1.The working principle of dried sawdust biomass pellet processing equipment

Core Forming: Fiber reorganization and densification under mechanical extrusion is a key step in converting sawdust into pellets. The core principle is "high-pressure extrusion + wood fiber self-bonding." Lignin in the sawdust (a natural adhesive that softens under pressure and frictional heat) works together with moisture to tightly bind the fibers, forming pellets with a fixed shape.

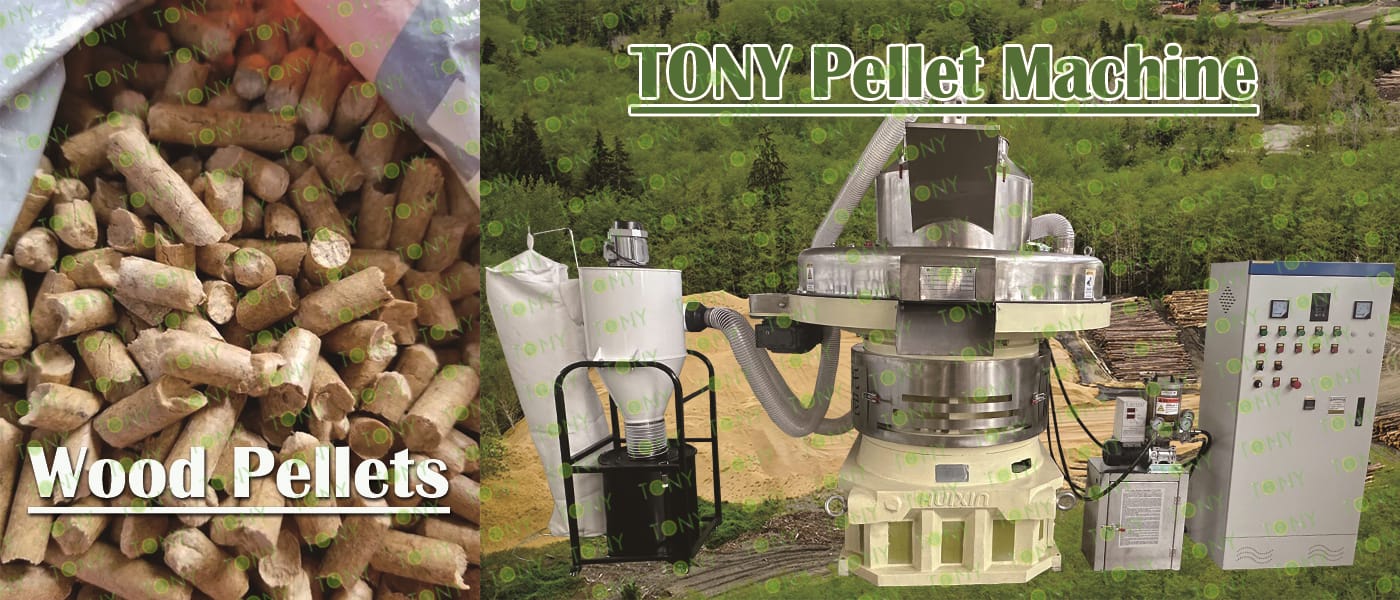

Core component: The forming machine—the "ring die pellet machine"—is more adaptable to wet materials and less prone to clogging.

During the extrusion process, intense friction between the sawdust and the inner wall of the die and the surface of the rollers generates frictional heat of 60-90°C. This temperature softens the lignin in the sawdust (the softening point of lignin is approximately 70-100°C). Simultaneously, the moisture forms "liquid bridges" that bind the dispersed fibers together, providing a foundation for subsequent shaping.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)High efficiency and energy saving: For example, pellet machines have low energy consumption, high output, compact process, small footprint, good dust removal effect, low noise, and a good production environment. A production line only requires 2-3 workers and can be operated automatically, reducing labor costs.

(2)Low maintenance cost and easy operation: Sawdust pellet machines have low maintenance costs and do not require grease injection. Non-professionals do not need much time to complete maintenance. The wearing parts are practical and durable. The roller bearings are made of international brands and are not easy to damage. They are easy to operate and do not require professional operation.

