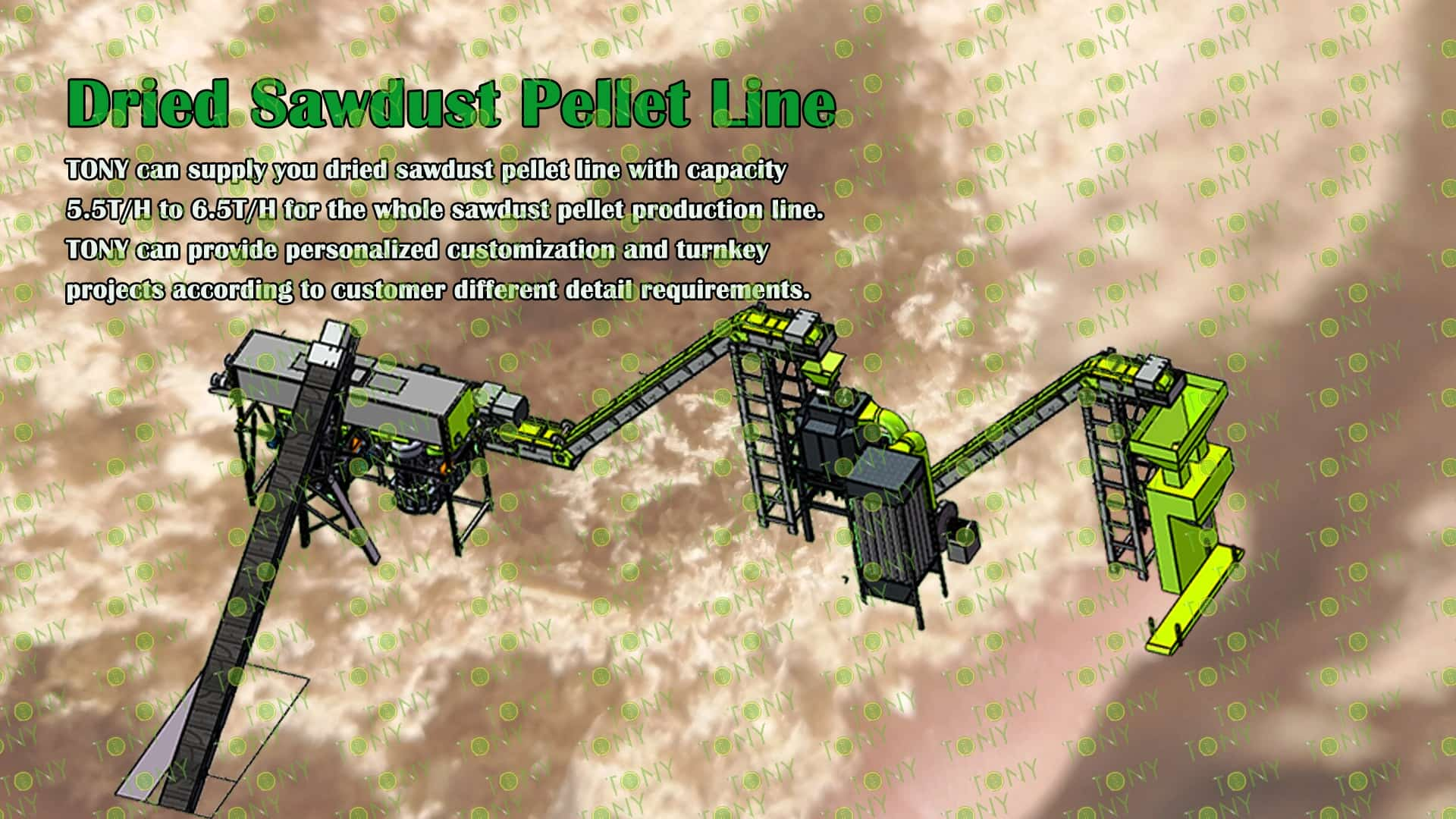

Project Brief Introduction:

1.Product:Dried Sawdust Pellet Line

2.Capacity: 5.5-6.5T/Hour

3.TONY Brand 5.5-6.5Ton /Hour Dried Sawdust Pellet Line Project Process

4.Main Machine:TONY Pellet Machine TYJ760-Ⅲ-185KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 410KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of dried sawdust biomass pellet processing equipment

(1)Sawdust is fed to the "distributor" through a feeder, which evenly distributes the material to the gap between the ring die and the pressure wheel.

(2)The high-speed rotating ring die generates centrifugal force, pushing the sawdust toward the pressure wheel. The pressure wheel rotates synchronously with the ring die under the reaction force of the material, and at the same time "presses" the sawdust into the forming hole of the ring die. The sawdust is subjected to high-intensity compression in the forming hole (pressure can reach 100-200MPa), and frictional heat causes the lignin to fully soften. After tightly bonding, it is "extruded" from the hole on the outer wall of the ring die to form long strips of material.

