Project Brief Introduction:

1.Product:Dried Wood Pallets Pellet Line

2.Capacity: 4-5T/Hour

3.TONY Brand 4-5Ton /Hour Dried Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, TONY Pellet Machine TYJ551-Ⅲ-132KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 560KW

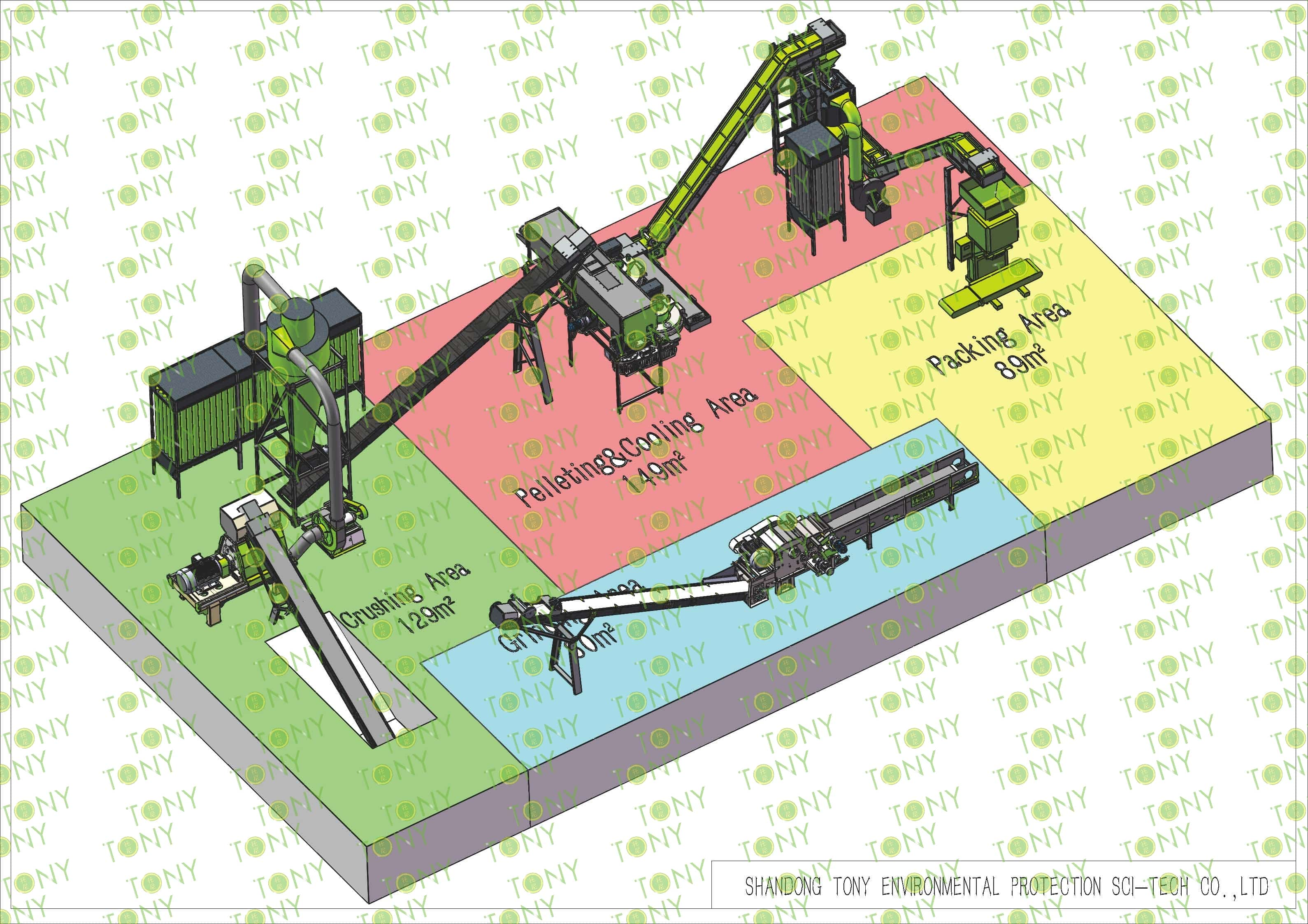

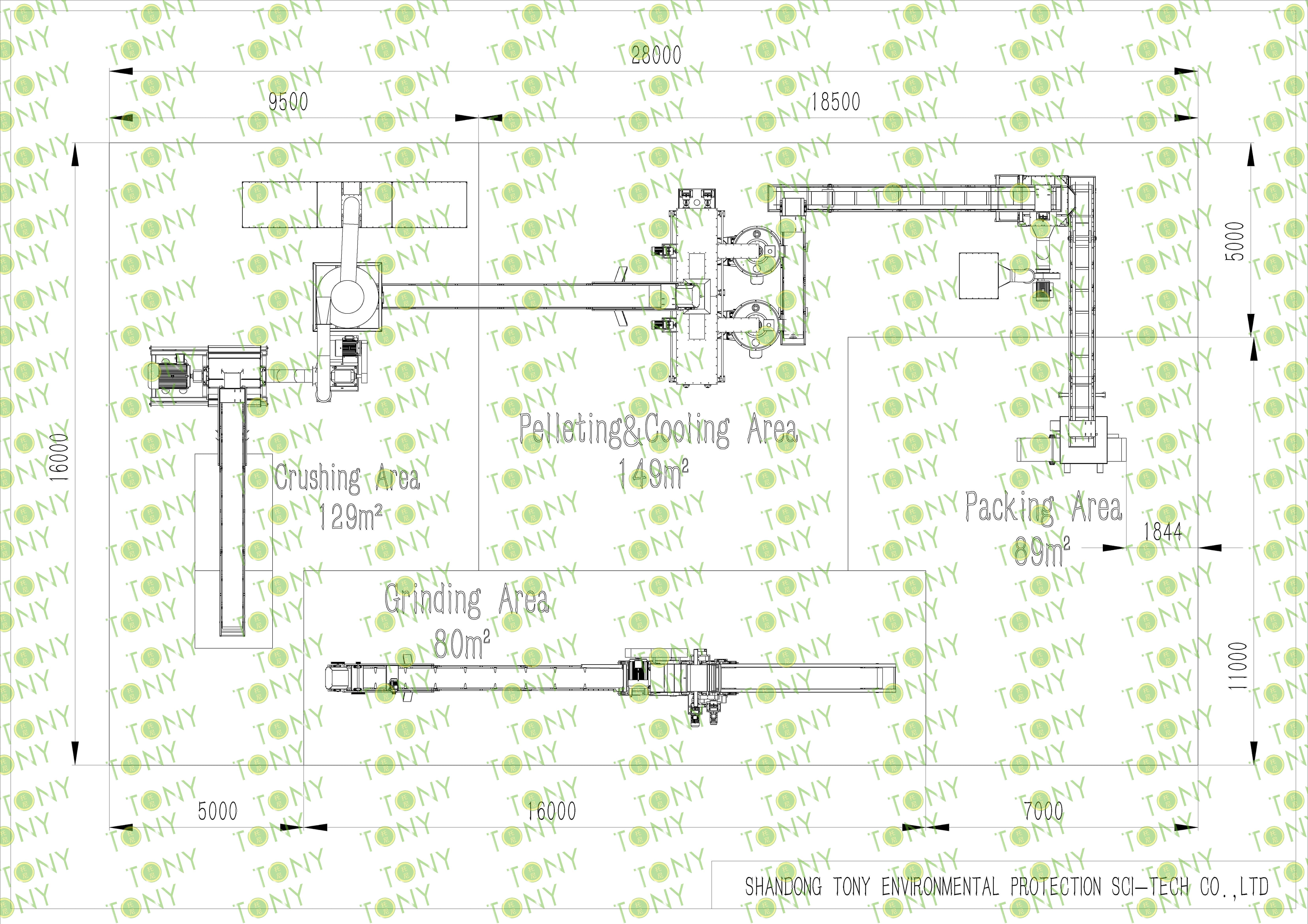

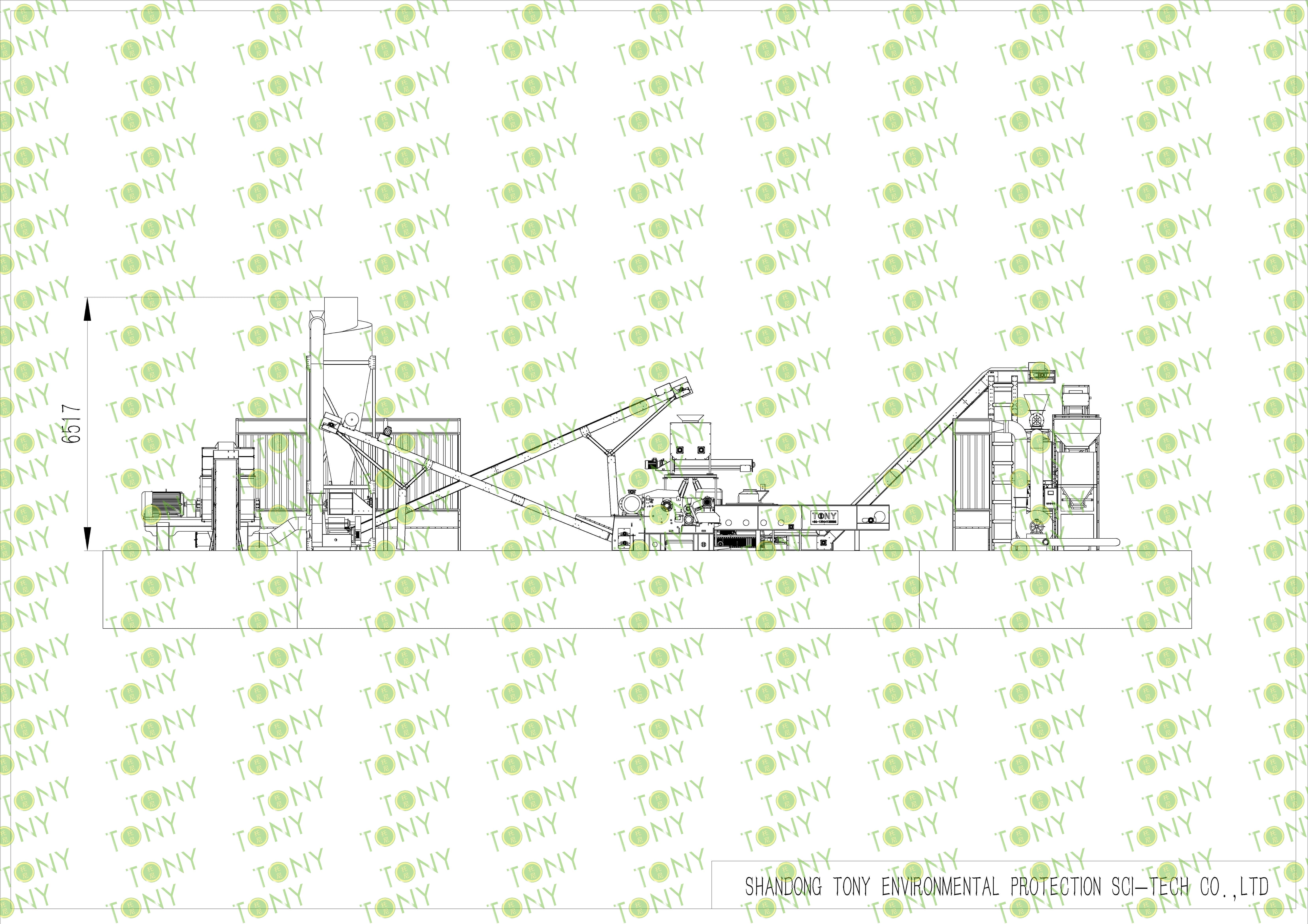

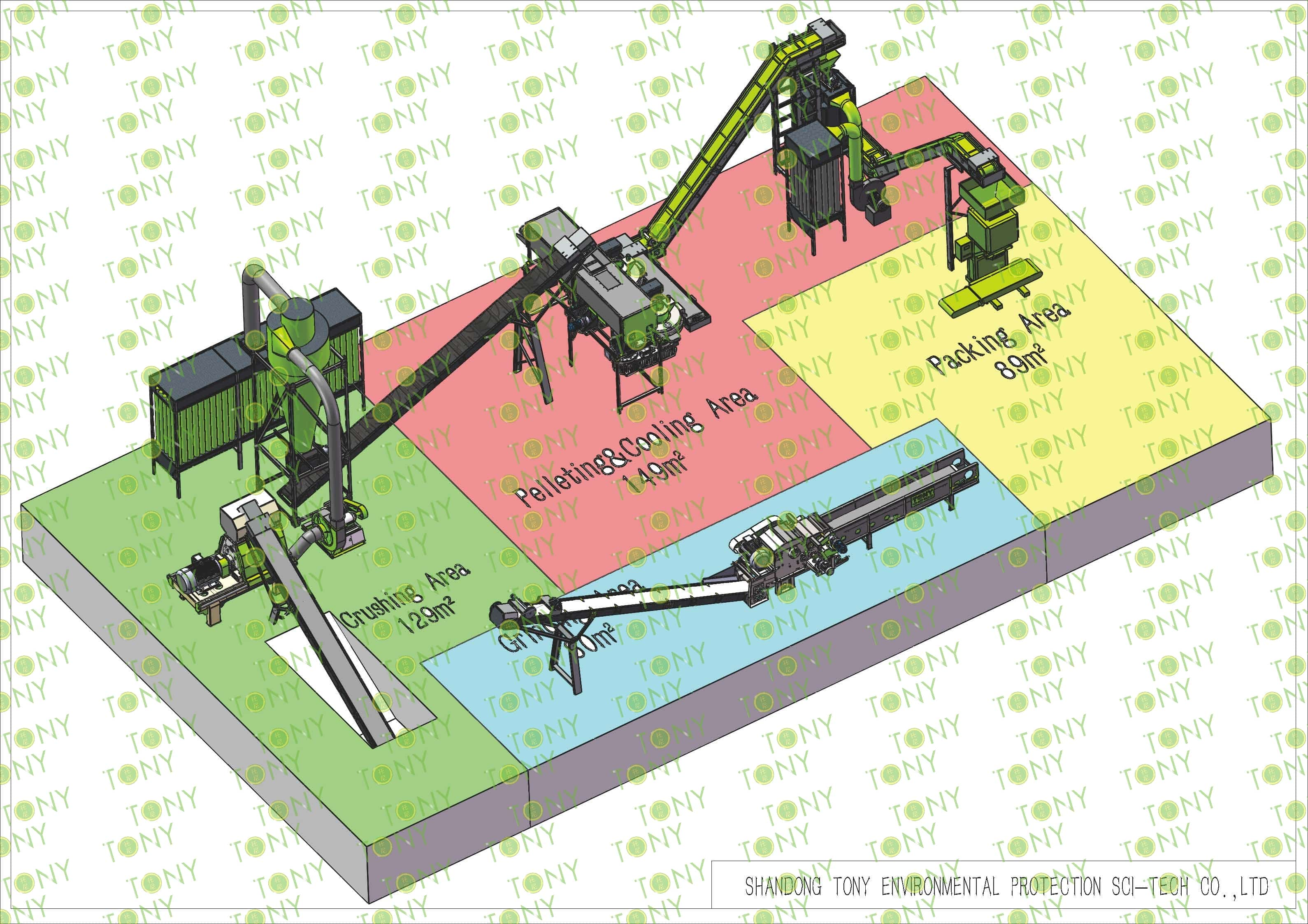

6.Need Area: About 448㎡ L: 28 M W: 16 M H: 6.517 M

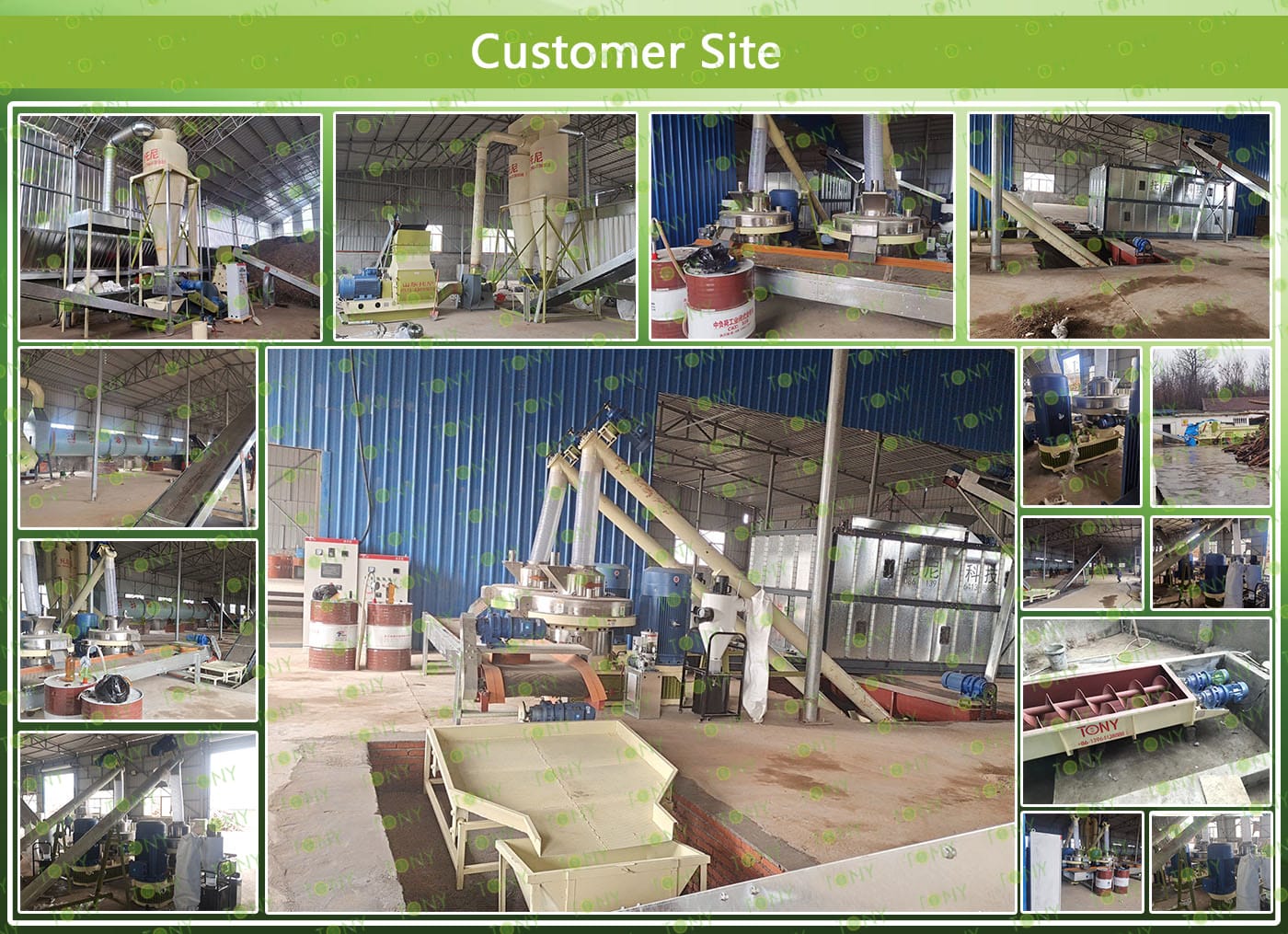

Project Layout For Customer:

