1.图片

图片

Project Brief Introduction:

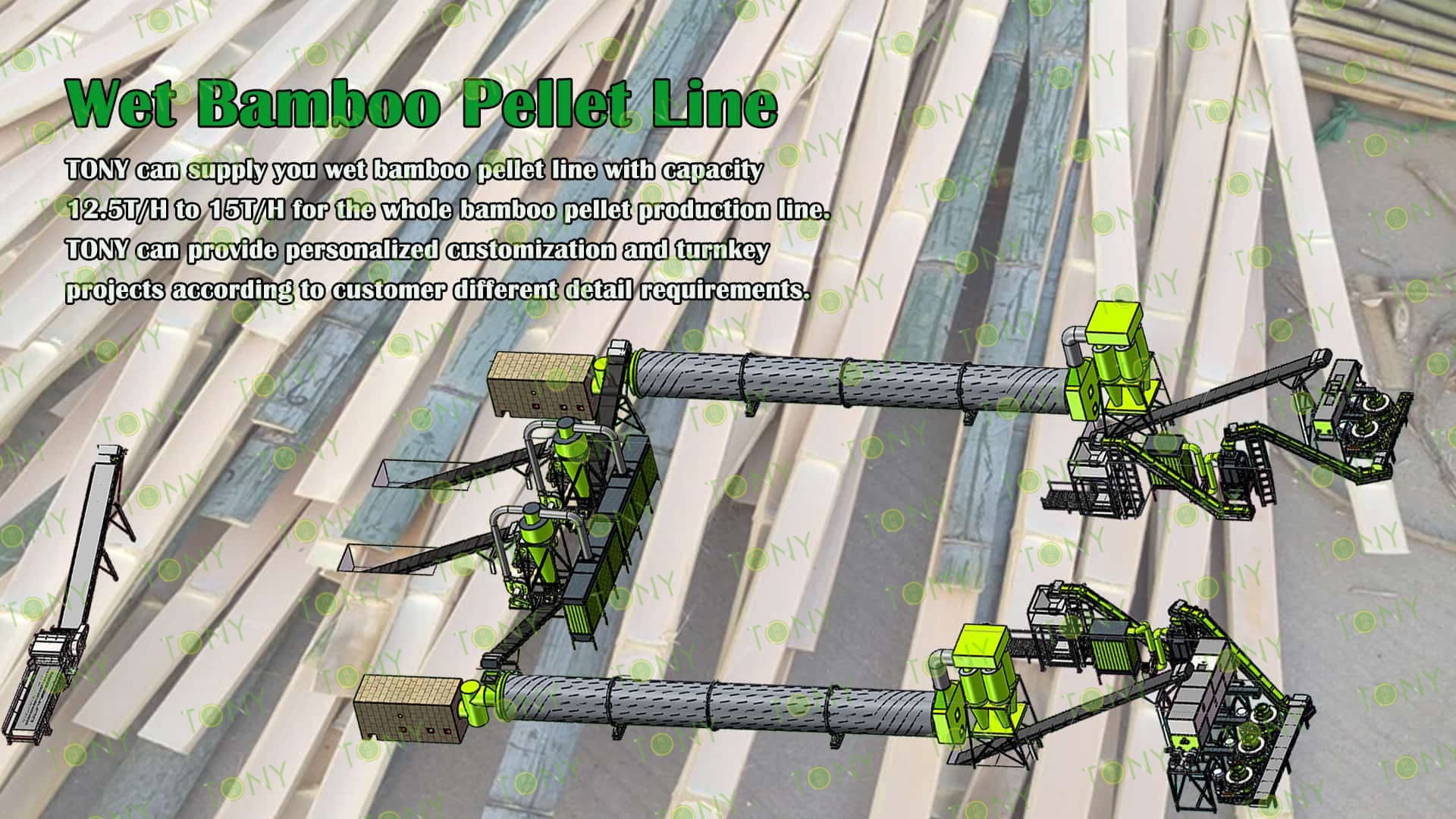

1.Product:Wet Bamboo Pellet Line

2.Capacity: 12.5-15 T/Hour

3.TONY Brand 12.5-15 Ton /Hour Wet Bamboo Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1850 kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D图

1. The working principle of wet bamboo biomass pellet processing equipment

Wet bamboo biomass pellet processing equipment is used to chop and compress bundled or bulk wet bamboo and other biomass materials into pellet fuel. Its working principle is to first crush and dry the wet bamboo through pre-processing equipment such as crushers, grinders, and dryers, and then press it into shape through a pelletizer to produce pelletized biomass fuel that meets quality standards.

