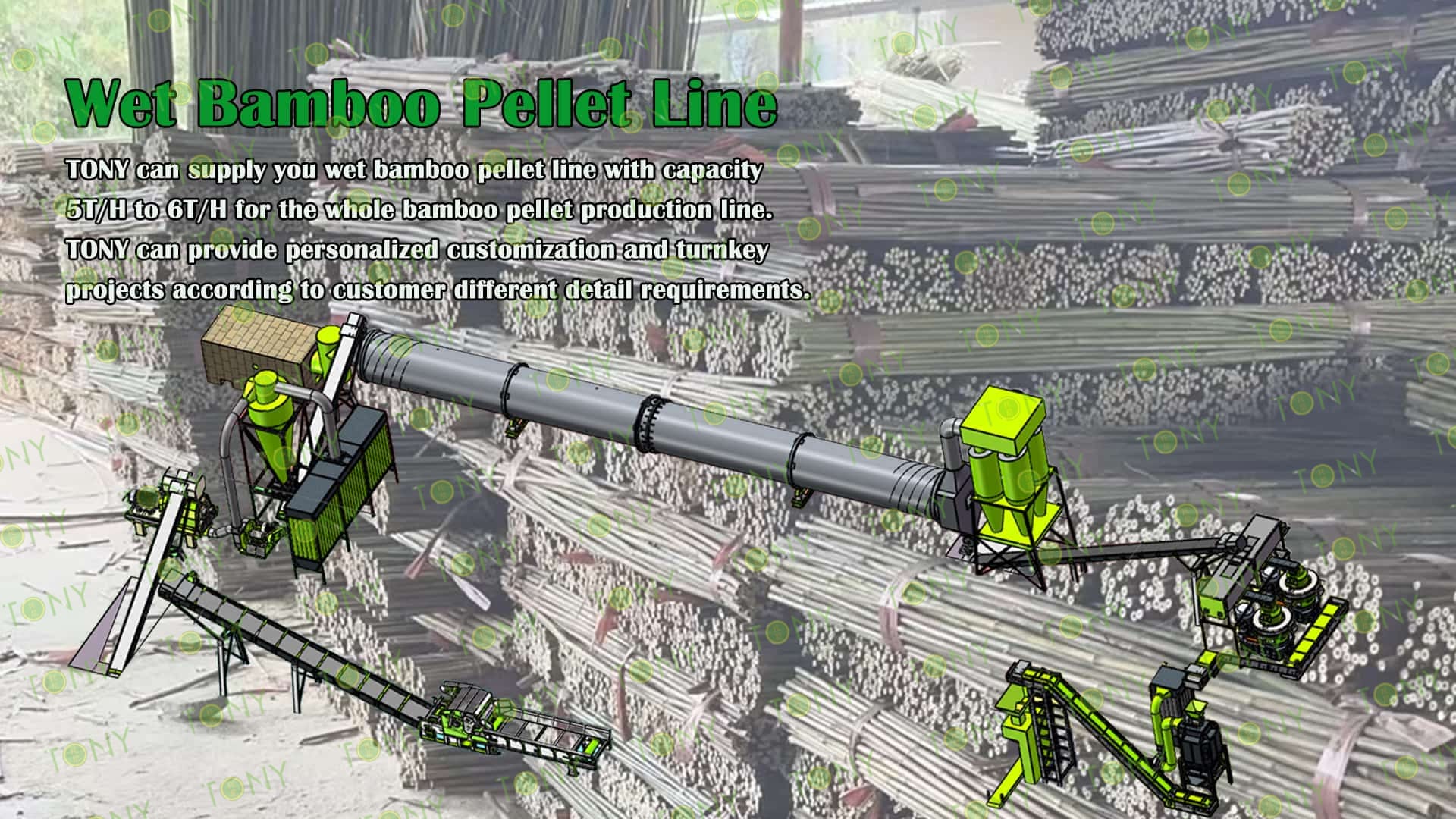

Project Brief Introduction:

