Project Brief Introduction:

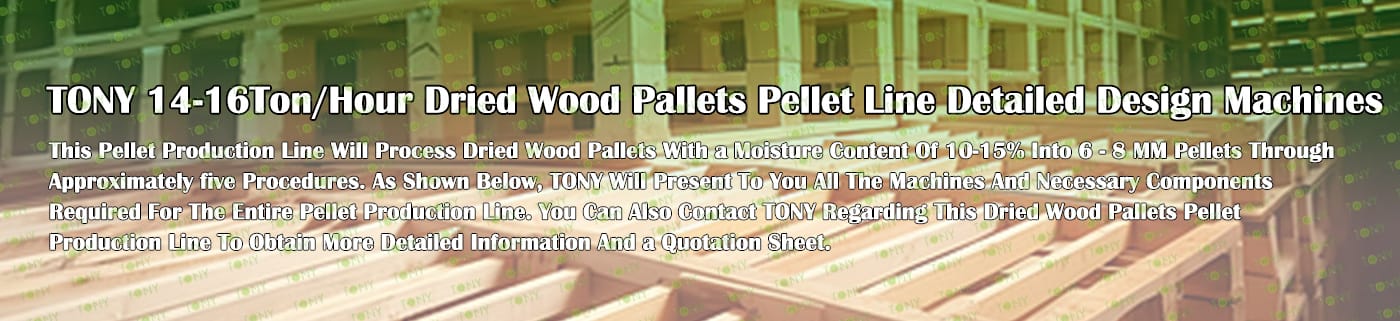

1.Product:Dried Wood Pallets Pellet Line

2.Capacity: 14-16T/Hour

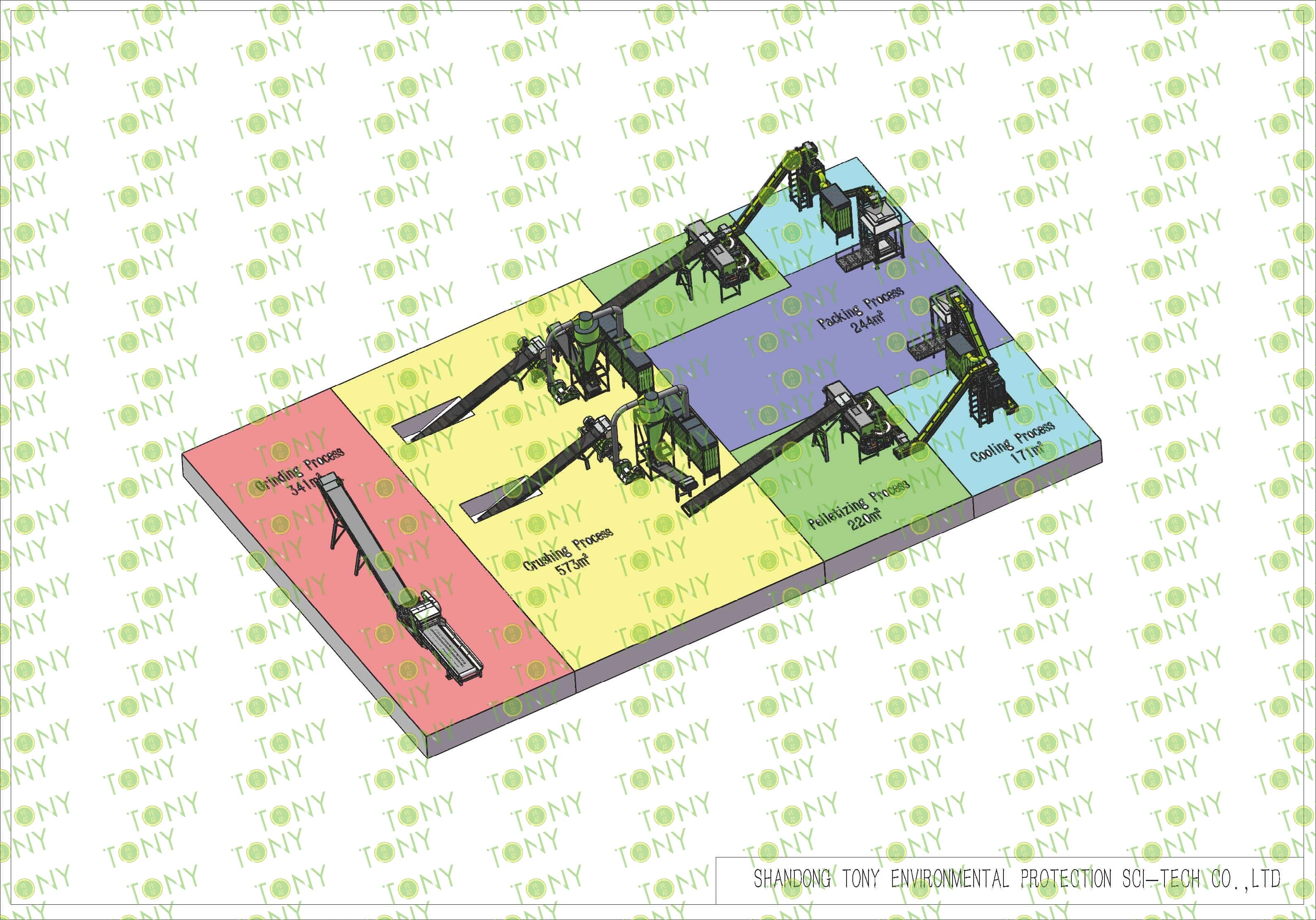

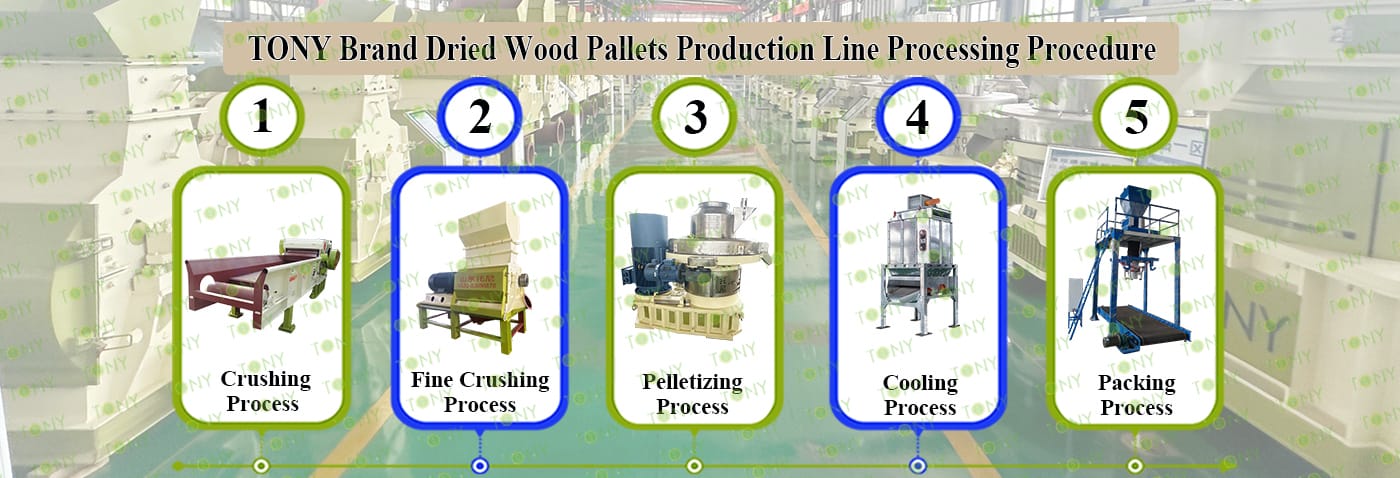

3.TONY Brand 14-16Ton /HourDried Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, TONY Pellet Machine TYJ860-Ⅲ-250KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 2000KW

