1.The working principle of dried sawdust biomass pellet processing equipment

The overall principle of dry sawdust processing equipment can be summarized as follows: First, the dry sawdust is pre-treated to meet the requirements for pelletizing (removing impurities and adjusting moisture content). Then, high-pressure extrusion and frictional heating in the pelletizing machine soften and bind the lignin in the sawdust, forming high-density pellets. Finally, post-processing ensures that the pellets are stable, uniform, and meet quality standards for shipment. This entire process uses no chemical additives; it relies solely on physical processes and the natural lignin in the wood for pellet formation. This ensures the environmental friendliness of the final product and the stability of the processing, making it the core technology supporting the resource utilization of dry sawdust.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)Outstanding Processing Efficiency: Equipped with a high-pressure compression system, it can compress loose sawdust into pellets with a density of 1.1-1.3 t/m³, achieving a high pelletizing rate. A temperature control system prevents pellet cracking by regulating the processing temperature, improving the finished product quality and reducing energy consumption, thus meeting the requirements for efficient production.

(2)Stable Structure and Operation: The modular design allows for flexible configuration of different components to suit various production capacities (from several hundred kg to several tons per hour). Wear-resistant alloy materials are used for critical components (such as rollers and molds) to extend their lifespan. Some models feature a PLC control system for automated operation, minimizing manual intervention. A robust sealing design reduces the probability of malfunctions, and the equipment is easy to start and stop, suitable for both intermittent and continuous production.

(3)Environmental Protection and Safety: Most machines are equipped with dust collection systems (such as pulse jet dust collectors) to reduce dust pollution during processing. Some models also feature noise reduction design, complying with environmental standards. Overload protection and emergency stop buttons ensure safe operation by automatically shutting down the machine in case of malfunctions.

3.Application scenarios of dried sawdust biomass pellet processing equipment

(1)Agriculture and Planting: Preparation of Organic Substrates/Fertilizers,

In agriculture, forestry, and edible mushroom cultivation, processed sawdust can serve as a functional substrate, enhancing cultivation efficiency:

Edible Mushroom Cultivation: Dry sawdust can be processed into uniform granules (or pulverized and refined) and mixed with bran, gypsum, etc., to create a growth medium for large-scale cultivation of shiitake, black fungus, and oyster mushrooms. The porous structure of sawdust provides good aeration, beneficial for mycelial growth.

Organic Fertilizer Carrier: Dry sawdust granules can be mixed with animal manure, straw, etc., and fermented to produce organic compound fertilizers. Sawdust regulates the carbon-nitrogen ratio of the fertilizer, improving water retention and nutrient-holding capacity, suitable for fruit and vegetable cultivation and seedling nurseries.

Soil Conditioner: Processed, fine sawdust granules can be directly mixed into sandy or heavy clay soils to improve soil structure, increase aeration, and enhance organic matter content, particularly suitable for soil improvement in greenhouses and orchards.

(2)Pet Supplies and Packaging: Production of Functional Additives,

With the growth of the pet industry and the demand for environmentally friendly packaging, processed sawdust products are expanding into various consumer applications:

Pet Bedding: Dry sawdust can be processed into dust-free, absorbent granules for use as bedding for cats (mixed with bentonite or used alone), hamsters, rabbits, and other small pets. It is highly absorbent, easy to clean, and biodegradable.

Eco-friendly Packaging Filler: Sawdust can be processed into lightweight granules or chips to replace traditional foam or bubble wrap for cushioning electronic products and ceramics during transportation. It is biodegradable, reducing plastic waste.

TONY Brand 20-25Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 20-25Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 20-25 tons per hour