1.Product:Wet Bamboo Pellet Line

2.Capacity: 5-6T/Hour

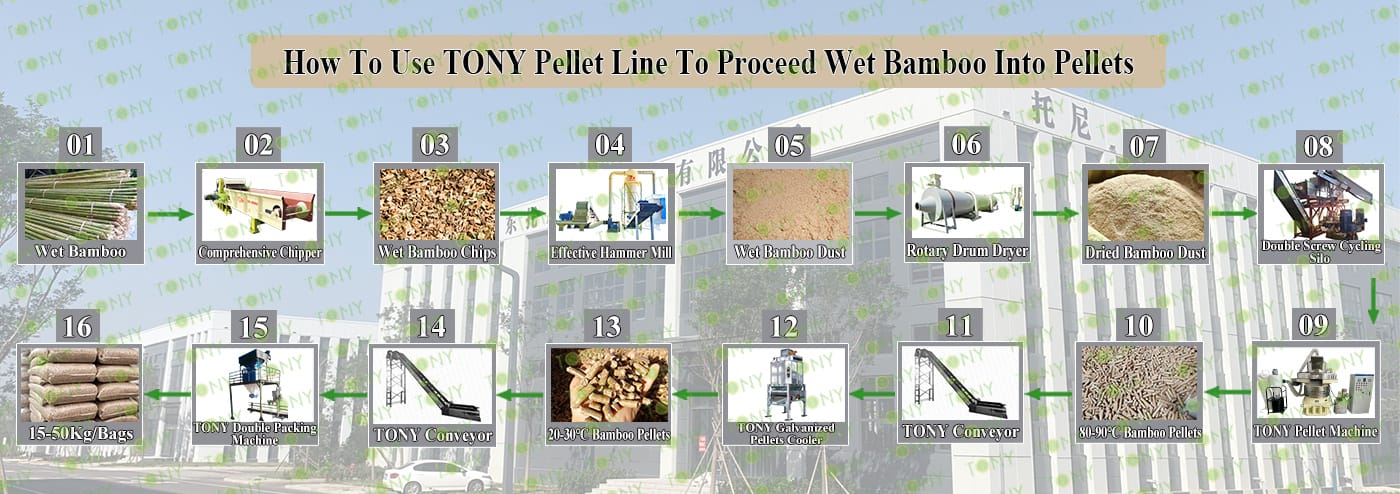

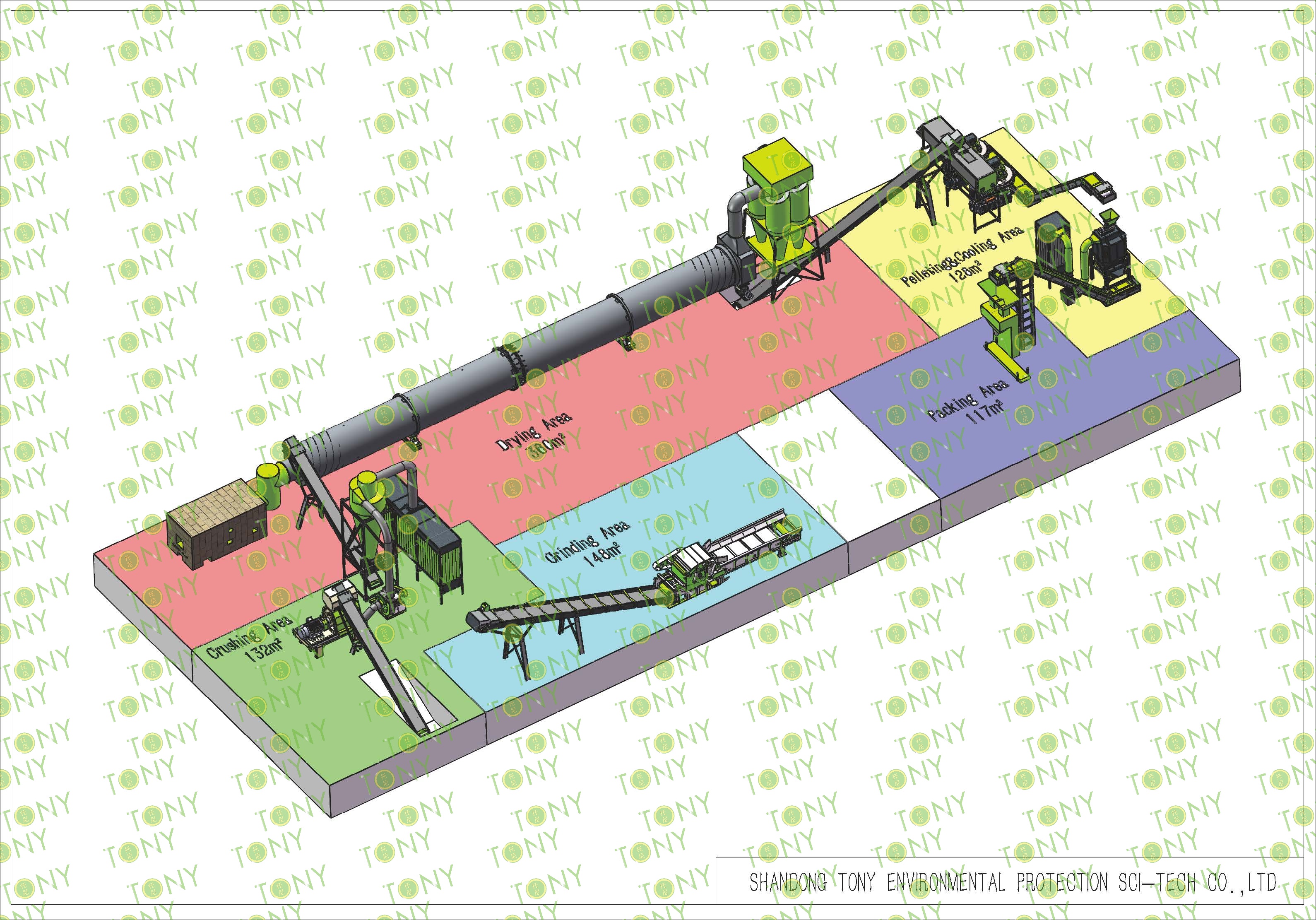

3.TONY Brand 5-6Ton /Hour Wet Bamboo Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 680KW