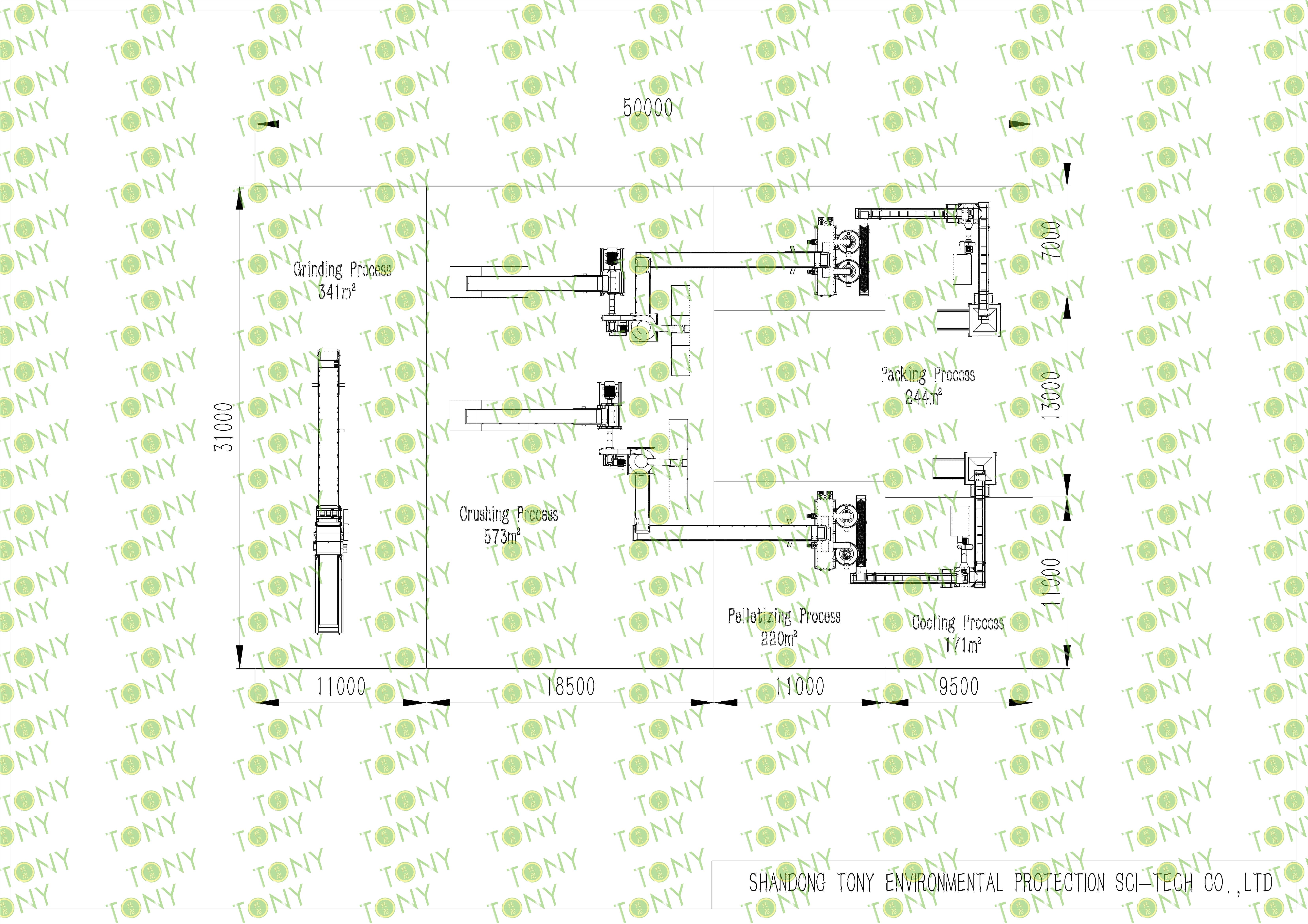

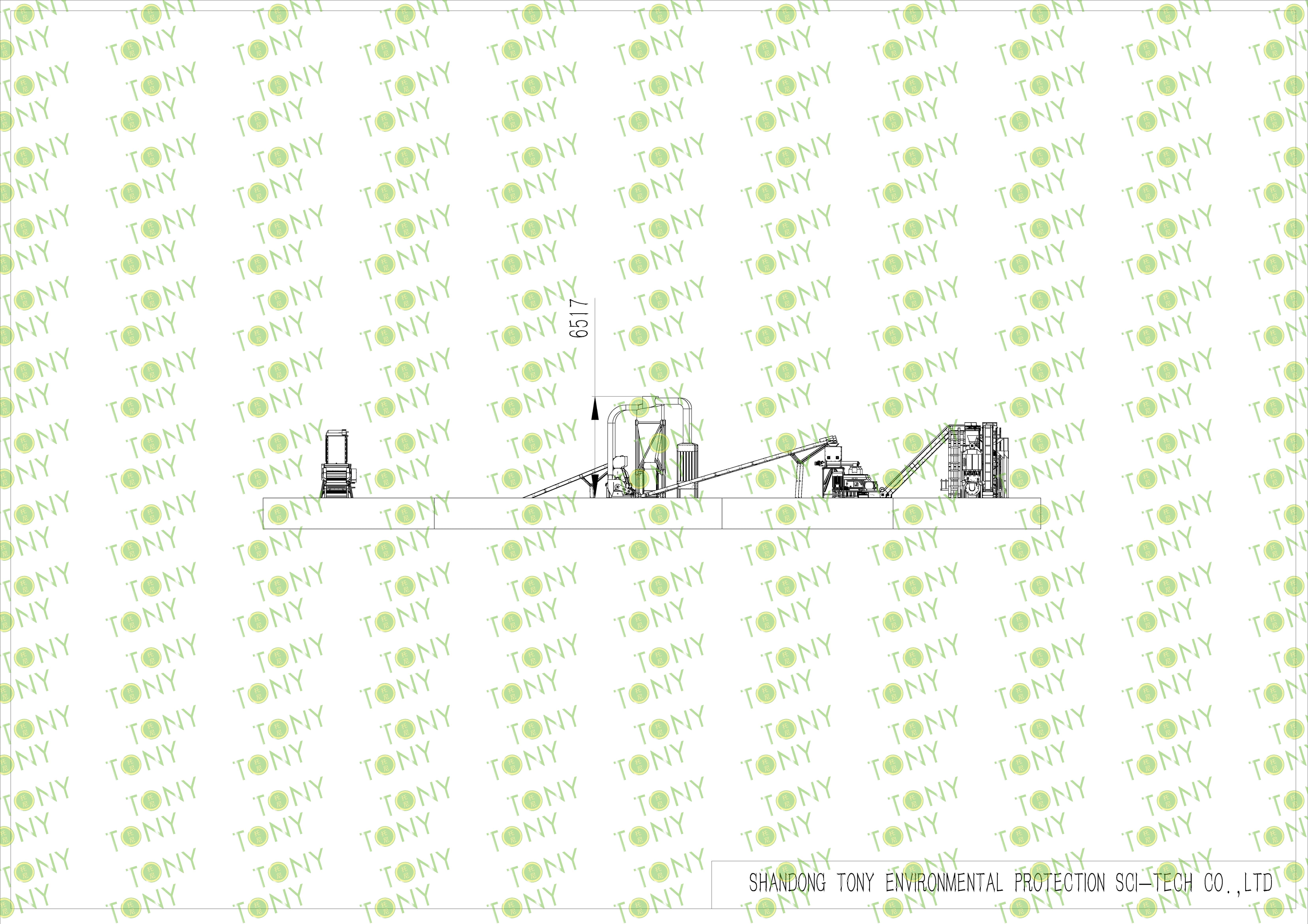

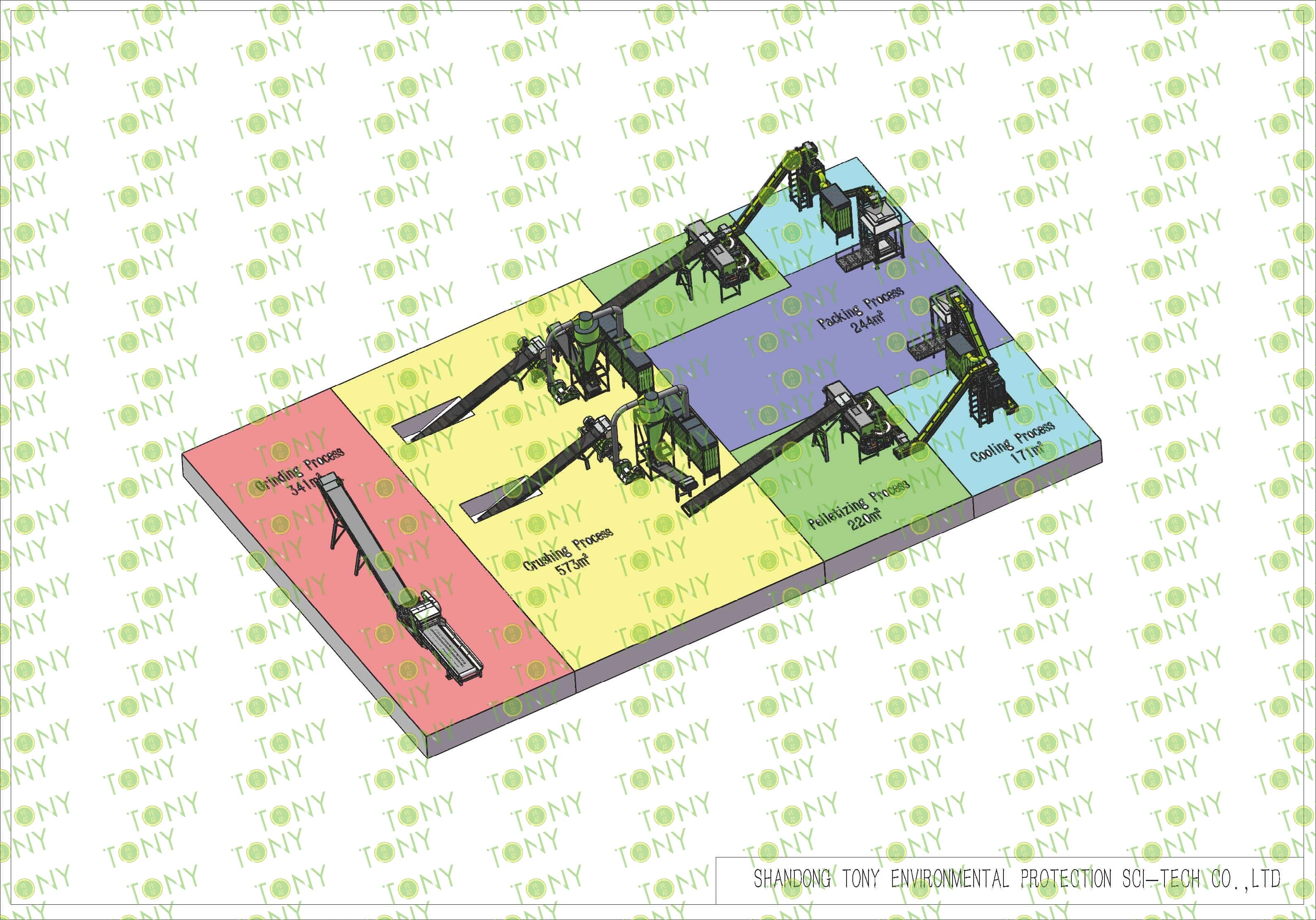

6.Need Area: About 1550㎡ L: 50 M W: 31 M H: 6.517 M

Project Layout For Customer:

1.The working principle of dried wood pallets biomass pellet processing equipment

The operating principle of biomass pellet processing equipment is based on a process that combines thermoplastic deformation of lignin with mechanical extrusion. The core principle is to utilize the softening and bonding of lignin in the raw material under high temperature and high pressure to achieve physical forming.

