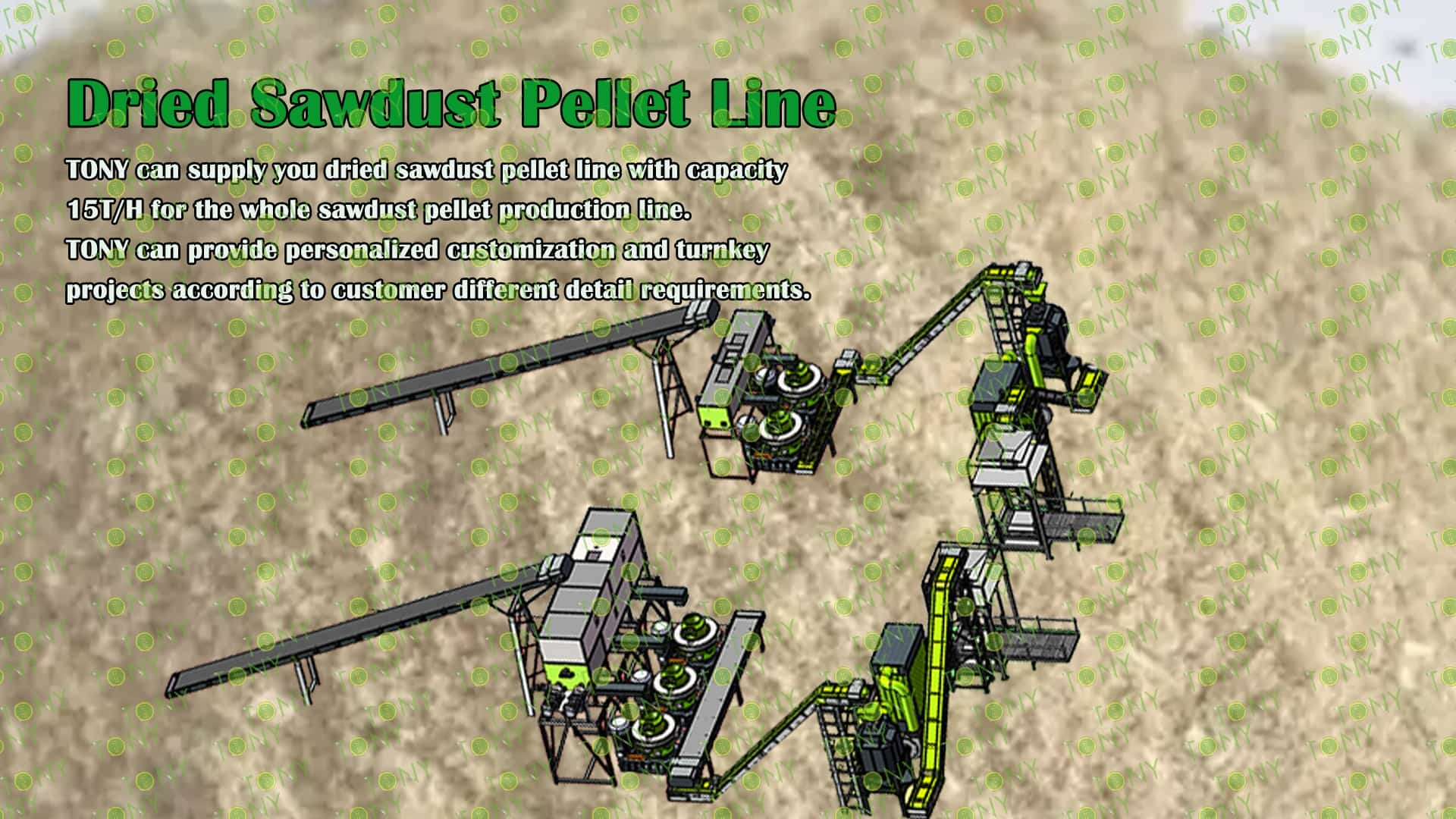

Project Brief Introduction:

1.Product:Dried Sawdust Pellet Line

2.Capacity: 15T/Hour

3.TONY Brand 15Ton /Hour Dried Sawdust Pellet Line Project Process

4.Main Machine:TONY Pellet MachineTYJ760-III-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1100KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D

1.The working principle of dried sawdust biomass pellet processing equipment

The entire process of dry sawdust processing is essentially "physical compression + natural bonding": using dry sawdust as raw material, pre-treatment ensures the purity and uniformity of the raw material; then through the high temperature and high pressure of the extrusion system, the sawdust's own lignin is used to achieve bonding, transforming the low-density raw material into high-density pellets; finally, after cooling and screening, biomass pellet fuel that meets the requirements of storage, transportation and combustion is obtained. No chemical additives are added throughout the process, making it environmentally friendly and efficient.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)Efficient Molding Process:

Using the extrusion molding principle, the friction and extrusion forces between the rollers and the die plate solidify raw materials such as sawdust into pellets without the addition of binders. This machine is adaptable to a wide range of raw materials, including wood chips, straw, rice husks, bark, and other agricultural and forestry waste.

(2)Optimized Structural Design:

Some models feature a tapered roller that matches the linear speed of the die plate, reducing misalignment and friction, lowering energy consumption, and extending die life. The pelletizing chamber features multiple inspection doors for easy maintenance and cleaning. Uniformly distributed rollers enhance operational smoothness and production efficiency.

(3)Flexible Adjustment:

Equipped with a central screw pressure adjustment mechanism, the die gap can be adjusted according to different material properties, adapting to diverse raw material pressing needs and improving pellet quality.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Biomass power generation: Pellets can be used directly in biomass power plants as a raw material for power generation to replace coal and reduce carbon emissions.

(2)Industrial boilers and heating: In cement plants, food processing plants, paper mills and other enterprises, pellet fuel provides steam or thermal oil for boilers, replacing traditional coal-fired boilers. The combustion efficiency is 1.3-1.5 times higher than that of coal-fired boilers, and the NO2 and smoke emissions are far lower than the national standards.

(3)Home heating and cooking: Pellets can be used in household fireplaces, heating stoves and other equipment. They are clean, hygienic, easy to store and transport, and have become the mainstream choice to replace fuel or electric heating in Northern Europe, North America and other places.

(4)Commercial heating: The heating systems of hotels, office buildings and other places can use pellet fuel boilers with automatic feeding systems to achieve efficient and low-carbon heating.

(5)Agricultural waste resource utilization: The equipment can process agricultural waste such as sawdust, crop straw, and discarded edible mushroom sticks, converting them into environmentally friendly pellet fuel, reducing environmental pollution caused by incineration or waste, while achieving resource recycling.

(6)Fertilizer and feed processing: Some pellet products can be used as raw materials for organic fertilizers and biofertilizers, or used in feed production through process adjustments, expanding the value of the agricultural industry chain.

