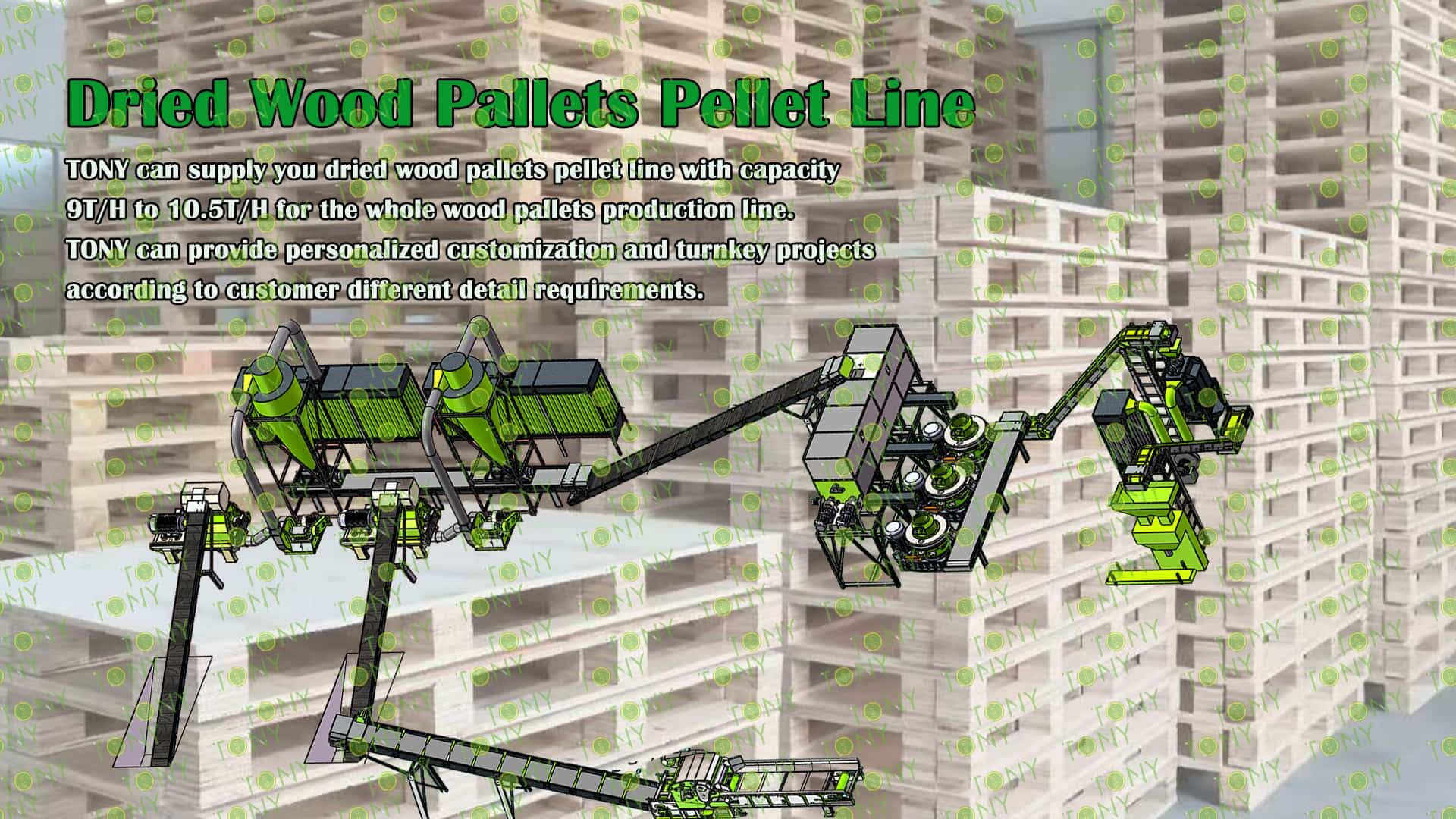

Project Brief Introduction:

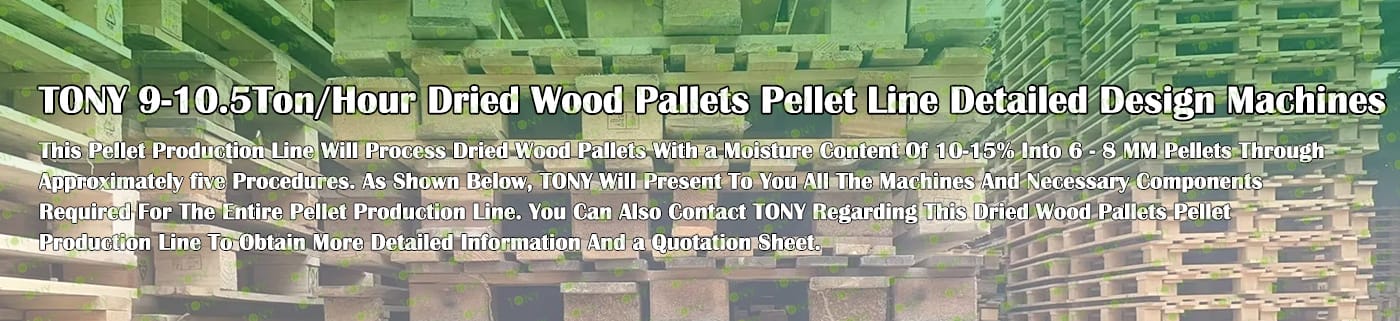

1.Product:Dried Wood Pallets Pellet Line

2.Capacity: 9-10.5T/Hour

3.TONY Brand 9-10.5Ton /HourDried Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, TONY Pellet Machine TYJ860-Ⅲ-220KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1250KW

