Project Brief Introduction:

1.Product:Dried Sawdust Pellet Line

2.Capacity: 15-18T/Hour

3.TONY Brand 15-18Ton /Hour Dried Sawdust Pellet Line Project Process

4.Main Machine:TONY Pellet MachineTYJ760-III-160KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1060KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D

1.The working principle of dried sawdust biomass pellet processing equipment

(1)Core Forming: Fiber reorganization and densification under mechanical extrusion is a key step in converting sawdust into pellets. The core principle is "high-pressure extrusion + wood fiber self-bonding." Lignin in the sawdust (a natural adhesive that softens under pressure and frictional heat) works together with moisture to tightly bind the fibers, forming pellets with a fixed shape.

(2)Core component: The forming machine—the "ring die pellet machine"—is more adaptable to wet materials and less prone to clogging.

During the extrusion process, intense friction between the sawdust and the inner wall of the die and the surface of the rollers generates frictional heat of 60-90°C. This temperature softens the lignin in the sawdust (the softening point of lignin is approximately 70-100°C). Simultaneously, the moisture forms "liquid bridges" that bind the dispersed fibers together, providing a foundation for subsequent shaping.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)Outstanding Processing Efficiency: Equipped with a high-pressure compression system, it can compress loose sawdust into pellets with a density of 1.1-1.3 t/m³, achieving a high pelletizing rate. A temperature control system prevents pellet cracking by regulating the processing temperature, improving the finished product quality and reducing energy consumption, thus meeting the requirements for efficient production.

(2)Stable Structure and Operation: The modular design allows for flexible configuration of different components to suit various production capacities (from several hundred kg to several tons per hour). Wear-resistant alloy materials are used for critical components (such as rollers and molds) to extend their lifespan. Some models feature a PLC control system for automated operation, minimizing manual intervention. A robust sealing design reduces the probability of malfunctions, and the equipment is easy to start and stop, suitable for both intermittent and continuous production.

(3)Environmental Protection and Safety: Most machines are equipped with dust collection systems (such as pulse jet dust collectors) to reduce dust pollution during processing. Some models also feature noise reduction design, complying with environmental standards. Overload protection and emergency stop buttons ensure safe operation by automatically shutting down the machine in case of malfunctions.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Biomass Energy Sector: Producing Clean Fuel

This is one of the core applications of the equipment. It can compress dry sawdust into biomass pellets, serving as a clean alternative to traditional fossil fuels like coal and natural gas. These pellets are compatible with various combustion equipment:

Industrial Boilers/Kilns: Used for heating processes in industries such as building materials, chemicals, and food processing, for applications like tile firing, feed drying, and factory heating, thus complying with environmental policies requiring reduced coal and carbon emissions.

Residential Heating/Cooking: The processed pellets can be used in home boilers and biomass stoves, widely used in rural areas in northern China for "coal-to-clean energy" projects. They burn cleanly with minimal smoke and low ash content.

Power Generation: Some large biomass power plants purchase pellets produced by this equipment as raw material for their biomass power generation systems, achieving energy recycling.

(2)Wood Processing and Furniture Industry: Recycling Waste Materials

In wood processing plants, furniture factories, and particleboard plants, the production process generates large amounts of dry sawdust (from cutting solid wood panels or sanding furniture). The equipment can be integrated directly into the production line to transform this "internal waste" into a usable resource:

Producing Particleboard Core Material: By mixing sawdust with adhesive and then pre-pressing and shaping it, the equipment produces core material for particleboard and fiberboard, reducing the dependence on raw timber and saving costs.

Producing Wood-Plastic Composite Materials: Mixing processed sawdust pellets with plastic granules, and then using further processing, produces wood-plastic flooring, outdoor walkways, trash bins, etc., suitable for municipal projects and home decoration. These products combine the natural look of wood with the durability of plastic.

