Project Brief Introduction:

1.Product:Dried Sawdust Pellet Line

2.Capacity: 12-14T/Hour

3.TONY Brand 12-14Ton /Hour Dried Sawdust Pellet Line Project Process

4.Main Machine:TONY Pellet Machine TYJ860-III-220KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 960KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D

1.The working principle of dried sawdust biomass pellet processing equipment

The core principle of wood pellet processing equipment, such as wood pellet mills, is to convert biomass feedstock into high-density pellet fuel through mechanical compression. The basic process involves three steps: pelletizing, cooling, and packaging. For example, in a ring die pellet mill, a motor connected to a reducer via a coupling drives the ring die. The feedstock enters the compression zone under gravity, where rollers squeeze the material into the ring die holes. After the pellets are formed in the die, they are cut into fixed lengths by a cutter.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)High efficiency and energy saving:

For example, pellet machines have low energy consumption, high output, compact process, small footprint, good dust removal effect, low noise, and a good production environment. A production line only requires 2-3 workers and can be operated automatically, reducing labor costs.

(2)Low maintenance cost and easy operation:

Sawdust pellet machines have low maintenance costs and do not require grease injection. Non-professionals do not need much time to complete maintenance. The wearing parts are practical and durable. The roller bearings are made of international brands and are not easy to damage. They are easy to operate and do not require professional operation.

(3)Raw material processing and environmental protection:

The moisture content of the raw materials before pellet processing needs to be controlled at about 10-15%. Therefore, in actual production, drying equipment may be required. Sawdust pellets contain few harmful substances and the content of harmful gas components during combustion is extremely low. The ash after combustion can be used as potash fertilizer, which meets environmental protection requirements.

3.Application scenarios of dried sawdust biomass pellet processing equipment

Processing equipment provides fuel for factory boilers and kilns (replacing coal and oil), such as steam boilers in textile and food processing plants, and heating kilns in the ceramics and building materials industries. Stable pellet production ensures energy supply.

(1)Power Generation:Biomass power plants require large quantities of standardized pellets as fuel. Large-scale processing equipment can meet the power plant's stringent requirements for pellet calorific value and density, ensuring efficient combustion and stable power generation.

(2)Residential Heating:For pellets used in home fireplaces and space heaters, processing equipment must control pellet size and hardness to accommodate residential combustion equipment. The equipment's refined production capabilities directly impact the user experience of these pellets.

(3)Environmental Protection and Waste Management:In waste and sewage treatment plants, processing equipment converts organic waste (such as sludge and food waste) into fuel pellets for resource recovery. Corrosion-resistant and clogging-resistant designs are crucial.

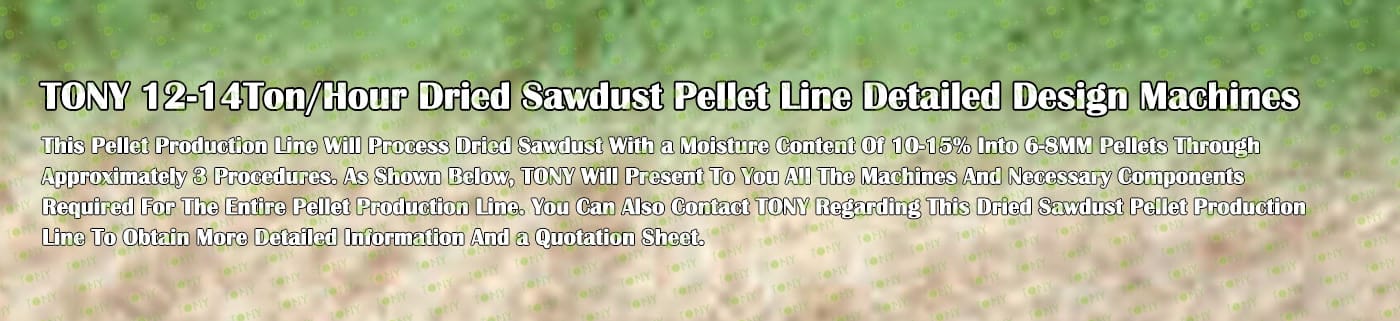

TONY Brand 12-14Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 12-14Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 12-14 tons per hour

