1.The working principle of dried sawdust biomass pellet processing equipment

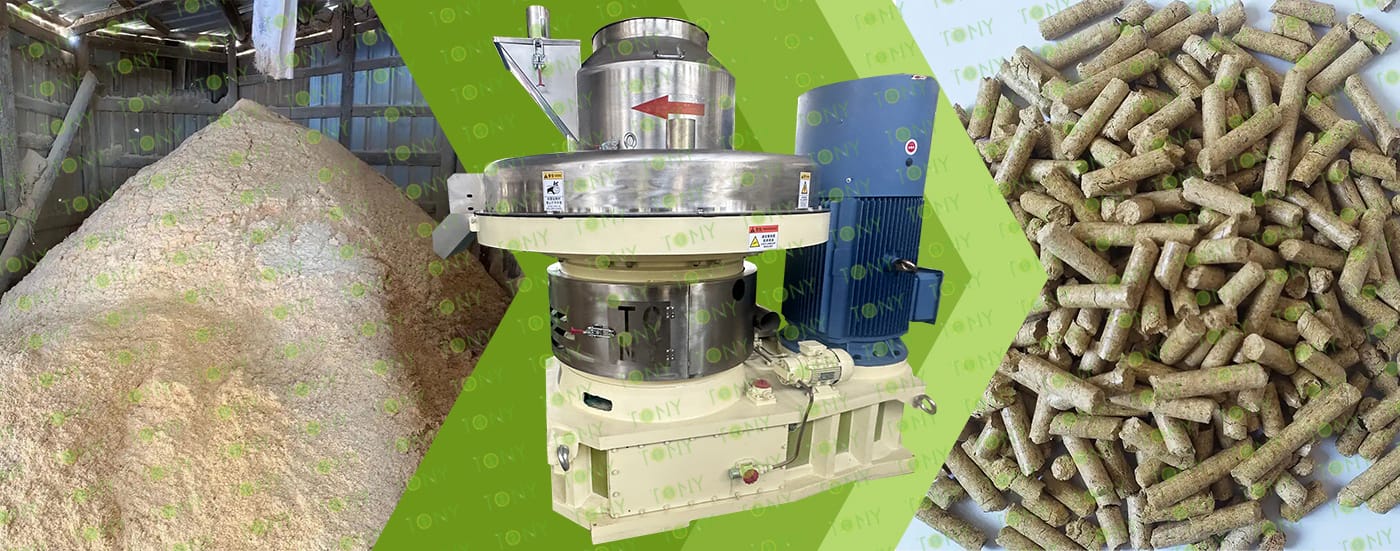

Sawdust biomass pellet equipment works by compressing sawdust into pellets through mechanical pressure.Specifically, this equipment typically consists of a rotating roller and a ring die. Sawdust and other raw materials are pre-processed in the equipment before entering the pelletizing chamber. The rotating roller squeezes the raw materials through the die holes in the ring die, forming pelletized biomass fuel. This process does not require additional adhesives; instead, mechanical pressure generates frictional heat between the raw materials, which solidifies and forms the pellets.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)High Efficiency and Energy Saving: The sawdust pellet machine features an optimized design, low power consumption, high production efficiency, and reliable operation. The mold uses an extended die for better molding results.

(2) High Degree of Automation: The sawdust pellet machine is highly automated, requiring virtually no manual supervision. During startup, the loading speed automatically adjusts according to the machine's operating current, increasing production, reducing electricity costs, and avoiding problems such as machine stalling caused by excessively fast material feeding.

(3)Environmental Protection and Energy Saving: As an environmentally friendly and energy-saving biomass energy production machine, the biomass sawdust pellet machine uses agricultural and forestry waste, such as sawdust, straw, rice husks, and bark, as raw materials. Through pretreatment and processing, it solidifies and forms high-density pellet fuel, making it an ideal alternative to kerosene. It saves energy and reduces emissions, offering significant economic and social benefits. It is a highly efficient, clean, and renewable energy source.

(4)Reasonable Structure: The sawdust pellet machine boasts a rational structure, easy maintenance, and a small footprint, making it suitable for production needs of all sizes.

(5) Wide range of applications: Finished wood pellets can be used in a variety of applications such as biomass power generation, boilers, fireplaces, and household appliances.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Heat supply: Industrial boiler/kiln fuel

Applicable scenarios: Building materials factories (cement and tile burning), paper mills (pulp drying), food processing plants (baking, sterilization heating), chemical plants (low-temperature reaction heating), and other enterprises that require a continuous and stable heat source.