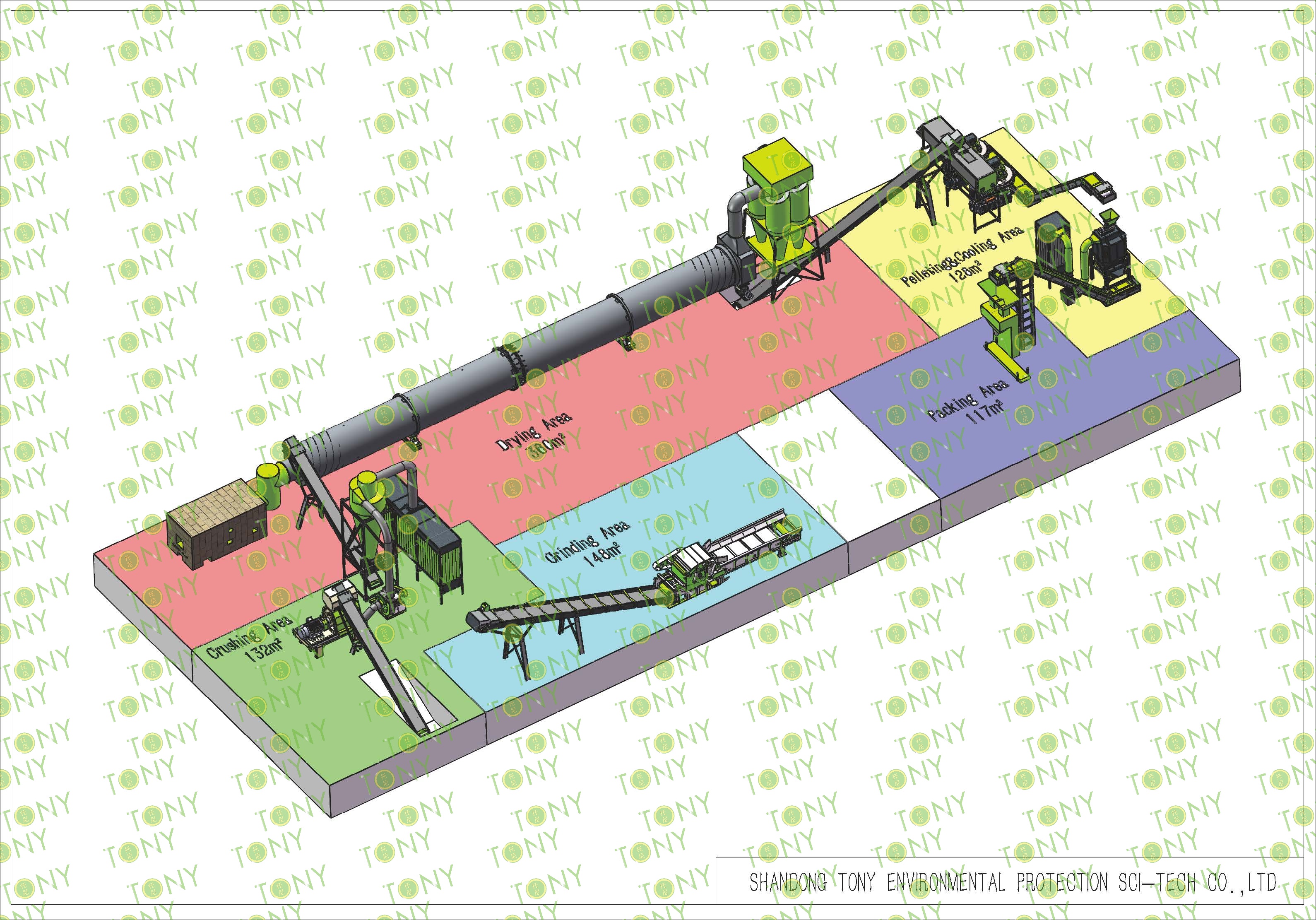

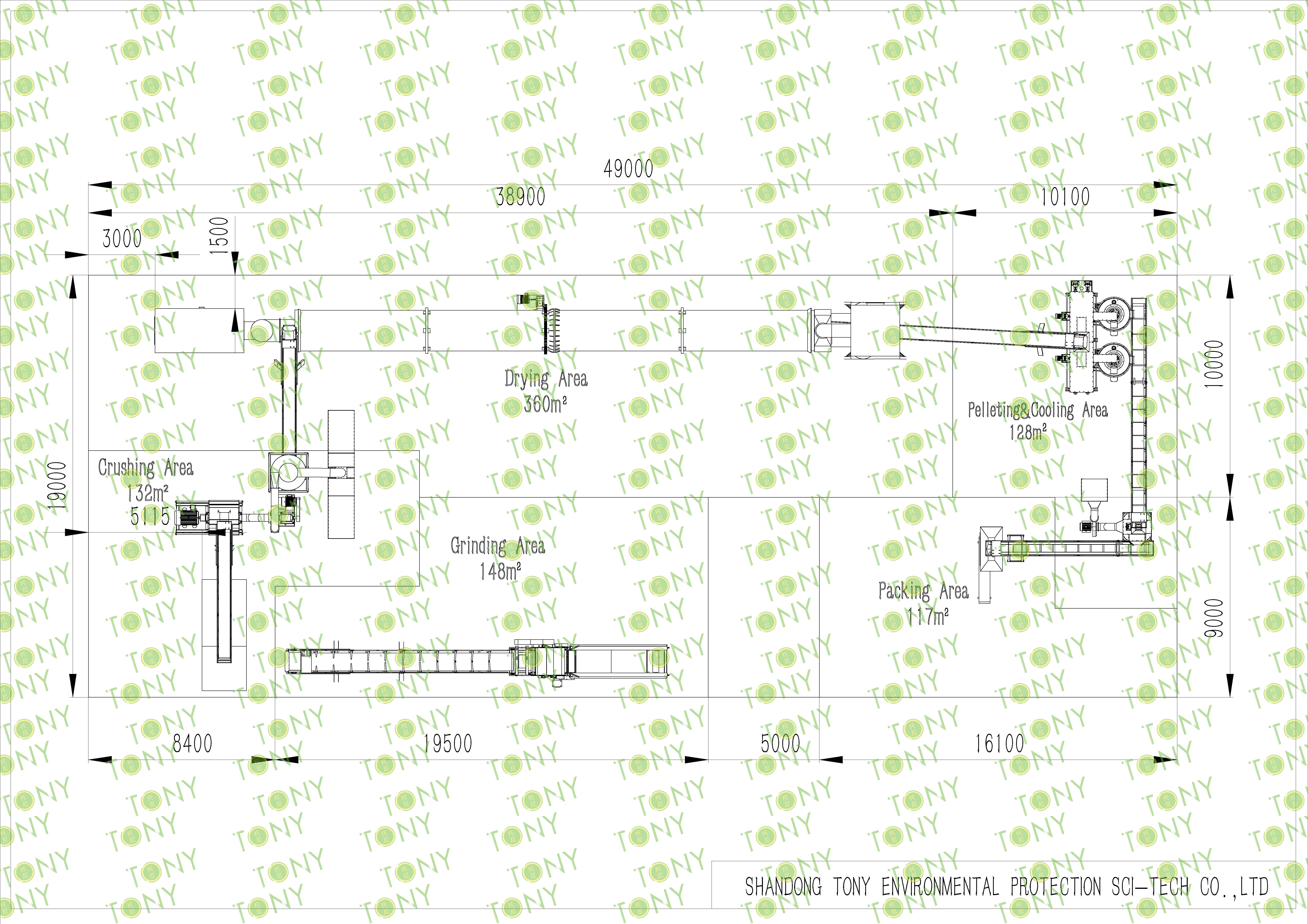

6.Need Area: About 931㎡ L:49M W: 19M H:7.065M

Project Layout For Customer:

1.The working principle of wet bamboo biomass pellet processing equipment

The wet bamboo biomass pellet machine uses high temperature and high pressure to compress wet bamboo into pellets.

The specific process is as follows: First, the wet bamboo is pre-treated, crushed, finely pulverized, and dried before being fed into the biomass pellet machine through a feed system. Next, the bamboo shavings pass through a compression system, where they are compressed into pellets. This process requires high temperature and high pressure to ensure the pellets are formed properly. Finally, the pellets are cooled and screened through a cooling and screening device to ensure pellet quality.

2.Characteristics of wet bamboo biomass pellet processing equipment

Functional characteristics and application advantages of key equipment

(1)Multifunctionality of bamboo crusher: In addition to bamboo, it can also process a variety of biomass raw materials such as cotton stalks, branches, corn stalks, etc. The processed products are widely used in power generation, papermaking, wood-based panels and other industries, realizing resource recycling.

(2)Energy-saving and environmentally friendly design: crushers, dryers, and pelletizers can use energy-saving motors and closed operation modes to reduce dust emissions and energy consumption; the drying process can use processing waste as a heat source to reduce operating costs.

(3)Automation and safety: The equipment is usually equipped with an automatic feeding device and an overload protection system, which is easy to operate and has low maintenance costs, making it suitable for large-scale production scenarios.

3.Application scenarios of wet bamboo biomass pellet processing equipment

(1)Energy sector: Biomass fuel production

Core application: Crushing bamboo into high-density pellet fuel to replace traditional fossil fuels such as coal and liquefied gas, and used in scenarios such as home heating, industrial boiler combustion and power generation.

Advantages: Pellets have high combustion efficiency and low pollution emissions, and bamboo raw materials are widely available (such as bamboo processing waste and bamboo forest prunings), realizing "turning waste into treasure".

