1.The working principle of wet wood pallets biomass pellet processing equipment

The essence of pallet pelleting is the physical process of converting loose, irregular wood powder into high-density, regular, and easily storable biomass pellets through a series of processes: conditioning and softening the fibers, densifying them through high-pressure extrusion, activating natural binders through high temperatures, and then precisely cutting them to length. This process requires no chemical adhesives and relies entirely on the hot-melt bonding of the wood's natural components (lignin and hemicellulose). This ensures the pellets' environmental friendliness while fully utilizing the wood's natural resource properties, making it a key step in achieving "waste resource utilization."

2.Characteristics of wet wood pallets biomass pellet processing equipment

(1)High-strength crushing/smashing system to cope with "large block + hard" raw materials

Wood pallets are mostly whole boards (usually 1.2m×1.0m, 1.1m×1.1m in size), and some are plywood and solid wood hard materials. The crusher needs to have high torque and wear resistance

(2)High-efficiency impurity removal device to accurately separate "metal + non-metal" impurities

The key pain point of wood pallet processing is "containing metal nails and plastic accessories". The equipment usually integrates a multi-stage impurity removal system to ensure the purity of the particles

(3)Wide range of moisture content adaptation to reduce drying energy consumption

Wood pallets have different storage environments and large differences in moisture content (15%-30%). The drying system of the equipment (mostly a drum hot air dryer) can achieve precise temperature control (80-120℃) and humidity adjustment, stabilizing the moisture content of wood chips at 10%-15% (the optimal humidity for pelletizing)

(4)Wood pallet pellet processing requires multiple steps: crushing → impurity removal → pulverization → drying → pelletizing → cooling → screening. Equipment typically comes in the form of a complete production line, with core features including a consistent process flow and a high degree of automation.

(5)Wood pallet raw materials (especially plywood and hardwood) subject equipment components to significant wear and tear, making durability a key feature.

(6)Wood pallet processing is prone to dust and noise, and poses significant risks to mechanical safety. Therefore, the equipment features specific environmental and safety design features.

(7)Wood pallet pellet production equipment can be flexibly adjusted based on the user's production capacity, site, and intended use of the finished product, meeting diverse needs.

3.Application scenarios of wet wood pallets biomass pellet processing equipment

Wood pallet pellet processing equipment is the core equipment for realizing the transformation of “waste wood pallets → biomass pellets”. Its application scenarios are centered around the source of raw materials, production scale, and processing needs. It is mainly divided into two categories: “centralized processing projects” and “supporting processing scenarios”:

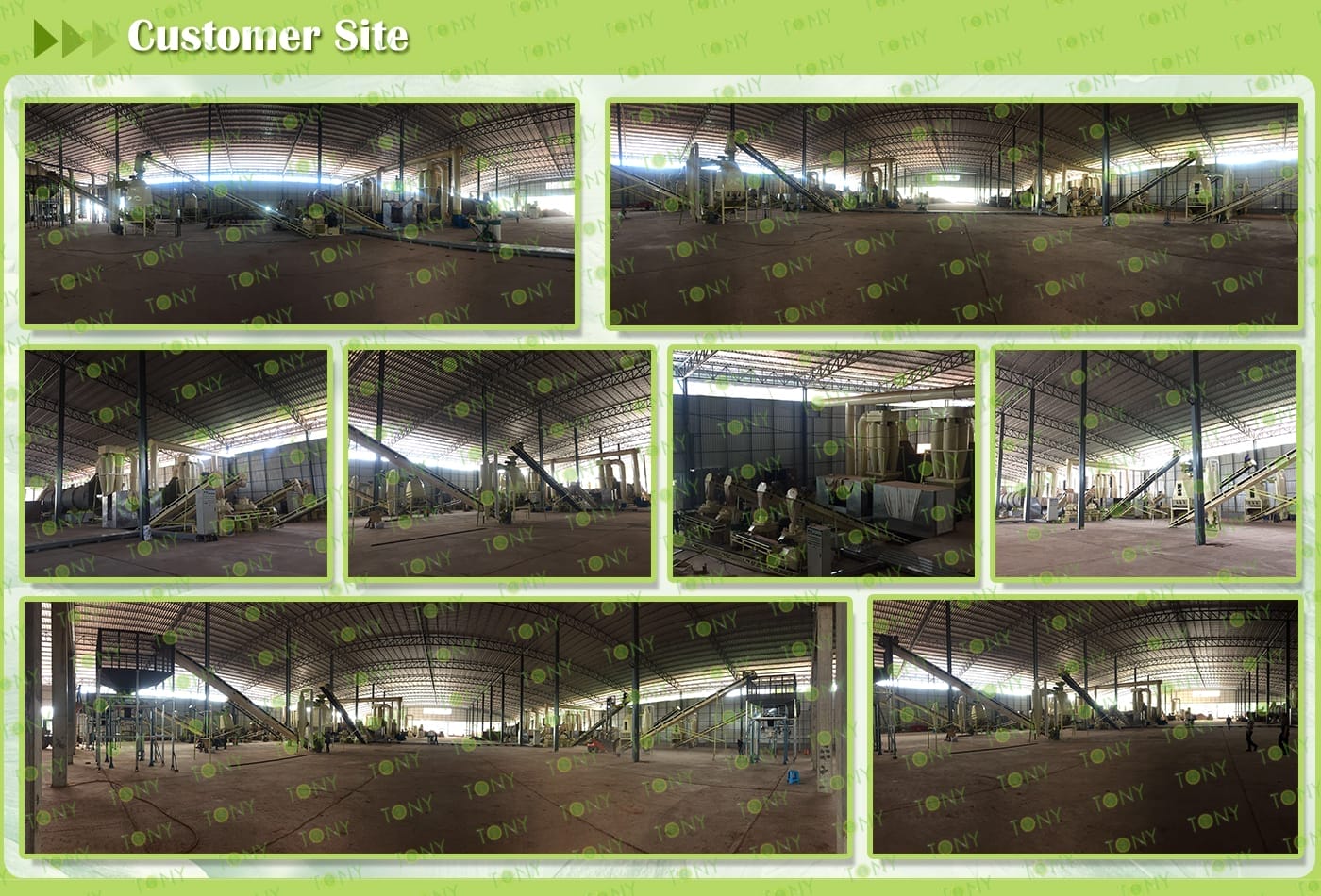

(1)Centralized processing projects: large-scale production scenarios

This type of scenario takes “large-scale processing of waste wood pallets and batch production of biomass pellets” as its core goal. The equipment must have high production capacity and a high degree of automation. It is usually implemented as an independent biomass pellet processing plant:

Professional biomass pellet plant: Build a large-scale processing plant in an area with developed logistics and abundant waste wood pallet resources, and configure a complete production line of “wood pallet dismantling machine → crusher → dryer → pelletizer → cooling and screening machine → packaging machine” with a daily production capacity of 50-200 tons. The products are mainly supplied to B-end customers such as industrial boilers and power stations;

Supporting processing lines for solid waste treatment centers: Large-scale industrial solid waste treatment centers (such as centers for processing waste wood and waste packaging in the manufacturing industry) add wood pallet pellet processing equipment to convert waste wood pallets that originally needed to be landfilled/incinerated into high-value-added pellets, realizing "Solid waste reduction (over 80% reduction) + resource utilization" while also receiving environmental protection subsidies (such as solid waste treatment subsidies and pellet sales subsidies).

(2)Supporting processing scenarios: on-demand processing and local utilization

This type of scenario aims to "reduce the cost of raw material transportation and meet the energy needs of itself/surrounding areas". The equipment scale is flexible (small/medium-sized) and is usually directly matched with the producers and users of wood pallets:

Logistics parks/manufacturing factories self-processing: Large logistics parks and production enterprises (such as auto parts factories and furniture factories) generate a large number of waste wood pallets every year. They build supporting "small processing workshops" to process the processed pellets directly for their own factory heating and production heat, without the need to purchase energy from outside, thus reducing energy costs (saving 20%-30% compared to purchasing natural gas/coal);

Biomass boiler user supporting processing: Enterprises using biomass boilers (such as textile factories and chemical plants) build supporting processing lines within the factory area to process the recycled waste wood pallets into pellets and directly supply them to their own boilers, avoiding quality fluctuations (such as excessive ash content and insufficient calorific value) and transportation costs of purchased pellets, thus realizing the internal cycle of "raw materials - production - energy use";

Rural/ Small-scale processing sites in townships: In townships with developed agriculture and scattered waste wood pallet resources, small-scale processing sites are built, equipped with simple production lines (such as "mobile crusher + small pelletizer"). Products are mainly supplied to surrounding farmers for heating and small-scale agricultural drying (such as greenhouse heating and grain drying), meeting regional scattered needs and reducing farmers' energy costs.