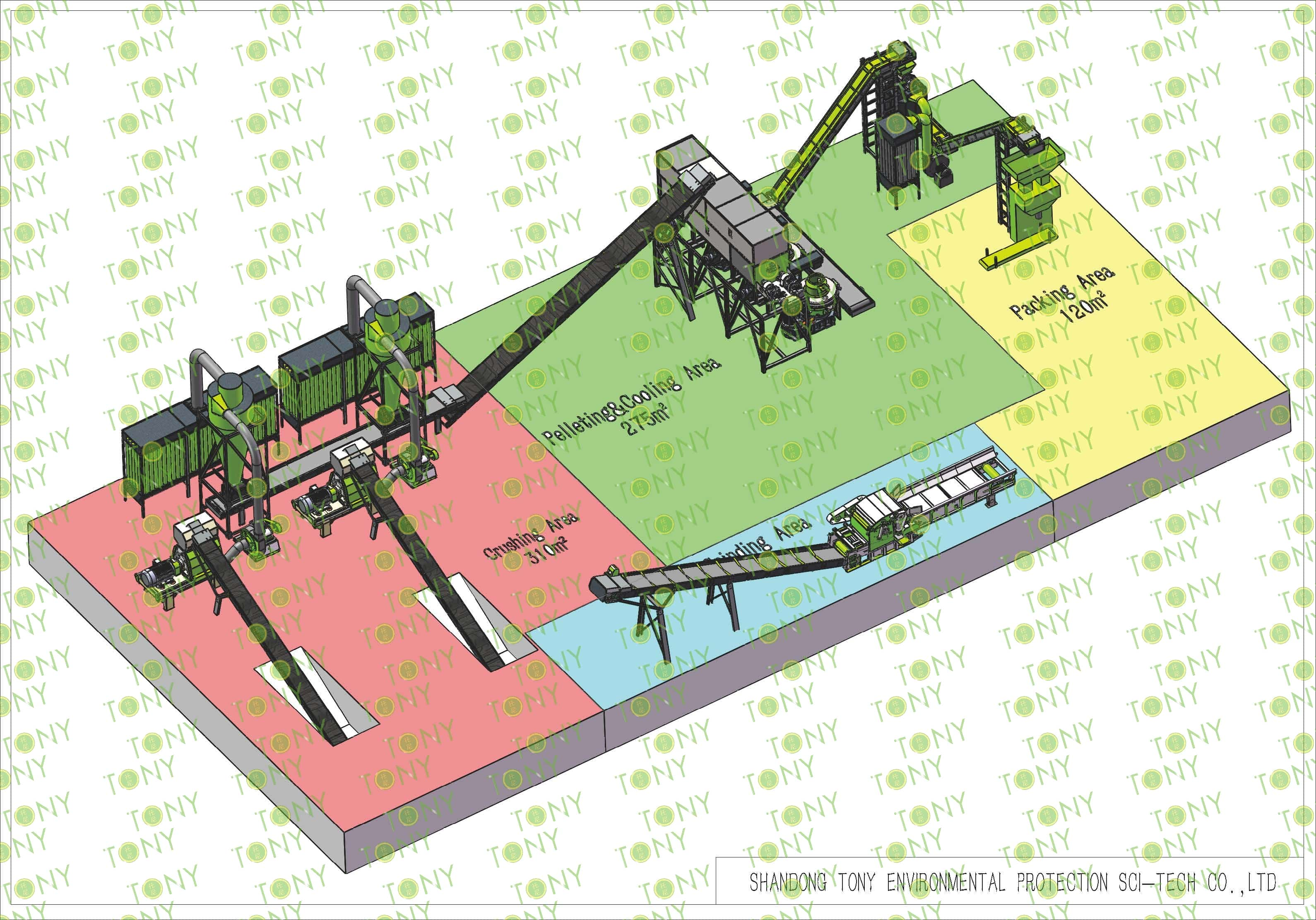

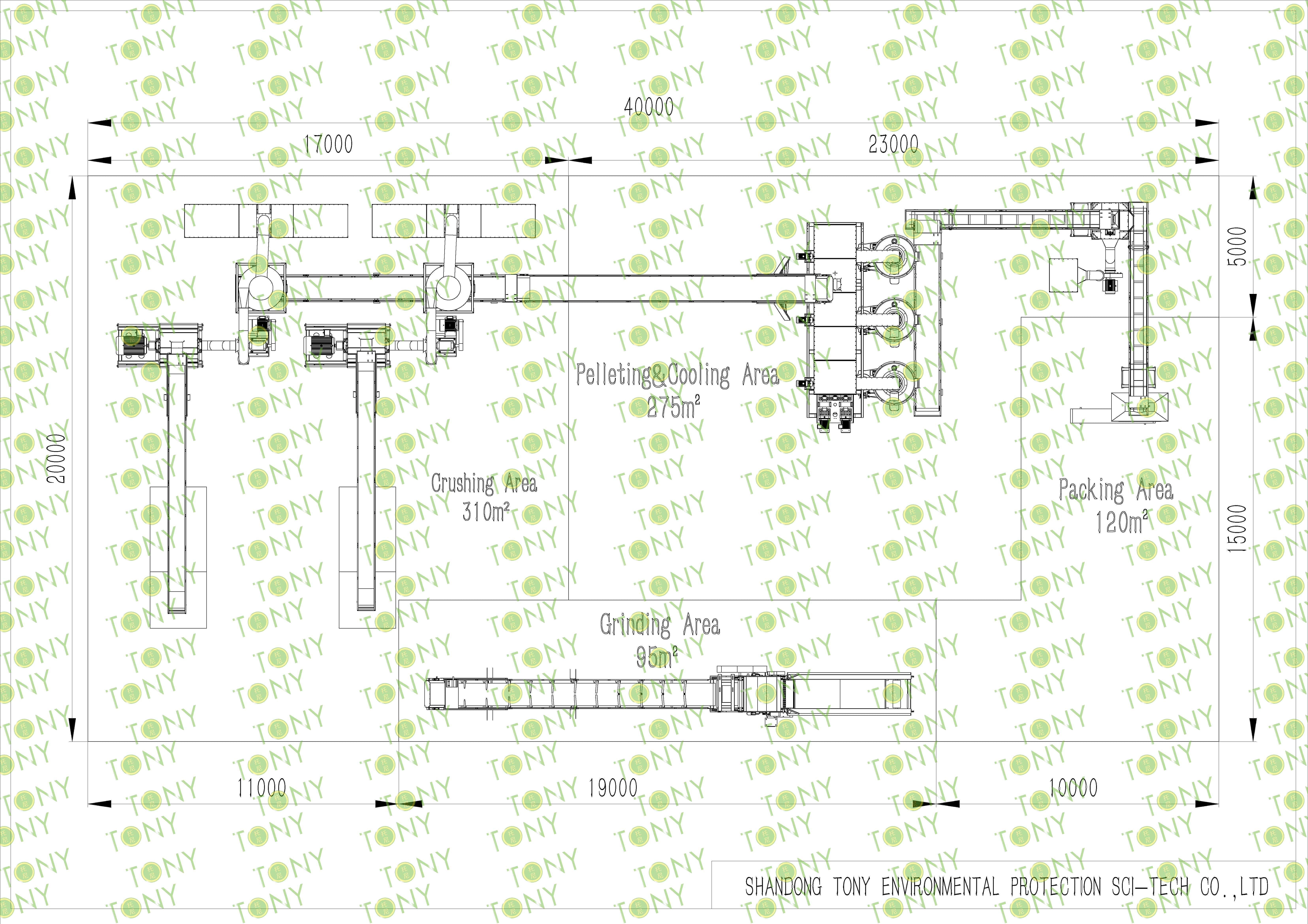

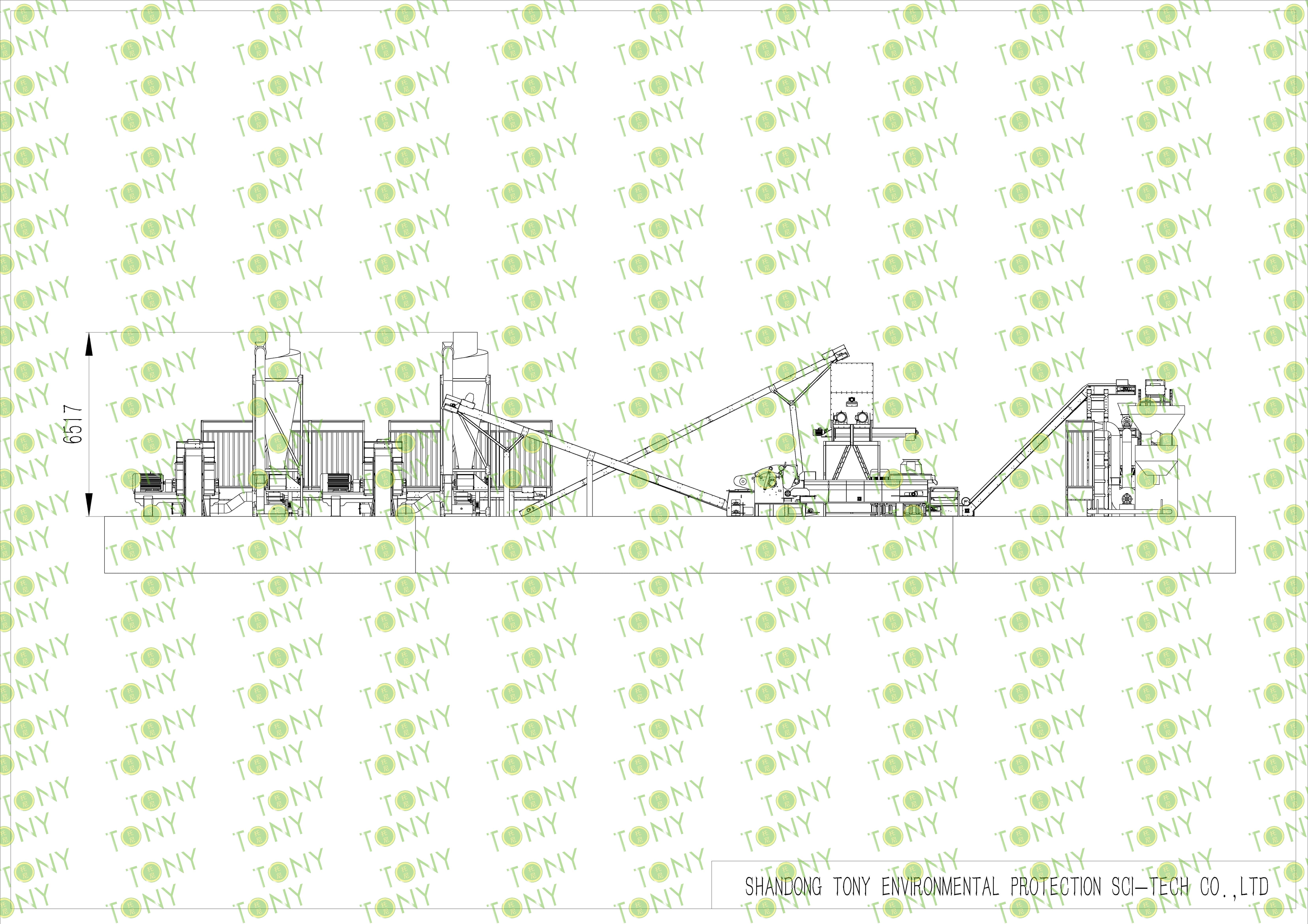

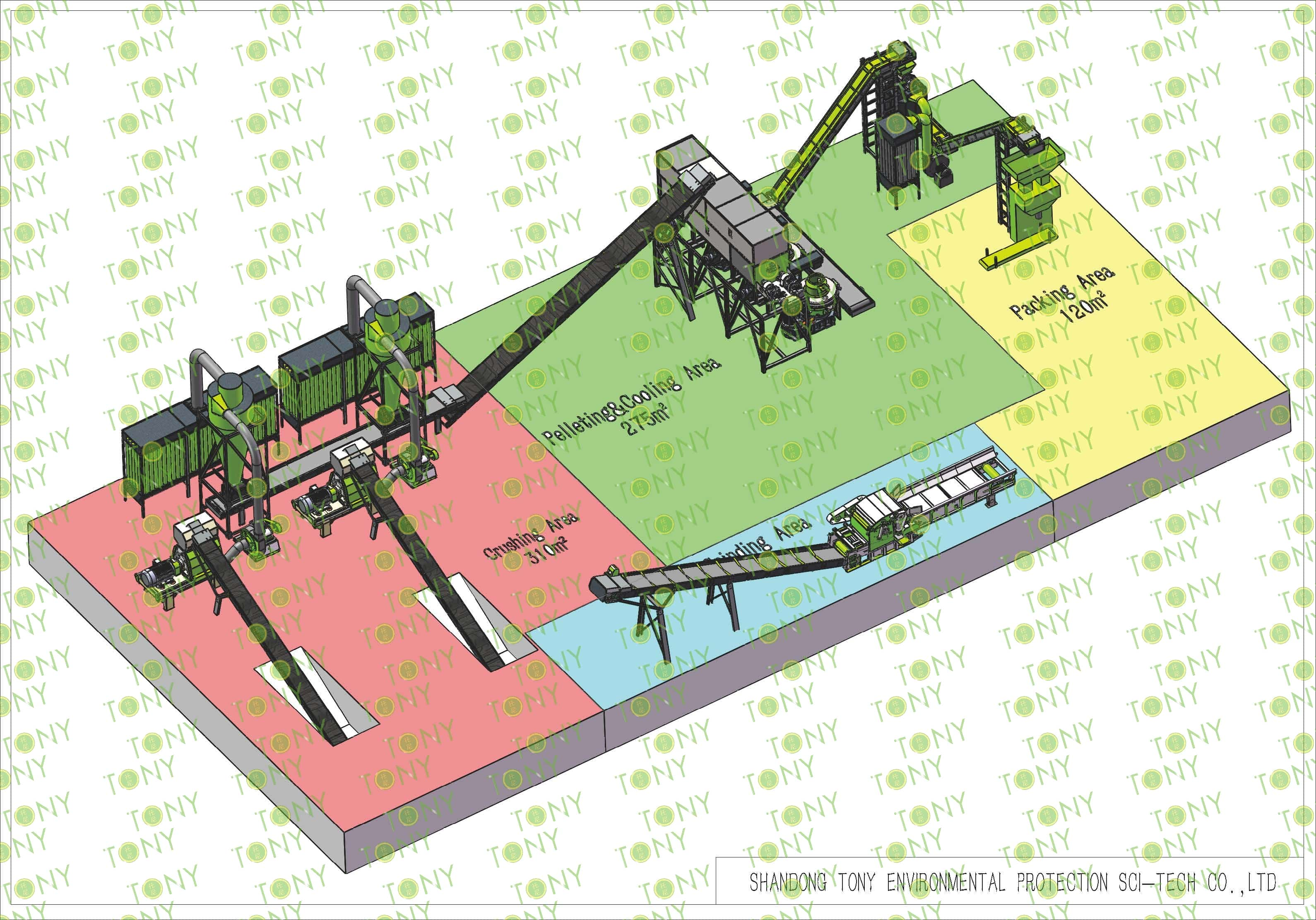

6.Need Area: About 800㎡ L: 40 M W: 20 M H: 6.517 M

Project Layout For Customer:

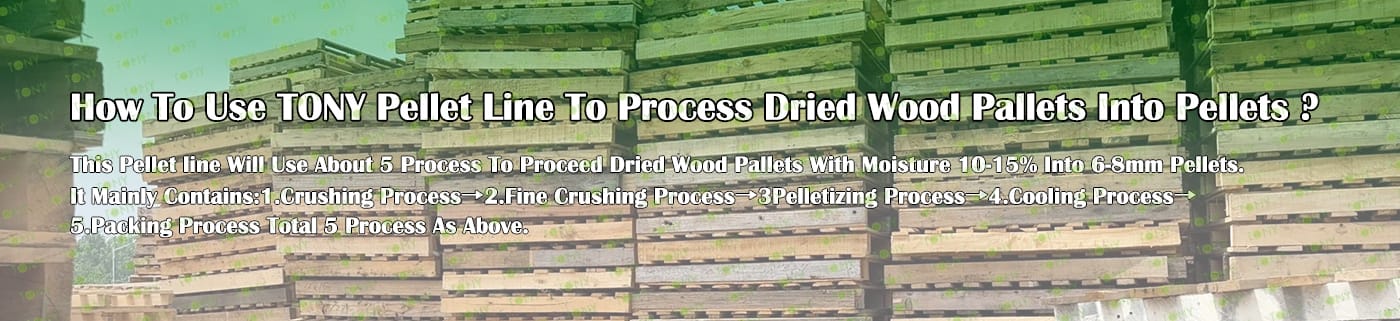

1.The working principle of dried wood pallets biomass pellet processing equipment

The core of the equipment for processing dry pallet pellet fuel is to convert wooden dry pallets (mainly composed of cellulose, hemicellulose, and lignin) into high-density, easy-to-store pellet fuel through the continuous process of "pretreatment → crushing → extrusion molding → cooling and screening". The working principle of the equipment system can be disassembled and explained according to the core process. The functions and principles of the equipment in each link are closely connected, ultimately realizing the transformation of raw materials into finished products.