(2)Agricultural sector: Feed and cultivation substrate

Feed processing: Bamboo pellets can be used as feed raw materials and mixed with corn, soybean meal, etc. to press pellet feed, which is suitable for poultry and livestock breeding. High temperature (65-75℃) during processing can kill microorganisms and improve feed safety.

Cultivation substrate: Crushed bamboo pellets can be used as soilless cultivation substrates for flowers, vegetables and other plants. They have good water retention and air permeability and can also be used for soil improvement.

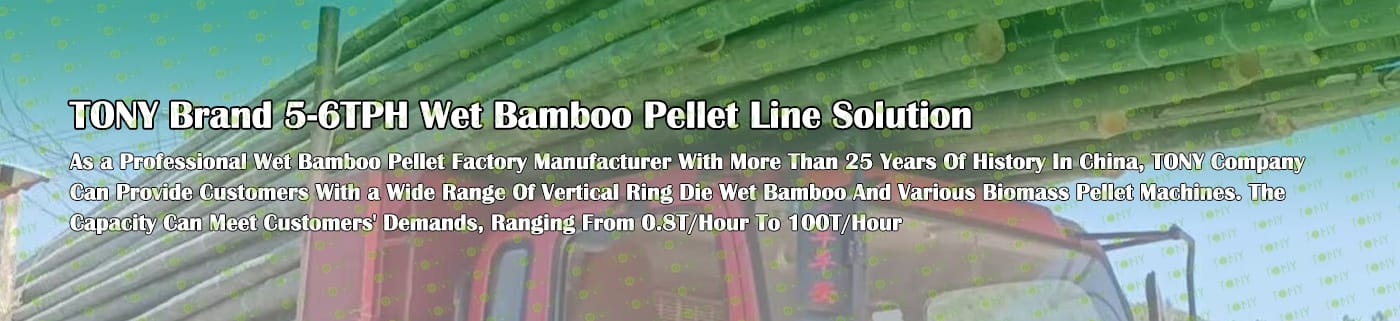

TONY Brand 5-6Ton/Hour Wet Bamboo Pellet Manufacturing Plant can take wet bamboo as the main raw material. After pretreatment and processing, it is solidified into high - density bamboo pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bamboo resources.

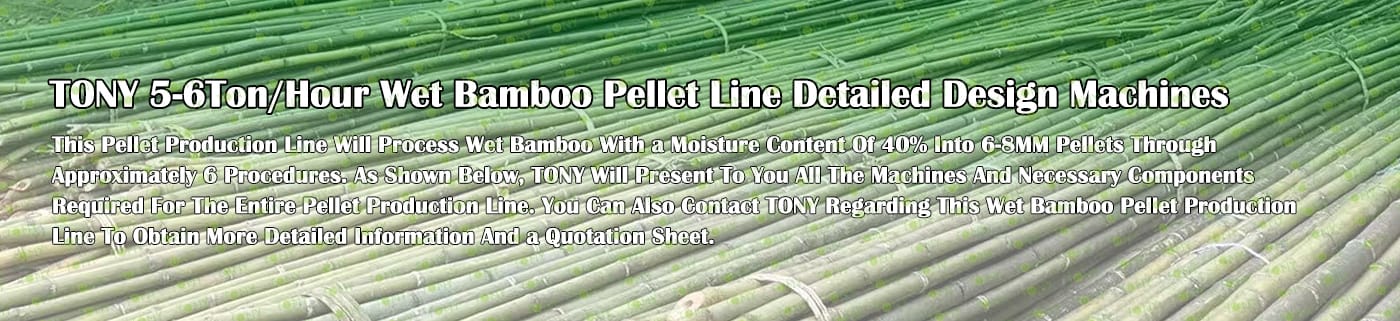

1. Capacity: 5-6Ton/Hour

2. Raw materials: Wet Bamboo

3. Moisture: Wet type, about 40%.

4. Application: All kinds of bamboo materials suitable for pellet production.

Suitable customers: Bamboo product processing companies, large-scale farms, agricultural/forestry parks, areas with dense bamboo resources, biomass energy companies/fuel traders, green environmental protection technology companies, and other places where bamboo raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Bamboo Pellet Production Line

2. Raw Material: All kinds of wet bamboo

3. Moisture Content of Raw Material: 40%

4. Capacity: 5-6 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000 - 90KW, Effective Hammer Mill-TFD75*160-160KW, Rotary Drum Dryer-1.8*24m, TONY Pellet Machine TYJ760-Ⅲ-160KW, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