2. Characteristics of wet bamboo biomass pellet processing equipment

Environmental Advantages: Low Pollution, Carbon Neutrality, and Policy Compliance

Extremely Low Emissions: No black smoke during combustion; sulfur dioxide emissions are only 0.005-0.01 g/m³ (far lower than 0.1-0.3 g/m³ for coal), nitrogen oxide emissions are <50 mg/m³, and particulate matter emissions are <10 mg/m³. These all meet the "Special Emission Limits" in the National Standard for Boiler Air Pollutant Emission (GB 13271-2014), eliminating the need for complex flue gas treatment equipment.

Zero Carbon Emissions through Carbon Cycle: Sawdust originates from wood that absorbed CO2 during tree growth. The CO2 released during combustion is reabsorbed by newly planted trees, creating a carbon cycle. Compared to coal (fossil carbon, which releases new carbon emissions upon combustion), this essentially achieves carbon neutrality, aligning with the national "dual carbon" target and making it a clean fuel promoted by government policy.

Recyclable Solid Waste: The ash produced (less than 5% of the total) is rich in potassium, calcium, and other elements, and can be used directly as fertilizer or soil conditioner, avoiding secondary solid waste pollution. Coal ash, on the other hand, requires special treatment and can cause heavy metal pollution of the soil.

3. Application scenarios of wet bamboo biomass pellet processing equipment

Wet bamboo is essentially forestry waste (or primary processing raw material). The core function of its processing equipment is to "convert loose, high-moisture biomass into a dense, easily usable form." Therefore, it can be extended to the processing of similar agricultural/forestry resources, including:

(1) Agricultural planting: auxiliary production of organic fertilizers. Applicable scenarios: pre-composting treatment of bamboo biomass in ecological farms and organic fertilizer plants.

(2) Forestry ecology: reduction and reuse of bamboo forest waste. Applicable scenarios: treatment of waste from natural bamboo forest protection areas and artificial bamboo forests (such as bamboo branches pruned every winter and withered bamboo stalks).

With the development of biomass material technology, wet bamboo processing equipment can also serve some niche but high-value fields:

(3) Biomass molded fuel derivatives: barbecue charcoal, fireplace charcoal. Applicable scenarios: production of clean barbecue charcoal in outdoor product factories and charcoal product factories. The "extrusion molding" function of bamboo processing equipment is the key to ensuring that the carbonized charcoal blocks are not easy to break.

(4) Environmental Management: Volume Reduction of High-Moisture Biomass Waste

Applicable Scenario: Biomass waste treatment in bamboo processing industrial concentration areas (such as wet bamboo chips and bamboo skin waste from bamboo product factories).

2.图片

TONY Brand 12.5-15 Ton/Hour Wet Bamboo Pellet Manufacturing Plant can take wet bamboo as the main raw material. After pretreatment and processing, it is solidified into high - density bamboo pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bamboo resources.

1. Capacity: 12.5-15 Ton/Hour

2. Raw materials: Wet Bamboo

3. Moisture: Wet type, about 40%.

4. Application: All kinds of bamboo materials suitable for pellet production.

Suitable customers: Bamboo product processing companies, large-scale farms, agricultural/forestry parks, areas with dense bamboo resources, biomass energy companies/fuel traders, green environmental protection technology companies, and other places where bamboo raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3.图片

图片

1. Project Name: Wet Bamboo Pellet Production Line

2. Raw Material: All kinds of wet bamboo

3. Moisture Content of Raw Material: 40%

4. Capacity: 12.5-15 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1400-600-200KW, Effective Hammer Mill-TFD85*220-220kw, Rotary Drum Dryer-2.2*24m, TONY Pellet Machine TYJ760-Ⅲ-160kw, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

4.图片

|

How to use the TONY pellet production line to make pellets from wet bamboo? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut wet bamboo with a diameter of less than 35 cm into bamboo chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm bamboo chips into 8-14 mm bamboo dust. 3. Use TONY rotary drum dryer to dry the bamboo dust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

