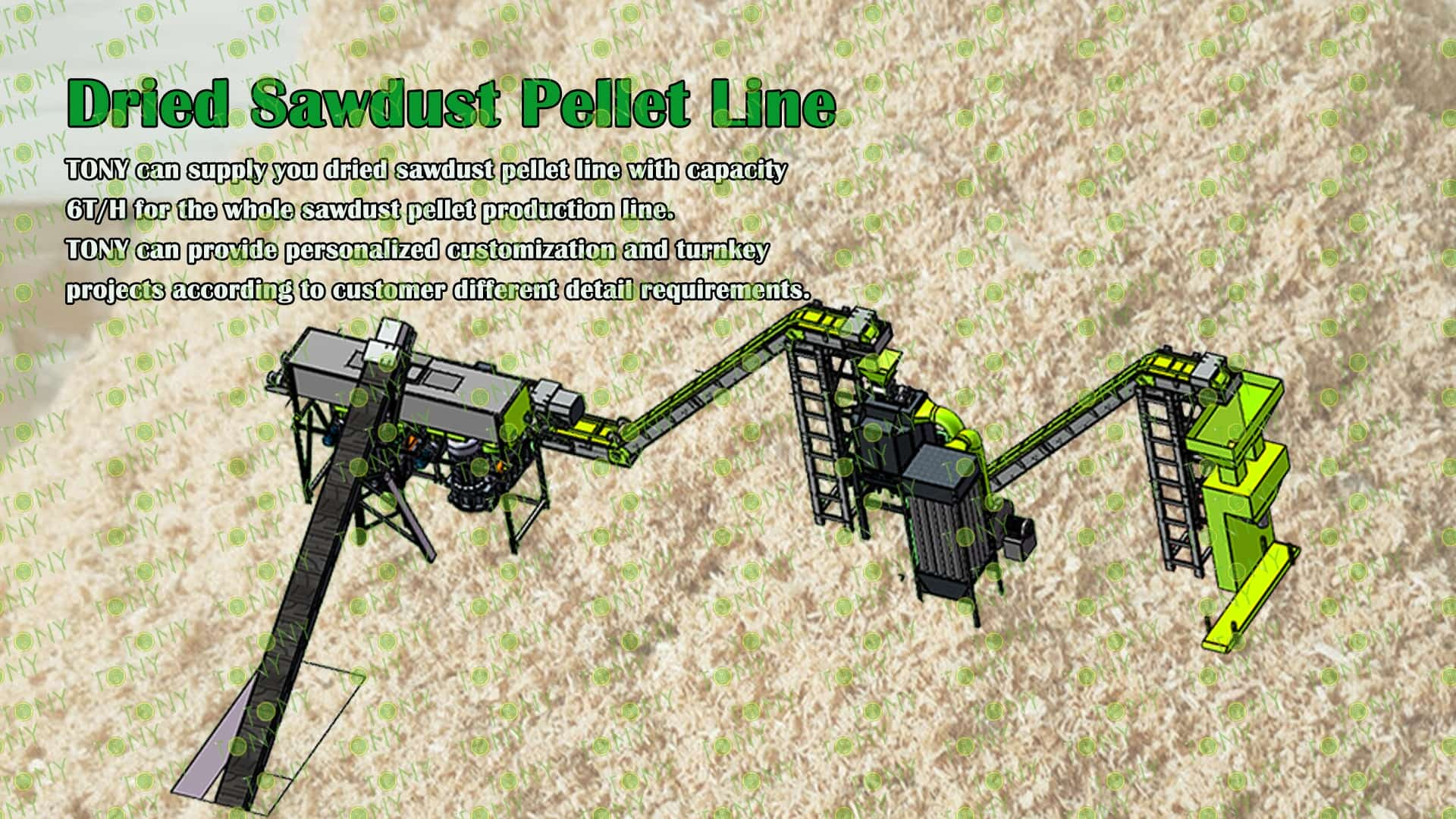

Project Brief Introduction:

