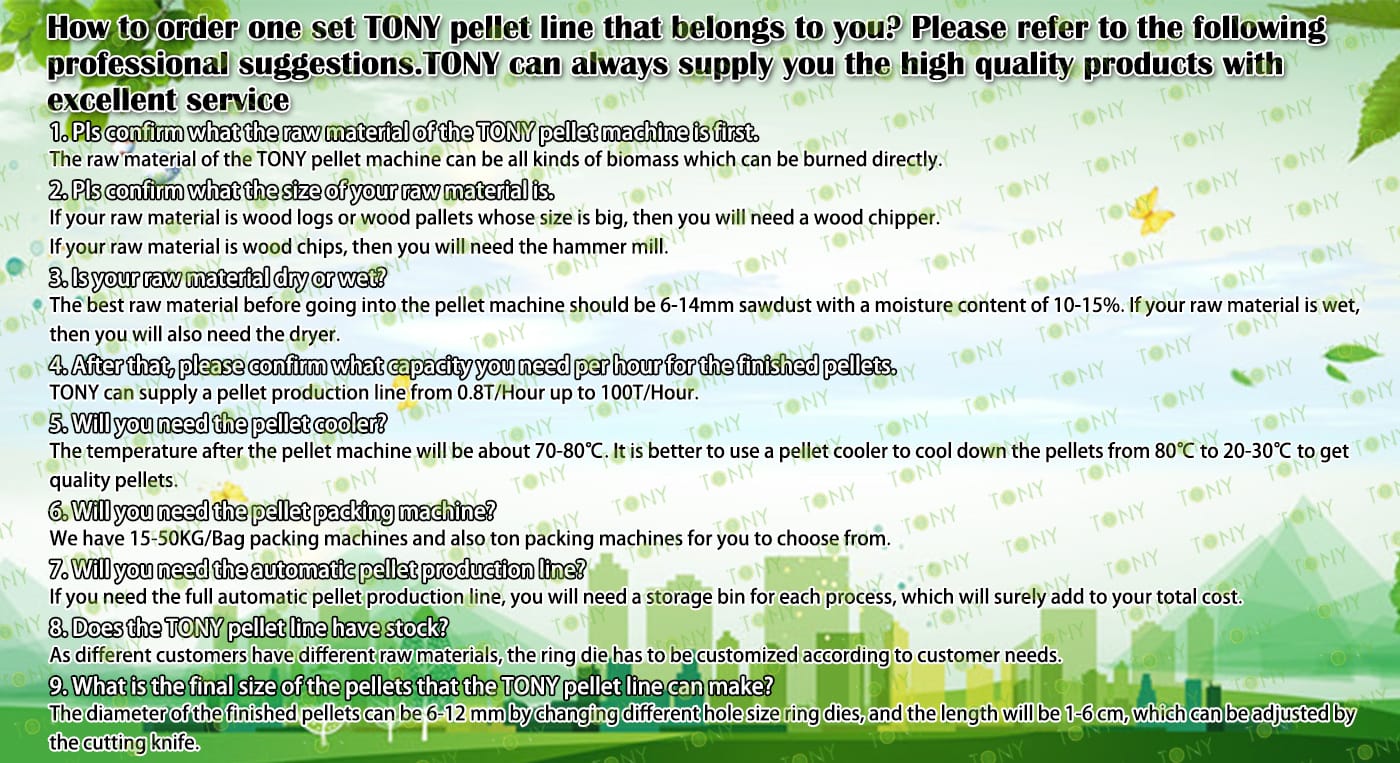

1.The working principle of dried wood pallets biomass pellet processing equipment

The core principle of wood pellet processing equipment, such as wood chip pellet mills, is to convert biomass feedstock into high-density pellet fuel through mechanical compression. The basic process involves three steps: feedstock pretreatment (crushing, pulverizing, and drying), mechanical compression, and finished product processing (cooling and packaging). For example, in a vertical ring die pellet mill, a motor connected to a reducer via a coupling drives the ring die. The feedstock enters the compression zone under gravity, where rollers squeeze the material into the ring die holes. After forming the pellets in the die, a cutter cuts them into pellets of fixed lengths.