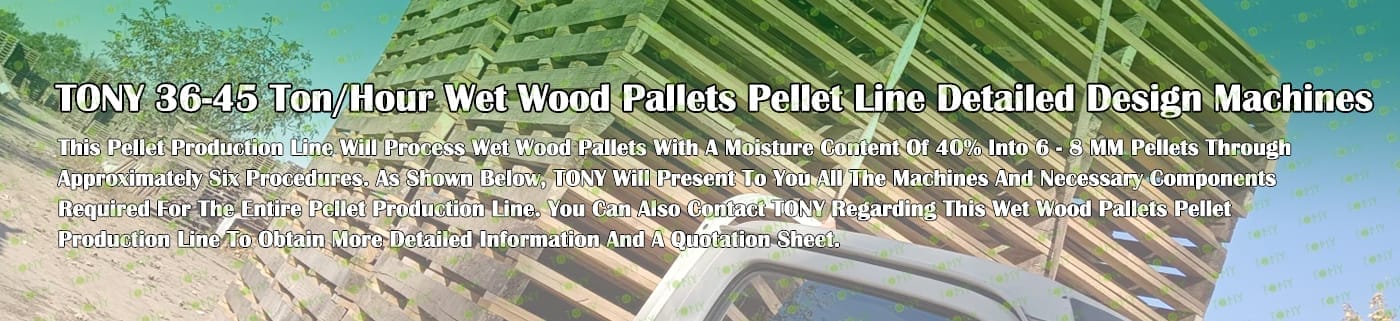

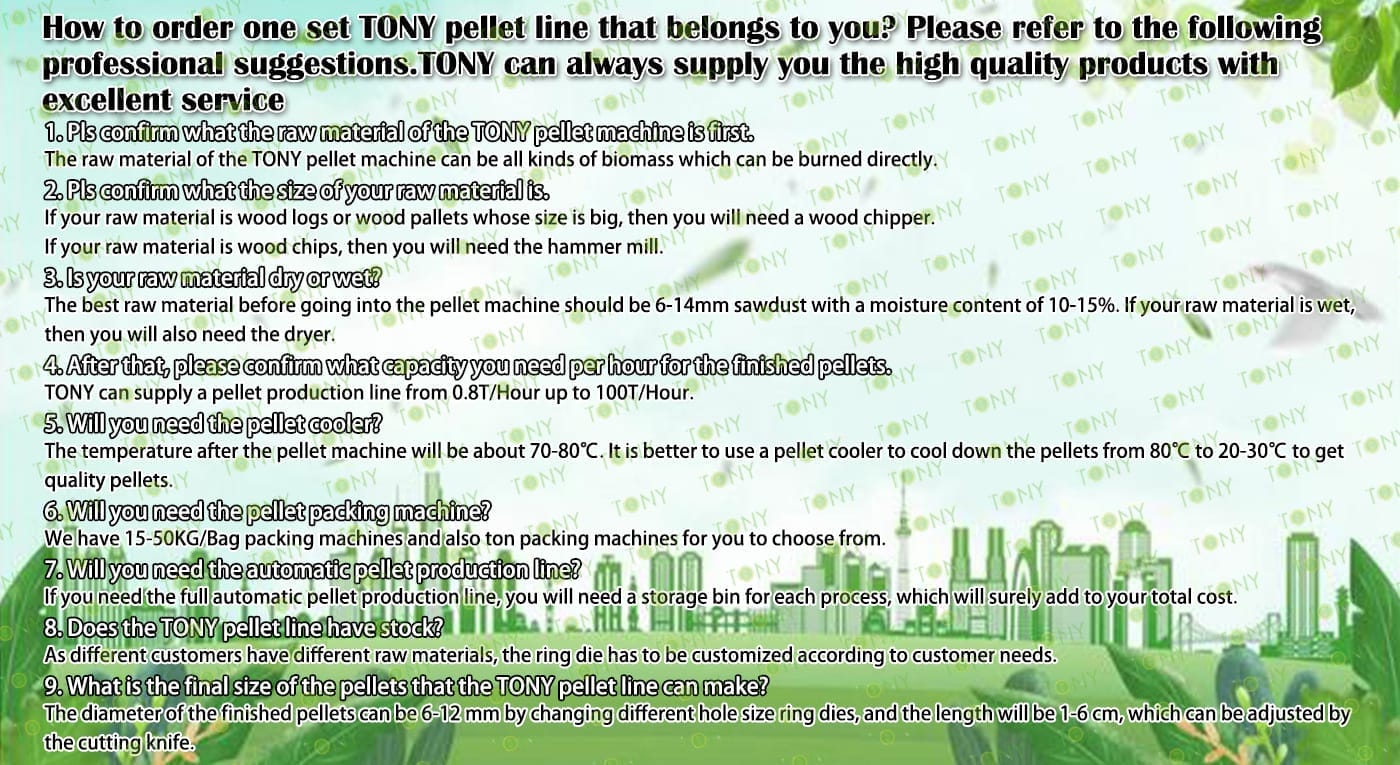

TONY Brand 36-45Ton/Hour Wet Wood Pallets Pellet Manufacturing Plant can take wet wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 36-45Ton/Hour

2. Raw materials: Wet wood pallets

3. Moisture: Wet type, about 40%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Pallets Pellet Production Line

2. Raw Material: All kinds of wet wood pallets