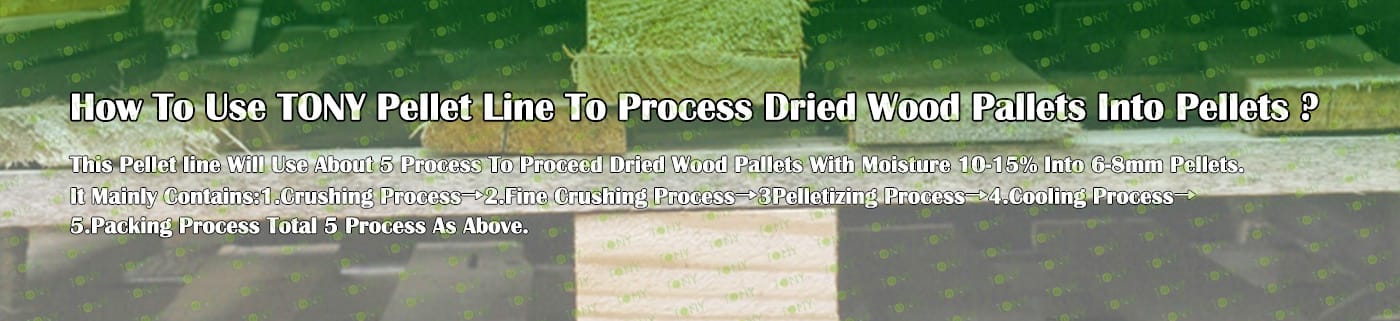

1.The working principle of dried wood pallets biomass pellet processing equipment

The overall principle of wood pallet pellet processing equipment is essentially to transform "irregular, high-impurity, high-moisture" waste wood pallets into "regular, impurity-free, high-density, and easy-to-store" biomass pellets through the continuous physical processing of "dismantling and impurity removal → crushing and volume reduction → crushing and refinement → drying and moisture control → high-temperature and high-pressure molding → cooling and