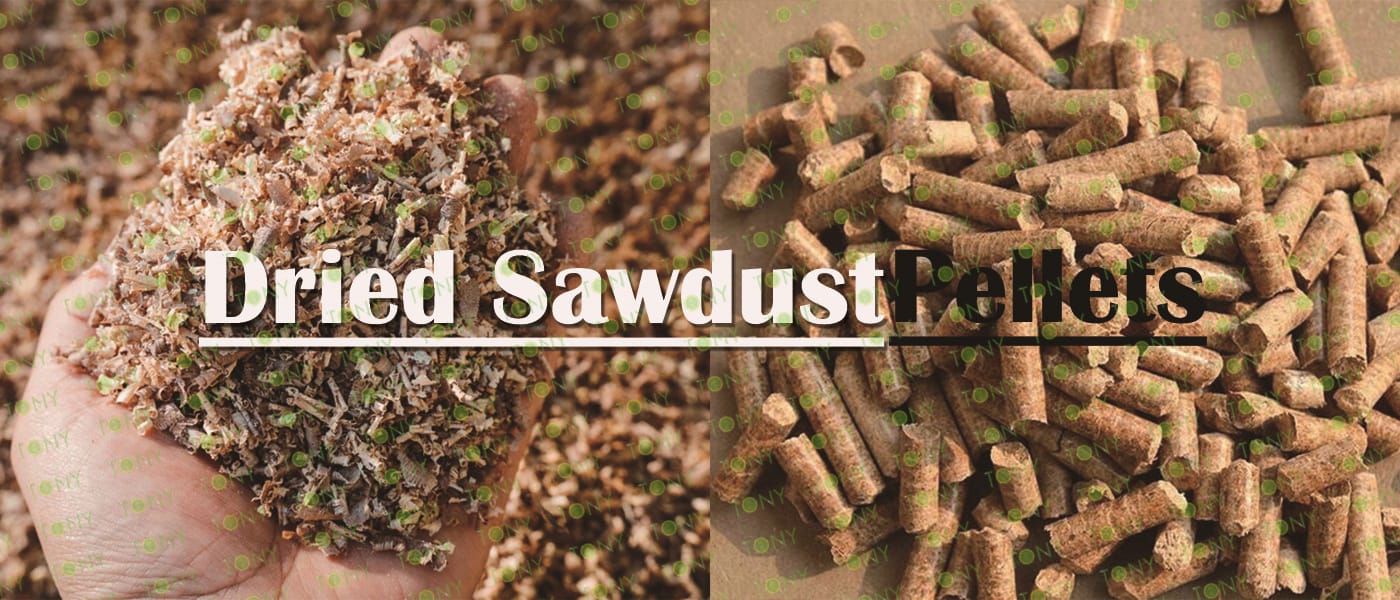

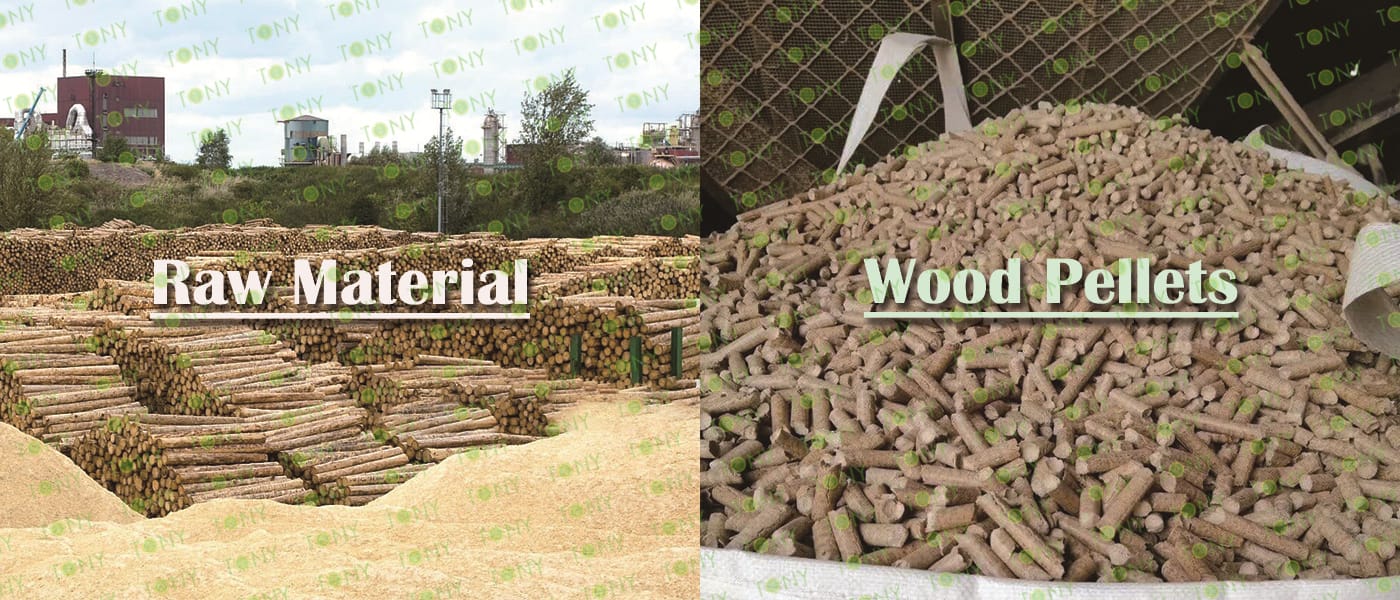

TONY Brand 15Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 15Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 15 tons per hour