Pretreatment: The raw material undergoes crushing, pulverization, and drying to control the moisture content to 14%-16%. Magnetic separation is used to remove iron to prevent impurities from entering the subsequent process.

High-Temperature and High-Pressure Forming: After the raw material enters the pelletizer, the friction between the rollers and the die, combined with the high temperature, softens the lignin and bonds the cellulose molecules, forming pellets.

Physical Extrusion: Utilizing the compressive force and friction between the rollers and the die, the material is pelletized at room temperature without the addition of any chemical binders.

2.Characteristics of dried wood pallets biomass pellet processing equipment

(1)Wide adaptability of raw materials, achieving "waste resource conversion"

It can directly process discarded dry pallet wood (including common pallet materials such as pine, fir, poplar, and miscellaneous wood), eliminating the need for complex sorting (only metal parts need to be removed). This solves the problem of difficult dry pallet recycling and environmental pollution, aligning with the concept of a "circular economy."

(2)Stable pellet quality and excellent fuel performance

Using "ring die-roller" high-pressure extrusion technology, combined with the wood's own lignin bonding, the finished pellets achieve a density of 1.1-1.3 g/cm³, high hardness, and resistance to breakage, making them easy to transport and store over long distances.

The finished pellets have a low moisture content, stable calorific value, and are smokeless and odorless when burned. Pollutant emissions are significantly lower than coal (SO₂ emissions are only 1/10 of coal, and NOx emissions are reduced by over 30%), meeting environmental standards (such as GB/T 31740-2015 "Biomass Solid Pellet Fuels").

3.Application scenarios of dried wood pallets biomass pellet processing equipment

(1)Industrial Sector: Industrial Heating and Boiler Fuel Supply

The biomass pellets produced by this equipment can be used as an alternative fuel for industrial boilers and hot air furnaces in food processing (such as baking and drying), chemical production, and building materials manufacturing (such as tile drying). They replace traditional coal or natural gas, reducing fuel costs and carbon emissions, meeting the industrial sector's "coal reduction and carbon reduction" needs.

(2)Energy Sector: Distributed Energy and Biomass Power Generation

In small and medium-sized distributed energy stations (such as industrial parks and township heating stations), the pellets produced by this equipment can be directly used in biomass burners and gasifiers, providing stable heat or electricity to the region. Qualified pellets produced by some large-scale production lines can also be supplied to biomass power plants as a supplementary power generation feedstock, contributing to the development of a renewable energy system.