1.Product:Dried Sawdust Pellet Line

2.Capacity: 6T/Hour

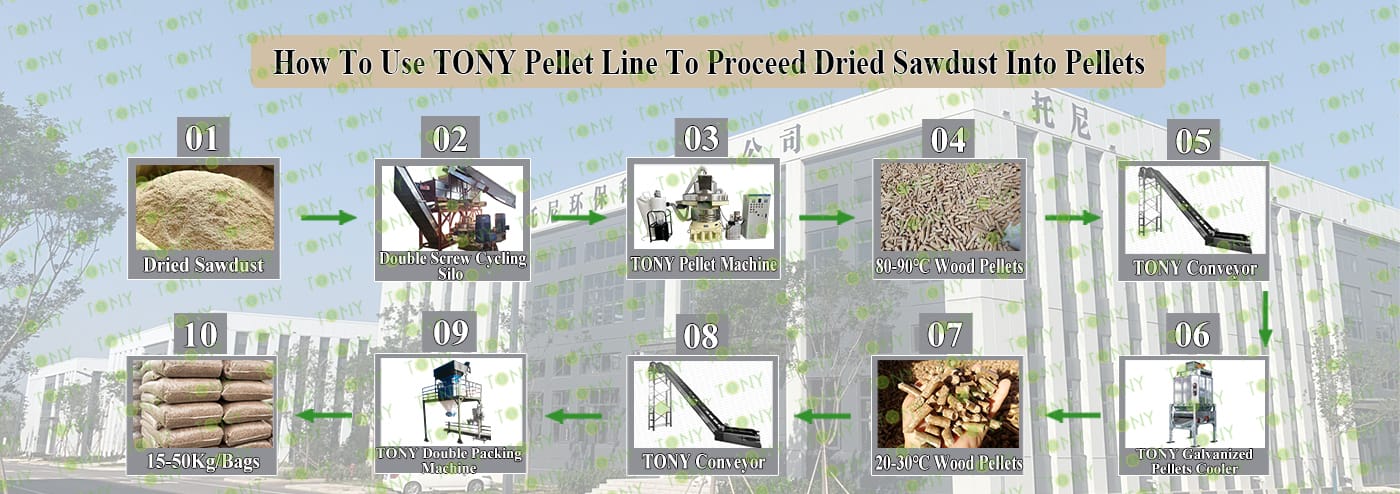

3.TONY Brand 6Ton /Hour Dried Sawdust Pellet Line Project Process

4.Main Machine:TONY Pellet Machine TYJ760-Ⅱ-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 440KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of dried sawdust biomass pellet processing equipment

(1)Core Forming: Fiber reorganization and densification under mechanical extrusion is a key step in converting sawdust into pellets. The core principle is "high-pressure extrusion + wood fiber self-bonding." Lignin in the sawdust (a natural adhesive that softens under pressure and frictional heat) works together with moisture to tightly bind the fibers, forming pellets with a fixed shape.

(2)Core component: The forming machine—the "ring die pellet machine"—is more adaptable to dried materials and less prone to clogging.

During the extrusion process, intense friction between the sawdust and the inner wall of the die and the surface of the rollers generates frictional heat of 60-90°C. This temperature softens the lignin in the sawdust (the softening point of lignin is approximately 70-100°C). Simultaneously, the moisture forms "liquid bridges" that bind the dispersed fibers together, providing a foundation for subsequent shaping.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)The dry sawdust pellet processing equipment is highly efficient and low-consumption, and can quickly process biomass raw materials into fuel pellets, significantly improving production efficiency.

(2)The biomass pellet machine has strong material adaptability and is suitable for molding various biomass raw materials. The pellet machine is equipped with molds of various specifications, and the corresponding molds can be selected for processing according to different biomass raw materials, which enhances the adaptability of processing.

(3)The dry sawdust pellet processing equipment has a mature design, and the finished pellets are stably molded, with stable output and excellent quality.

(4)The biomass pellet processing equipment is simple to operate, easy to use, highly automated, requires less labor, effectively reduces labor intensity, and increases output.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Biomass Energy: Dry sawdust pellets can be used as biomass fuel for power generation, heating, etc., replacing traditional fossil fuels and reducing environmental pollution.

(2)Environmentally Friendly Processing: Dry sawdust pellet processing equipment can effectively process wood waste and convert it into useful pellet fuel, reducing environmental pollution.

(3)Energy Saving: Since dry sawdust pellets are a renewable energy source, using them can save energy and reduce dependence on limited fossil fuels.

TONY Brand 6Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 6Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 6 tons per hour

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ760-Ⅲ-200KW, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