|

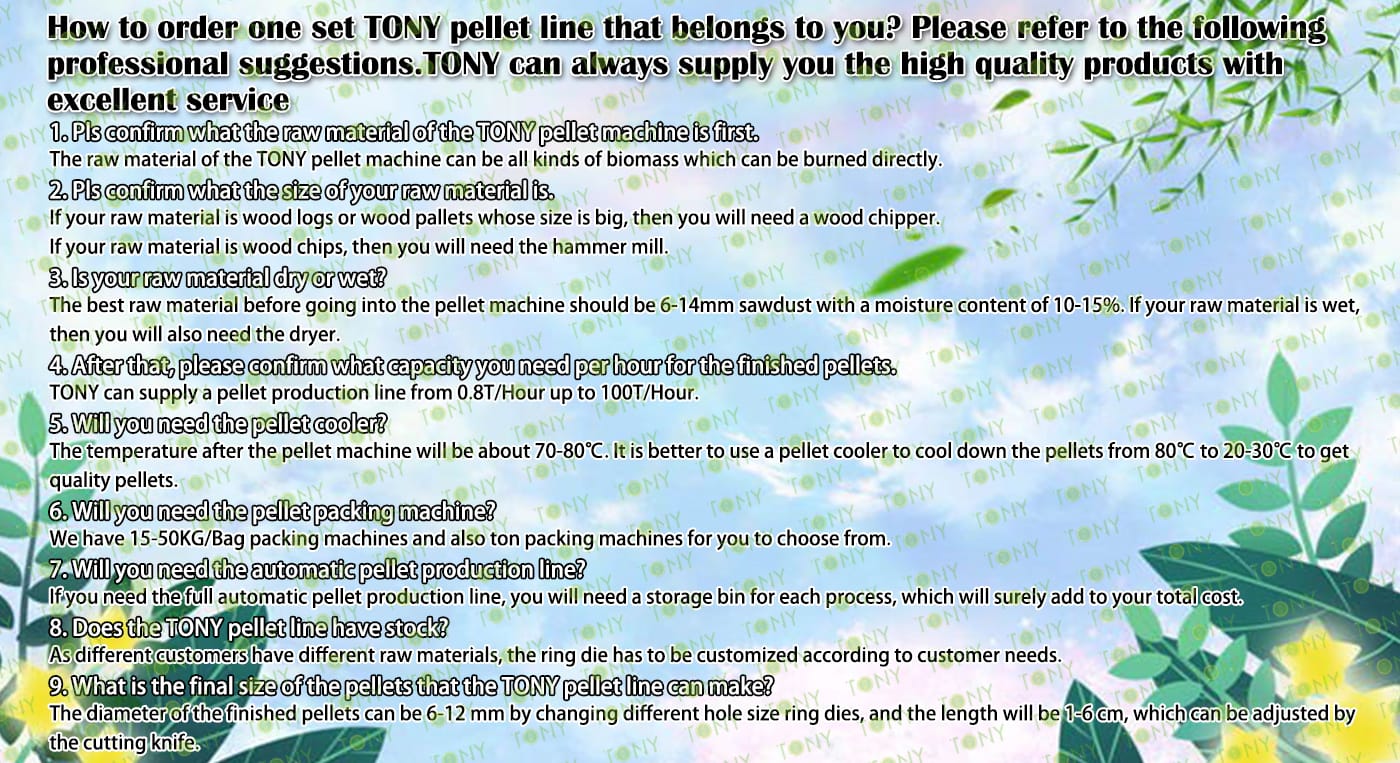

How to use the TONY pellet production line to make pellets from wet bamboo? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to cut wet bamboo with a diameter of less than 20 cm into bamboo chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm bamboo chips into 8-14 mm bamboo dust. 3. Use TONY rotary drum dryer to dry the bamboo dust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Silo |

|

1.To Grind Bamboo φ ≤25 cm Into25-55mm Bamboo Chips. 2.Model: TPC1000-90KW With 6 Baldes*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Bamboo Chips Into 8-14mm Bamboo Dust. 2.Model: TFD75*160-160KW*1set 3.Capacity: 5-6Ton/Hour/Set |

1.To Dry The 40% Bamboo Dust Into 10-15% Bamboo Dust. 2.Model: THGD1.8*24*1set 3.Capacity:5-6Ton/Hour/Set |

1.To Stroage Bamboo Dust Before Pellet Machine; Adjust The Speed Of Bamboo Dust Entering The Pellet Machine 2.Model: TLC-6*1set 3.Capacity:5-6Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

|

1.To Press Dry Bamboo Dust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-160KW*2 sets 3.Capacity:2.5-3Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1 set 3.Capacity:5-6Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1 set 3.Capacity: 5-6Ton/Hour |

1.To Transport Bamboo Chips,Bamboo Dust,Pellets. 2.Width: 80cm*6 sets 3.Capacity:Designed With The Whole Line |