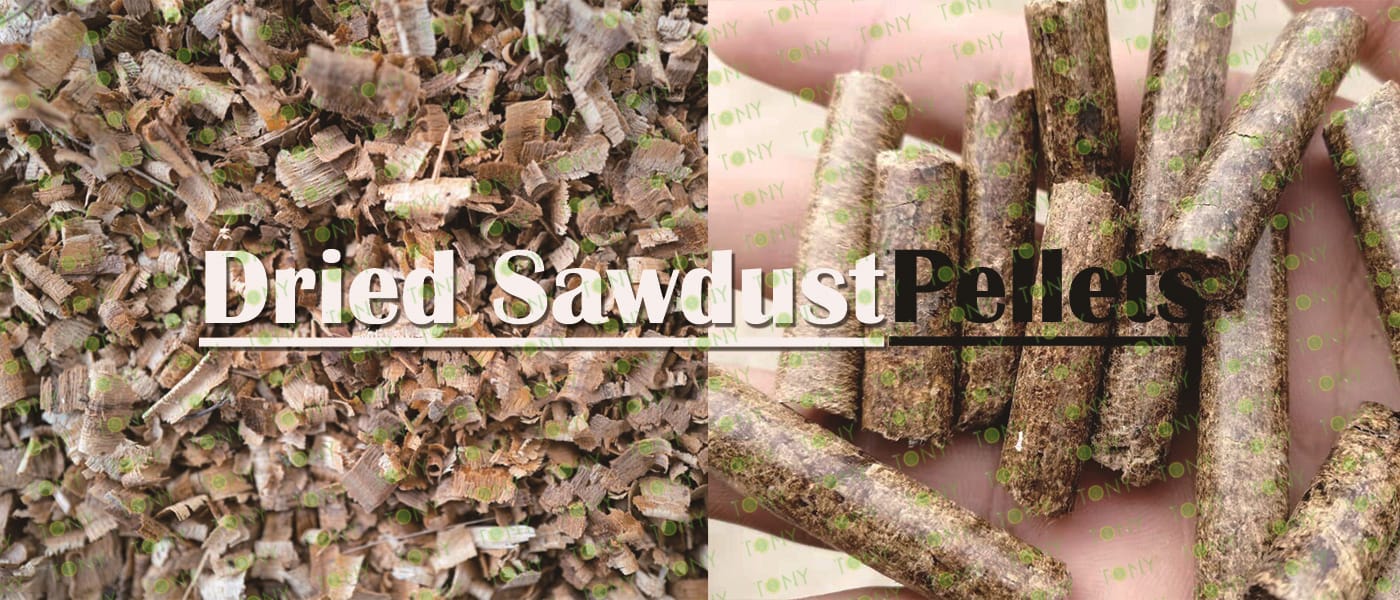

TONY Brand 15-18Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 15-18Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 15-18 tons per hour

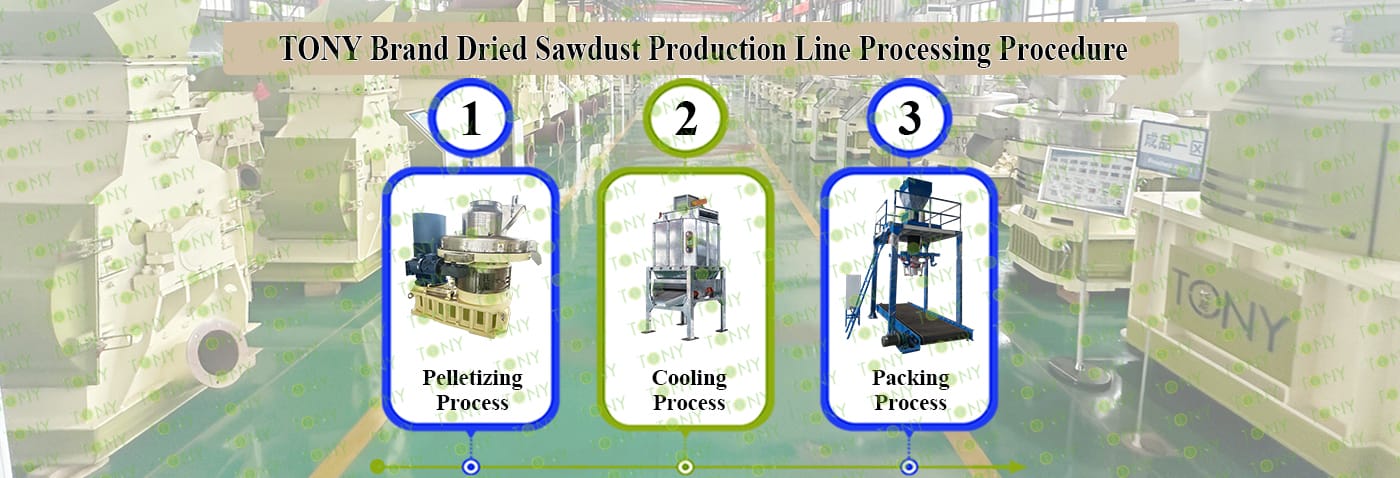

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ760-Ⅲ-160KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