图片

图片

5.图片

图片

图片

3D图

3D图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

| Comprehensive Chipper | Effective Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Grind Bamboo φ ≤35 cm Into25-55mm Bamboo Chips. 2.Model: TPC1400-600-200KW With 6 Blades*1set 3.Capacity:14-20Ton/Hour. |

1.To Crush 25-55mm Bamboo Chips Into 8-14mm Bamboo Dust. 2.Model: TFD85*220-220kw*2sets 3.Capacity: 7-8 Ton/Hour/Set |

1.To Dry The 40% Bamboo Dust Into 10-15% Bamboo Dust. 2.Model: THGD2.2*24*2 sets 3.Capacity:7-8 Ton/Hour/Set |

1.To Stroage Bamboo Dust Before Pellet Machine; Adjust The Speed Of Bamboo Dust Entering The Pellet Machine 2.Model: TLC-15*1 set 3.Capacity:12.5-15 Ton/Hour/Set |

| Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Press Dry Bamboo Dust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-160KW*5 sets 3.Capacity:2.5-3 Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:12.5-15 Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags 2.Model: TBD*1 set 3.Capacity: 12.5-15 Ton/Hour |

1.To Transport Bamboo Chips,Bamboo Dust,Pellets. 2.Width: 80cm*9 sets 3.Capacity:Designed With The Whole Line |

3D图

5.1图片

图片

1.Wet Bamboo To Bamboo Chips Process:

A.This process is mainly used to grind the bamboo whose diamater is under 35 cm into bamboo chips with size 25-55mm. The finish bamboo chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand comprehensive chipper TPC1400-600-200Kw with 6 flying blades type*1 set

C.Capacity:14-20Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

5.2图片

图片

2.Bamboo Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm bamboo chips into 8-14mm bamboo dust.

B.Capacity:12.5-15 Ton/Hour.

C.TONY brand effective hammer mill TFD85*220-220kw*2 sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.3图片

图片

3.Bamboo Dust Drying Process:

A.This process is mainly used to dry the bamboo dust from 40% to 10-15%.

B.Capacity:12.5-15 Ton/Hour.

C.TONY use 2 sets of 2.2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.4图片

图片

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:12.5-15Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-Ⅲ-160kw*5 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.5图片

图片

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:12.5-15 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.6图片

图片

6.Packing Process:

A.This process is mainly used to pack pellets into 1 Ton/Bags.

B.Capacity:12.5-15 Ton/Hour.

C.TONY brand ton packing machine*1 set

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

6.图片

图片

7.图片

图片

From a market perspective, the global energy structure is undergoing rapid transformation, and my country is actively promoting clean energy. The annual growth rate of demand for biomass pellet fuel exceeds 15%. Project investment can be flexibly adjusted, raw material costs are low, and the payback period is typically 1-2 years. Furthermore, the project benefits from government policies such as renewable energy subsidies and tax exemptions, possessing strong potential for sustainable development. The resulting biomass pellets have a combustion efficiency of over 85%, far exceeding that of traditional coal (approximately 60%), with ash content of only 2-5% and sulfur content below 0.05%. This meets national environmental emission standards and can replace fossil fuels such as coal and natural gas, finding widespread application in industrial boilers, residential heating, and agricultural greenhouse heating.

8.图片

图片

From a performance perspective, its high combustion efficiency and low pollution levels are its key advantages: with a combustion efficiency exceeding 85%, far higher than traditional coal, it releases heat rapidly; the ash content after combustion is only 2-5%, and the sulfur content is less than 0.05%, both significantly lower than coal. Emissions of pollutants such as sulfur dioxide and dust are extremely low, meeting national environmental standards, and it can directly replace fossil fuels like coal and natural gas. From an application and value standpoint, it has a wide range of uses, suitable for industrial boilers, power plants, and even for home heating and agricultural greenhouse heating. It is compatible with most existing combustion equipment, requiring minimal modifications; and it offers stable economic returns, along with potential benefits such as renewable energy subsidies and tax breaks, thus combining environmental benefits with economic value.

9.图片

图片

10.图片

图片

11.图片

公司服务图

2025 Tony Machinery - All Rights Reserved. Map