(3)Raw material processing and environmental protection: The moisture content of the raw materials before pellet processing needs to be controlled at about 10-15%. Therefore, in actual production, drying equipment may be required. Sawdust pellets contain few harmful substances and the content of harmful gas components during combustion is extremely low. The ash after combustion can be used as potash fertilizer, which meets environmental protection requirements.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Biomass energy field

As a clean fuel: The processed sawdust pellets have high calorific value and high combustion efficiency, and their sulfur, ash and nitrogen content are much lower than fossil fuels such as coal and oil. They can be directly used for fireplaces and boiler heating, or as fuel for biomass power plants, achieving energy substitution and emission reduction goals.

Energy conversion advantages: Compared with traditional fuels, sawdust pellets are smokeless and odorless when burned, with low pollutant emissions, which meets the needs of modern green energy, especially in Europe and America where the demand for biomass energy is relatively high.

(2)Animal feed field

Feed pellet production: Sawdust pellets processed by sawdust pellet machines can be used as high-quality feed for poultry and livestock breeding, improving feed utilization and animal production efficiency. Some equipment is specially designed for feed pellets to meet the process requirements of feed processing.

(3 Environmental protection and resource recycling field

Wood waste processing: The equipment uses wood chips, sawdust, branches and other wood processing waste as raw materials, converting waste that would have been discarded into high-value pellet products, achieving resource recycling and reducing environmental pollution.

