Project Brief Introduction:

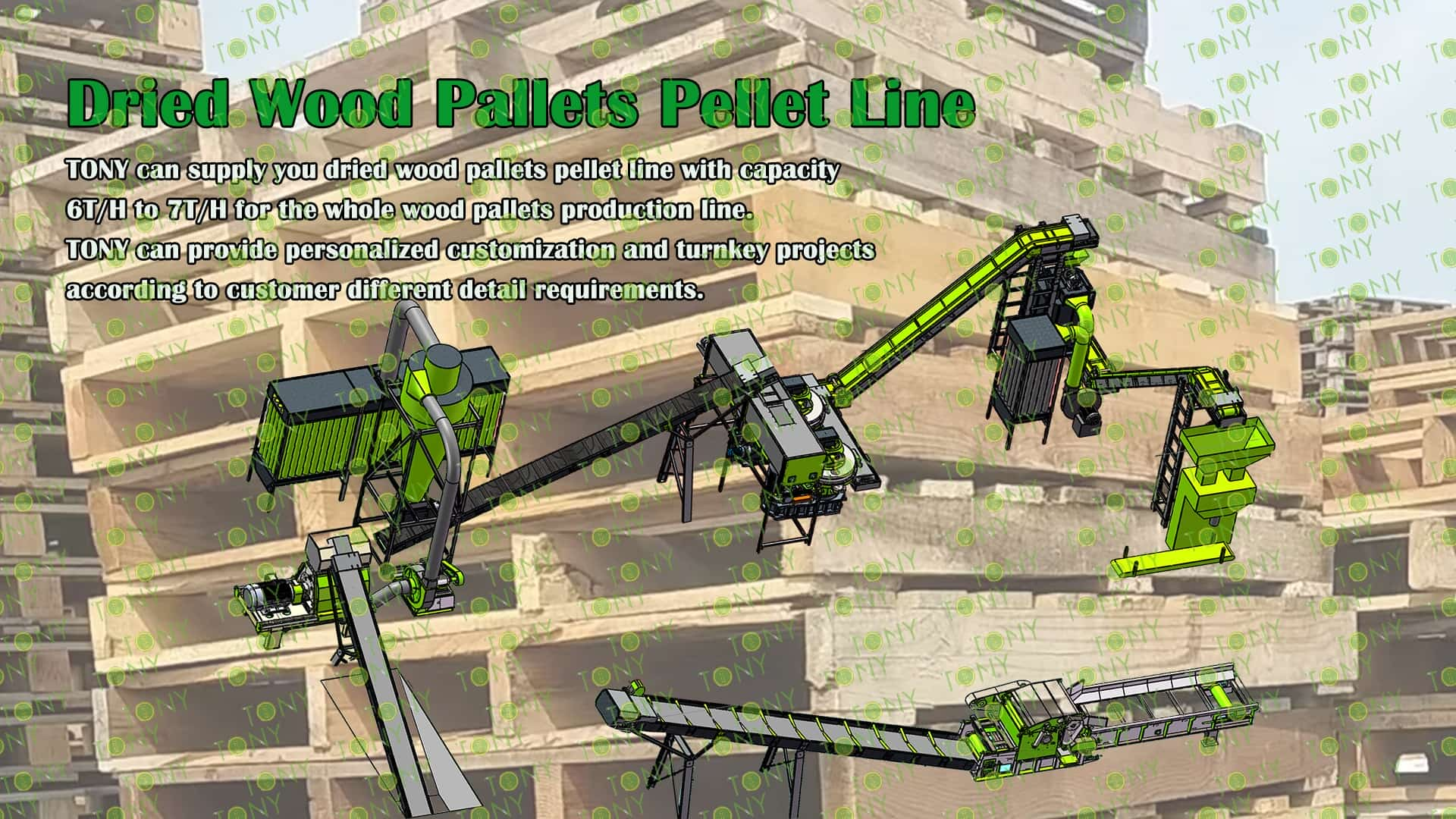

1.Product:Dried Wood Pallets Pellet Line

2.Capacity: 6-7T/Hour

3.TONY Brand 6-7Ton /Hour Dried Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, TONY Pellet Machine TYJ860-Ⅲ-220KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 925KW