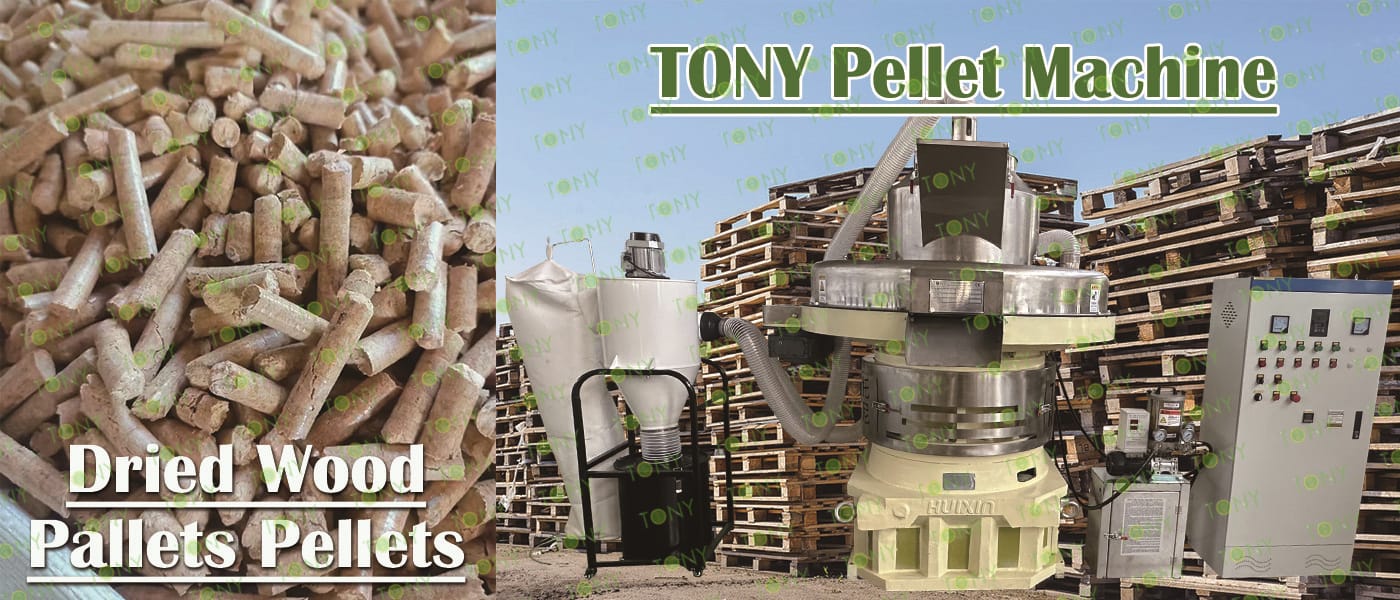

TONY Brand 14-16Ton/Hour Dried Wood Pallets Pellet Manufacturing Plant can take dried wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings. After pretreatment and processing, dried wood pallets is solidified into high - density wood pellet fuel.The content of pollutants such as sulfur dioxide and nitrogen oxides produced by biomass pellets during combustion is extremely low, and the dust emission is also low, which can effectively reduce air pollution. Moreover, the raw material sources of biomass pellets are very wide, and the combustion efficiency is high. Compared with traditional fossil energy, it reduces the production and use costs and has higher economic efficiency. It has received a lot of attention and promotion.

1. Capacity: 14-16Ton/Hour

2. Raw materials: Dried wood pallets

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Pallets Pellet Production Line

2. Raw Material: All kinds of dried wood pallets

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 14-16 tons per hour

5. Process: Crushing Process - Fine Crushing Process -Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1400-700-250KW, Effective Hammer Mill-TFD85*250-250KW, TONY Pellet Machine TYJ860-Ⅲ-250KW, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