3. Moisture Content of Raw Material: 40%

4. Capacity: 36-45 tons per hour

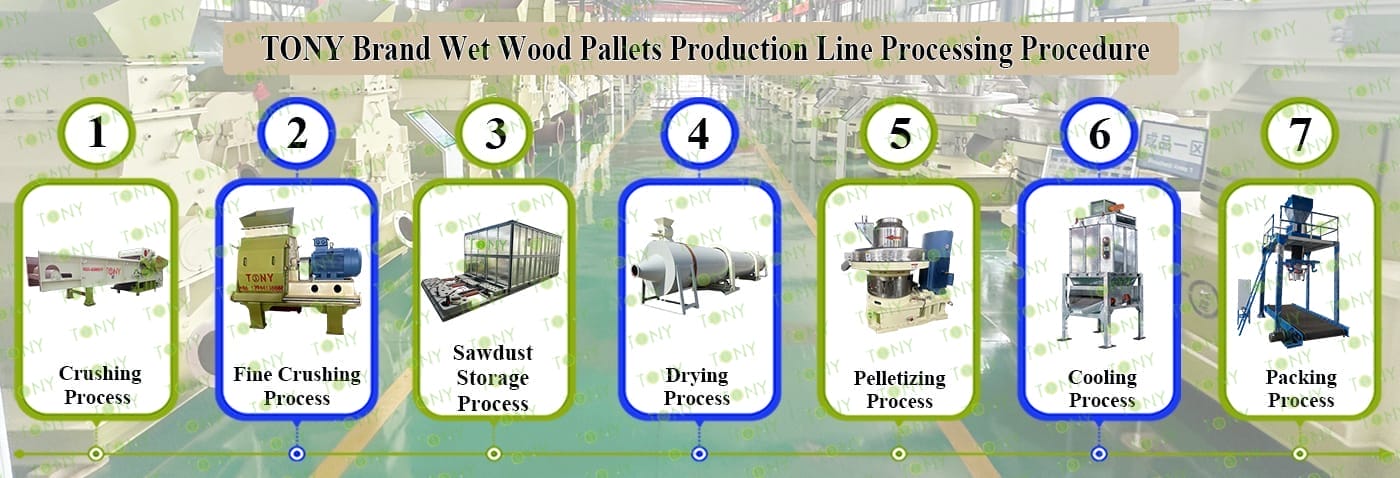

5. Process: Crushing Process - Fine Crushing Process -Sawdust Storage Process- Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1600-1000-315KW, Effective Hammer Mill-TFD100*200-315KW, TONY Large Hydraulic Storage Silo,Rotary Drum Dryer-3.2*24m, TONY Pellet Machine TYJ860-Ⅲ-280KW, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