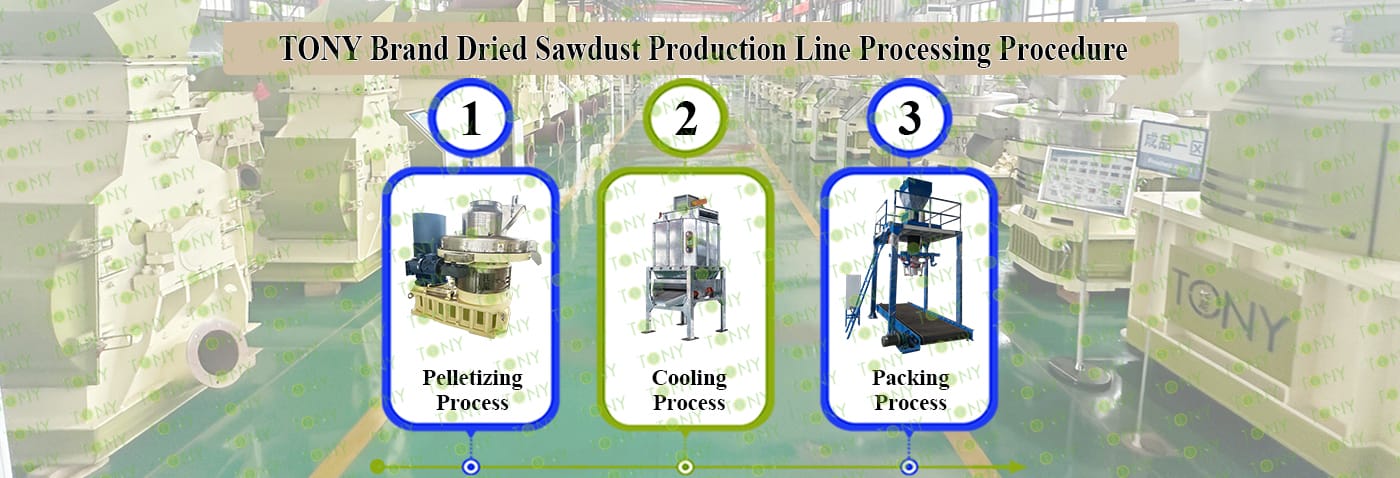

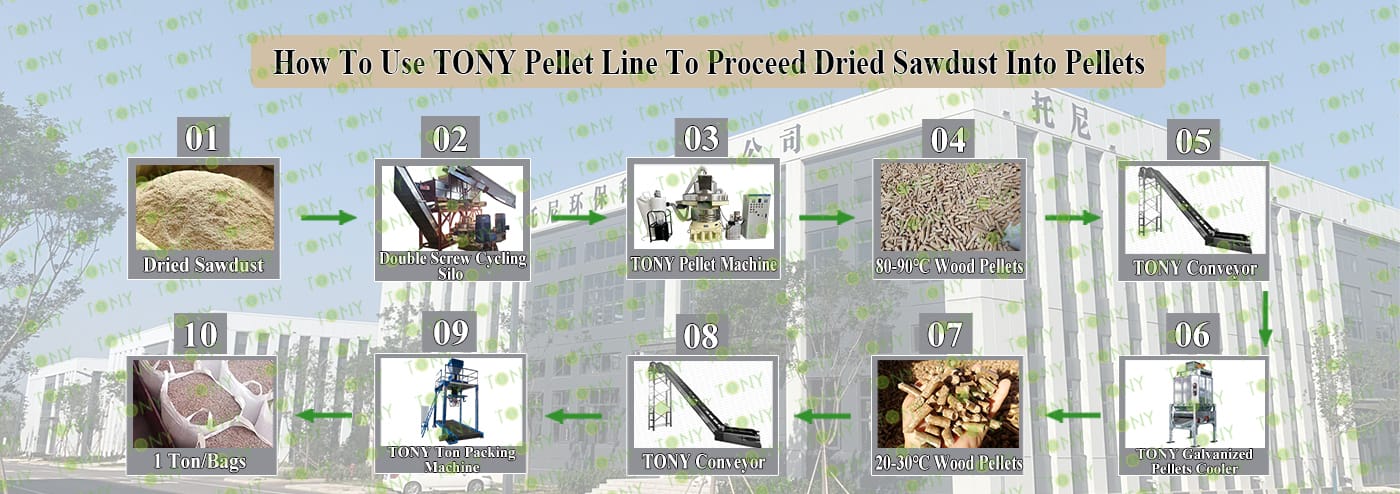

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ860-Ⅲ-280KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-25*1set 3.Capacity:20-25Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*5sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:20-25Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*1set 3.Capacity:20-25Ton/Hour |

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:20-25Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-280KW*5sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:20-25Ton/Hour.

C.TONY brand galvanized pellets cooler *2sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:20-25Ton/Hour.

C.TONY band ton packing machine*2sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

The dry sawdust processing biomass pellet project utilizes dry sawdust waste generated by the forestry and wood processing industries. Through specialized equipment, it transforms this waste into high-density, high-calorific value biomass pellets. This project addresses the environmental issue of sawdust waste accumulation while producing a clean fuel as an alternative to fossil fuels. It offers environmental, economic, and social benefits, making it a hot area for entrepreneurship and investment in the biomass energy sector.

1.Raw Material Base: Abundant and Low-Cost

The raw material for this project is dry sawdust, sourced primarily from:

(1)Wood processing plants and furniture factories: Sawdust generated from cutting and sanding solid wood. Most companies pay to dispose of this waste, allowing the project to acquire it at a low cost or even for free;

(2)Forestry operations: Dry sawdust from crushed branches and trunks;

(3)Manufactured board factories: Sawdust generated as waste during board processing.

The raw material is low-cost, has a stable supply, and the transportation radius is typically within 50-100 km, reducing logistics costs.

2.Product Positioning: Clean Biomass Pellet Fuel

The core product is biomass pellet fuel, with clearly defined specifications:

(1)Physical properties: Density 1.1-1.3 t/m³, resistant to breakage, easy to store and transport;

(2)Combustion performance: Calorific value 3500-5000 kcal/kg, ash content <5%, sulfur content <0.05%, no black smoke during combustion, and pollutant emissions far lower than coal, complying with national "reduce coal, reduce carbon" environmental policies.

In terms of raw materials and production, they boast a broad and low-cost source. Relying on waste sawdust from wood processing plants and furniture factories, they eliminate the need for additional farmland or the consumption of high-quality resources, resulting in a low raw material price. Furthermore, the production process is chemical-free, relying solely on the sawdust's own fibers bonded together under high temperature and high pressure, preserving the product's natural properties. Furthermore, their uniform shape makes them easy to store and stack, reducing warehouse space and transport costs by 30%-50%.

In terms of performance, their high combustion efficiency and low pollution levels are their key advantages: Their combustion efficiency exceeds 85%, far exceeding that of traditional coal, enabling rapid heat release. Their ash content after combustion is only 2%-5%, and their sulfur content is less than 0.05%, significantly lower than that of coal. Pollutants such as sulfur dioxide and dust are minimal, meeting national environmental standards and offering a direct alternative to fossil fuels such as coal and natural gas.

In terms of application and value, it has a wide range of applications, meeting the heating needs of industrial boilers and power plants, as well as household heating and agricultural greenhouse heating. It is compatible with most existing combustion equipment, eliminating the need for major retrofits. It also offers stable economic returns and can benefit from renewable energy subsidies, tax exemptions, and other policies, combining environmental benefits with economic value.

2025 Tony Machinery - All Rights Reserved. Map