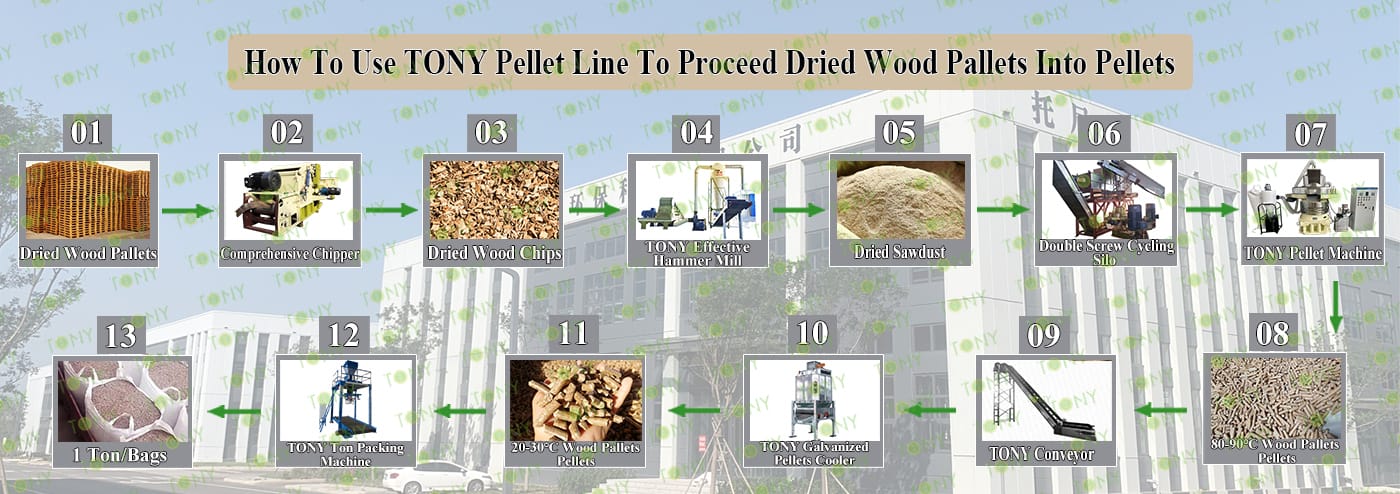

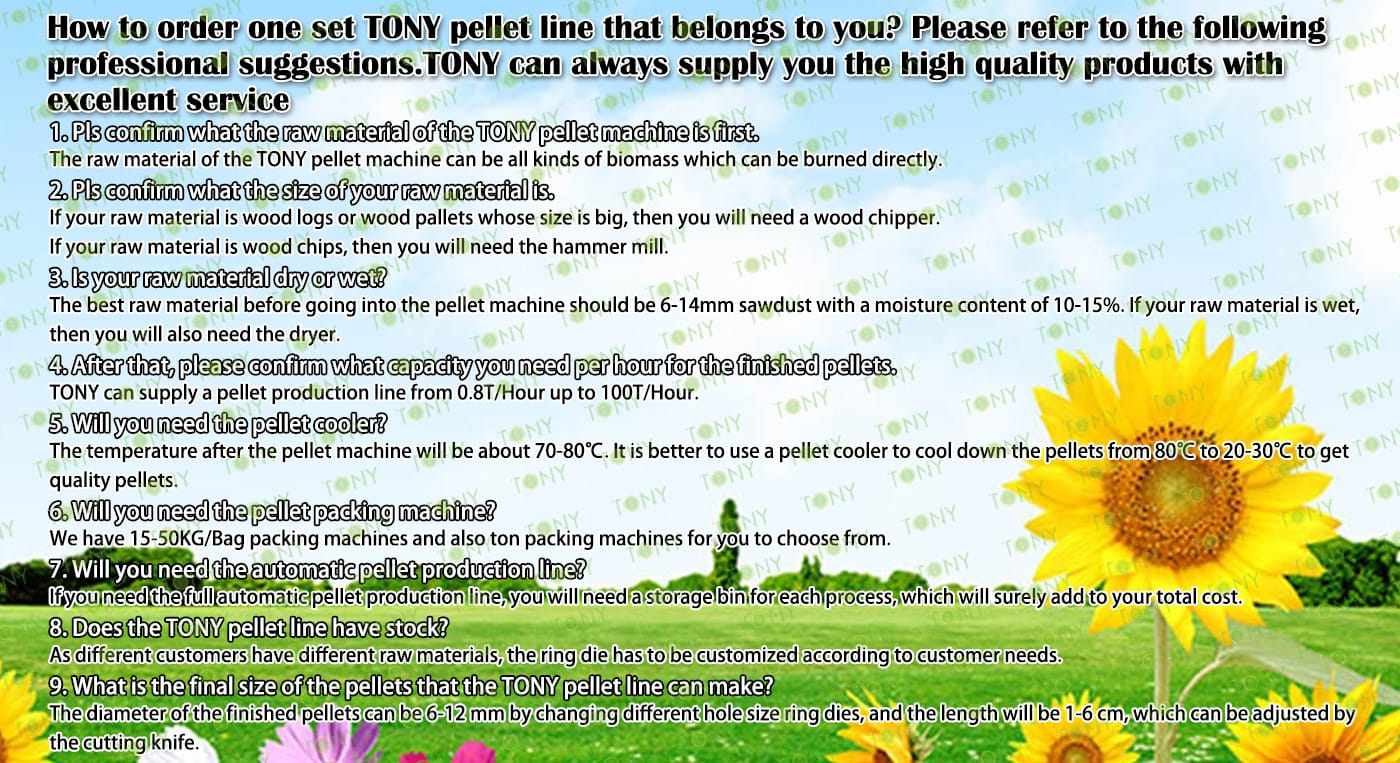

How to use the TONY pellet production line to make pellets from dried wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind dried wood pallets with width 1.4m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

| 1.To Grind Wood pallets Width ≤1.4m Into25-55mm Wood Chips. 2.Model: TPC1400-700-250KW With 24 Hammer Heads*1set 3.Capacity: 20-30Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*2sets 3.Capacity: 7-8Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-8*2sets 3.Capacity:7-8Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-250KW*4sets 3.Capacity:3.5-4.