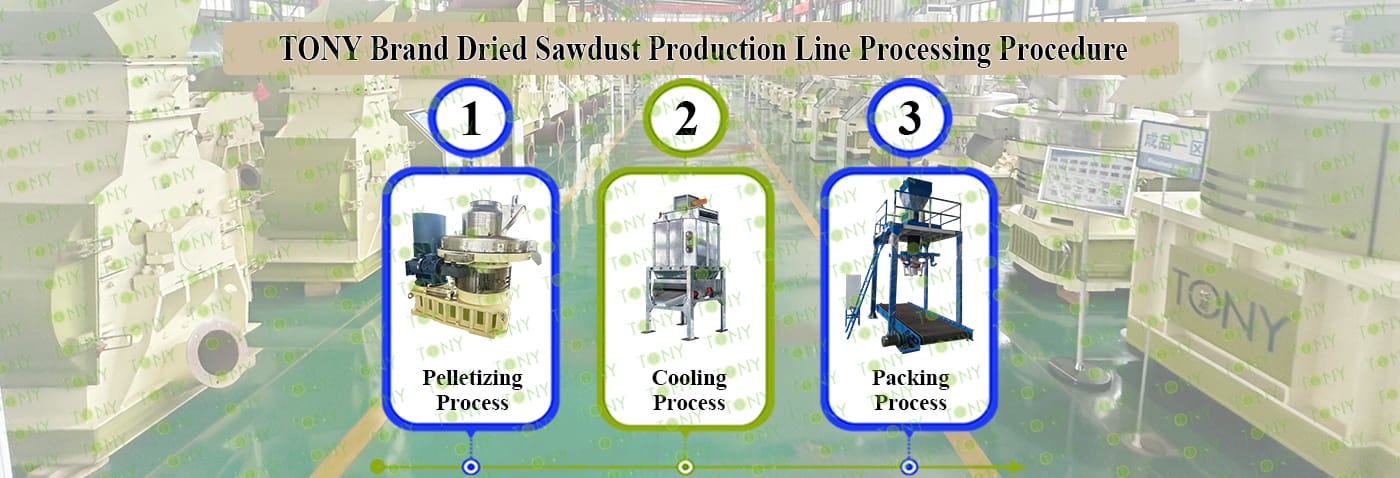

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ860-Ⅲ-220KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

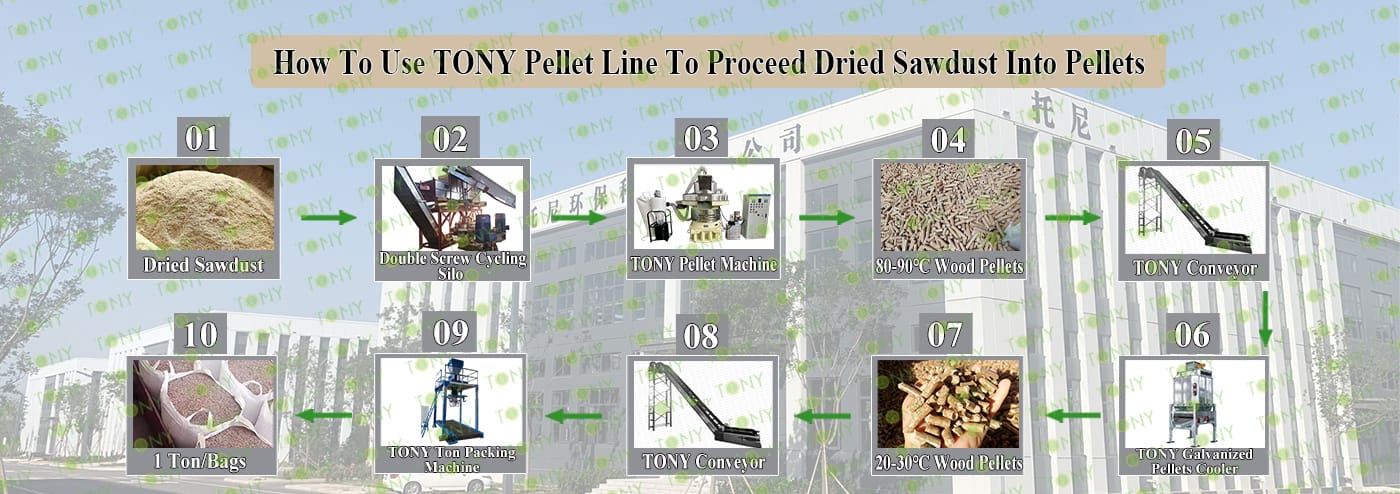

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-14*1set 3.Capacity:12-14Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*4sets 3.Capacity:3-4Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:12-14Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. |

三维图

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:12-14Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-220KW*4sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:12-14Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:12-14Ton/Hour.

C.TONY band ton packing machine*1set

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

For investors, it is better to give priority to regions with abundant raw materials and strong policy support. By locking in raw material supply, improving production capacity utilization and expanding high-end markets (such as exports and civilian use), the return cycle can be further shortened and rapid profits can be achieved.

Wood Pellet Processing Investment Costs

1.Equipment Investment:

Equipment investment varies significantly depending on the project scale and equipment selected. A small semi-automatic production line may cost only tens to hundreds of thousands of yuan, while a large fully automated production line can cost millions or even more.

2.Plant and Site Costs:

You need to select an appropriate plant and site based on your production scale. Rental or construction costs vary by region.

Raw Material Procurement and Transportation Costs: Raw material costs are affected by factors such as region, season, and raw material type, while transportation costs are related to the raw material sourcing radius and product sales range.

3.Environmental and Other Expenses:

These include the investment and operating costs of environmental protection equipment, utilities, and employee salaries.

1.Environmentally friendly features

(1)Low pollution emissions: The sulfur and phosphorus content during combustion is extremely low, and the concentration of SO₂ and NOx in the flue gas is much lower than that of coal. It will not produce acid rain, and CO₂ emissions are zero (because plants absorb CO₂ during growth)

(2)Ash utilization: Ashes after combustion are rich in organic potassium and can be recycled as high-efficiency organic fertilizer

2.Economical

(1)Wide range of raw materials: waste such as wood processing waste and crop straw can be used, and the production cost is lower than traditional fossil fuels.

(2)Substitution benefits: Replacing coal can save about 20% to 30% of fuel costs

3.Wide range of application scenarios

(1)Industrial applications: Widely used in boiler heating, power generation and industrial production, such as textile factories, food factories, etc.

(2)Civil heating and living energy: Wood pellets have high combustion efficiency, are easy to store and use, and are safe and hygienic.

(3)Biomass industrial boiler: As the main fuel for industrial boilers, it replaces coal, heavy oil and natural gas to solve environmental pollution problems.

2025 Tony Machinery - All Rights Reserved. Map