2.Characteristics of dried wood pallets biomass pellet processing equipment

(1)The wood pallet pellet processing equipment is highly efficient and low-consumption, and can quickly process biomass raw materials into fuel pellets, significantly improving production efficiency.

(2)The biomass pellet machine has strong material adaptability and is suitable for molding various biomass raw materials. The pellet machine is equipped with molds of various specifications, and the corresponding molds can be selected for processing according to different biomass raw materials, which enhances the adaptability of processing.

(3)The wood pallet biomass pellet processing equipment has a mature design, and the finished pellets are stably molded, with stable output and excellent quality.

(4)The biomass pellet processing equipment is simple to operate, easy to use, highly automated, requires less labor, effectively reduces labor intensity, and increases output.

3.Application scenarios of dried wood pallets biomass pellet processing equipment

Wood pellets (also known as "biomass pellet fuel") are a key alternative to traditional fossil fuels like coal and heavy oil due to their high combustion efficiency, low pollution emissions, and convenient storage and transportation. They are also the most popular application for wood pallet pellet processing equipment, including:

(1)Industrial Boiler/Kiln Fuel:Small and medium-sized boilers (steam boilers and hot water boilers) in the food processing, textile, chemical, and building materials industries, as well as heating equipment such as ceramic and glass kilns, can directly use wood pallet pellets (with a calorific value of approximately 4200-4800 kcal/kg, similar to medium-quality coal).

(2)Residential Heating/Household Energy:Wood pallet pellets can be used as fuel for household biomass heating stoves and fireplaces. The pellets burn stably (no black smoke or odor) and are automatically fed through a dedicated hopper, eliminating the need for frequent refills. Furthermore, some catering businesses (such as small restaurants) use them to replace liquefied petroleum gas for heating, reducing energy costs.

(3)Power Plant Supplemental Fuel:Some biomass power plants mix wood pallet pellets with other biomass fuels, such as straw and sawdust, for power generation or combined heat and power (cogeneration) (generating both electricity and steam). The high density of wood pallet pellets (0.8-1.2 g/cm³) reduces transportation and storage space, lowering raw material storage costs for power plants. Furthermore, the high purity of the wood fiber (free of sand and impurities found in straw) reduces the risk of boiler slagging.

TONY Brand 3Ton/Hour Dried Wood Pallets Pellet Manufacturing Plant can take dried wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings. After pretreatment and processing, dried wood pallets is solidified into high - density wood pellet fuel.The content of pollutants such as sulfur dioxide and nitrogen oxides produced by biomass pellets during combustion is extremely low, and the dust emission is also low, which can effectively reduce air pollution. Moreover, the raw material sources of biomass pellets are very wide, and the combustion efficiency is high. Compared with traditional fossil energy, it reduces the production and use costs and has higher economic efficiency. It has received a lot of attention and promotion.

