Project Brief Introduction:

1.Product:Dried Sawdust Pellet Line

2.Capacity: 5-6T/Hour

3.TONY Brand 5-6Ton/Hour Dried Sawdust Pellet Line Project Process

4.Main Machine:TONY Pellet Machine TYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 360KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of dried sawdust biomass pellet processing equipment

Extrusion shaping is the core process of the equipment. Currently, the mainstream sawdust pelletizer on the market is the ring die pelletizer, which is highly efficient and suitable for industrial mass production. Its core structure consists of a rotating ring die (a cylindrical mold with evenly spaced forming holes on the inner wall) and two to three pressure rollers fixed inside the ring die. The ring die is driven by a motor at high speed (typically 50-100 rpm), and the pressure rollers can oscillate flexibly (pressure is adjusted by springs or hydraulic devices).

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)Raw material adaptability: It can process a variety of agricultural and forestry wastes such as sawdust, rice husks, and crop straw, realizing "turning waste into treasure."

(2)Environmentally friendly properties: Through high-temperature and high-pressure physical compression molding, no chemical adhesives are added, and the production process is green and pollution-free; the finished pellet fuel is renewable and has low carbon emissions, and replacing fossil fuels can reduce greenhouse gas emissions.

(3)Key parameters can be adjusted: By adjusting the mold aperture, roller pressure, and speed, the particle size (usually 6-12mm in diameter), density, and calorific value can be controlled to ensure that the product meets the requirements of different combustion scenarios (such as boilers, fireplaces, biomass power generation, etc.).

(4)Automation integration: Achieve full process automation from raw materials to finished products, reduce manual intervention, and improve production efficiency.

(5)Maintenance convenience: The vertical equipment has a compact structure and low maintenance cost. The core components (such as molds and rollers) are highly wear-resistant and have a long service life, and long-term operating costs are controllable.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Biomass energy field

As a clean fuel: The processed sawdust pellets have high calorific value and high combustion efficiency, and their sulfur, ash and nitrogen content are much lower than fossil fuels such as coal and oil. They can be directly used for fireplaces and boiler heating, or as fuel for biomass power plants, achieving energy substitution and emission reduction goals.

Energy conversion advantages: Compared with traditional fuels, sawdust pellets are smokeless and odorless when burned, with low pollutant emissions, which meets the needs of modern green energy, especially in Europe and America where the demand for biomass energy is relatively high.

(2)Animal feed field

Feed pellet production: Sawdust pellets processed by sawdust pellet machines can be used as high-quality feed for poultry and livestock breeding, improving feed utilization and animal production efficiency. Some equipment is specially designed for feed pellets to meet the process requirements of feed processing.

(3)Environmental protection and resource recycling field

Wood waste processing: The equipment uses wood chips, sawdust, branches and other wood processing waste as raw materials, converting waste that would have been discarded into high-value pellet products, achieving resource recycling and reducing environmental pollution.

TONY Brand 5-6Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 5-6Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 5-6 tons per hour