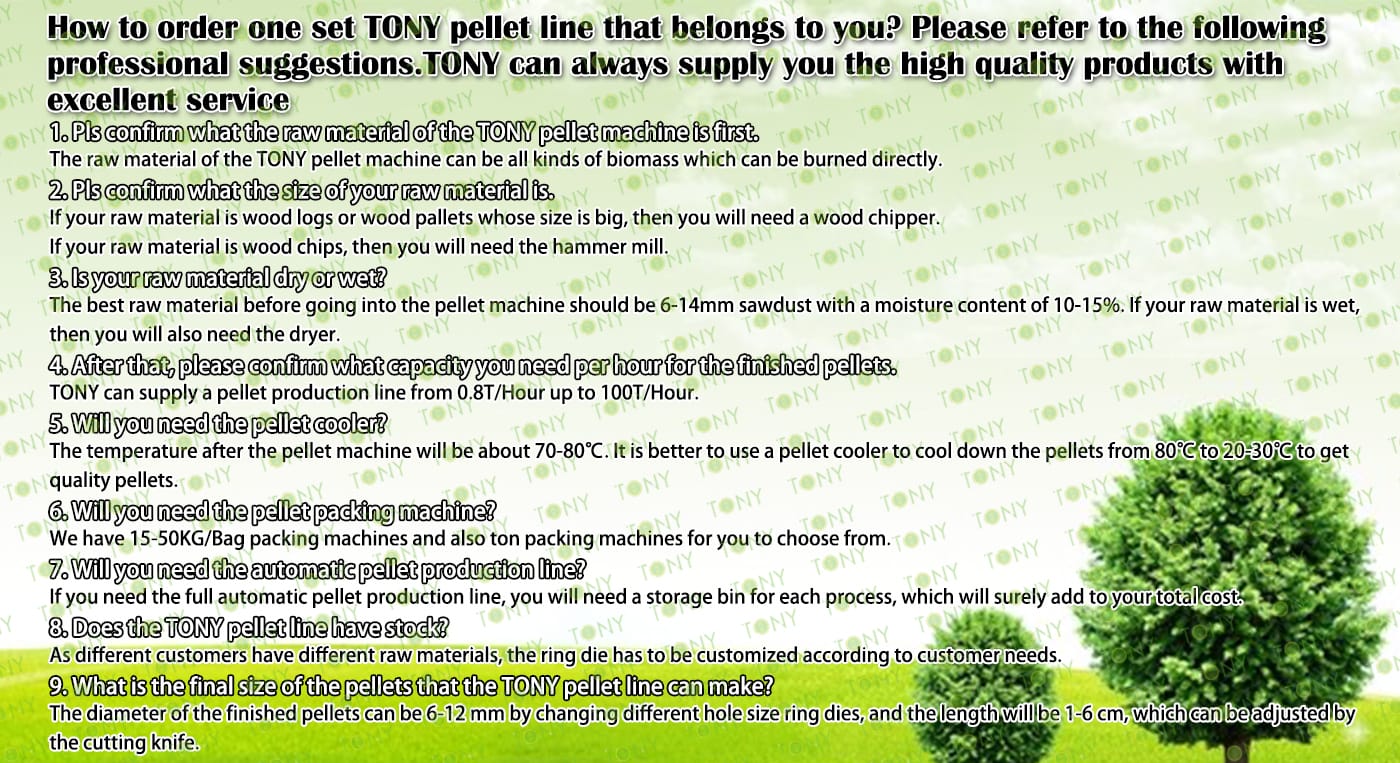

TONY Brand 28-35Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 28-35Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 28-35 tons per hour

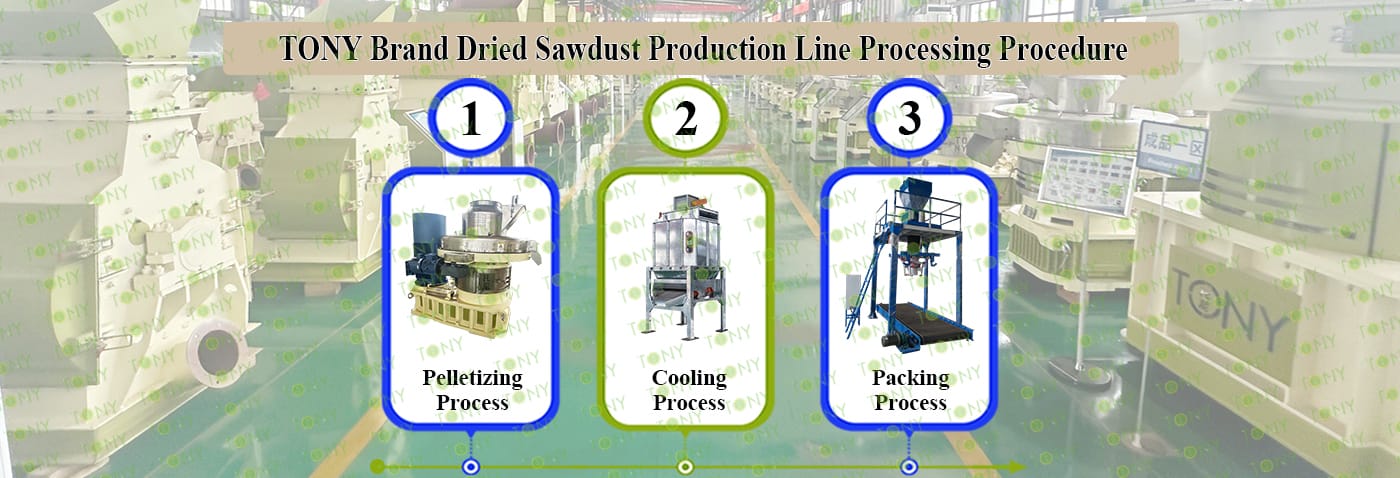

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ860-Ⅲ-280kw, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