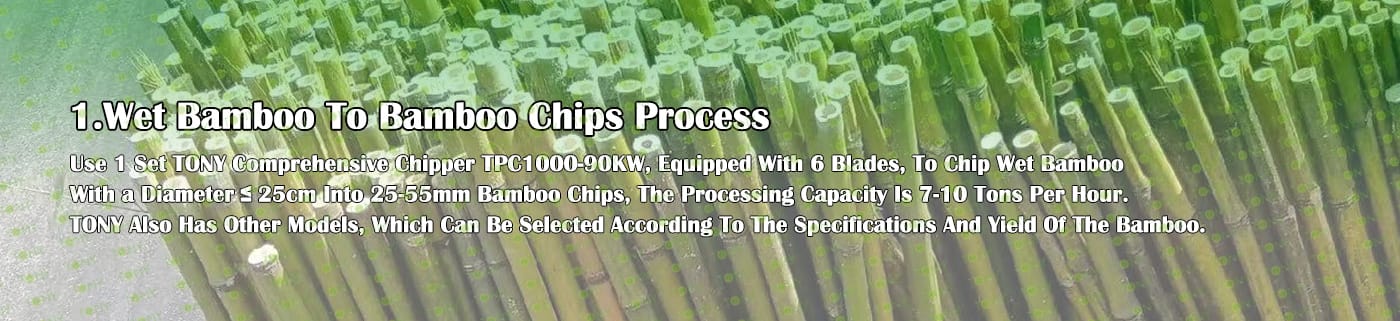

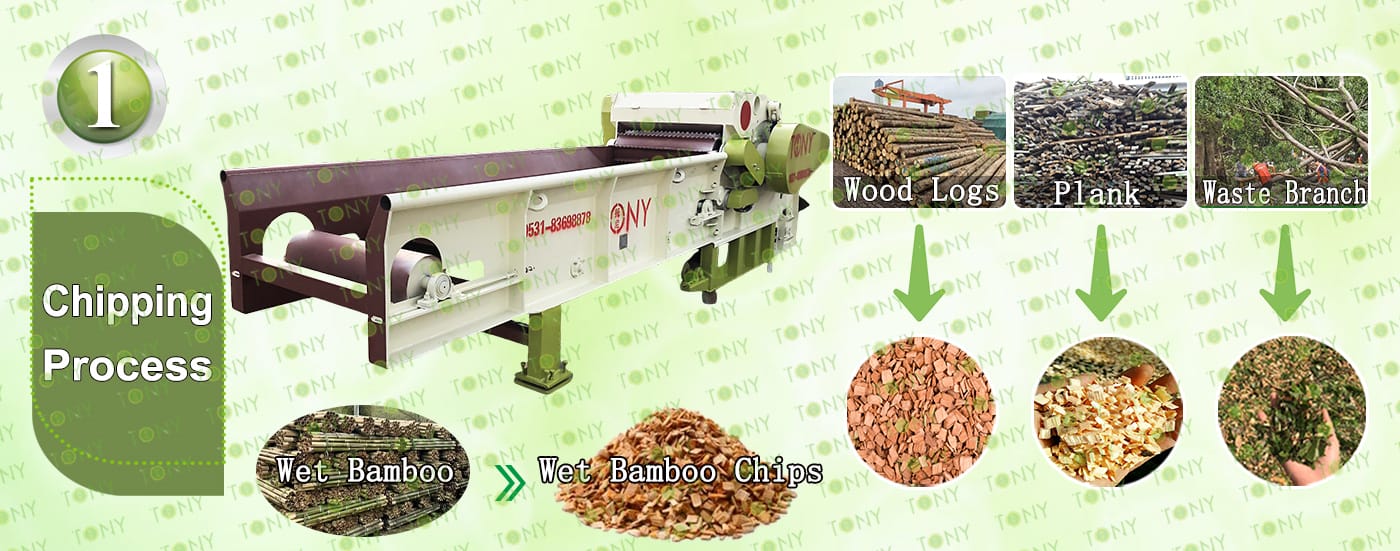

1.Wet Bamboo To Bamboo Chips Process:

A.This process is mainly used to grind the bamboo whose diamater is under 25 cm into bamboo chips with size 25-55mm. The finish bamboo chips size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand comprehensive chipper TPC1000-90KW with 6 flying blades type*1 set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Bamboo Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm bamboo chips into 8-14mm bamboo dust.

B.Capacity:5-6Ton/Hour.

C.TONY brand effective hammer mill TFD75*160-160KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

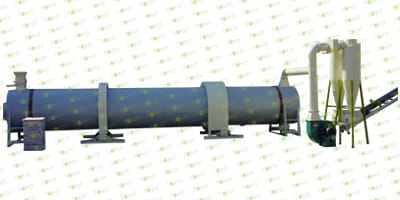

3.Bamboo Dust Drying Process:

A.This process is mainly used to dry the bamboo dust from 40% to 10-15%.

B.Capacity:5-6Ton/Hour.

C.TONY use 1 set of 1.8*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:5-6Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-160KW*2 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:5-6Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