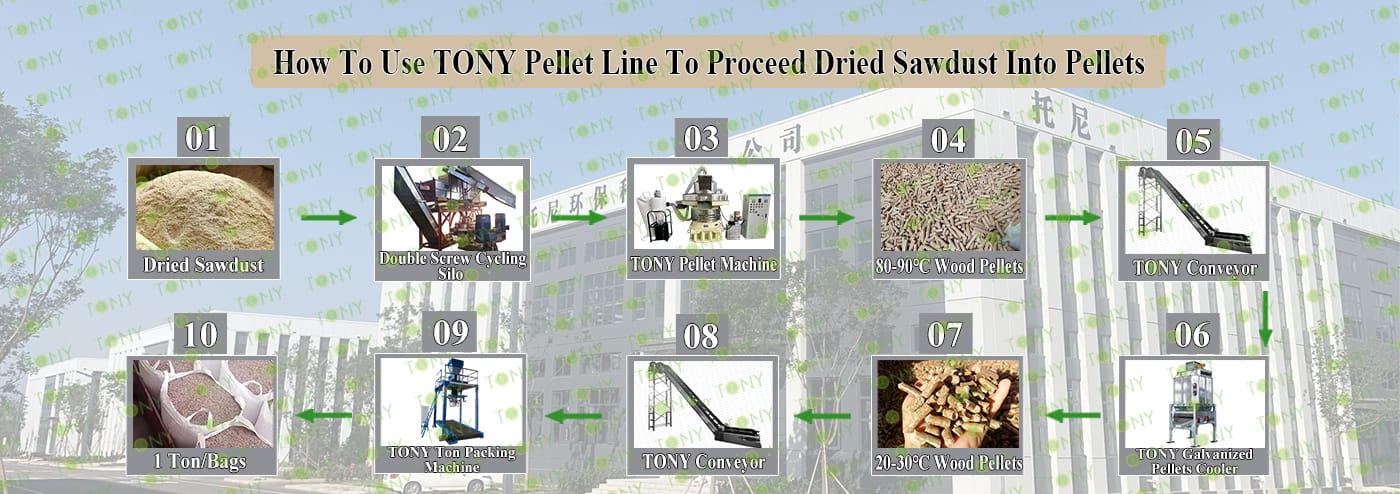

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-9*2sets 3.Capacity:8-9Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-160KW*6sets 3.Capacity:2.5-3Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*2sets 3.Capacity:15-18Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD* 2sets 3.Capacity:15-18Ton/Hour |

三维图

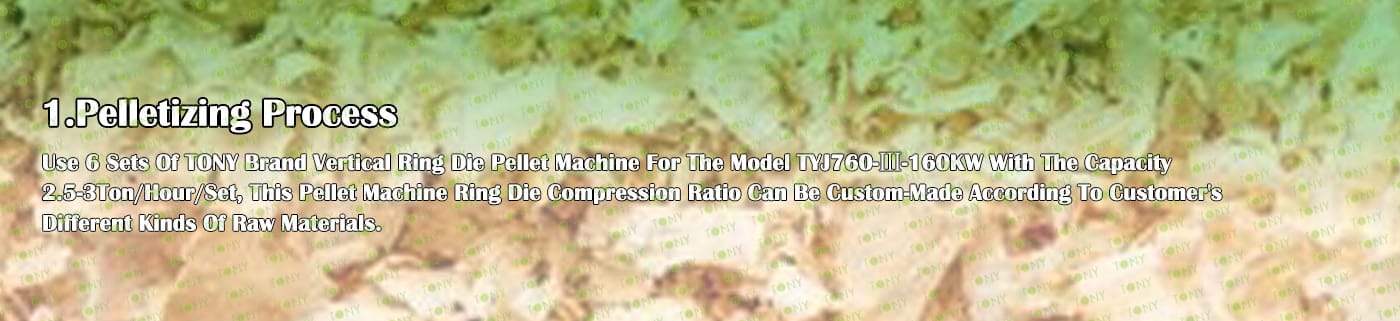

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:15-18Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-Ⅲ-160KW*6sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:15-18Ton/Hour.

C.TONY brand galvanized pellets cooler *2sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:15-18Ton/Hour.

C.TONY band ton packing machine*2sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Policy Support: Under the national "dual carbon" target, many regions have implemented policies to restrict coal use (e.g., "coal-to-electricity/coal-to-biomass" projects in northern China), and biomass pellet fuel benefits from tax rebates and environmental subsidies;

Market Demand: Policy-Driven and Strong End-User Needs

1.Industrial Sector:

Boiler heating in building materials plants, food processing plants, and feed mills, with high demand for pellet fuel (up to several thousand tons per plant annually);

2.Residential Sector:

Heating in rural areas of northern China and cooking in suburban households, with a stable retail market;

3.Energy Sector:

Raw material procurement for biomass power plants, with large and stable long-term orders.

1.Environmental Advantages:

Low Pollution, Carbon Neutrality, and Policy Compliance

2.Extremely Low Emissions:

No black smoke during combustion; sulfur dioxide emissions are only 0.005-0.01 g/m³ (far lower than 0.1-0.3 g/m³ for coal), nitrogen oxide emissions are <50 mg/m³, and particulate matter emissions are <10 mg/m³. These all meet the "Special Emission Limits" in the National Standard for Boiler Air Pollutant Emission (GB 13271-2014), eliminating the need for complex flue gas treatment equipment.

3.Zero Carbon Emissions through Carbon Cycle:

Sawdust originates from wood that absorbed CO2 during tree growth. The CO2 released during combustion is reabsorbed by newly planted trees, creating a carbon cycle. Compared to coal (fossil carbon, which releases new carbon emissions upon combustion), this essentially achieves carbon neutrality, aligning with the national "dual carbon" target and making it a clean fuel promoted by government policy.

4.Recyclable Solid Waste:

The ash produced (less than 5% of the total) is rich in potassium, calcium, and other elements, and can be used directly as fertilizer or soil conditioner, avoiding secondary solid waste pollution. Coal ash, on the other hand, requires special treatment and can cause heavy metal pollution of the soil.

2025 Tony Machinery - All Rights Reserved. Map