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*2sets 3.Capacity:14-16Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags 2.Model: TBD*2sets 3.Capacity: 14-16Ton/Hour |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1.4 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1400-700-250KW model with 24 hammer heads*2sets

C.Capacity:20-30Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

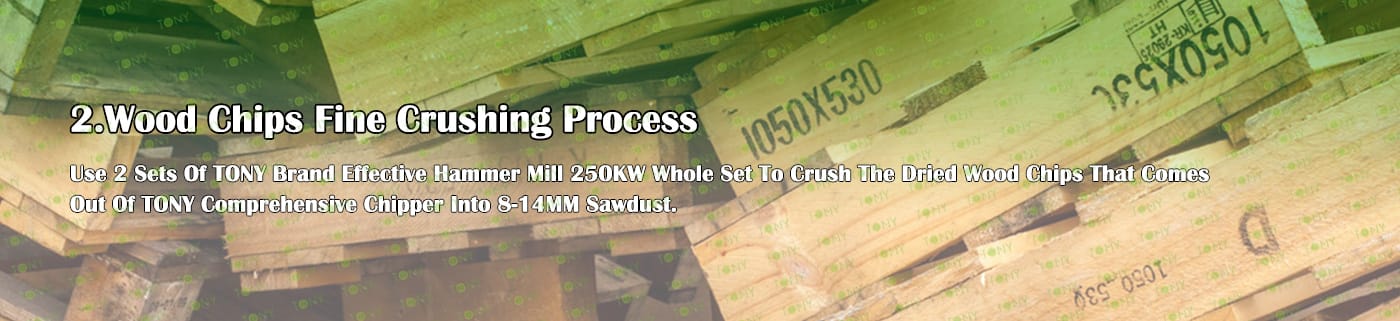

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:14-16Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250KW*2sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