1. Capacity: 3Ton/Hour

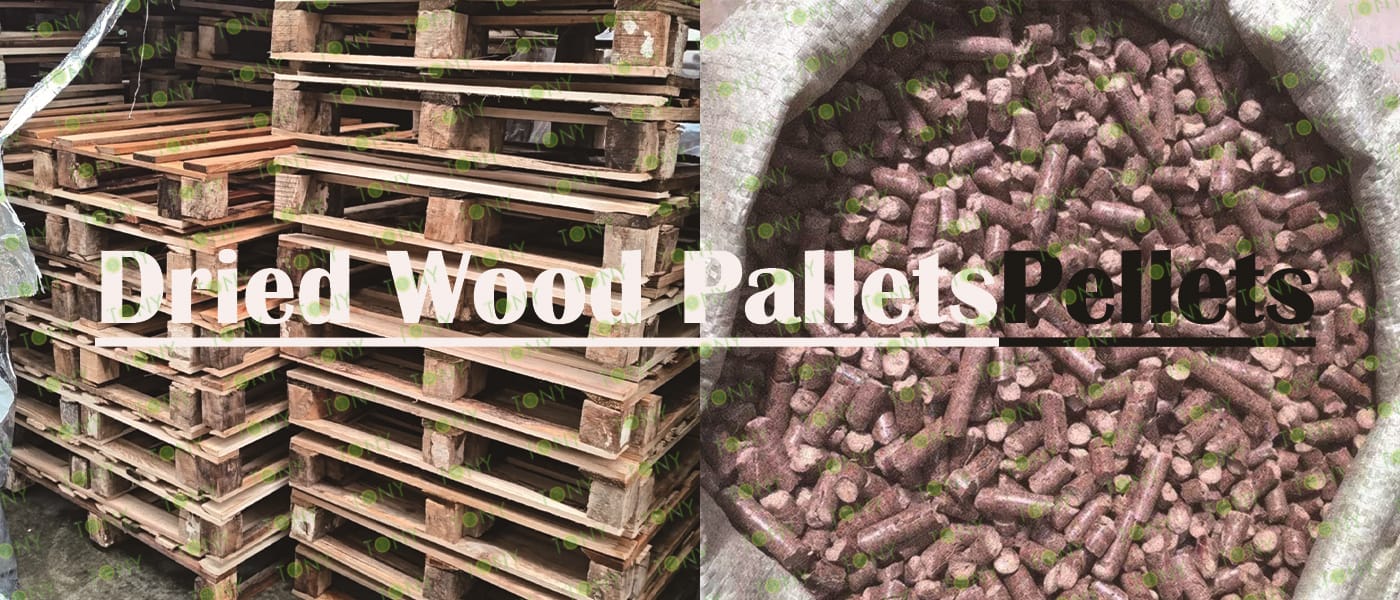

2. Raw materials: Dried wood pallets

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Pallets Pellet Production Line