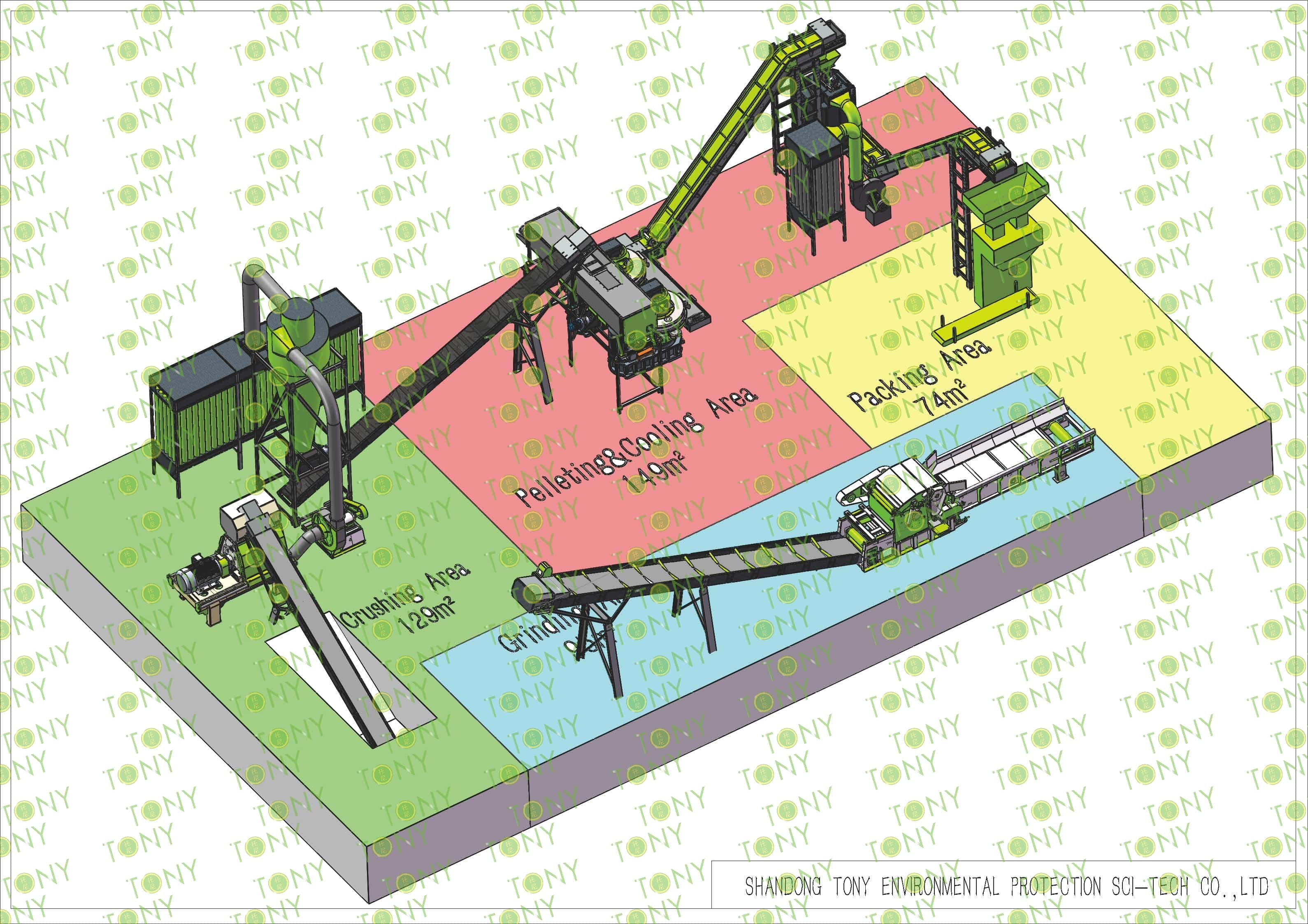

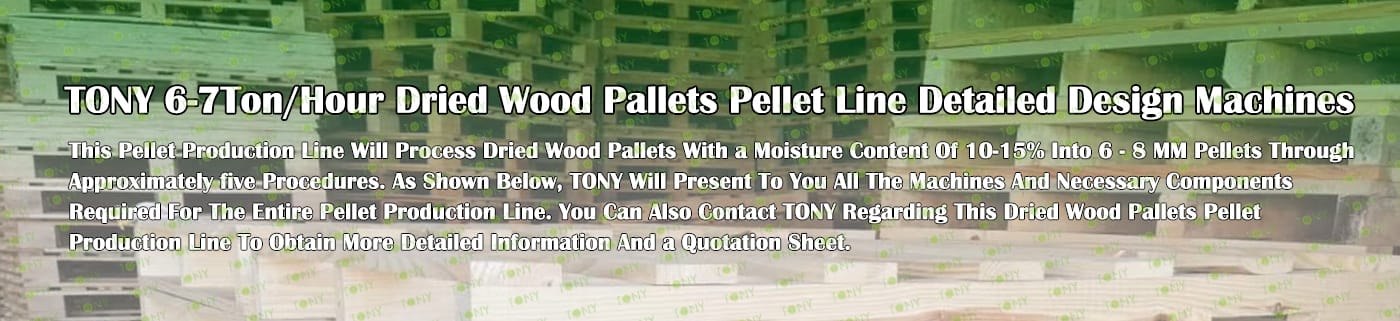

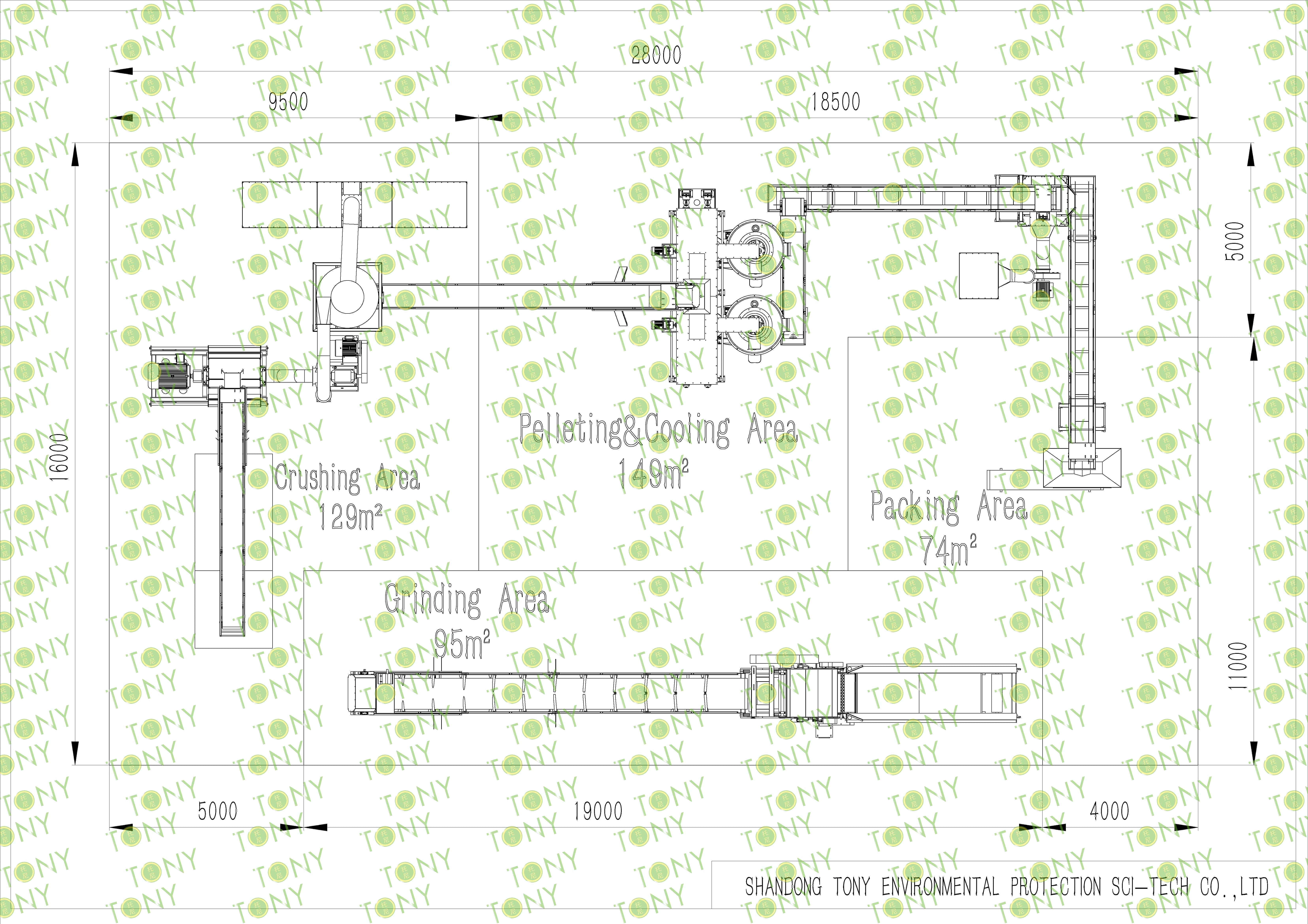