|

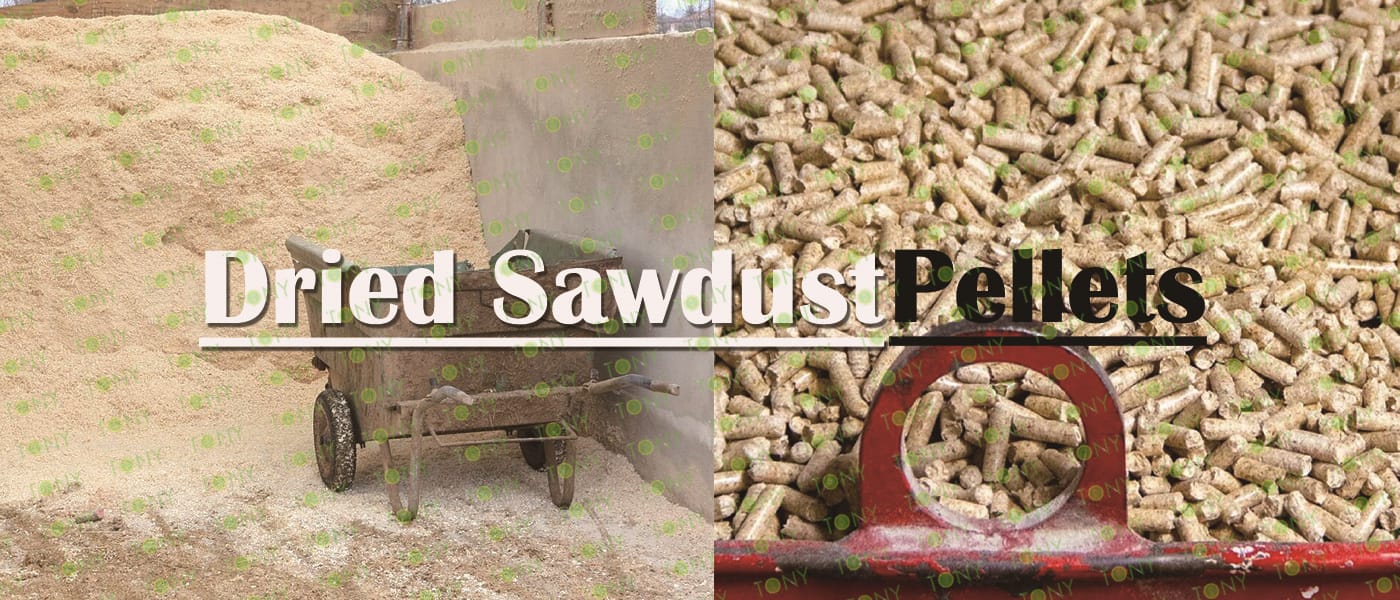

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY Double Packing Machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-6*1set 3.Capacity:6Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-160KW*2sets 3.Capacity:3Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:6Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6Ton/Hour |

三维图

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:6Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-200KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:6Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:6Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

For investors, it is better to give priority to regions with abundant raw materials and strong policy support. By locking in raw material supply, improving production capacity utilization and expanding high-end markets (such as exports and civilian use), the return cycle can be further shortened and rapid profits can be achieved.

Wood Pellet Processing Investment Costs

1.Equipment Investment:

Equipment investment varies significantly depending on the project scale and equipment selected. A small semi-automatic production line may cost only tens to hundreds of thousands of yuan, while a large fully automated production line can cost millions or even more.

2.Plant and Site Costs:

You need to select an appropriate plant and site based on your production scale. Rental or construction costs vary by region.

Raw Material Procurement and Transportation Costs: Raw material costs are affected by factors such as region, season, and raw material type, while transportation costs are related to the raw material sourcing radius and product sales range.

3.Environmental and Other Expenses:

These include the investment and operating costs of environmental protection equipment, utilities, and employee salaries.

Advantages of Wood Pellets

Processing dry sawdust into biomass pellets not only offers numerous advantages in terms of environmental protection, economic and social development, and energy structure, but also boasts excellent combustion performance. The main advantages are as follows:

1.Calorific Value and Combustion Residues

The calorific value and ash content of sawdust pellets after combustion are approximately 10% lower than those of medium-quality coal. However, wood pellets burn completely under normal operating conditions. Coal, on the other hand, does not burn completely, leaving residual ash containing 10% to 15% combustible components. Therefore, in practical applications, the effective calorific value of the two is comparable.

2.Combustibility

Wood pellets are more flammable and easier to ignite than coal, significantly reducing the ignition time required for combustion.

3.Solid Emissions

Wood pellets produce significantly lower solid emissions than coal. This not only reduces slag disposal costs but also reduces environmental pollution. Solid emissions from biomass pellets are primarily ash, accounting for approximately 0.4% to 7.0% of the total weight. In contrast, coal combustion produces a mixture of ash, alkali, and unburned coal, accounting for approximately 25% to 40% of the total weight.

4.Air Pollution and Corrosion

Coal causes far greater levels of air pollution and boiler corrosion than biomass pellets. Coal smoke contains large amounts of particulate carbon as well as toxic and corrosive gases such as sulfur dioxide and carbon monoxide. Sawdust biomass pellets are primarily composed of C-H organic matter, and their flue gas contains no particulate carbon or sulfur dioxide. Instead, it is primarily composed of C-H volatile gases, with virtually no sulfur dioxide or carbon monoxide. The smoke color during combustion is below Ringelmann Class I, significantly reducing air pollution and carbon dioxide emissions. Wood biomass pellets are internationally recognized as a "clean fuel."

5.Cost and Time Savings

Compared to coal, using biomass pellets as boiler fuel can save costs and time. For example, using wood biomass pellets for a 0.5-ton boiler can reduce costs by 11% and time by 34%. For example, compared to coal-fired power generation, a 0.5-ton boiler can reduce fuel costs by 10% and time by 16%. 6. Sustained Combustion

Wooden biomass pellets typically burn 8 to 10 times longer than loose, soft materials, maintaining a stable and continuous combustion state, ensuring a more reliable energy supply.

2025 Tony Machinery - All Rights Reserved. Map