(3)The "fixed cutter" on the outside of the ring die cuts the long strips of material (the cutting length can be controlled by adjusting the cutter position) to form standard pellets, which then enter the cooling system (pellet cooler) to cool to room temperature (to prevent the pellets from getting damp due to residual heat when they accumulate).

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)Raw material adaptability: Precisely match the characteristics of dry sawdust. The equipment's feeding system and extrusion system are optimized for "10%-15% moisture content dry sawdust", and the core components have a long service life.

(2)Core molding characteristics: Relying on physical action to achieve efficient bonding. Dry sawdust does not have excess moisture to assist in bonding. The equipment needs to enhance the "physical extrusion + lignin melting" effect through structural design to ensure stable pellet molding.

(3)Operation and operation characteristics: Stable, convenient, and low maintenance. The equipment design focuses on "reducing manual intervention and reducing downtime" and is suitable for long-term continuous operation. For example, the "variable frequency screw feeder" is used to automatically adjust the feeding speed according to the raw material inventory in the extrusion chamber. The core components (ring die, pressure roller) adopt a "quick-release design" and can be replaced without disassembling the entire machine. The medium and large equipment integrates a "PLC control system" to monitor parameters such as feeding volume, extrusion temperature, and pellet output speed in real time.

(4)Finished product guarantee characteristics: Ensure that the pellets meet the use requirements. The equipment solves the "high temperature and broken pellets" after the dry sawdust pellets are formed through the subsequent processing module. Problems are solved to ensure the quality of the finished product. The standard "counter-current cooler" quickly cools the pellets to room temperature (±5°C) and removes trace amounts of residual heat to prevent moisture and agglomeration during pellet storage. After cooling, it is equipped with a "double-layer vibrating screen" to ensure that the qualified rate of finished pellets can reach over 98%.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Heat supply: Industrial boiler/kiln fuel

Applicable scenarios: Building materials factories (cement and tile burning), paper mills (pulp drying), food processing plants (baking, sterilization heating), chemical plants (low-temperature reaction heating), and other enterprises that require a continuous and stable heat source.

(2)Power generation: Biomass power plant raw material processing

Applicable scenarios: Large-scale biomass direct-fired power plants, cogeneration projects (simultaneous power supply + heat supply)

(3)Agricultural drying: Dehydration of agricultural products

Applicable scenarios: Grain drying (rice, corn, wheat), cash crop drying (tea, tobacco, Chinese medicinal materials, dried fruits), livestock and poultry breeding bedding drying (sawdust particles can be used as bedding first, dried and then burned after use, achieving "one material for two purposes")

(4)Commercial home heating/hot water: Replacement of gas and electric heating

Heating or daily hot water supply in hotels, B&Bs, nursing homes, shopping malls, office buildings, etc.

TONY Brand 5.5-6.5Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 5.5-6.5Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 5.5-6.5 tons per hour

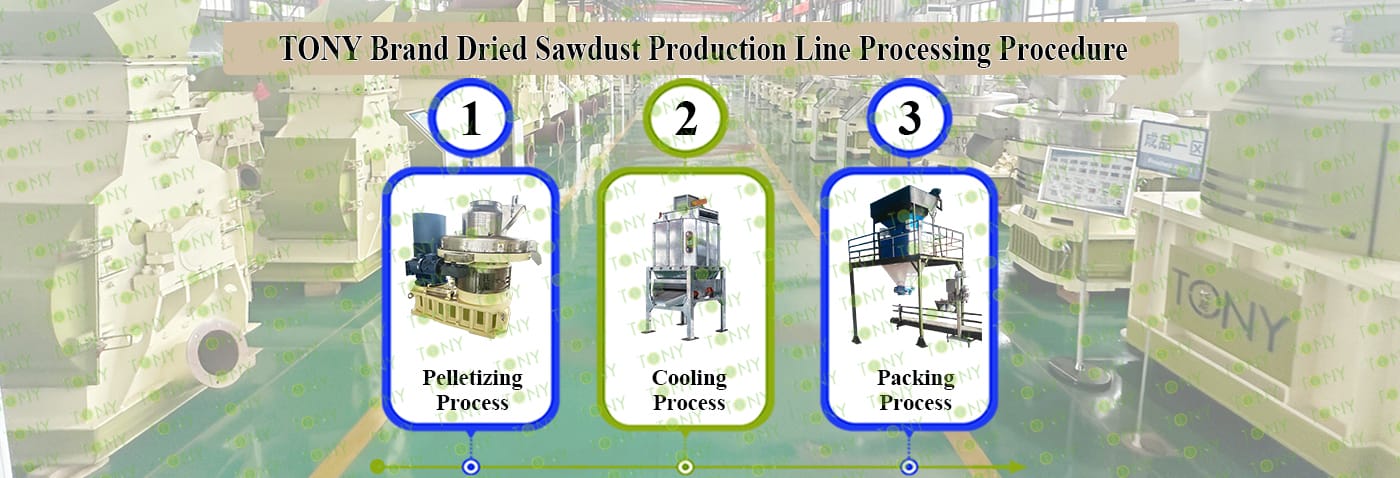

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ760-Ⅲ-185KW, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