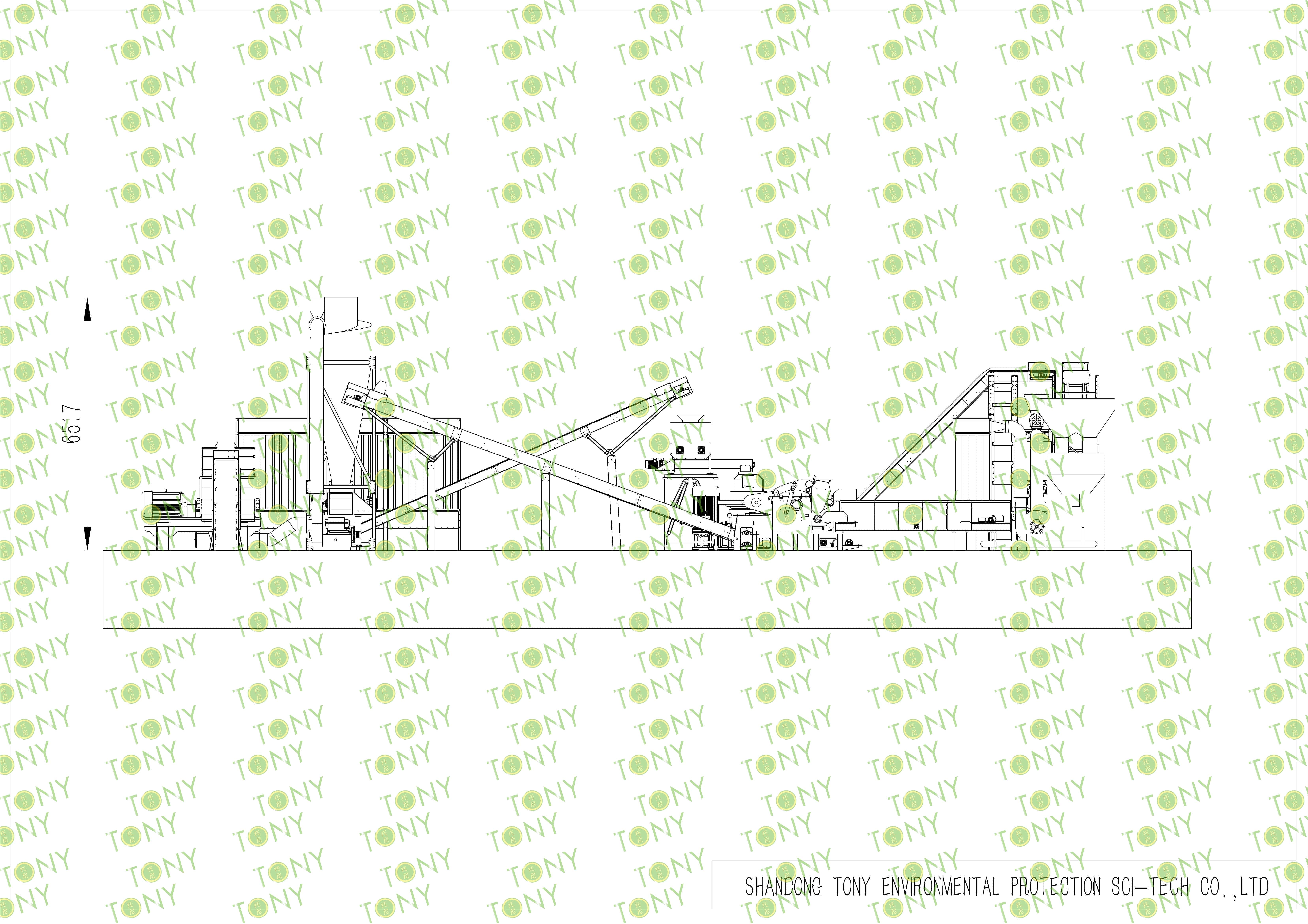

6.Need Area: About 448㎡ L: 28 M W: 16 M H: 6.517 M

Project Layout For Customer:

1.The working principle of dried wood pallets biomass pellet processing equipment