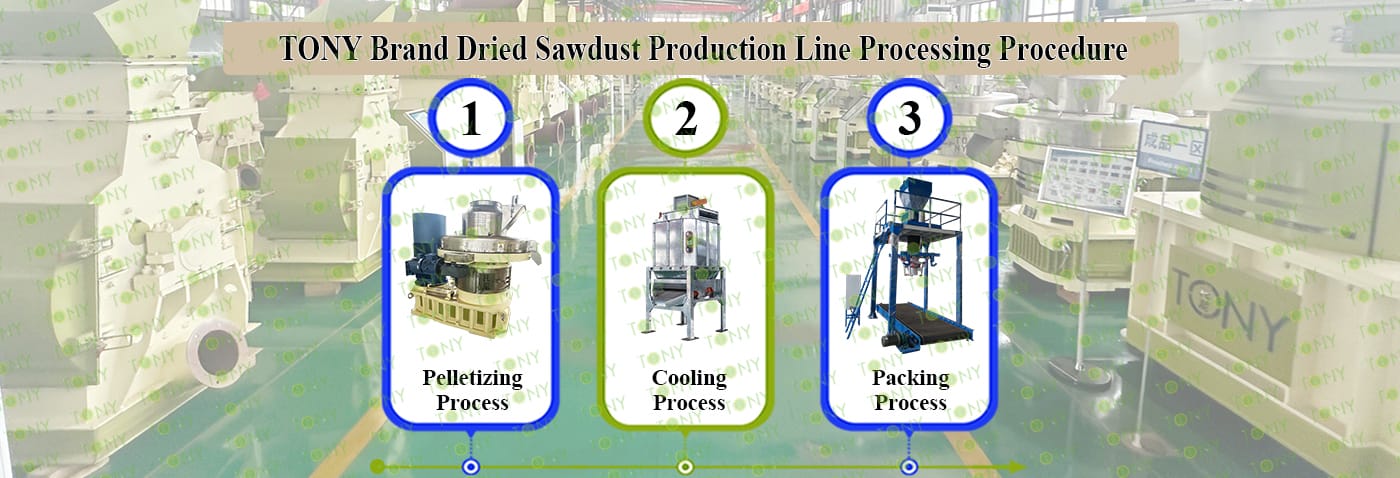

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ760-Ⅲ-200KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