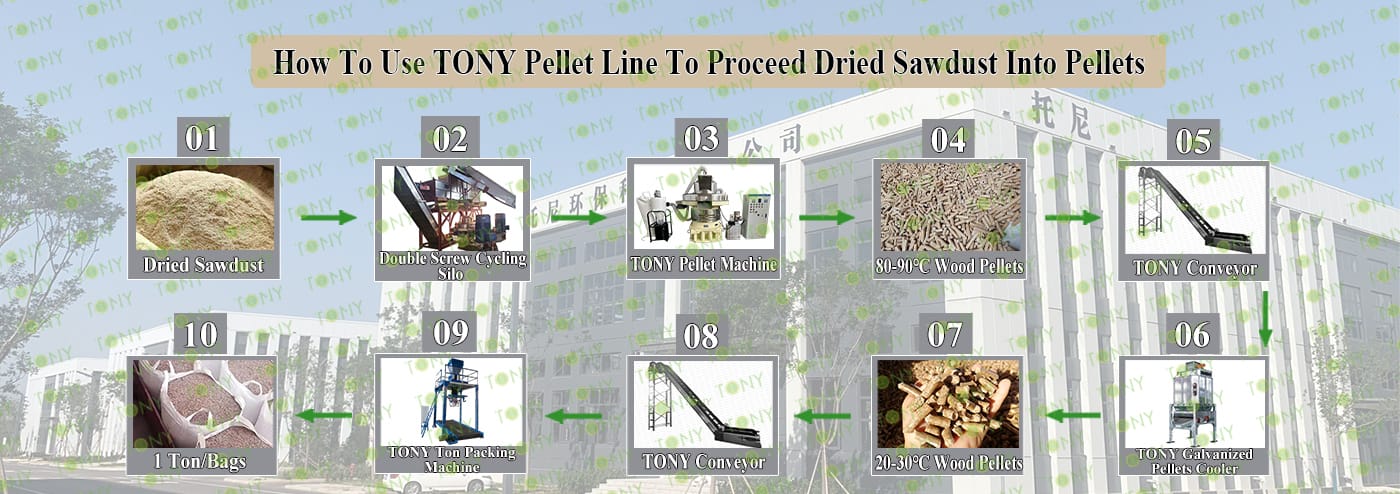

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-18*2sets 3.Capacity:18Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*7sets 3.Capacity:4-5Ton/Hour/Set |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*2 sets 3.Capacity:28-35Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags. 2.Model: TBD* 2sets 3.Capacity:28-35Ton/Hour |

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:28-35Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-280KW*7 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:28-35Ton/Hour.

C.TONY brand galvanized pellets cooler *2 sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:28-35Ton/Hour.

C.TONY band ton packing machine*2 sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

1.Project Core Positioning and Market Demand

(1)Project Positioning

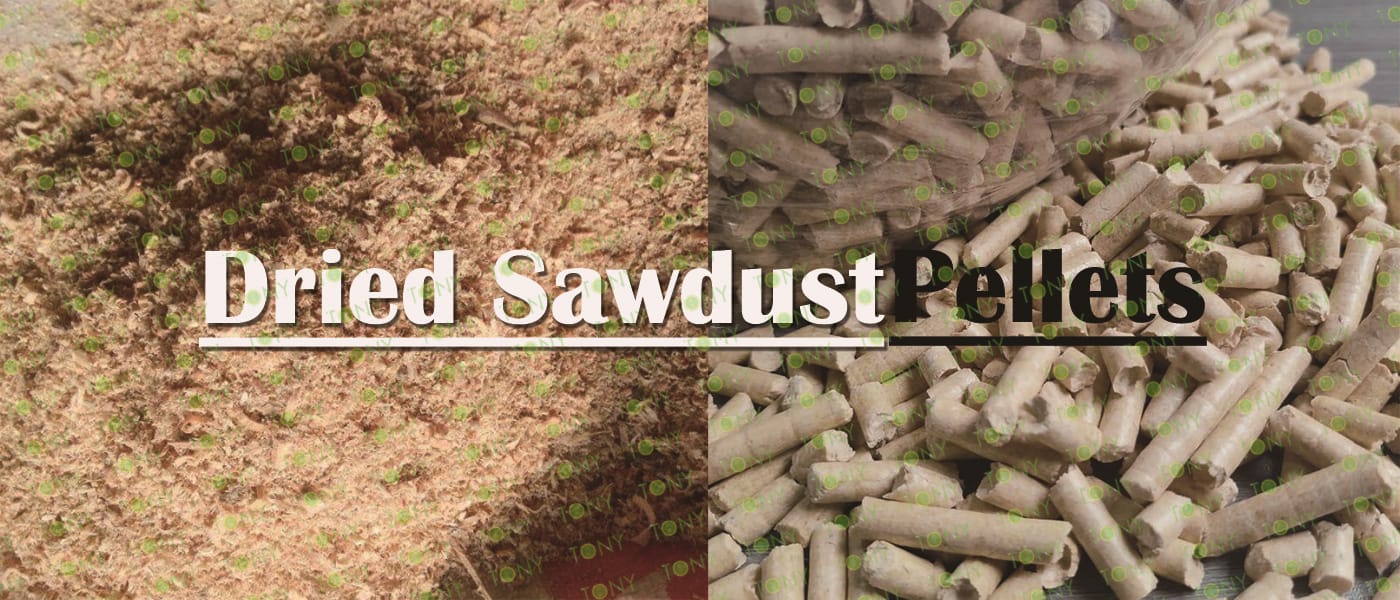

Core product: cylindrical sawdust biomass pellets with a diameter of 6-10mm and a length of 10-30mm (moisture content 10%-15%, calorific value 4200-4800 kcal/kg, ash content 2%-5%).

