Project Brief Introduction:

1.Product:Dried Sawdust Pellet Line

2.Capacity: 1-1.5T/Hour

3.TONY Brand 1-1.5Ton /Hour Dried Sawdust Pellet Line Project Process

4.Main Machine:TONY Pellet Machine TYJ551-Ⅲ-90KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 120KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of dried sawdust biomass pellet processing equipment

(1)Core Forming: Fiber reorganization and densification under mechanical extrusion is a key step in converting sawdust into pellets. The core principle is "high-pressure extrusion + wood fiber self-bonding." Lignin in the sawdust (a natural adhesive that softens under pressure and frictional heat) works together with moisture to tightly bind the fibers, forming pellets with a fixed shape.

(2)Core component: The forming machine—the "ring die pellet machine"—is more adaptable to wet materials and less prone to clogging.

During the extrusion process, intense friction between the sawdust and the inner wall of the die and the surface of the rollers generates frictional heat of 60-90°C. This temperature softens the lignin in the sawdust (the softening point of lignin is approximately 70-100°C). Simultaneously, the moisture forms "liquid bridges" that bind the dispersed fibers together, providing a foundation for subsequent shaping.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)Precise machining accuracy: The main housing is made of high-quality steel, with uniform thickness and compact structure; it is carefully machined by imported CNC machining centers, with zero machining accuracy, providing stronger support for normal operation.

(2)Reliable lubrication system: The bearings and oil seals used in the transmission part are all made of high-precision bearings and wear-resistant and temperature-resistant fluororubber oil seals, and a special automatic lubrication system is added, with oil circulation cooling and automatic timed lubrication to ensure that the bearings are fully lubricated and the operation is safer and more reliable.

(3)Durable ring die: The ring die is made of precision and has a unique compression ratio design, which makes the product quality better and the service life of the ring die longer, minimizing the production cost.

(4) ontinuous operation capability: The new generation of biomass pellet mill can achieve 24-hour continuous operation

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Biomass power generation/heating enterprises

Typical scenarios: Biomass power plants and industrial boilers (such as heating boilers in textile factories and food factories) require a large amount of stable pellet fuel

(2)Small and medium-sized heating/drying users

Typical scenarios: Rural heating stations, agricultural product drying plants (such as grain, fruit and vegetable drying), greenhouse heating; processed pellets are directly stored in the silo of the heating station and can be taken out as needed.

(3)"Self-circulating" processing in orchards/tea gardens

Typical scenarios: After being processed into pellets, they can be used as fuel for the orchard's "biomass hot air furnace" (for fruit tree frost protection and fruit drying), or crushed and buried in the soil to improve soil quality, realizing "self-circulating waste in the park";

(4) Environmental protection and solid waste treatment fields

Typical scenarios: Urban solid waste treatment plants (sorted wet wood waste), garden waste treatment stations (wet branches, wet shrub slices)