stabilization." No chemical agents are added throughout the process, and molding is achieved by relying on the adhesiveness of the wood's own fibers. This not only solves the problem of environmentally friendly disposal of wood pallet waste, but also achieves resource recycling (the pellets can be used as fuel, feed carrier, etc.).

2.Characteristics of dried wood pallets biomass pellet processing equipment

(1)High-strength crushing/smashing system to cope with "large block + hard" raw materials

Wood pallets are mostly whole boards (usually 1.2m×1.0m, 1.1m×1.1m in size), and some are plywood and solid wood hard materials. The crusher needs to have high torque and wear resistance

(2)High-efficiency impurity removal device to accurately separate "metal + non-metal" impurities

The key pain point of wood pallet processing is "containing metal nails and plastic accessories". The equipment usually integrates a multi-stage impurity removal system to ensure the purity of the particles

(3)Wide range of moisture content adaptation to reduce drying energy consumption

Wood pallets have different storage environments and large differences in moisture content (15%-30%). The drying system of the equipment (mostly a drum hot air dryer) can achieve precise temperature control (80-120℃) and humidity adjustment, stabilizing the moisture content of wood chips at 10%-15% (the optimal humidity for pelletizing)

(4)Wood pallet pellet processing requires multiple steps:

crushing → impurity removal → pulverization → drying → pelletizing → cooling → screening. Equipment typically comes in the form of a complete production line, with core features including a consistent process flow and a high degree of automation.