Core Value: Realize "waste resource utilization" (sawdust → fuel) and "energy cleanliness" (replacing coal and natural gas), and adapt to multiple scenarios such as industrial heating, civil heating, and agricultural drying.

(2)Target Groups:

Industrial: boiler heating and production line drying needs of small and medium-sized factories (food, building materials, textiles);

Civilian: clean heating in winter and fireplace heating in urban households;

Agricultural: drying and processing needs of grain, tea, medicinal materials, fruits and vegetables.

2.Market demand background

(1)Policy-driven: Biomass pellets are included in the government procurement catalogues of many places as "zero-carbon fuel" (such as schools, hospitals, and nursing homes with priority procurement);

(2)Cost-driven: The unit heat cost of biomass pellets is only 1/2 of natural gas and 1/3 of liquefied gas, and enterprises have a strong demand for cost reduction;

(3)Resource-driven: Sawdust raw materials are sufficient and low-priced, providing a stable supply for the project.

3.Project suitable groups and core advantages

(1)Suitable groups

Wood processing industry practitioners (such as furniture factory and panel factory owners, who can use their own sawdust raw materials to reduce costs);

Small and medium-sized investors (seeking "low-risk, stable return" projects, such as returning entrepreneurs and county entrepreneurs);

Energy traders (expanding clean fuel categories to meet the long-term heating needs of industrial customers).

(2)Core advantages of the project

Low threshold: mature production technology, simple equipment operation, no professional technical background is required, and the core process can be mastered in 3-5 days;

Quick effect: the production line installation and commissioning cycle is short (production can be put into operation in 1-2 months), and the product demand is rigid, and there will be stable orders as soon as production starts;

Sustainability: the raw material (sawdust) is a sustainable waste, the market (clean energy demand) exists for a long time, and the project life cycle can reach more than 10 years;

Environmental protection: no wastewater or exhaust gas emissions are generated throughout the entire process (dryer exhaust gas can be treated by dust removal equipment and meet emission standards), in line with national environmental protection policies, and without policy risks.

The physical and chemical properties of sawdust biomass pellets are key to their combustion efficiency, which surpasses that of loose sawdust and approaches that of traditional fossil fuels. This is primarily reflected in the following three key aspects:

1.Stable calorific value and high energy density

The lower calorific value of sawdust pellets is typically 4200-4800 kcal/kg (this varies slightly depending on the wood type; hardwood sawdust pellets have a higher calorific value, reaching 4600-4800 kcal/kg), approaching that of Class II bituminous coal (4500-5500 kcal/kg). Furthermore, due to the "drying (moisture content controlled at 10%-15%) + compression" process during processing, the calorific value is evenly distributed, avoiding the "calorific value loss" associated with excessive moisture content in loose sawdust (which often exceeds 20%) (each 1% increase in moisture reduces the calorific value by approximately 50 kcal/kg).

2.Excellent combustion completeness and low heat loss

The pellets have a regular shape (6-10mm diameter, 20-30mm length) and a dense structure. This allows for sufficient air contact with the pellet surface during combustion. The combustion process does not cause "coking" like coal (the ash content of sawdust pellets is only 2%-5%, far lower than the 10%-20% of coal), nor does it cause "accumulation and smoldering" like loose sawdust. The final burnout rate can reach over 95% (coal burnout rates are approximately 85%-90%, loose sawdust approximately 80%-85%), with minimal unburned "charcoal residue" and significantly reduced heat loss.

3.Fast ignition and stable combustion, reducing startup losses.

The pellets have a low moisture content and a moderate surface area (smaller than pulverized coal, making them less prone to deflagration; larger than lump wood, making them easier to ignite). Ignition takes only 3-5 minutes (loose sawdust takes 10-15 minutes, and wet coal can be difficult to ignite). Furthermore, the combustion process is stable, with minimal temperature fluctuations (the furnace temperature can remain stable at 800-1000°C), avoiding excessive heat loss caused by repeated ignition or fluctuating fires.

2025 Tony Machinery - All Rights Reserved. Map