2.Characteristics of dried wood pallets biomass pellet processing equipment

(1)Strong Raw Material Adaptability: Compatible with the diverse characteristics of waste dry pallets.

Dry pallets, as raw materials, can be made of a variety of materials (pine, poplar, and other woods), vary in size, and may contain small amounts of impurities (after pretreatment). The equipment is specifically designed to accommodate this raw material, reducing raw material restrictions.

(2)High-Quality Finished Pellets: Meeting the requirements of "efficient combustion + easy storage."

Through precise process control, the equipment produces pellets with outstanding density, combustibility, and stability, far exceeding the value of bulk wood waste.

(3)High Production Efficiency: Automated and continuous operation reduces labor costs.

The equipment system utilizes a "continuous production line + automated control" system, reducing manual intervention and increasing output per unit time, making it suitable for large-scale production.

(4)Significant Environmental Benefits: Achieving the dual environmental benefits of "solid waste recycling + clean combustion."

One of the core advantages of dry pallet pellet processing equipment is its environmental friendliness. It not only addresses the pollution problem of waste pallets but also replaces fossil fuels and reduces carbon emissions.

(5) High Economic Value: "Low-cost raw materials + high-demand finished products" creates significant profit potential.

From an industry chain perspective, the equipment offers significant advantages. Low raw material costs and high market demand for finished products make this processing project highly profitable.

(6)Convenient Operation and Maintenance: Lowering the technical barrier to entry makes it suitable for a wide range of operations. The equipment is designed with practicality in mind, offering easy operation and manageable maintenance costs, making it easy for both small and medium-sized businesses and individual operators to get started quickly.

3.Application scenarios of dried wood pallets biomass pellet processing equipment

(1)Small and medium-sized pellet plants (regional): After introducing dry pallet pellet processing equipment, they can supplement raw materials by recycling discarded pallets from surrounding logistics companies, broaden raw material channels, reduce dependence on a single wood chip supplier, and ensure full-load operation of the production line.