(5)Wood pallet raw materials (especially plywood and hardwood) subject equipment components to significant wear and tear, making durability a key feature.

(6)Wood pallet processing is prone to dust and noise, and poses significant risks to mechanical safety. Therefore, the equipment features specific environmental and safety design features.

(7)Wood pallet pellet production equipment can be flexibly adjusted based on the user's production capacity, site, and intended use of the finished product, meeting diverse needs.

3.Application scenarios of dried wood pallets biomass pellet processing equipment

Processing equipment provides fuel for factory boilers and kilns (replacing coal and oil), such as steam boilers in textile and food processing plants, and heating kilns in the ceramics and building materials industries. Stable pellet production ensures energy supply.

(1)Power Generation:Biomass power plants require large quantities of standardized pellets as fuel. Large-scale processing equipment can meet the power plant's stringent requirements for pellet calorific value and density, ensuring efficient combustion and stable power generation.

(2)Residential Heating:For pellets used in home fireplaces and space heaters, processing equipment must control pellet size and hardness to accommodate residential combustion equipment. The equipment's refined production capabilities directly impact the user experience of these pellets.

(3)Environmental Protection and Waste Management:In waste and sewage treatment plants, processing equipment converts organic waste (such as sludge and food waste) into fuel pellets for resource recovery. Corrosion-resistant and clogging-resistant designs are crucial.

TONY Brand 4-5Ton/Hour Dried Wood Pallets Pellet Manufacturing Plant can take dried wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings. After pretreatment and processing, dried wood pallets is solidified into high - density wood pellet fuel.The content of pollutants such as sulfur dioxide and nitrogen oxides produced by biomass pellets during combustion is extremely low, and the dust emission is also low, which can effectively reduce air pollution. Moreover, the raw material sources of biomass pellets are very wide, and the combustion efficiency is high. Compared with traditional fossil energy, it reduces the production and use costs and has higher economic efficiency. It has received a lot of attention and promotion.

1. Capacity: 4-5Ton/Hour

2. Raw materials: Dried wood pallets

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Pallets Pellet Production Line

2. Raw Material: All kinds of dried wood pallets

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 4-5 tons per hour

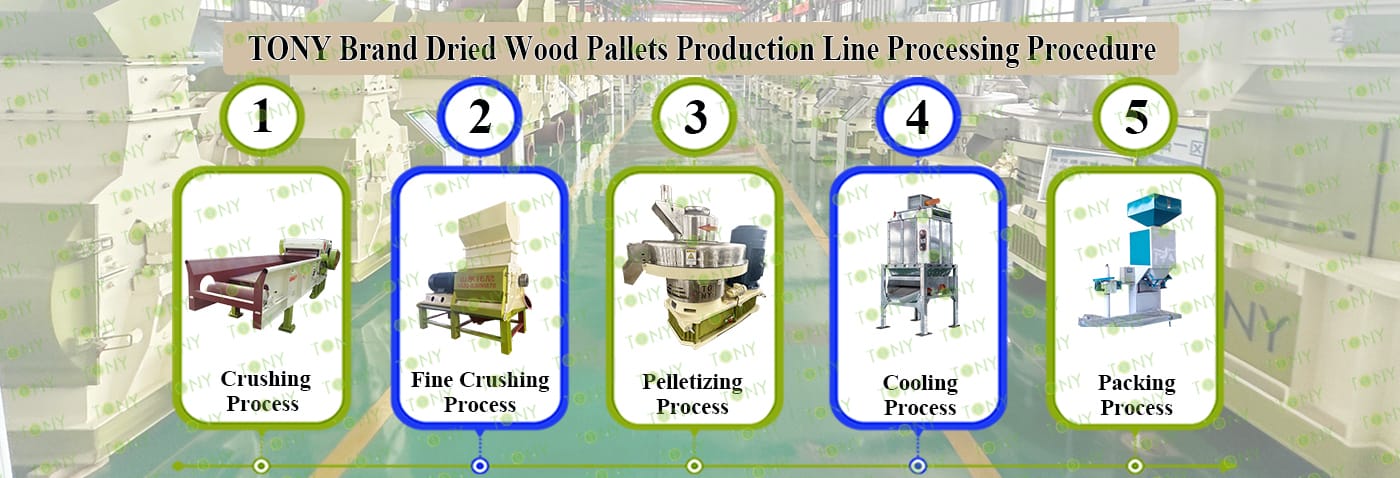

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer Mill-TFD75*132-132KW, TONY Pellet Machine TYJ551-Ⅲ-132KW, Pellet Cooler, Semi-automatic Packing Machine and Belt Conveyors