(2)Power generation: Biomass power plant raw material processing

Applicable scenarios: Large-scale biomass direct-fired power plants, cogeneration projects (simultaneous power supply + heat supply)

(3)Agricultural drying: Dehydration of agricultural products

Applicable scenarios: Grain drying (rice, corn, wheat), cash crop drying (tea, tobacco, Chinese medicinal materials, dried fruits), livestock and poultry breeding bedding drying (sawdust particles can be used as bedding first, dried and then burned after use, achieving "one material for two purposes")

(4)Commercial home heating/hot water: Replacement of gas and electric heating

Heating or daily hot water supply in hotels, B&Bs, nursing homes, shopping malls, office buildings, etc.

TONY Brand 36-45Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 36-45Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 36-45 tons per hour

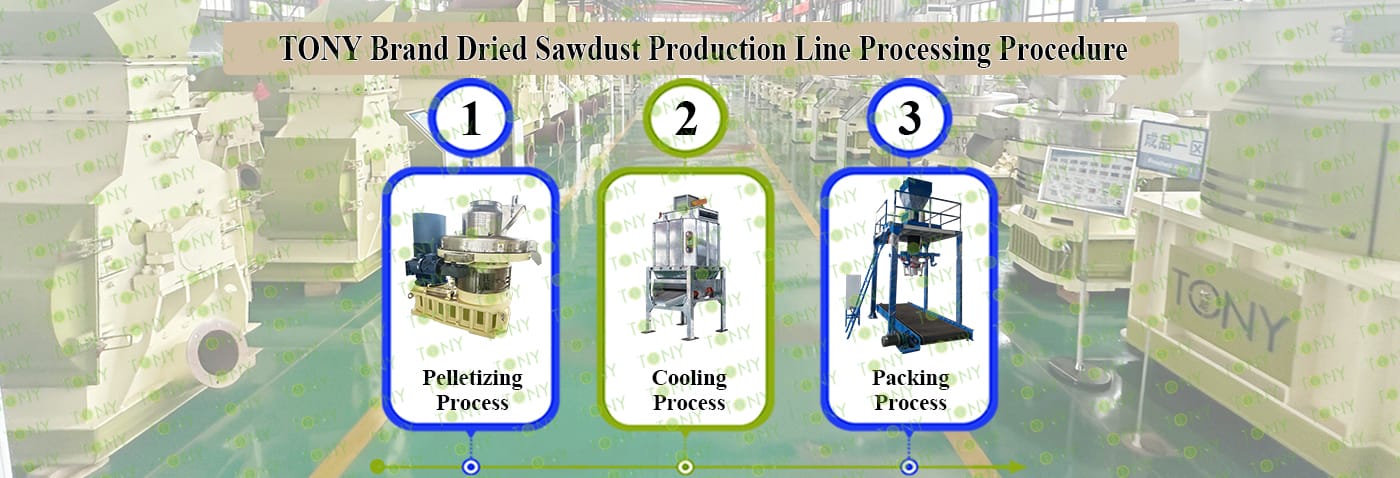

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ860-Ⅲ-280kw, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

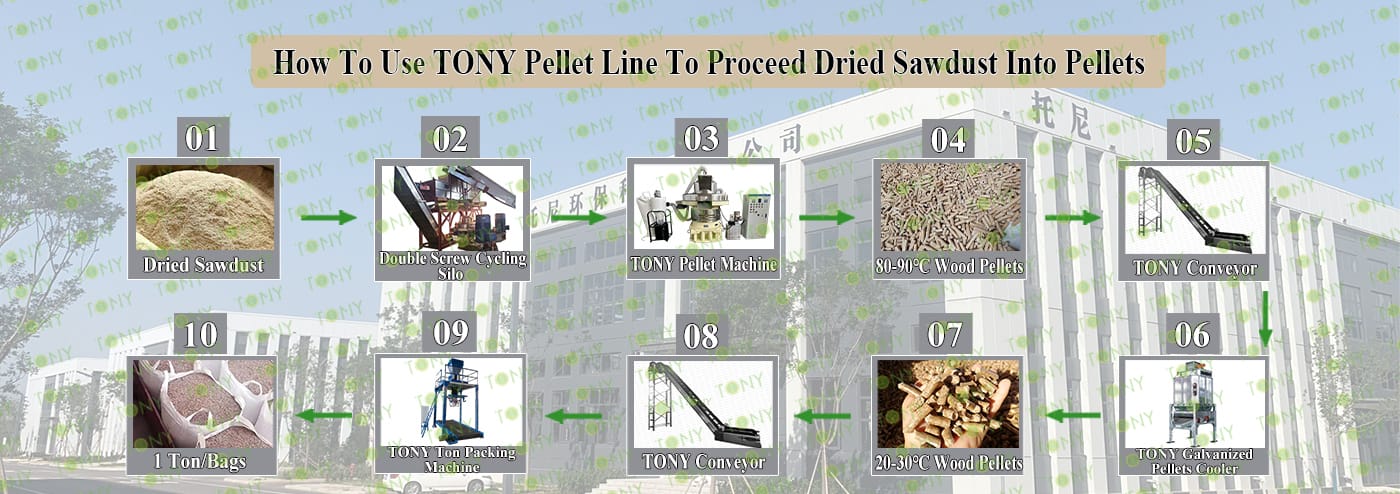

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-15*3 sets 3.Capacity:12-15 Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*9 sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*3 sets 3.Capacity:36-45Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags. 2.Model: TBD* 3 sets 3.Capacity:36-45 Ton/Hour |

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:36-45 Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-280KW*9 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:36-45 Ton/Hour.