The pelletizing equipment is the core of the entire production line. Its principle is to use "mechanical extrusion + lignin softening" to compress loose fine wood chips into high-density pellets with a circular cross-section (diameter 6-12mm, commonly 8mm) and a length of 3-10mm. The key lies in the ring die pelletizer (mainstream equipment in the industry)

(1)Feeding and pre-pressing: The fine wood chips that meet the standards are evenly fed into the pelletizing chamber by the feeding agitator. The feed plate in the chamber distributes the wood chips to the gap between the ring die and the pressure roller (the ring die is a circular steel die with uniform small holes, and the pressure roller is 2-3 rotatable cylindrical rollers. The ring die is fixed and the pressure roller is driven by the ring die to rotate);

(2)High-pressure extrusion: The pressure roller rotates at high speed under the friction of the ring die (ring die speed 15-30r/min), forcibly pressing the wood chips into the small holes of the ring die - at this time, the extrusion pressure can reach 50-150MPa. The loose wood chips are compressed under high pressure and their volume is reduced to their original size. 1/5-1/3, the density is increased to 1.1-1.3g/cm³ (much higher than the raw material 0.2-0.5g/cm³);

(3)Lignin bonding: During the extrusion process, the friction heat generated by high pressure (temperature can reach 80-120℃) will soften and melt the lignin (natural adhesive) in the wood chips, wrapping the cellulose and hemicellulose particles; when the material is extruded from the ring die holes, the temperature drops and the lignin re-solidifies, firmly bonding the wood chips together to form cylindrical particles with stable structure;

Pelletizing: The cutter (adjustable position) on the outside of the ring die cuts the extruded continuous particles into set lengths (3-10mm), completing the pelletizing process

2.Characteristics of dried wood pallets biomass pellet processing equipment

The dry wood pallet biomass pellet processing equipment is highly targeted and practical, with key features focused on raw material compatibility, processing efficiency, environmental protection and energy conservation, and guaranteed finished product quality.

In terms of raw material compatibility, the equipment is optimized for the characteristics of dry wood pallets. Equipped with high-strength shredding and crushing components, it can efficiently process pallets with metal connectors (such as nails). Pre-processing ensures uniform sawdust particle size, making it suitable for subsequent pelletizing, eliminating the need for additional raw material sorting and improving raw material utilization.

The pelletizer boasts outstanding processing efficiency and low energy consumption. The pelletizer utilizes wear-resistant rollers and a ring die, enabling continuous operation and easy replacement of wearing parts. A single unit can process up to several tons of dry wood pallets daily. Furthermore, heat is generated through extrusion friction, eliminating the need for additional heating devices and reducing energy consumption. The pelletizing rate remains consistently above 95%, and pellet density meets the required standards.

The equipment offers significant environmental and resource-saving advantages. It converts waste dry wood pallets into clean biomass fuel, reducing solid waste accumulation. A dust collection device is also included during the processing process to minimize dust pollution, comply with environmental regulations, and achieve a "waste-to-treasure" resource recycling process.

3.Application scenarios of dried wood pallets biomass pellet processing equipment

(1)Small and medium-sized pellet plants (regional): After introducing dry pallet pellet processing equipment, they can supplement raw materials by recycling discarded pallets from surrounding logistics companies, broaden raw material channels, reduce dependence on a single wood chip supplier, and ensure full-load operation of the production line.

(2)Large-scale pellet plants (industrial grade): For example, large-scale pellet plants serving power plants and chemical plants require a large amount of wood raw materials to support production. Pellets processed from discarded dry pallets (high density and stable wood fiber) have "higher combustion value and lower ash content" (better than ordinary wood chip pellets) and can be used as raw materials for "high-end pellets" (such as pellets for industrial boilers), increasing the selling price of finished products (10%-20% higher than ordinary pellets).

(3)Professional wood solid waste treatment companies: For example, environmental protection companies that process discarded furniture and construction wood waste. Discarded dry pallets are compatible with this type of wood waste (both are solid wood/artificial wood). The equipment can be "integrated for processing" without the need for separate classification, improving processing efficiency; the processed pellet fuel can be used as the company's "core product for export", expanding from "single processing service" to a complex business of "processing + product sales", thereby improving profitability.