(2)Large-scale pellet plants (industrial grade): For example, large-scale pellet plants serving power plants and chemical plants require a large amount of wood raw materials to support production. Pellets processed from discarded dry pallets (high density and stable wood fiber) have "higher combustion value and lower ash content" (better than ordinary wood chip pellets) and can be used as raw materials for "high-end pellets" (such as pellets for industrial boilers), increasing the selling price of finished products (10%-20% higher than ordinary pellets).

(3)Professional wood solid waste treatment companies: For example, environmental protection companies that process discarded furniture and construction wood waste. Discarded dry pallets are compatible with this type of wood waste (both are solid wood/artificial wood). The equipment can be "integrated for processing" without the need for separate classification, improving processing efficiency; the processed pellet fuel can be used as the company's "core product for export", expanding from "single processing service" to a complex business of "processing + product sales", thereby improving profitability.

(4)Regional new energy entrepreneurs: By recycling waste dry pallets from surrounding enterprises and processing pellets, the raw material acquisition cost is low (even free), and the finished products can be sold to local factories and heating companies (within a sales radius of 50 kilometers, and transportation costs are controllable). The investment is small and the return is fast, which is suitable for small and medium-sized entrepreneurs.

(5)Environmental protection investment companies: This type of enterprise focuses on "green and low-carbon projects". Dry pallet pellet processing projects combine "solid waste treatment (environmental protection attributes)" and "biomass energy (new energy attributes)". After investment, stable returns are obtained, while improving the company's ESG rating.

TONY Brand 9-10.5Ton/Hour Dried Wood Pallets Pellet Manufacturing Plant can take dried wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings. After pretreatment and processing, dried wood pallets is solidified into high - density wood pellet fuel.The content of pollutants such as sulfur dioxide and nitrogen oxides produced by biomass pellets during combustion is extremely low, and the dust emission is also low, which can effectively reduce air pollution. Moreover, the raw material sources of biomass pellets are very wide, and the combustion efficiency is high. Compared with traditional fossil energy, it reduces the production and use costs and has higher economic efficiency. It has received a lot of attention and promotion.

1. Capacity: 9-10.5Ton/Hour

2. Raw materials: Dried wood pallets

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Pallets Pellet Production Line

2. Raw Material: All kinds of dried wood pallets

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 9-10.5 tons per hour

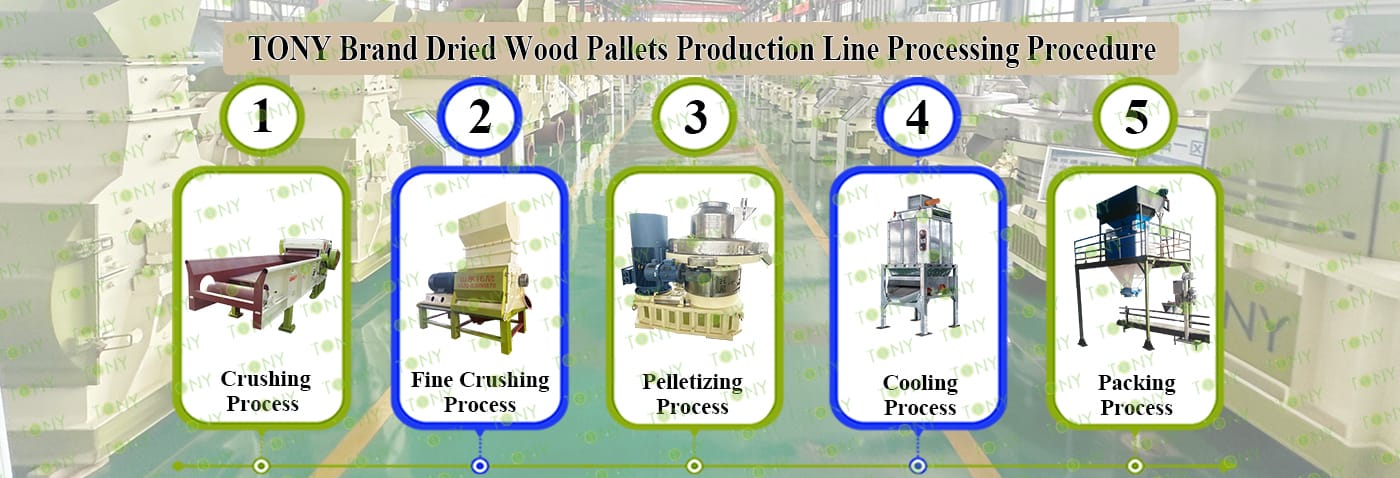

5. Process: Crushing Process - Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1300-600-132KW, Effective Hammer Mill-TFD75*132-132KW, TONY Pellet Machine TYJ860-Ⅲ-220KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