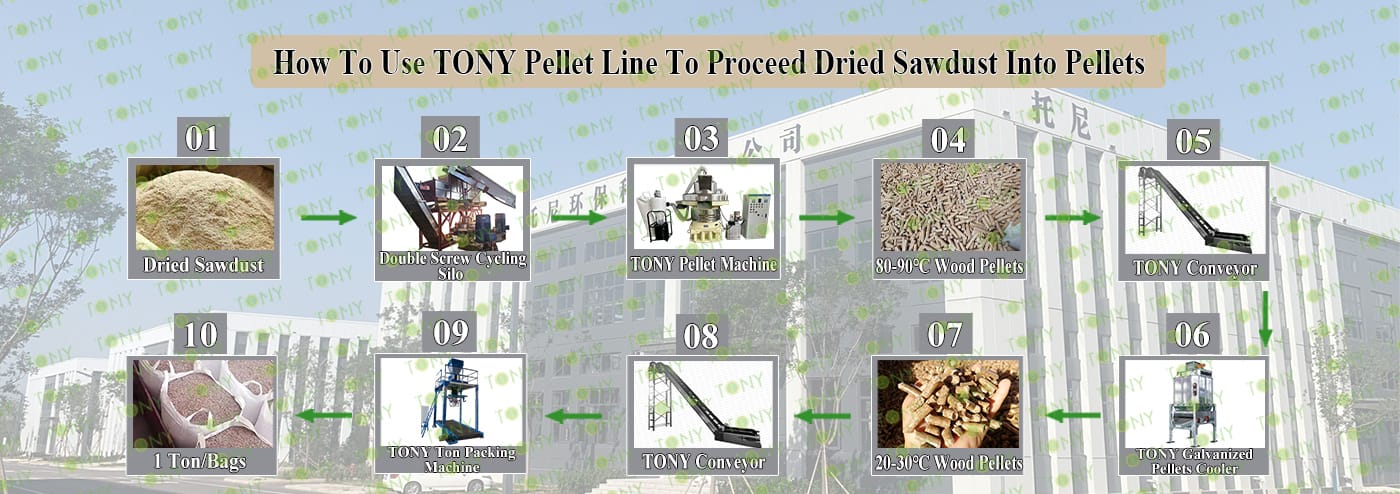

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-15*1set 3.Capacity:15Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*5sets 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:15Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags. 2.Model: TBD* 1set 3.Capacity:15Ton/Hour |

三维图

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:15Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-Ⅲ-200KW*5sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:15Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:15Ton/Hour.

C.TONY band ton packing machine*1set

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

The process is mature and easy to use, and the equipment is highly stable. Compared to other new energy projects (such as biomass gasification and waste incineration), sawdust biomass pellets have a low technical barrier to entry, mature technology, and are investor-friendly:

Technical Advantages of Sawdust Biomass Pellets

1.Simple Core Process:

The entire production process consists of just 3 steps: sawdust extrusion pelletizing (high-pressure forming), cooling, and packaging. It requires no complex chemical reactions and can be operated by ordinary workers after 1-2 weeks of training.

2.High Equipment Reliability:

Domestic pelletizing technology is highly mature, such as ring die pelletizers. Mainstream equipment offers a single unit production capacity of 1-5 tons/hour and a low failure rate (typically less than 5% annually). Maintenance costs are only 2%-3% of the total equipment price per year, eliminating the need for long-term reliance on a technical team.

3.Energy consumption and environmental protection standards are met:

During the production process, only the granulation stages consume electricity, and there is no wastewater or exhaust gas emission, making it easy to pass environmental protection acceptance.

1.Environmental and Sustainable Development Advantages of Sawdust Biomass Pellets

As a green energy source, sawdust biomass pellets excel in environmental protection and sustainability. Their primary component is C-H organic matter. When burned, SO₂ and CO emissions are near zero, and solid emissions are limited to ash, accounting for 0.4%-7.0% of the total weight, far lower than the 25%-40% solid emissions from traditional coal combustion. This significantly reduces air pollution. Furthermore, sawdust and other forestry waste are used as raw materials, making them renewable resources. The ash from combustion can be returned to the fields as potash fertilizer, creating a resource recycling system, effectively solving waste disposal issues, and providing clean energy.

2.Economic and Combustion Performance Advantages of Sawdust Biomass Pellets

Significant economic benefits: Their calorific value is comparable to that of coal, and they burn easily, reducing fuel waste. Their stable price helps lower production costs. Their high purity and ease of feeding reduce labor costs.

Excellent combustion performance: Good ignition, shortened fire start-up time, and sustained combustion time 8-10 times longer than soft bulk materials; high calorific value density, reaching 3500-5500 kcal, high thermal efficiency, and stable flame performance.

3.Practical Application Advantages of Sawdust Biomass Pellets

Easy Storage and Transportation: After compression molding, the volume is only 1/30 of the original sawdust, with a high specific gravity, small footprint, and resistance to moisture and deterioration, making it easy to mass-produce and transport over long distances.

Wide Applications: Suitable for residential heating stoves, industrial boilers, biomass power plants, and more, it can replace coal, oil, electricity, and natural gas. It contains no sulfur or phosphorus, is non-corrosive, and can extend boiler life.

2025 Tony Machinery - All Rights Reserved. Map