1.图片

Project Brief Introduction:

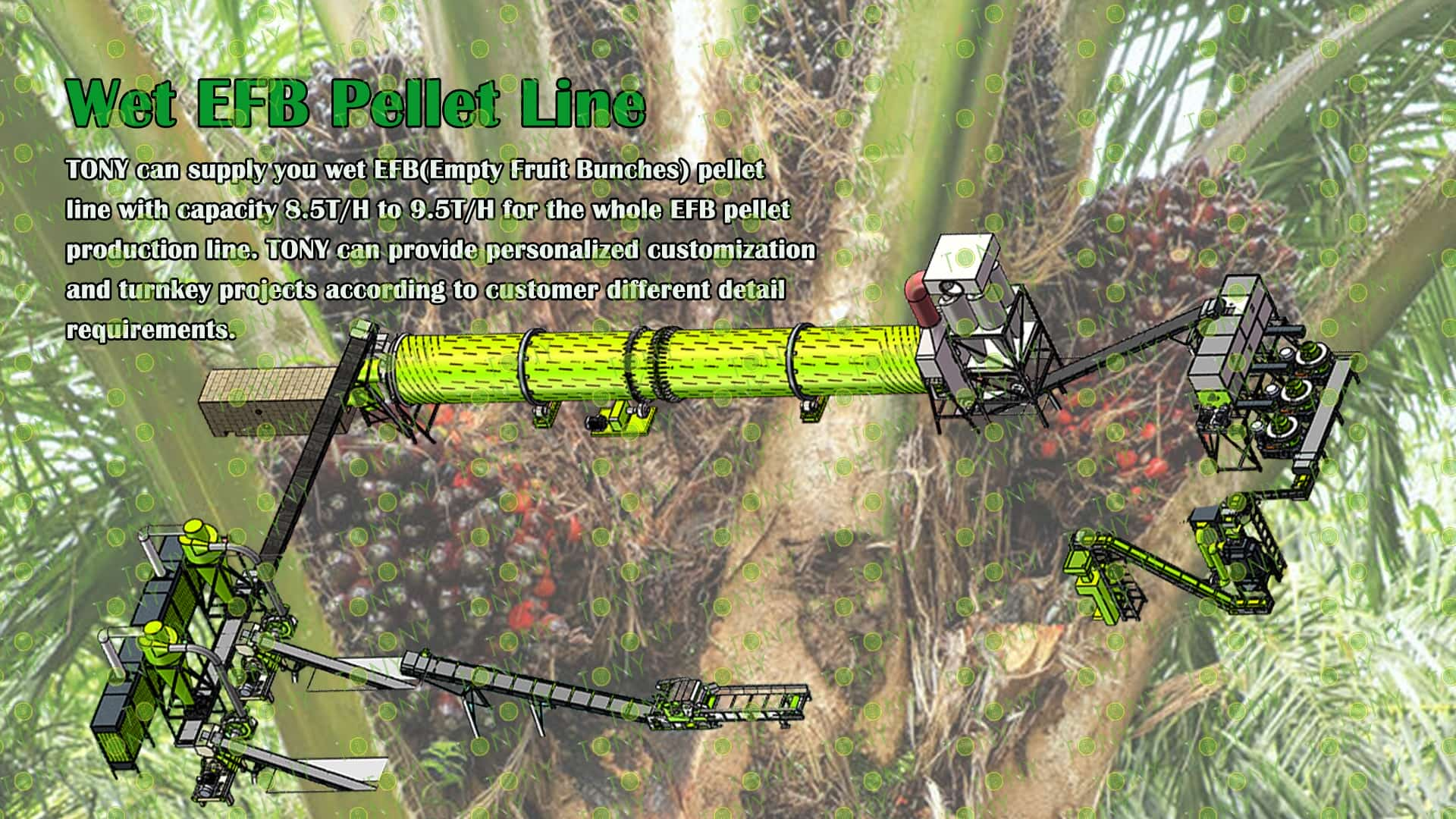

1.Product:Wet EFB Pellet Line

2.Capacity: 8.5-9.5 T/Hour

3.TONY Brand 8.5-9.5 Ton /Hour Wet EFB Pellet Line Project Process

4.Main Machine:Comprehensive Chipper, Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-185KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About kw

6.Need Area: About 1200 ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

原材料图+颗粒机图片

1. The working principle of wet EFB biomass pellet processing equipment

The core of palm kernel processing equipment lies in its "pre-treatment - molding - cooling - packaging" process, which transforms palm shells, fibers, and other raw materials into standardized pellets. The key principles revolve around adapting to the characteristics of the raw materials and ensuring pellet stability. During pre-treatment, the raw materials are crushed to 4-14mm using a crusher, and then dried to a moisture content of 10-15% using a dryer, preparing them for molding.