(4)Regional new energy entrepreneurs: By recycling waste dry pallets from surrounding enterprises and processing pellets, the raw material acquisition cost is low (even free), and the finished products can be sold to local factories and heating companies (within a sales radius of 50 kilometers, and transportation costs are controllable). The investment is small and the return is fast, which is suitable for small and medium-sized entrepreneurs.

(5)Environmental protection investment companies: This type of enterprise focuses on "green and low-carbon projects". Dry pallet pellet processing projects combine "solid waste treatment (environmental protection attributes)" and "biomass energy (new energy attributes)". After investment, stable returns are obtained, while improving the company's ESG rating.

TONY Brand 6-7Ton/Hour Dried Wood Pallets Pellet Manufacturing Plant can take dried wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings. After pretreatment and processing, dried wood pallets is solidified into high - density wood pellet fuel.The content of pollutants such as sulfur dioxide and nitrogen oxides produced by biomass pellets during combustion is extremely low, and the dust emission is also low, which can effectively reduce air pollution. Moreover, the raw material sources of biomass pellets are very wide, and the combustion efficiency is high. Compared with traditional fossil energy, it reduces the production and use costs and has higher economic efficiency. It has received a lot of attention and promotion.

1. Capacity: 6-7 Ton/Hour

2. Raw materials: Dried wood pallets

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Pallets Pellet Production Line

2. Raw Material: All kinds of dried wood pallets

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 6-7 tons per hour

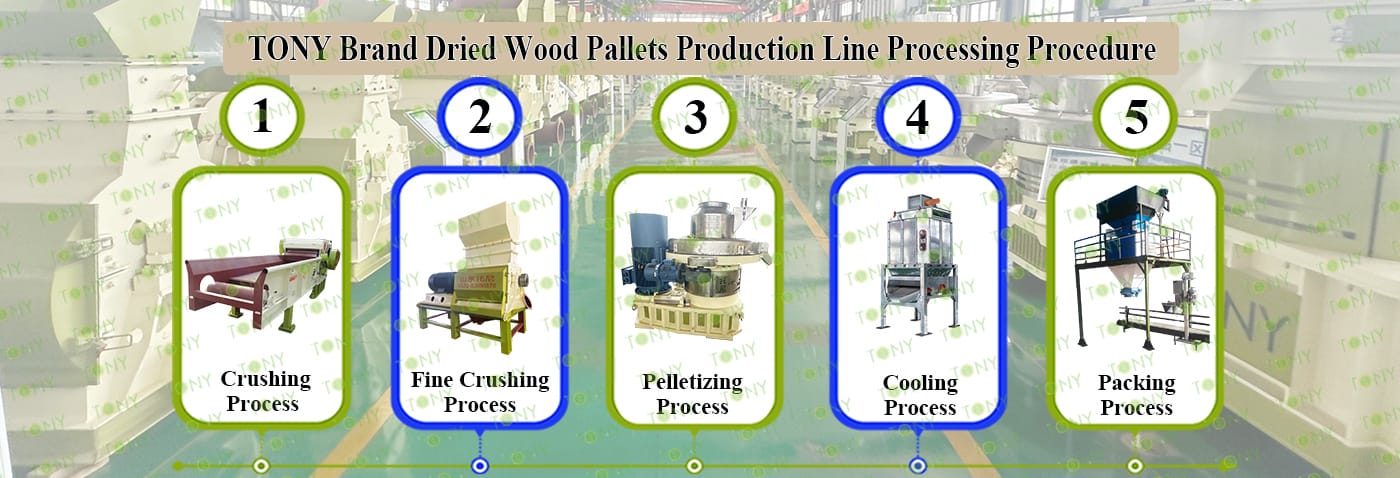

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer Mill-TFD85*250-250KW, TONY Pellet Machine TYJ860-Ⅲ-200KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