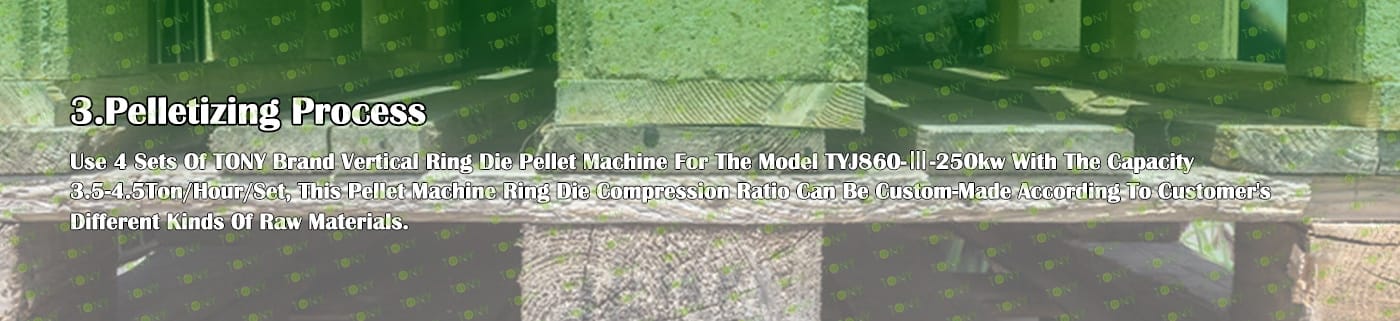

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:14-16Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-250KW*4sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:14-16Ton/Hour.

C.TONY brand galvanized cooler separator*2sets

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 1ton/bags.

B.2 sets of TONY ton packing machine

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Three Fundamental Supports for the Feasibility of Processing Wooden Pallets into Biomass Pellets

The success of this project hinges critically on the maturity of three key factors: raw material supply, policy guidance, and market demand. These factors are also the core focus of preliminary research.

1.Raw Material Supply: Stable and low-cost raw material supply is a prerequisite.

The source, supply volume, and cost of discarded wooden pallets directly determine project profitability and require critical assessment:

Raw Material Source Scenario:

Core Channels: E-commerce logistics warehouses, manufacturing factories (auto parts, home appliances, machinery), ports/bonded areas (discarded IPPC pallets from cross-border trade), and pallet rental companies (damaged and retired pallets).

Supply Characteristics: Discarded pallets in these scenarios are typically generated in bulk and are often recycled for free or at a low price, resulting in extremely low raw material costs.

Suitability of Raw Material Processing:

Wooden pallets (especially solid wood pallets) have a high wood fiber density, resulting in pellets with a calorific value of 4200-4800 kcal/kg (similar to medium-quality coal), surpassing agricultural waste such as straw and rice husks. Removal of metal (nails, clips) and minimal oil contamination is required, eliminating the need for complex pre-treatment and making them highly suitable for processing.

2.Policy Direction: Dual Benefits of Environmental and Energy Policies

Biomass pellets, as a compliant alternative fuel, have low market entry barriers. This project falls under the "solid waste resource utilization" category, meeting the "reduction and resource utilization" requirements.

3.Market Demand: Strong demand in both industrial and residential applications

The market demand for biomass pellet fuel has stabilized, eliminating the need to worry about "selling out":

Industrial (Core Customers): Small and medium-sized boilers (1-10 tons) in food processing, textile, and building materials factories, ceramic kilns, and biomass power plants (for co-firing).

Residential (Supplementary Customers): Home heating stoves, cooking energy in southern farmhouses and small restaurants, and home fireplace users.

Project Advantages

1.Abundant and affordable raw materials:

Crop straw, logging residues, and other raw materials are widely available, and in some regions, they are available at low cost or even for free. For example, in major grain-producing regions, large quantities of straw urgently need to be properly processed, providing a sufficient and affordable source of raw materials for the project.

2.Strong Market Demand:

Biomass pellet fuel can be used for heating, heat supply, cooking, gasification combustion, drying, drying, and power generation. It is widely used in industrial boilers, heating equipment, livestock farms, food processing, textile printing and dyeing, and the building materials industry. As environmental protection policies tighten, traditional coal-fired boilers are being phased out. As a high-quality alternative to coal, market demand for biomass pellets continues to grow.

3.Strong Policy Support:

The country has introduced numerous preferential policies to promote the development of biomass energy. The "14th Five-Year Plan for Renewable Energy Development" explicitly encourages the development and application of biomass energy. Many regions offer tax exemptions, equipment subsidies, and project interest subsidies to companies engaged in biomass pellet processing, lowering the barriers to entry and costs of entrepreneurship.

At a time when environmental awareness is gaining widespread acceptance and energy transitions are accelerating, investing in biomass pellet processing is both responsive to the current trend and offers enormous commercial potential. This project, with its diverse raw material sources, strong market demand, and robust policy support, has become a promising prospect for many entrepreneurs.

Biomass pellets are clean fuel pellets made from agricultural and forestry waste, such as wood chips, straw, rice husks, and sawdust, through a series of processes including crushing, mixing, drying, and extrusion. They offer significant advantages, including high thermal efficiency. High-temperature compression significantly reduces their volume, making them easy to store and transport. Derived from natural biowaste, they contain no harmful chemicals and are safe and reliable. Combustion from waste or residual materials also allows for the ash to be used as fertilizer, making them highly sustainable.

2025 Tony Machinery - All Rights Reserved. Map