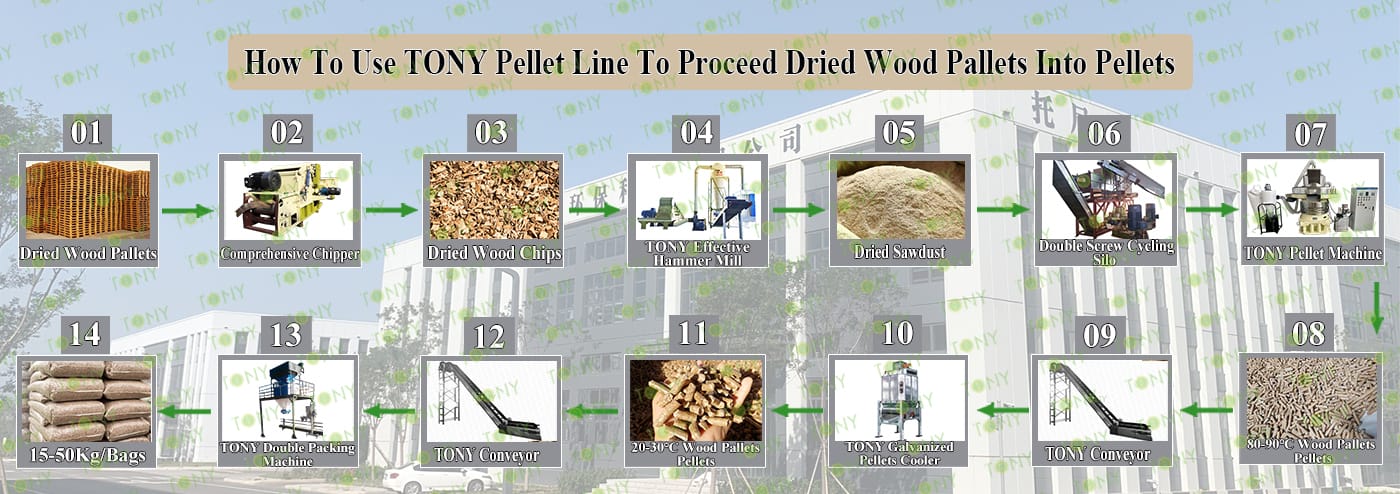

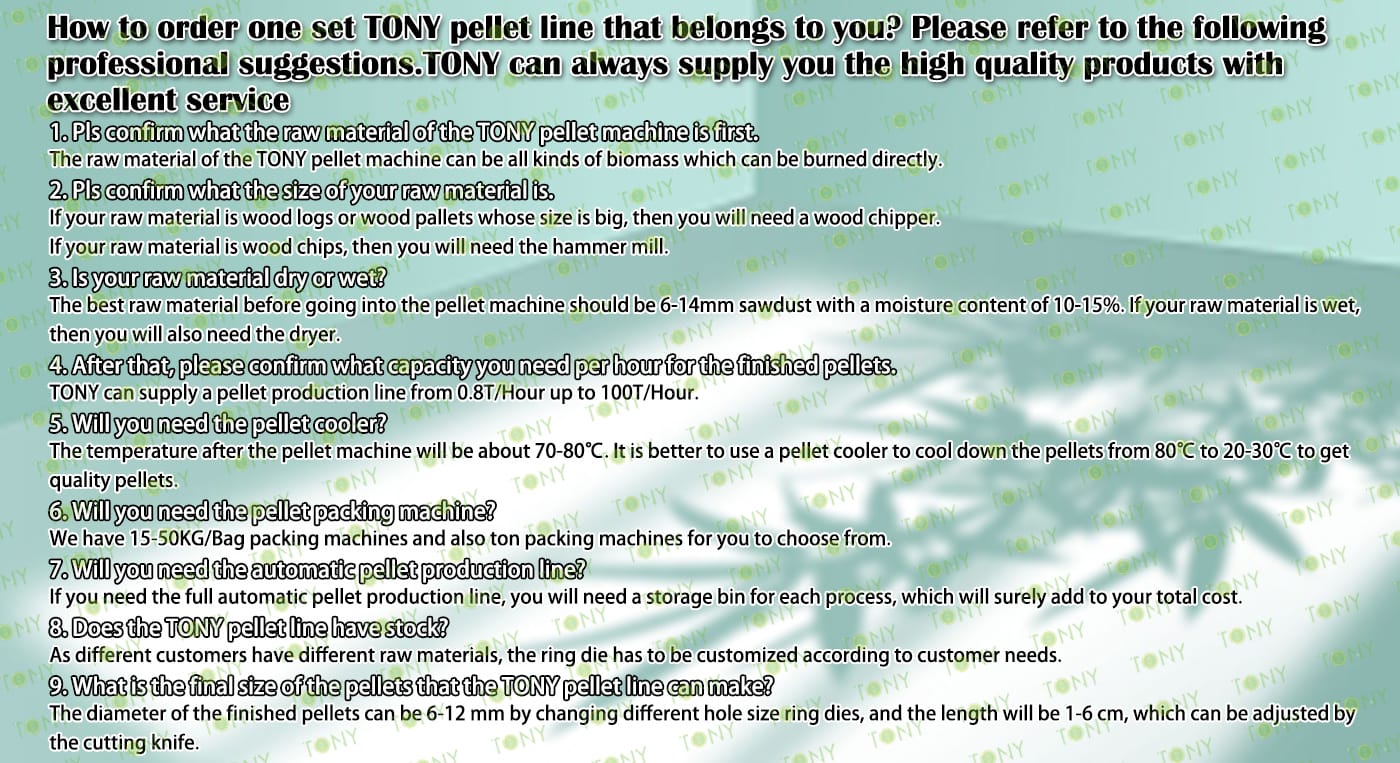

How to use the TONY pellet production line to make pellets from dried wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind dried wood pallets with width 1.3m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. |