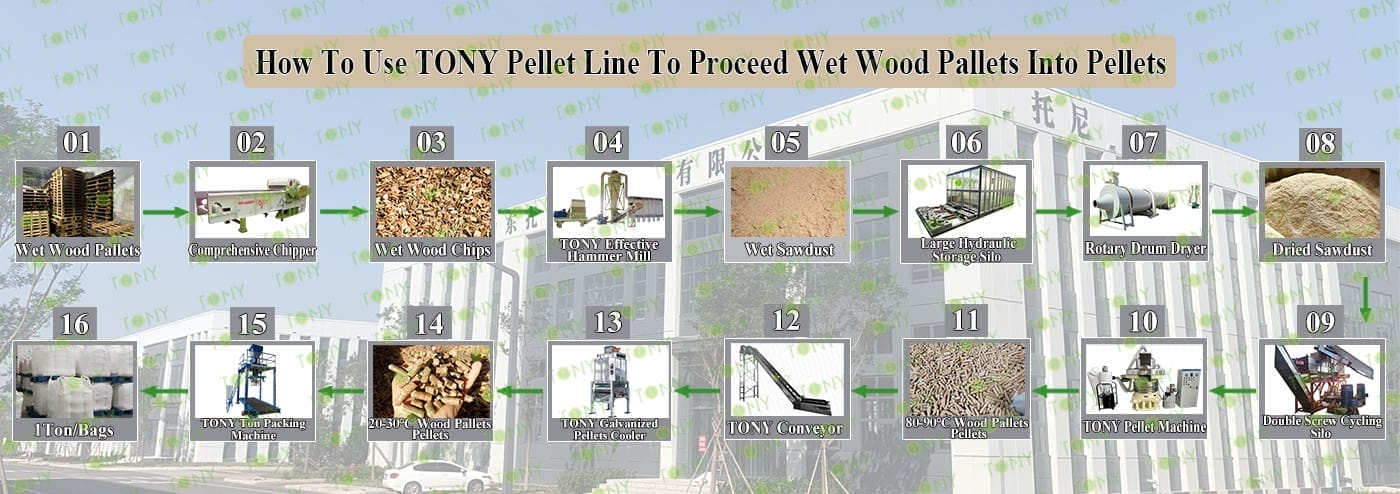

How to use the TONY pellet production line to make pellets from wet wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind wet wood pallets with width 1.6m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 4. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 5. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 6. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 7. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Comprehensive Chipper | Effective Hammer mill | Large Hydraulic Storage Silo | Rotary Drum Dryer |

| 1.To Grind Wood pallets Width ≤1.6m Into25-55mm Wood Chips. 2.Model: TPC1600-1000-315KW With 32Hammer Heads*3sets 3.Capacity: 36-45 Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD100*200-315KW*4sets 3.Capacity: 9-12Ton/Hour/Set |

1.To Storage Sawdust Before Dryer Control Sawdust Flow Entering The Dryer Model: TCY-30*4sets 2.TONY Uses Galvanized Material |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD3.2*24*4sets 3.Capacity: 9-12Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*9sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*3sets 3.Capacity:36-45Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags. 2.Model: TBD* 3sets 3.Capacity: 36-45 Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*28sets 3.Capacity:Designed With The Whole Line |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1.6 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY Brand comprehensive chipper TPC1600-1000-315KW model with 24 hammer heads*2sets

C.Capacity:36-45Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:36-45Ton/Hour.

C.TONY brand effective hammer mill TFD100*200-315KW*4sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B. TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's new Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

4.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:36-45Ton/Hour.

C.TONY use 4 sets of 3.2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:36-45Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-280KW*9sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

6.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:36-45Ton/Hour.

C.TONY brand galvanized cooler separator*3sets

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

7.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:36-45Ton/Hour.

C.TONY brand ton packing machine*3sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

The raw materials and production advantages of the wood pallet processing biomass pellet project:

1.Raw material side: low cost, easy to obtain, solving the "raw material bottleneck" problem

Raw materials are the core cost source of biomass pellet projects, and discarded wood pallets just avoid the "high cost and difficult collection" pain points of traditional biomass raw materials (such as special wood chips and straw):

(1)Extremely low cost or even negative cost: Logistics parks, manufacturing factories, e-commerce warehouses and other scenarios will regularly eliminate discarded wood pallets caused by wear, breakage, and outdated specifications. This type of raw material is mostly "free recycling" (some companies will even pay fees to entrust recycling to reduce waste disposal fees). Compared with purchasing wood chips, the raw material cost can be reduced by more than 80%, and in some cases, additional income can be obtained through recycling;