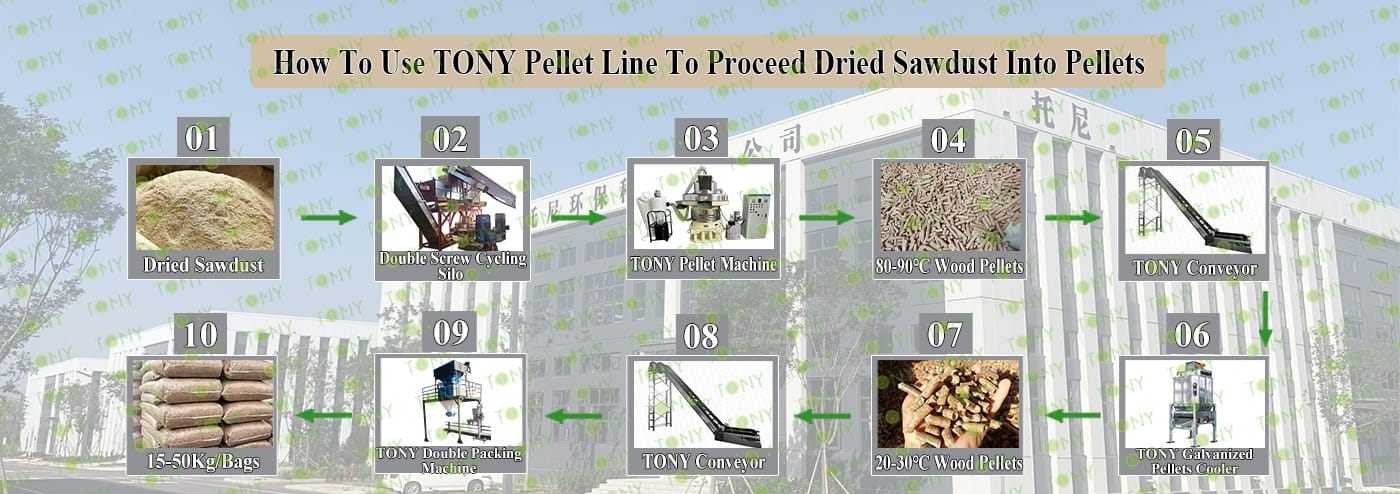

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ760-Ⅲ-160KW, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-6*1set 3.Capacity:5-6 Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-160KW*2sets 3.Capacity:2.5-3Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:5-6Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity:5-6Ton/Hour |

三维图

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:5-6Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-160KW*2sets

D.Double screw cyclingsilo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:5-6Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:5-6Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Market Advantages of Sawdust Processing Biomass Pellets

Demand continues to grow, and the application scenarios are diverse. As a "clean alternative fuel," biomass pellets can directly replace traditional energy sources such as coal, natural gas, and heavy oil. Market demand spans three core sectors: industry, civil use, and power generation, and the market has enormous growth potential:

1.Industrial Sector (Core Demand):

Small and medium-sized boilers (under 10 tons) in industries such as food processing, textiles, and chemicals are the preferred choice for "coal-to-biomass" because the cost of switching from coal to biomass is lower than switching from coal to gas (the unit price of biomass pellets is only 1/2-2/3 that of natural gas). Industrial boiler conversions alone generate over 5 million tons of annual demand.

2.Civilian Sector (Incremental Demand):

Biomass pellets are used for clean heating in rural areas and fireplace heating in homes. Biomass pellets are smokeless and odorless, have a low ash content (only 2%-5%, far lower than the 10%-20% of coal), and are easy to store (bagged pellets can be stored for long periods). The civil market is experiencing an annual growth rate exceeding 15%.

3.Power generation (stable demand):

Biomass power plants use pellets as fuel and sign long-term supply agreements (usually 1-3 years) with power plants to ensure "stable orders" for the project and avoid the risk of market price fluctuations.

1.Environmental and Sustainable Development Advantages of Sawdust Biomass Pellets

As a green energy source, sawdust biomass pellets excel in environmental protection and sustainability. Their primary component is C-H organic matter. When burned, SO₂ and CO emissions are near zero, and solid emissions are limited to ash, accounting for 0.4%-7.0% of the total weight, far lower than the 25%-40% solid emissions from traditional coal combustion. This significantly reduces air pollution. Furthermore, sawdust and other forestry waste are used as raw materials, making them renewable resources. The ash from combustion can be returned to the fields as potash fertilizer, creating a resource recycling system, effectively solving waste disposal issues, and providing clean energy.

2.Economic and Combustion Performance Advantages of Sawdust Biomass Pellets

Significant economic benefits: Their calorific value is comparable to that of coal, and they burn easily, reducing fuel waste. Their stable price helps lower production costs. Their high purity and ease of feeding reduce labor costs.

Excellent combustion performance: Good ignition, shortened fire start-up time, and sustained combustion time 8-10 times longer than soft bulk materials; high calorific value density, reaching 3500-5500 kcal, high thermal efficiency, and stable flame performance.

3.Practical Application Advantages of Sawdust Biomass Pellets

Easy Storage and Transportation: After compression molding, the volume is only 1/30 of the original sawdust, with a high specific gravity, small footprint, and resistance to moisture and deterioration, making it easy to mass-produce and transport over long distances.

Wide Applications: Suitable for residential heating stoves, industrial boilers, biomass power plants, and more, it can replace coal, oil, electricity, and natural gas. It contains no sulfur or phosphorus, is non-corrosive, and can extend boiler life.

2025 Tony Machinery - All Rights Reserved. Map