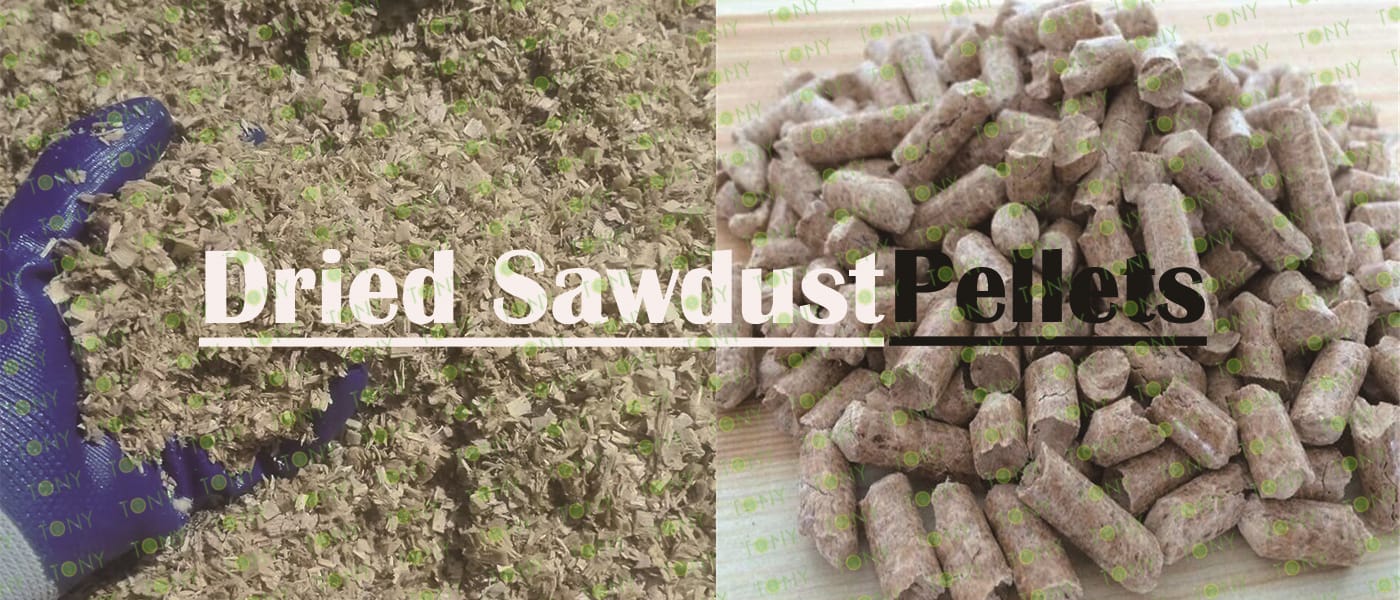

TONY Brand 1-1.5Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 1-1.5Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