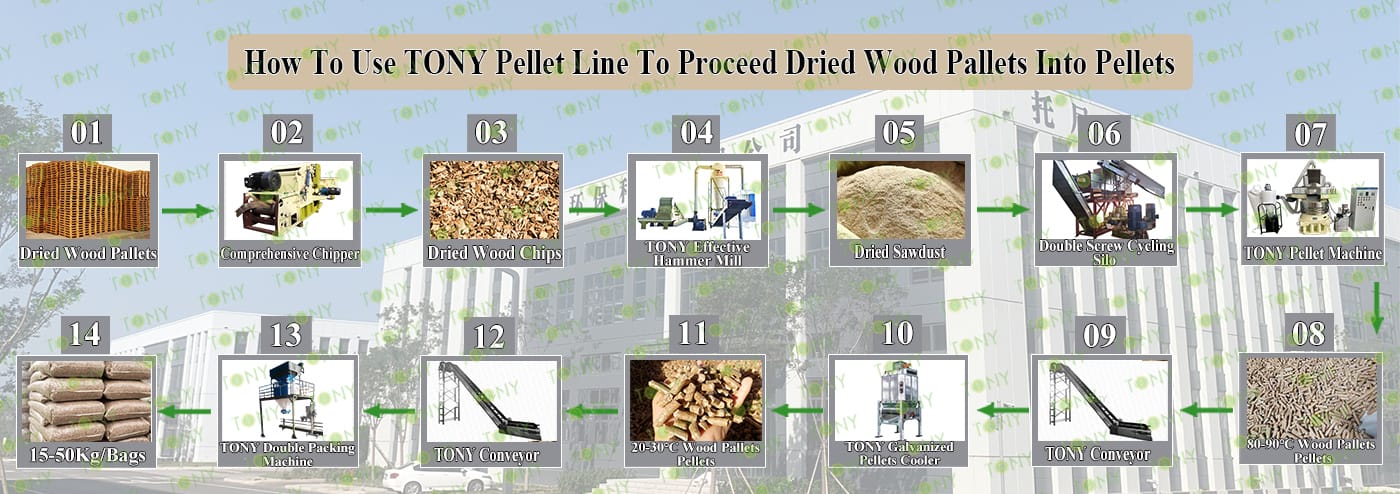

How to use the TONY pellet production line to make pellets from dried wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind dried wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

|

1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 16 Hammer Heads*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*1set 3.Capacity: 6-7Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; 2.Model: TLC-7*1set 3.Capacity:6-7Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*2sets 3.Capacity:3-4Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:6-7Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6-7Ton/Hour |