Molding is the core process. A vertical ring die pelletizer uses high pressure between the rollers and the ring die to extrude the raw material through the die holes. The natural lignin in the palm material acts as a binder. After extrusion, the pellets are cut to 2-5cm lengths. In the cooling stage, a counter-current cooler reduces the temperature of the hot pellets (70-90°C) to room temperature, simultaneously reducing moisture content to below 10% to prevent clumping and mold growth. Finally, an automatic weighing and packaging machine completes the process. Different types of pellets have slight variations; fuel pellets require higher molding pressure and no binders, while horticultural pellets require lower pressure and can include environmentally friendly additives.

2. Characteristics of wet EFB biomass pellet processing equipment

(1) Full-process integration capability: The crushing and pelletizing equipment forms a continuous production line, covering the crushing, screening, pelletizing, cooling and other links of raw materials. It is suitable for a variety of biomass raw materials such as bamboo, straw, sawdust, FEB, etc. The finished products can be used in power generation, wood-based panels, papermaking and other fields.

(2) Environmental protection and economy: By processing agricultural and forestry waste such as wet EFB, resource waste is reduced. Pellet fuel has high combustion efficiency and low smoke, which is in line with the trend of energy conservation and environmental protection. The equipment is easy to operate and has low maintenance costs, which is suitable for large-scale production or individual businesses.

(3) Application scenarios and industry adaptability: The processed EFB pellets can be used as biomass fuel for home heating, industrial boilers or biomass power plants; the crushed EFB can also be directly used in papermaking or wood-based panel production, realizing the diversified utilization of raw materials.

3. Application scenarios of wet EFB biomass pellet processing equipment

In the horticulture and landscaping sector, palm fiber granules produced by this equipment can be used as a mulch for potted plants and green spaces (improving moisture retention, nutrient retention, and suppressing weeds), or as a potting mix (mixed with peat moss to enhance aeration). They are suitable for nurseries, municipal landscaping, and home gardening. Some equipment can even produce pest-resistant granules by adjusting parameters, catering to high-end landscaping needs. In the industrial filling sector, the processed palm fiber granules can serve as an environmentally friendly filling material for mattresses and sofas (replacing traditional synthetic fibers), or as a filtration material for industrial applications (such as wastewater treatment), meeting the large-scale raw material needs of furniture manufacturers and environmental equipment manufacturers.

2.图片

TONY Brand 8.5-9.5 Ton/Hour Wet EFB Pellet Manufacturing Plant can take wet EFB as the main raw material. After pretreatment and processing, it is solidified into high - density EFB pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in EFB resources.

1. Capacity: 8.5-9.5 Ton/Hour

2. Raw materials: Wet EFB

3. Moisture: Wet type, about 40%.

4. Application: All kinds of EFB materials suitable for pellet production.

Suitable customers: Palm plantation owners or related agricultural enterprises have abundant EFB resources. For example, palm oil mills generate a large amount of EFB waste during the production process. Energy companies, EFB biomass pellets as a clean energy, can be used in industrial heating, power generation and other fields, and have synergy with the existing business of energy companies. Environmental investors, investors with financial strength, technology investors, etc.and other places where EFB raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3.图片

原材料--成品图

1. Project Name: Wet EFB Pellet Production Line

2. Raw Material: All kinds of wet EFB

3. Moisture Content of Raw Material: 40%

4. Capacity: 8.5-9.5 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper -TPC1300-600-132kw, Effective Hammer Mill-TFD75*132-132kw, Rotary Drum Dryer-2.5*24m, TONY Pellet Machine- TYJ760-Ⅲ-185kw, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

4.图片

|

How to use the TONY pellet production line to make pellets from wet EFB? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind EFB Into 25-55mm palm fiber. 2. Use TONY effective hammer mill to crush the 25-55 mm palm fiber into 8-14 mm palm dust.If customer has enough Investment budget,he can also chose TONY special cutting machine for palm silk which will be more expensive than the hammer mill. 3. Use TONY rotary drum dryer to dry the palm dust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

流程图1

流程图2

5.图片

原材料+颗粒图

颗粒+机器图

三维图长宽

三维图高

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

| 图1 | 图2 | 图3 | 图4 |

| Comprehensive Chipper | Effective Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Grind EFB Into25-55mm Palm Fiber. 2.Model: TPC1300-600-132KW With 6 Baldes*1set 3.Capacity: 10-15 Ton/Hour. |

1.To Crush 25-55mm Palm Fiber Into 8-14mm Palm Dust. 2.Model: TFD75*132-132KW*2set 3.Capacity: 4-5 Ton/Hour/Set |

1.To Dry The 40% Palm Dust Into 10-15% Palm Dust. 2.Model: THGD2.5*24*1 set 3.Capacity:8.5-9.5 Ton/Hour/Set |