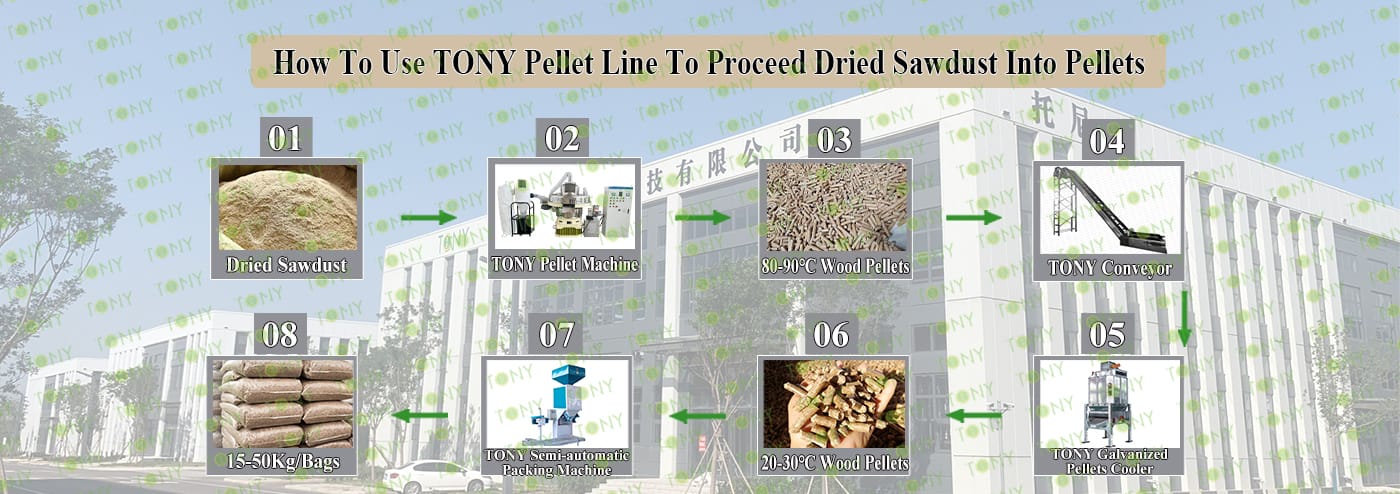

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 1-1.5 tons per hour

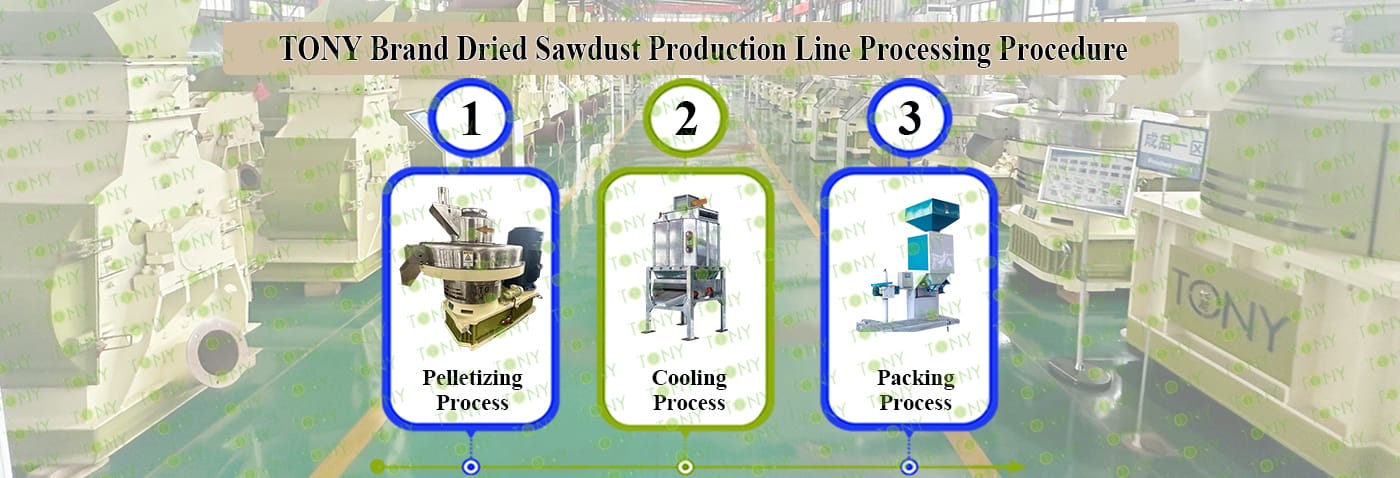

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ551-Ⅲ-90KW, Galvanized Pellets Cooler, Semi-automatic Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine | Belt Conveyor |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-III-90KW*1set 3.Capacity:1-1.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-1.5*1set 3.Capacity:1-1.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity:1-1.5Ton/Hour |

1.To Transport Sawdust,Pellets. 2.Width: 50cm*3sets 3.Capacity:Designed With The Whole Line |

三维图

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:1-1.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-III-90KW*1set

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:1-1.5Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:1-1.5Ton/Hour.

C.TONY semi-automatic packing machine*1set

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

1.Overview of the Sawdust Processing Biomass Pellets Project

Sawdust is a common waste from agricultural and forestry processing. It is abundant in source and low in cost. Processing it into biomass pellet fuel has significant economic and environmental value. This project processes sawdust through carbonization, fermentation, modification and other processes, combines it with other auxiliary raw materials, and extrudes it into high-density pellet fuel, which can effectively replace fossil fuels, reduce sulfur emissions and improve combustion efficiency.

2.Product advantages and technical indicators

(1)Core advantages

Environmental protection: The sulfur content is as low as 0.364% (better than the ultra-low sulfur coal standard of 0.5%), and no harmful gas is emitted after combustion.

High efficiency: The calorific value reaches 25.47MJ/kg (high calorific value coal range is 24.01-27.00MJ/kg), and the ash content is 7.59% (low ash coal category).

Economical efficiency: The raw material cost is low (sawdust, agricultural and forestry waste), and the process is simple and easy to operate12.

(2)Key Technical Indicators

Density: 0.943g/cm³, higher than ordinary biomass pellets

Sulfur content: 0.364%, better than ultra-low sulfur coal (≤0.5%)

Combustion calorific value: 25.47MJ/kg, reaching the level of high calorific value coal

Ash content: 7.59%, meeting the standard of low ash coal

3.Application Prospects

As a renewable energy source, biomass energy can be widely used in industrial boilers, home heating, power generation and other fields, replacing fossil fuels such as coal and gas, and the market demand is growing steadily.

The environmental advantages of sawdust biomass pellets are their core competitive advantage, primarily reflected in their "low carbon footprint throughout their lifecycle" and "low pollution during combustion":

1.Low carbon and renewable, aligning with the "double carbon" goal:

Sawdust, derived from wood processing waste, is a "biomass resource." The CO₂ absorbed during its growth is essentially balanced by the CO₂ released during combustion, achieving "carbon neutrality." Compared to coal (a fossil energy source whose combustion releases ancient carbon), it can reduce net carbon emissions by over 90%, making it an ideal alternative fuel for achieving both peak and neutral carbon emissions.

2.Low combustion pollutants, reducing the environmental burden:

Combustion is almost sulfur-free (sulfur content ≤ 0.05%) and nitrogen-free (nitrogen content ≤ 0.5%), and does not produce large amounts of SO₂ and NOₓ (the main pollutants from traditional coal combustion), which can significantly reduce the risk of acid rain and haze. The ash content is extremely low (only 2%-5%, far lower than the 10%-20% of coal). The small amount of ash remaining after combustion can be used as organic fertilizer or auxiliary building materials, eliminating the problem of "secondary pollution of solid waste."

3.Non-spontaneous combustion and safe storage:

Pellets have a low moisture content but a dense structure, resulting in a small contact area with air. They won't spontaneously combust at room temperature (they require a high-temperature open flame to ignite). In contrast, pulverized coal and loose sawdust, due to their large surface area, are susceptible to spontaneous combustion due to oxidation and heat generation. Pellets also contain no volatile flammable gases, preventing explosions from leaks like liquefied petroleum gas.

4.No toxic gases are produced during combustion, ensuring safe use:

Pellets do not produce toxic gases such as carbon monoxide (CO) and formaldehyde (assuming complete combustion and suitable combustion equipment). Incomplete combustion of coal can easily produce CO, while firewood can easily produce smoke and tar. Pellets are more health-friendly and are particularly suitable for applications involving direct human or product contact, such as residential heating and food processing (such as drying tea leaves and medicinal herbs).

2025 Tony Machinery - All Rights Reserved. Map