(2)Stable and concentrated supply: The generation of discarded wood pallets is "concentrated" (mostly concentrated in industrial parks and logistics hubs), and the recycling radius is usually controlled within 50-100 Within kilometers, the transportation cost is low, and there is no need to collect straw in a scattered manner (which requires covering a large area of farmland and has high labor and transportation costs);

(3)Low pre-processing difficulty: wooden pallets are mainly made of pine, poplar, and miscellaneous wood, with uniform wood density and stable fiber structure, and do not contain the "high ash content and high moisture content" problem of straw - only metal accessories such as nails and screws need to be removed through magnetic separation equipment, and then conventional crushing is performed (no fine grinding is required). The equipment energy consumption and labor costs in the pre-processing stage are about 30% lower than those of straw processing.

2.Production: The processing threshold is moderate, and small and medium-sized projects are easy to implement.

The "implementability" of the project is the core concern of small and medium-sized investors. The project has the characteristics of "low threshold and high adaptability" in the production process:

(1)Controllable equipment investment: The core equipment (crusher, pulverizer, dryer, pelletizer, cooling and screening machine) of small and medium-sized production lines (daily production capacity of 5-20 tons) has a moderate investment, does not require large-scale infrastructure, and has low financial pressure, which is suitable for individuals or small and medium-sized enterprises to start;

(2)Mature technology and easy operation: The processing process is standardized, without complex technical barriers. Ordinary workers can take up their posts after 1-2 weeks of training, and the equipment failure rate is low (wood raw materials cause less wear and tear on equipment than straw and rice husks), and the maintenance cost is low;

(3)High energy consumption and environmental compliance: During the production process, the drying process can utilize the waste heat generated by the combustion of some pellets (reducing energy consumption). 30%), and no wastewater discharge (only a small amount of equipment cooling water, which can be recycled), and the waste gas can meet the standard after simple bag dust removal.

Biomass pellets made from recycled wooden pallets (referred to as "pallet pellets") are essentially wood-based biomass pellets. However, due to the unique nature of their raw material (waste pallets), they offer several advantages over other biomass pellets, such as straw, rice husks, sawdust, and bark:

1.Raw material stability: A single ingredient eliminates "mixed material defects"

The raw material composition of biomass pellets directly determines product consistency, and pallet pellets offer a distinct advantage in this regard. Pallet pellets are primarily made from discarded solid wood pallets (such as pine, fir, and poplar) or plywood pallets, with wood comprising over 95% of the raw material. They are free of crude fiber from straw, silica from rice husks, or high-ash impurities from bark. They are also free of pesticide residues (unlike farmland straw) and odor (unlike pellets derived from food waste).

2.Raw material cost efficiency: "Turning waste into treasure," the cost is significantly lower than conventional wood-based raw materials.

The raw material cost of biomass pellets accounts for 60%-70% of the total cost. The raw material advantages of pallet pellets significantly lower the investment threshold. Pallet pellets are made from discarded pallets, considered industrial solid waste. Procurement costs are extremely low (in some areas, they can even be recycled for free with a small transportation fee), and recycling channels are stable (logistics parks, manufacturing plants, and warehouses generate large quantities of discarded pallets annually). Furthermore, pallets are typically standardized in size (e.g., 1200×1000mm), making them highly efficient to disassemble and crush, eliminating the need for additional sorting (unlike loose sawdust).

3.Product Calorific Value: High wood density results in superior combustion efficiency compared to herbaceous/miscellaneous pellets.

Calorific value is a core performance metric for biomass pellets (determining the cost-effectiveness of replacing coal and natural gas). Pallet pellets, due to their high wood density, offer a significant calorific value advantage. Average Lower Calorific Value (MJ/kg): 18-20 Density (kg/m³): 1.1-1.3 Combustion Efficiency (compared to standard coal): 80%-85%

Pallets are typically made from "finished wood" (e.g., pine pallets have a higher density than log sawdust), resulting in a denser fiber structure. The resulting pellets are denser and more resistant to breakage (lower transportation loss). 3%, while straw pellets can reach 5%-8%), and the heat released during combustion is more stable, making it suitable for "high-load energy scenarios" such as industrial boilers and biomass power stations.

2025 Tony Machinery - All Rights Reserved. Map