1.To Stroage Palm Dust Before Pellet Machine; Adjust The Speed Of Palm Dust Entering The Pellet Machine 2.Model: TLC-10*1set 3.Capacity:8.5-9.5Ton/Hour/Set |

| 图5 | 图6 | 图7 | 图8 |

| Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

| 1.To Press Dry Palm Dust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-185KW*3 sets 3.Capacity:2.8-3.3 Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*1 set 3.Capacity:8.5-9.5Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TPZ-50*1Set 3.Capacity: 8.5-9.5Ton/Hour |

1.To Transport Palm Fiber, Palm Dust,Pellets. 2.Width: 80cm*8 sets 3.Capacity:Designed With The Whole Line |

5.1图片

带原材料-成品图

1.Wet EFB To Palm Fiber Process:

A.This process is mainly used to grind the EFB into palm fiber with size 25-55mm. The finish palm fiber size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand comprehensive chipper TPC1300-600-132kw with 6 flying blades type*1 set

C.Capacity:8.5-9.5 Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

5.2图片

高效粉碎机带锯末图

2.Palm Fiber Fine Crushing Process:

A.This process is mainly used to crush 25-55mm palm fiber into 8-14mm palm dust.

B.Capacity:8.5-9.5Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132kw*2set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.3图片

烘干机带锯末图

3.Wet Palm Dust Drying Process:

A.This process is mainly used to dry the palm dust from 40% to 10-15%.

B.Capacity:8.5-9.5 Ton/Hour.

C.TONY use 1 set of 2.5*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.4图片

颗粒机四件套带 原材料,颗粒图

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:8.5-9.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-185kw*3 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.5图片

镀锌冷却仓加颗粒图

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:8.5-9.5 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.6图片

包装机

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50KG/Bags.

B.Capacity:8.5-9.5 Ton/Hour.

C.TONY brand double packing machine*1 set

Main Parts:

(1)TONY Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

6.图片

客户生产线案例图

7.图片

图 湿EFB+颗粒 颗粒机

Palm fruit bunches are made into pellets

Why are palm fruit bunches made into pellets? Can't we put palm biomass directly into boilers or power plants? The reasons are as follows:

1. In general, after the conversion of palm fruit biomass into particles, its energy content will increase.

2.The caloric value of 4,200-4,900 kg cal/kg 28 palm pellet fuel or briquette can be used to replace coal to relieve energy pressure and environmental pressure.

3. Palm pellets are sustainable and renewable, can be produced on a large scale and are very friendly to the environment.

4.The palm particles are dense and clean, easy to transport and store, and the particles produce little smoke when burning.

The main reason for using palm nut bunches is that palm nut bunches (EFB) are a waste material which has great potential for being recycled and burned as boiler fuel 1. Palm fiber is produced from oil palm empty fruit cluster (EFB), which is generally considered to be a waste product after the processing and refining of palm fresh fruit cluster (FFB). Palm fiber itself is 100% natural product, no harm, can be naturally decomposed, will not damage the environment .

Palm pellet production

Various palm pellets can be made according to the different requirements of consumers. When investing in the production of palm pellets, you can refer to the following advice from mature palm pellet plants:

1.A comprehensive understanding of the palm pellet production line is necessary.

2.Palm pellet production procedures should meet the requirements of the target market.

3.The raw materials should be sufficient to ensure the continuity of particle production.

4.The quality of raw materials to be guaranteed. The ideal moisture content of raw materials is 15%, and when it exceeds 15%, raw materials should be dried to control moisture.

5.The location of the palm pellet factory should be easy to transport raw materials.

6.Feasible research is required beforehand.

8.图片

湿EFB图 颗粒图

1.Environmental characteristics

(1)Low pollution emissions: The sulfur and phosphorus content during combustion is extremely low, and the concentration of SO₂ and NOx in the flue gas is much lower than that of coal. It will not produce acid rain, and the CO₂ emission is zero (because plants absorb CO₂ during their growth).

(2)Ash utilization: The ash after combustion is rich in organic potassium and can be recycled as a high-efficiency organic fertilizer.

2.Economic benefits

(1)Wide range of raw materials: Palm empty fruit bunches are the remaining parts after the oil palm fruit is harvested, mainly including the palm fruit stalks and shells. These empty fruit bunches are produced during the palm oil production process, and can produce millions of tons each year. The pellet production cost is lower than traditional fossil fuels.

(2)Substitution benefits: Replacing coal can save about 20% to 30% of fuel costs.

3.Wide range of application scenarios

(1)Industrial application: Widely used in boiler heating, power generation and industrial production, such as textile factories, food factories, etc.

(2)Civil heating and living energy: Bamboo pellets have high combustion efficiency, are easy to store and use, and are safe and hygienic.

(3)Biomass industrial boilers: As the main fuel for industrial boilers, it replaces coal, heavy oil and natural gas to solve environmental pollution problems.aste resource utilization.

9.图片

绿色地球+原材料+颗粒图

10.图片

图片

11.图片

公司优势图

2025 Tony Machinery - All Rights Reserved. Map