C.TONY brand galvanized pellets cooler *3 sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:36-45 Ton/Hour.

C.TONY band ton packing machine*3 sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Project Core Positioning and Market Demand

1.Overview of the Sawdust Processing Biomass Pellets Project

Sawdust is a common waste from agricultural and forestry processing. It is abundant in source and low in cost. Processing it into biomass pellet fuel has significant economic and environmental value. This project processes sawdust through carbonization, fermentation, modification and other processes, combines it with other auxiliary raw materials, and extrudes it into high-density pellet fuel, which can effectively replace fossil fuels, reduce sulfur emissions and improve combustion efficiency.

2.Product advantages and technical indicators

(1)Core advantages

Environmental protection: The sulfur content is as low as 0.364% (better than the ultra-low sulfur coal standard of 0.5%), and no harmful gas is emitted after combustion.

High efficiency: The calorific value reaches 25.47MJ/kg (high calorific value coal range is 24.01-27.00MJ/kg), and the ash content is 7.59% (low ash coal category).

Economical efficiency: The raw material cost is low (sawdust, agricultural and forestry waste), and the process is simple and easy to operate12.

(2)Key Technical Indicators

Density: 0.943g/cm³, higher than ordinary biomass pellets

Sulfur content: 0.364%, better than ultra-low sulfur coal (≤0.5%)

Combustion calorific value: 25.47MJ/kg, reaching the level of high calorific value coal

Ash content: 7.59%, meeting the standard of low ash coal

3.Application Prospects

As a renewable energy source, biomass energy can be widely used in industrial boilers, home heating, power generation and other fields, replacing fossil fuels such as coal and gas, and the market demand is growing steadily.

1.Outstanding environmental attributes: in line with "dual carbon" and extremely low pollution

This is the core advantage of sawdust biomass pellets, which runs through the entire life cycle of "production-combustion-waste":

(1)Carbon neutral cycle: Sawdust comes from wood processing waste. The CO₂ absorbed by trees during growth is basically balanced with the CO₂ released by pellet combustion, achieving "net zero carbon emissions". Compared with coal (fossil energy, releasing ancient carbon), it can reduce net carbon emissions by more than 90%, directly contributing to the "carbon peak and carbon neutrality" goals.

(2)Low combustion pollutants: sulfur content ≤0.05%, nitrogen content ≤0.5%, almost no SO₂ and NOₓ (the main pollutants of traditional coal combustion) are produced during combustion, reducing the risk of acid rain and haze from the source; the ash content is only 2%-5% (far lower than the 10%-20% of coal), and the small amount of ash remaining after combustion can be used as organic fertilizer or building material auxiliary material, without "secondary pollution of solid waste".

(3)Reduce solid waste pollution: Turn sawdust waste that was originally incinerated and landfilled into resources, avoid PM2.5 generated by incineration and methane released by landfill (the greenhouse effect is 28 times that of CO₂), and achieve an environmentally friendly closed loop of "turning waste into treasure".

2.High ease of use: Adaptable to existing equipment and simple to operate

Compared with loose wood chips, coal and other fuels, the "practicality" of sawdust pellets has been greatly improved, lowering the threshold for use:

(1)Easy to store and transport: The pellet density reaches 1.1-1.3 tons/cubic meter, which is 5-6 times that of loose sawdust. The energy of 1 cubic meter of pellets is equivalent to 0.7-0.8 tons of standard coal. Storage only requires ordinary factory buildings/simple sheds (saving more than 50% of space). The road transportation cost is 60%-70% lower than that of loose sawdust, and it is suitable for large-scale scenarios such as industry and civil use.

(2)Fast ignition and stable combustion: The moisture content is controlled at 10%-15%, and ignition takes only 3-5 minutes (loose sawdust takes 10-15 minutes, and wet coal is difficult to ignite); the particle shape is regular, the flame is stable during combustion (furnace temperature 800-1000℃), there is no "coking or flameout" problem, and the burnout rate is over 95% (coal is about 85%-90%).

(3)Adaptability to existing equipment: Industrial boilers and residential heating furnaces only need simple modifications (such as adjusting the feed inlet and air distribution system) to be used. The modification cost is only 5%-10% of the total equipment price, which is much lower than the cost of "coal to gas" (which requires replacing the entire gas system), and no large-scale investment is required.

2025 Tony Machinery - All Rights Reserved. Map