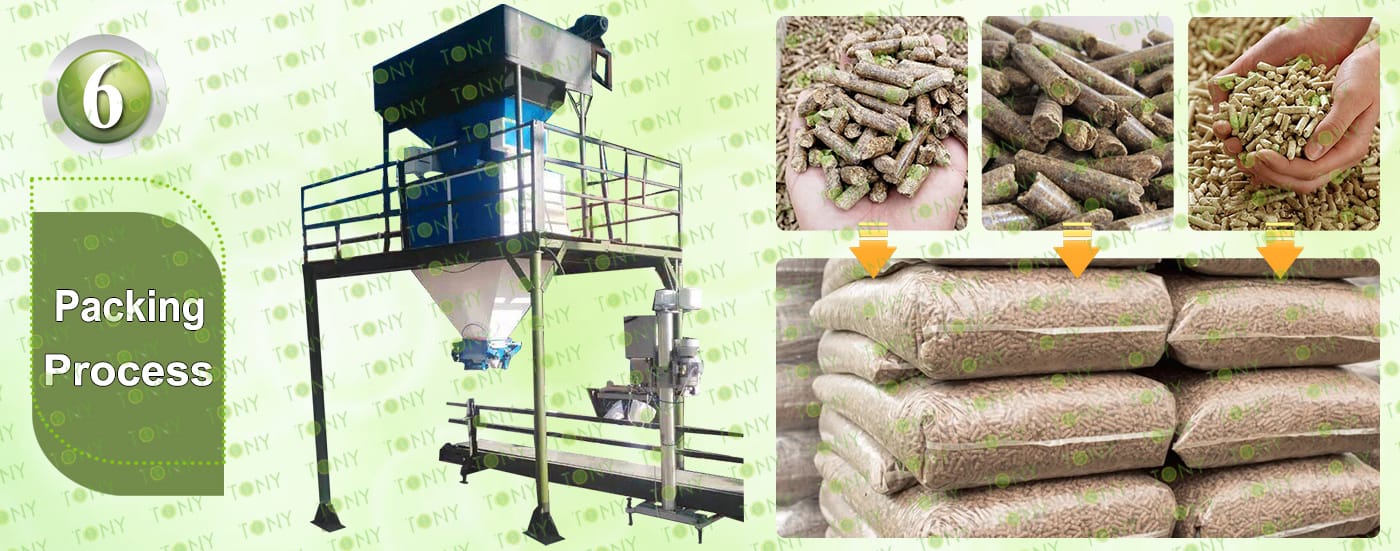

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:5-6Ton/Hour.

C.TONY brand double packing machine*1 set

Main Parts:

(1)TONY Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Raw material advantages of the wet bamboo biomass pellet project:Stable raw material supply, low cost, and strong adaptability

As the core raw material of the project, bamboo's natural properties provide a "source guarantee" for the project, resolving the pain points of traditional biomass pellets (such as wood chip pellets) that rely on forests and have unstable supply.

1.Fast growth and high renewability

Bamboo is one of the fastest-growing plants in the world. Most species (such as moso and nan bamboo) can mature into a forest in 1-2 years and reach harvestable maturity in 5 years, while trees typically take 10-20 years to mature. Furthermore, bamboo does not need to be replanted after harvesting. New bamboo shoots naturally sprout from the underground stems (bamboo rhizomes), achieving "one-time planting, perpetual use." This shortens the raw material supply cycle and enhances sustainability, avoiding the risk of resource depletion.

2.Wide Sources of Raw Materials and Controllable Costs

Diverse Supply Channels: In addition to targeted commercial bamboo forests, a large amount of recycled bamboo industry waste (such as bamboo board processing scraps, bamboo furniture offcuts, and discarded bamboo fences/scaffoldings) can be recycled. The procurement cost of this raw material is extremely low (in some areas, recycling is even free, requiring only transportation costs), and is 30%-50% lower than the cost of virgin wood (such as pine and fir).

Strong Regional Adaptability: Projects can be located nearby, reducing the raw material transportation radius (typically ≤ 50 kilometers), further reducing transportation costs (far lower than the cost of transporting wood across regions).

3.Wet Bamboo Properties Suitable for Processing Requirements

Bamboo fiber has a high density (approximately 0.6-0.8g/cm³) and strong toughness. Even with a high moisture content (30%-50%), it maintains good formability after crushing and drying. The pelletized pellets are hard (crushing strength ≥ 95%) and are resistant to moisture absorption, making them superior to herbaceous biomass materials such as straw and rice husks, which tend to loosen and become moldy due to moisture absorption, resulting in more stable product quality.

The environmentally friendly nature of bamboo biomass pellets is their core competitive advantage, as demonstrated by the following:

1.Carbon neutrality throughout the entire life cycle

Bamboo absorbs carbon dioxide through photosynthesis during its growth process and releases only an equivalent amount of CO₂ when burned, creating a "carbon cycle." This reduces carbon emissions by over 90% compared to coal (which emits 2.6 tons of CO₂ per ton burned). Furthermore, bamboo biomass pellets have extremely low sulfur (<0.05%) and nitrogen (<0.5%) contents, producing virtually no harmful gases like sulfur dioxide and nitrogen oxides when burned. This eliminates the need for additional desulfurization and denitrification equipment, reducing environmental investment.

2.Utilizing bamboo waste and reducing pollution

Bamboo tips, branches, and scraps generated after bamboo harvesting, as well as scraps from bamboo product processing, can easily rot and deteriorate, breeding mosquitoes, or generate black smoke pollution if left unused. Processing these into biomass pellets allows for "waste recycling," utilizing approximately 1.5-2 tons of bamboo waste per ton of pellets, achieving both environmental and resource recovery benefits.

2025 Tony Machinery - All Rights Reserved. Map