2. Raw Material: All kinds of dried wood pallets

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 3 tons per hour

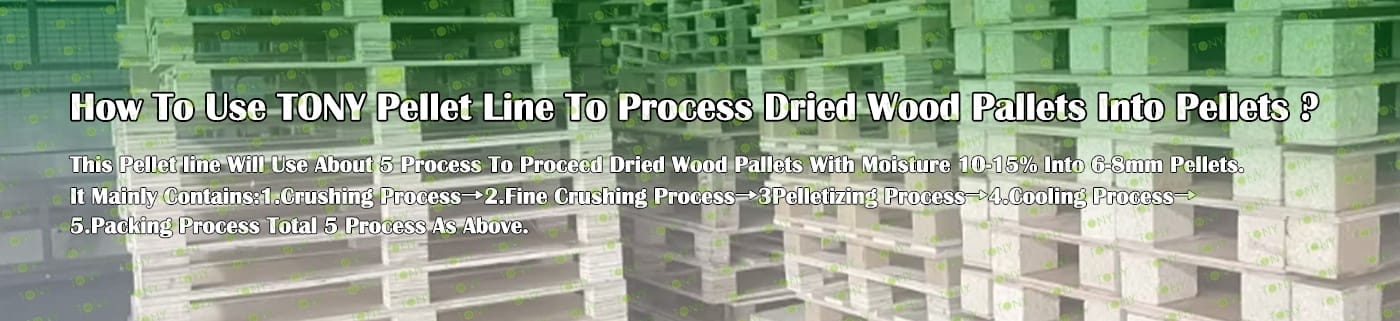

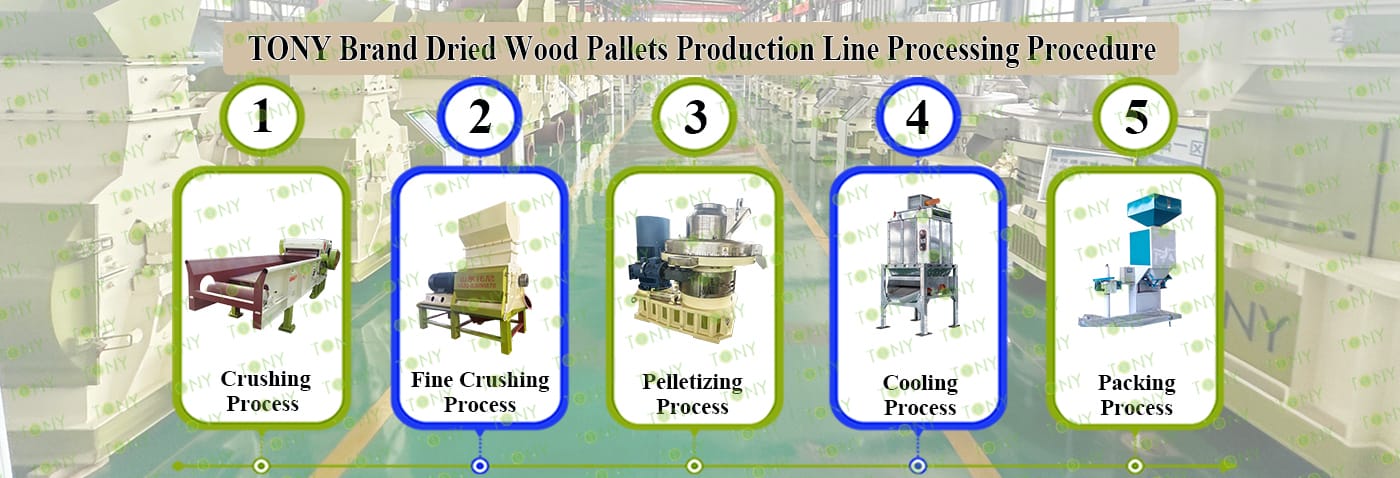

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer mill-TFD75*100-90KW, TONY Pellet Machine TYJ760-Ⅲ-200KW, Pellet Cooler, Semi-automatic Packing Machine and Belt Conveyors

|

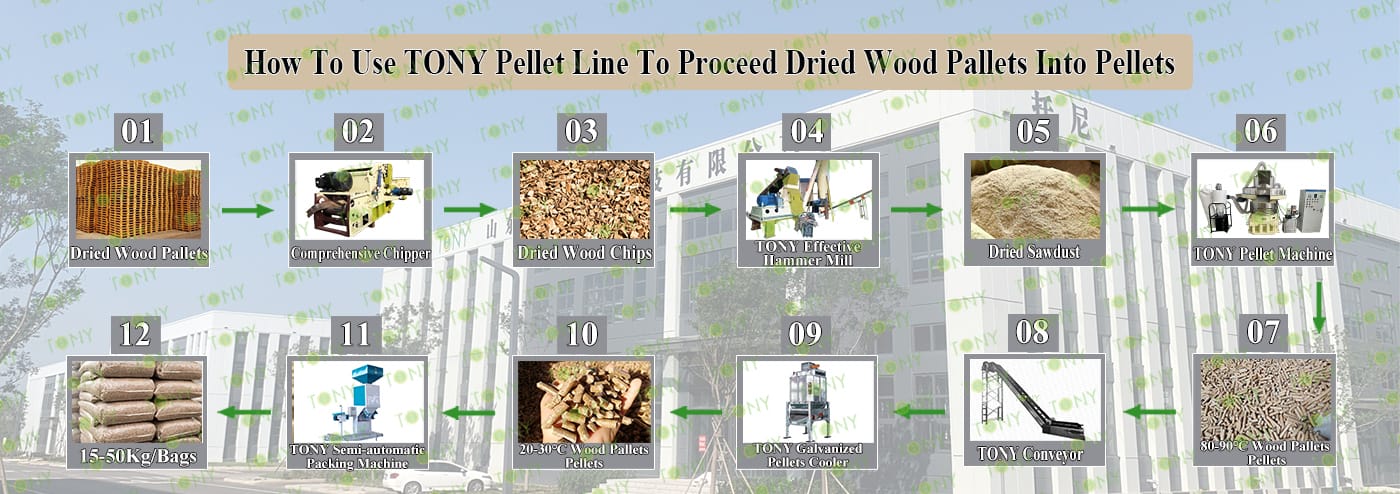

How to use the TONY pellet production line to make pellets from dried wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind dried wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY Effective Hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer mill | Vertical Ring Die Sawdust Pellet Machine |

| 1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 16 Hammer Heads*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*100-90KW*1set 3.Capacity: 3Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*1set 3.Capacity:3Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Semi-automatic Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity: 3Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 50cm*4sets 3.Capacity:Designed With The Whole Line |