|

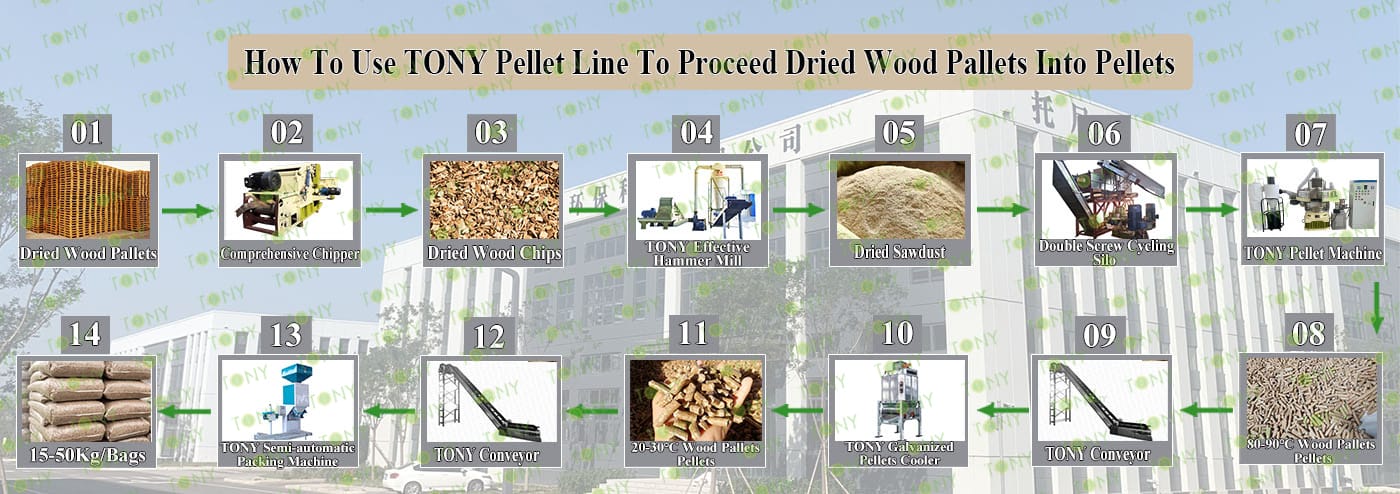

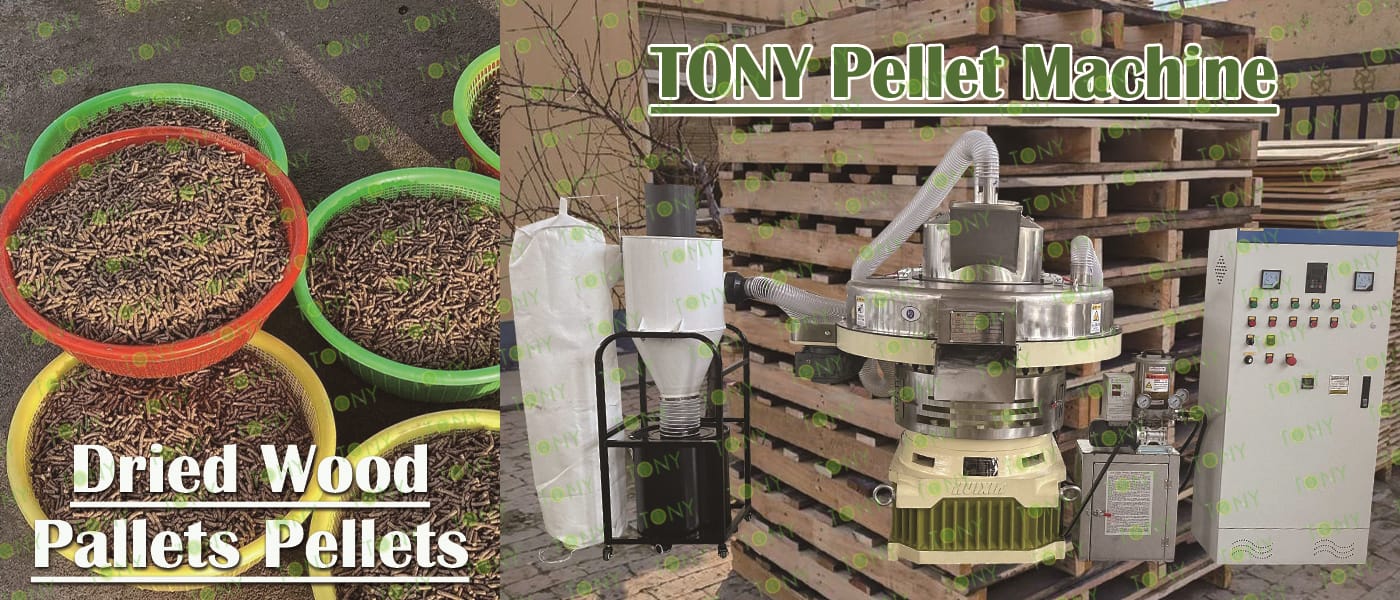

How to use the TONY pellet production line to make pellets from dried wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind dried wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

|

1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 16 Hammer Heads*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*132-132KW*1set. 3.Capacity: 4-5Ton/Hour/Set. |