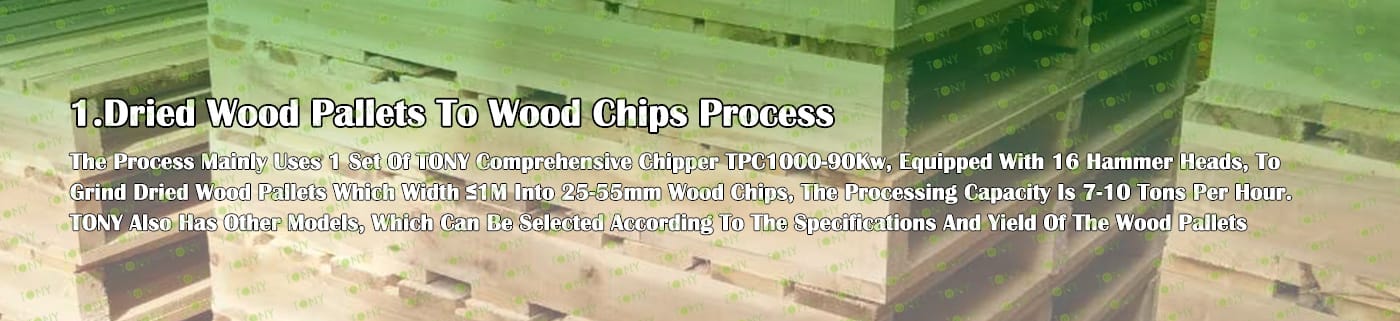

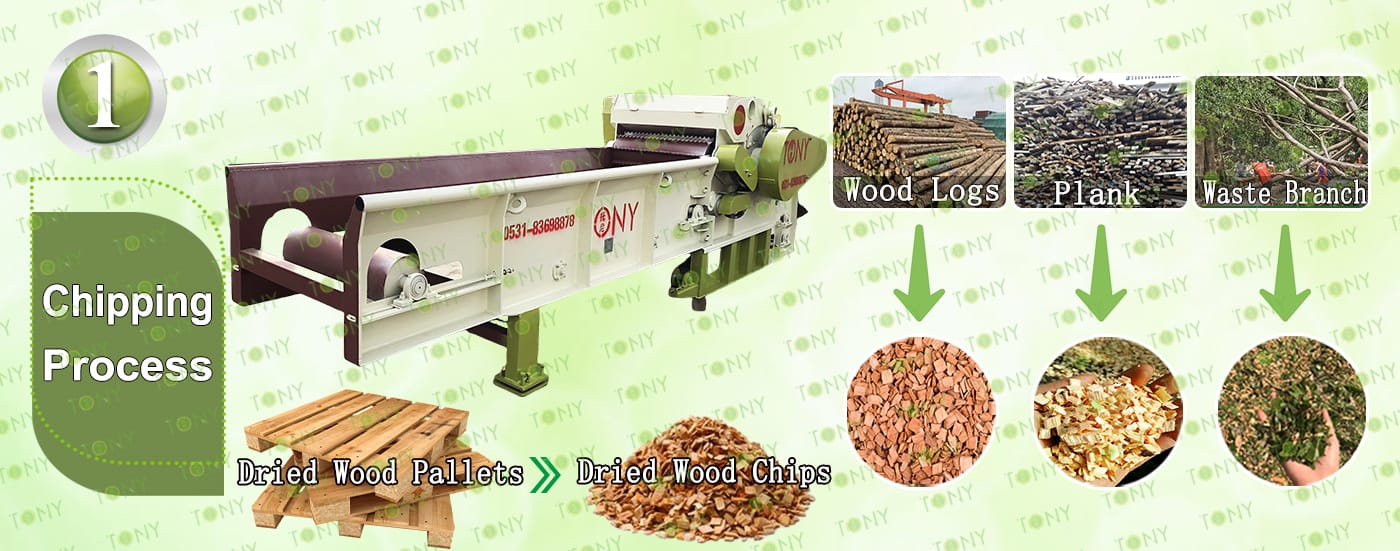

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1000-90KW model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:6-7Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:6-7Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-220KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:6-7Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:6-7Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

The biomass pellet processing startup project is an environmentally friendly venture capitalizing on the dual trends of "solid waste resource utilization" and "clean energy substitution." Using waste wood (such as discarded dry pallets from the logistics industry, lumber mill scraps, agricultural and forestry pruning branches, and furniture production waste) as its core raw material, it utilizes specialized equipment such as shredding, crushing, drying, and extrusion to produce high-density biomass pellet fuel. Suitable for small and medium-sized investors, it offers both economic returns and social value.

The project's core competitiveness lies primarily in its low cost and high adaptability of the raw material: The raw material is widely sourced, mostly from waste resources, and can be purchased at low prices in logistics parks, furniture factories, and forestry farms. Some partners even provide it free of charge (though transportation costs must be covered). Furthermore, the equipment can efficiently sort and process dry pallets with metal connectors and branches containing impurities through pre-processing, eliminating the need for extensive manual screening and achieving a raw material utilization rate of over 90%. Furthermore, to promote the development of "zero-waste cities," local governments often provide site and equipment subsidies for solid waste resource utilization projects, further reducing initial startup pressures.

In terms of market demand, the project aligns with the energy structure adjustment needs under the "dual carbon" policy. In the industrial sector, boiler heating in small and medium-sized factories and the drying process in food processing companies require alternatives to highly polluting coal fuels, and biomass pellets can be directly integrated into existing equipment. In the agricultural sector, there is a strong demand for low-cost fuels for winter insulation in greenhouses and heating livestock and poultry farms. In the civilian sector, biomass pellets are becoming a high-quality alternative to coal due to their convenient storage and smokeless combustion in rural areas of northern China. Demand for these products covers multiple scenarios and is growing year by year.

1.Widely available and low-cost raw materials.

Discarded wooden pallets are a common waste material in logistics, warehousing, wood processing, and manufacturing, generating significant quantities annually (e.g., discarded pallets from e-commerce and machinery companies). This raw material eliminates the need to purchase additional wood and can often be recycled at a low price. In some areas, collection is even free (companies are willing to pay for the removal of discarded pallets, even though they need to dispose of them). This significantly reduces raw material procurement costs and ensures project profitability.

2.Raw material pre-processing is relatively easy.

Wooden pallets are primarily made from common hardwoods or softwoods, such as pine, fir, and poplar. Their fiber structure is intact, requiring no complex sorting (only impurities like nails and plastic need to be removed). They can be directly crushed and processed, resulting in low energy consumption and high efficiency.

3.Strong raw material supply stability.

The logistics industry has a long-standing demand for wooden pallets, and the generation of discarded pallets has steadily increased with the scale of logistics. By establishing long-term recycling agreements with warehousing companies and manufacturing plants, a stable raw material supply chain can be established, avoiding the risk of running out of material to process.

2025 Tony Machinery - All Rights Reserved. Map