|

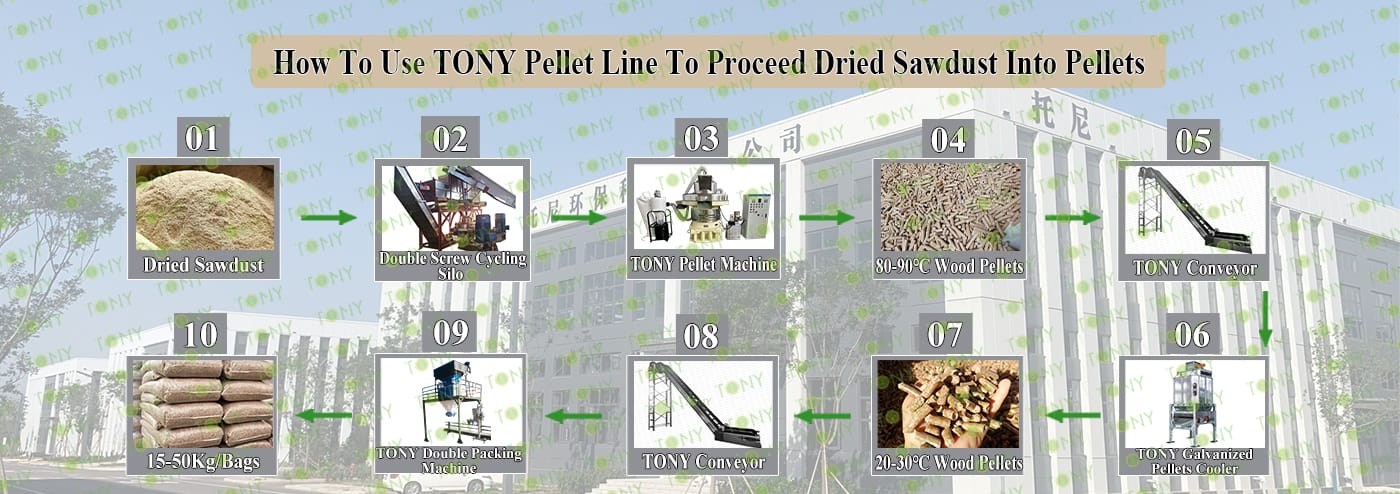

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-7*1set 3.Capacity:5.5-6.5 Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-185KW*2sets 3.Capacity:2.8-3.3Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:5.5-6.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity:5.5-6.5Ton/Hour |

三维图

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:5.5-6.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-185KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:5.5-6.5Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:5.5-6.5Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Technical Advantages of Sawdust Biomass Pellets

The process is mature and easy to use, and the equipment is highly stable. Compared to other new energy projects (such as biomass gasification and waste incineration), sawdust biomass pellets have a low technical barrier to entry, mature technology, and are investor-friendly:

1.Simple Core Process:

The entire production process consists of just 3 steps: sawdust extrusion pelletizing (high-pressure forming), cooling, and packaging. It requires no complex chemical reactions and can be operated by ordinary workers after 1-2 weeks of training.

2.High Equipment Reliability:

Domestic pelletizing technology is highly mature, such as ring die pelletizers. Mainstream equipment offers a single unit production capacity of 1-5 tons/hour and a low failure rate (typically less than 5% annually). Maintenance costs are only 2%-3% of the total equipment price per year, eliminating the need for long-term reliance on a technical team.

3.Energy consumption and environmental protection standards are met:

During the production process, only the granulation stages consume electricity, and there is no wastewater or exhaust gas emission, making it easy to pass environmental protection acceptance.

Sawdust itself is a waste product from wood processing (furniture, panel, and door factories, etc.). Processing it into pellets is essentially a "resource cycle," eliminating the issue of competing with grain crops for land or forest resources.

1.No additional raw material consumption and no productive resources are used:

No dedicated tree planting is required; existing industrial waste is directly utilized, eliminating the environmental pollution caused by sawdust incineration and landfills while also achieving "waste resource utilization."

2.Stable raw material supply, unrestricted by seasonality:

The wood processing industry operates year-round, resulting in a stable sawdust output (the furniture industry alone produces over 10 million tons annually). Sawdust can also be stored for long periods (dried sawdust has a low moisture content and is less susceptible to mold). This eliminates the risk of seasonal supply disruptions and ensures the continuity of pellet production.

3.High Cost-Effectiveness:

Amidst rising energy costs, sawdust pellets offer significantly better value for money than clean energy sources like natural gas and liquefied petroleum gas, and are even competitive with coal.

4.Long-Term Cost Stability and Strong Resistance to Fluctuations:

The raw material (sawdust) is an industrial waste product with minimal price fluctuations (annual fluctuations ≤10%). Coal and natural gas are significantly impacted by international energy markets and geopolitics. The cost stability of sawdust pellets makes them more suitable for long-term use by businesses and households.

2025 Tony Machinery - All Rights Reserved. Map