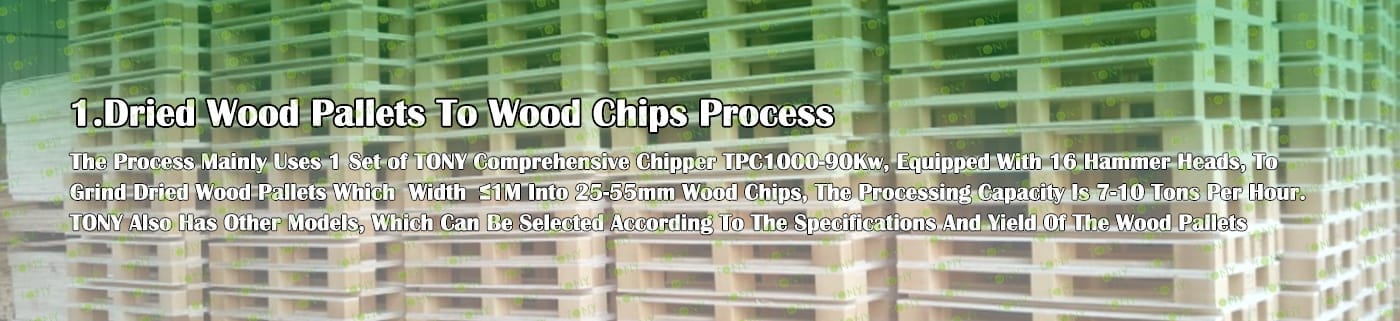

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY Brand comprehensive chipper TPC1000-90KW model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

TONY's Comprehensive Chipper.

(1)Feed And Discharge Belt Frequency Control To Prevent Card Material

(2)Hydraulic System Control Can Be Used For Thicker Materials

(3)Electronic Control System Allows The Equipment To Be Used Normally

(4)Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:3Ton/Hour.

C.TONY brand effective hammer mill TFD75*100-90KW*1set

Main Parts:

(1)TONY Effective Hammer mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:3Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-200KW*1set

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:3Ton/Hour.

C.TONY brand galvanized cooler seperator*1set

Main Parts:

(1)TONY's Galvanized Cooler Seperator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:3Ton/Hour.

C.TONY semi-automatic packing machine*1set

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Wood Pellet Processing Investment Costs

For investors, it is better to give priority to regions with abundant raw materials and strong policy support. By locking in raw material supply, improving production capacity utilization and expanding high-end markets (such as exports and civilian use), the return cycle can be further shortened and rapid profits can be achieved.

1.Equipment Investment:

Equipment investment varies significantly depending on the project scale and equipment selected. A small semi-automatic production line may cost only tens to hundreds of thousands of yuan, while a large fully automated production line can cost millions or even more.

2.Plant and Site Costs:

You need to select an appropriate plant and site based on your production scale. Rental or construction costs vary by region.

Raw Material Procurement and Transportation Costs: Raw material costs are affected by factors such as region, season, and raw material type, while transportation costs are related to the raw material sourcing radius and product sales range.

3.Environmental and Other Expenses:

These include the investment and operating costs of environmental protection equipment, utilities, and employee salaries.

1.Resource Recycling: Solving the "Solid Waste Problem"

Waste-to-Resource: Used wooden pallets are a common source of solid waste in the logistics and warehousing industries. If they are discarded or incinerated without proper treatment, they can lead to resource waste and environmental pollution. Pallet pellets transform them into high-value products.

2.Excellent performance: Suitable for multiple scenarios and easy to use.

As biomass pellet fuel or industrial auxiliary materials, pallet pellets offer stable physical and chemical properties, providing a superior user experience compared to traditional bulk wood, coal, and other materials.

3.Outstanding environmental performance: Low pollution.

The clean nature of pallet pellets is a core competitive advantage.

4.Significant economic value: Low cost and stable returns.

From production to application, the economic advantages of pallet pellets permeate the entire supply chain. Demand for biomass pellets is strong, and revenue is stable.

The core advantages of pallet pellets are their triple combination of environmental protection, cost-effectiveness, and practicality. They solve the solid waste disposal problem of used pallets and provide a clean and efficient alternative energy source. They balance low production costs with convenient application. Therefore, they have broad application prospects in logistics waste recycling, biomass energy, and clean heating. They are also a "circular economy + green energy" project encouraged by current policies.

2025 Tony Machinery - All Rights Reserved. Map