||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Double Screw Cycling Silo |

| 1.To Grind Wood pallets Width ≤1.3m Into25-55mm Wood Chips. 2.Model: TPC1300-600-132KW With 24 Hammer Heads*1set 3.Capacity: 10-15Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*132-132KW*2sets 3.Capacity:4-5Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-11*1set 3.Capacity:9-10.5Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*3sets 3.Capacity:3-4Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:9-10.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 9-10.5Ton/Hour |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1.3 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1300-600-132KW model with 24 hammer heads*1set

C.Capacity:10-15Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

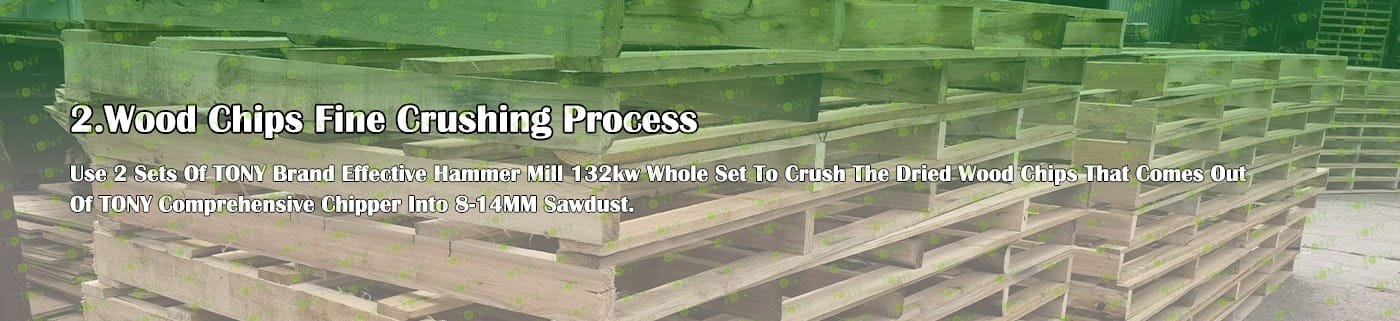

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:9-10.5Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132KW*2sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:9-10.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-220KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:9-10.5Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:9-10.5Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

How to deal with the profit fluctuations of the pallet pellet project? The sustainability of the project requires both "increasing revenue" and "reducing costs", while establishing a risk buffer mechanism:

1.Refining cost control to improve gross profit margin

(1)Control "variable costs": Raw materials (accounting for 50%-60%) are locked in price through long-term agreements; energy consumption (electricity and heat, accounting for 15%-20%) is reduced through waste heat recovery and equipment frequency conversion transformation; labor (accounting for 10%-15%) is reduced through automated equipment (such as automatic feeders and pellet packaging machines).

(2)Optimize "fixed costs": Equipment depreciation (depreciation based on 5-8 years) is diluted by improving capacity utilization; factory rent can be negotiated with the industrial park for "long-term low-price lease" (e.g., for a lease term of more than 5 years, the annual rent increase does not exceed 5%).

2.Develop a risk contingency plan to deal with emergencies

(1)Raw material supply disruption: Reserve 1-2 months of raw materials and sign emergency agreements with 2-3 "backup suppliers" (such as wood pallet recycling companies in surrounding cities) to ensure that raw materials are replenished within 72 hours.

(2)Response to market price drops: If the price of pellets drops due to competition or policy fluctuations, maintain gross profit margin and avoid losses by "reducing costs" (such as adjusting the raw material formula and increasing the proportion of low-priced straw) or "improving efficiency" (increasing production capacity and diluting unit costs).

Pallet pellet fuel (biomass pellet fuel processed from used pallets) is an environmentally friendly alternative energy source with advantages primarily in resource utilization, environmental performance, performance, and affordability. It is particularly well-suited to the current need to optimize the energy structure.

The combustion characteristics of pallet pellet fuel are compatible with a variety of heat sources, with no significant limitations on application scenarios:

1.Industrial Sector:

It can replace coal and natural gas in industrial boilers (such as steam boilers in textile and paper mills), drying equipment (such as grain and wood drying), and biomass power plants. It is particularly suitable for industrial enterprises in regions with high environmental protection requirements

2.Commercial/Residential Sector:

It can be used for central heating in commercial complexes, schools, and hospitals, as well as in home heating stoves and fireplaces. Some high-quality pellets can even be used in biomass cookers in the restaurant industry, offering ease of use and no odor.

In remote areas without grid coverage (such as mountainous areas and rural areas), pallet pellet fuel can be used in conjunction with small generators to provide electricity or as an emergency energy reserve. Its reliability is superior to that of solar and wind power (it is not affected by weather).

2025 Tony Machinery - All Rights Reserved. Map