1.To Stroage Sawdust Before Pellet Machine:Adjust The Speed Of Sawdust Entering The Pellet Machine. 2.Model: TLC-5*1set. 3.Capacity:4-5Ton/Hour/Set. |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets. 2.Model: TYJ551-III-132KW*2sets. 3.Capacity:2-2.5Ton/Hour/Set. 4.New 304SS Type. |

1.To Cool Pellets From 80-90℃ Into 20-30℃. 2.Model: TCN-2.5*1set. 3.Capacity:4-5Ton/Hour. |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TBF-50*1set. 3.Capacity: 4-5Ton/Hour |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1000-90KW model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:4-5Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:4-5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-132KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:4-5Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:4-5Ton/Hour.

C.TONY semi-automatic packing machine*1set

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Project Startup Suggestions

1.Preliminary Research:

First, visit local logistics parks and factories to confirm the monthly supply of discarded wood pallets (the raw material volume must meet "production capacity x 1.2" to avoid idle capacity). Simultaneously, contact two to three potential customers (such as nearby food factories and heating companies) and sign letters of intent for supply.

2.Pilot Operation:

If funding is limited, start with a "small-scale project" (1 ton per hour) and spend 6-12 months validating raw material supply, customer stability, and profit margins before gradually expanding production.

3.Long-Term Planning:

Once stable operations are achieved, the industry chain can be expanded—for example, by building a dedicated logistics fleet (to reduce transportation costs), developing customized pellets (such as "low-ash pellets" for fireplace users, which increase unit prices), or building a small biomass heating station (to directly supply steam to surrounding factories, resulting in higher profits). In summary, the project of processing wooden pallets into biomass pellet fuel is suitable for entrepreneurs or small and medium-sized enterprises with local resources (raw materials/customers) and medium-sized capital. The key is to control raw material costs, bind stable customers, and ensure environmental compliance to achieve sustainable profitability.

Advantages of Wood Pallet Pellets

Processing wood pallet pellets into biomass pellets not only offers numerous advantages in terms of environmental protection, economic and social development, and energy structure, but also boasts excellent combustion performance. The main advantages are as follows:

1.Calorific Value and Combustion Residues

The calorific value and ash content of biomass pellets after combustion are approximately 10% lower than those of medium-quality coal. However, pellets burn completely under normal operating conditions. Coal, on the other hand, does not burn completely, leaving residual ash containing 10% to 15% combustible components. Therefore, in practical applications, the effective calorific value of the two is comparable.

2.Combustibility

Pellets are more flammable and easy to ignite than coal, significantly reducing the ignition time required for combustion.

3.Solid Emissions

Biomass pellets produce significantly lower solid emissions than coal. This not only reduces slag disposal costs but also reduces environmental pollution. Solid emissions from biomass pellets are primarily ash, accounting for approximately 0.4% to 7.0% of the total weight. In contrast, solid emissions from coal combustion are a mixture of ash, alkali, and unburned coal, accounting for approximately 25% to 40% of the total weight.

4.Air Pollution and Corrosion

Coal causes far greater levels of air pollution and boiler corrosion than wood biomass pellets. Coal smoke contains large amounts of particulate carbon, as well as toxic and corrosive gases such as sulfur dioxide and carbon monoxide. Biomass pellets are primarily composed of C-H organic matter, and their flue gas contains no particulate carbon or sulfur dioxide. Instead, it consists primarily of C-H volatile gases, with virtually no sulfur dioxide or carbon monoxide. The smoke color during combustion is below Ringelmann Class I, significantly reducing air pollution and carbon dioxide emissions. Biomass pellets are internationally recognized as a "clean fuel."

5.Cost and Time Savings

Compared to coal, using biomass pellets as boiler fuel can save costs and time. For example, using wood biomass pellets for a 0.5-ton boiler can reduce costs by 11% and time by 34%. For example, compared to coal-fired power generation, a 0.5-ton boiler can reduce fuel costs by 10% and time by 16%.

6.Sustained Combustion

Wood biomass pellets typically burn 8 to 10 times longer than loose, soft materials, maintaining a stable and continuous combustion state, ensuring a more reliable energy supply.

2025 Tony Machinery - All Rights Reserved. Map