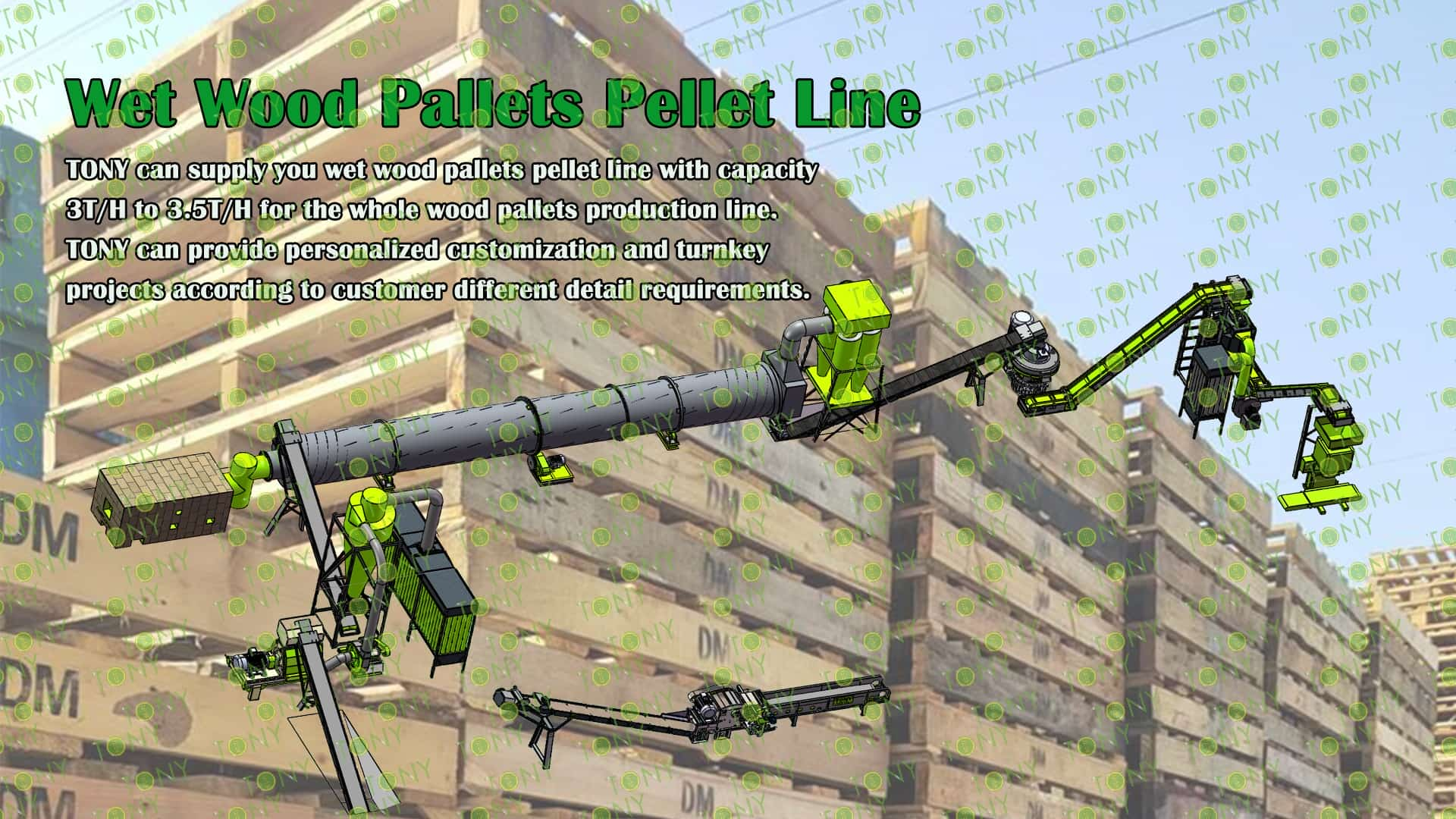

Project Brief Introduction:

1.Product:Wet Wood Pallets Pellet Line

2.Capacity: 3-3.5T/Hour

3.TONY Brand 3-3.5Ton /Hour Wet Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ860-Ⅲ-220KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 540KW

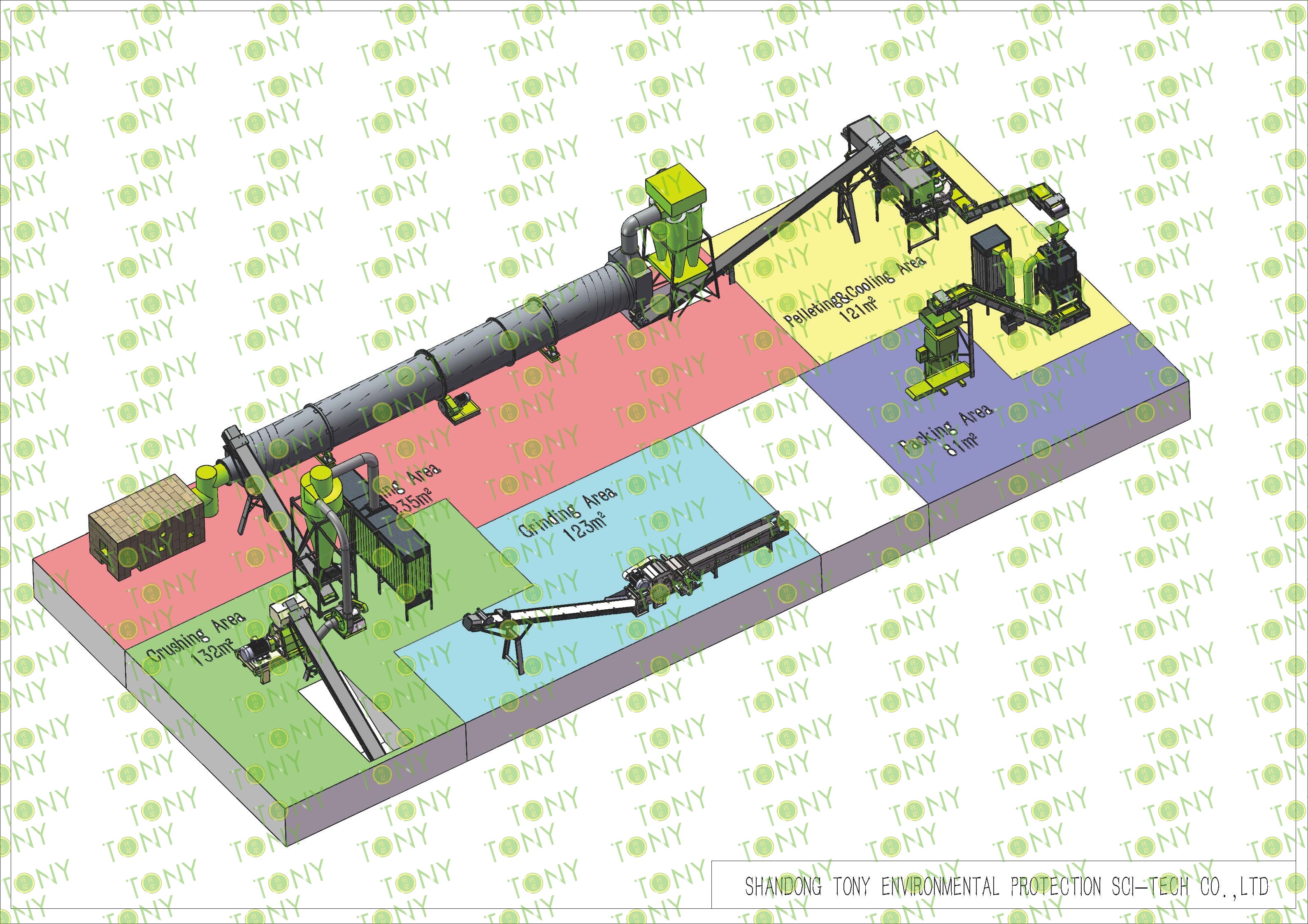

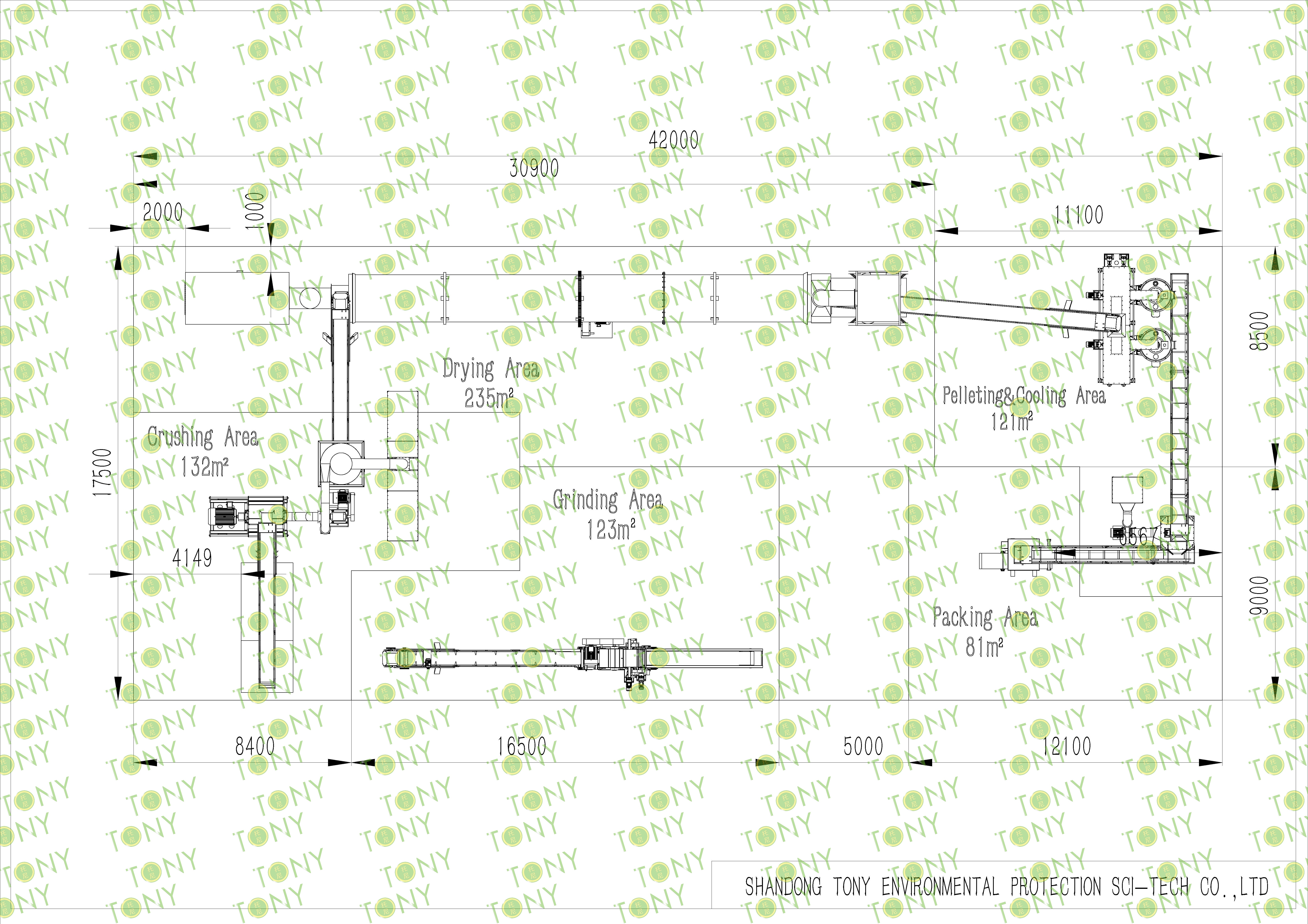

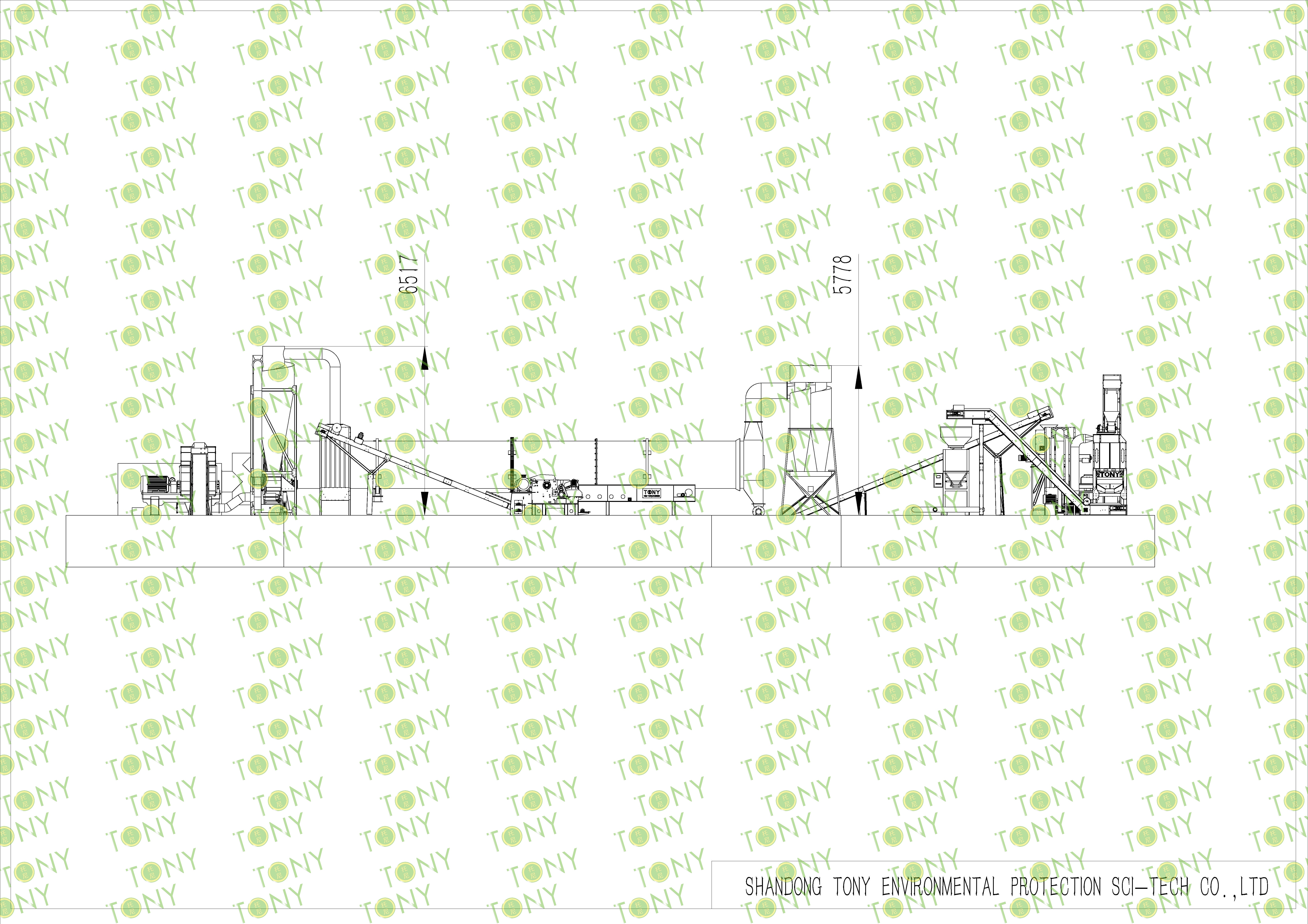

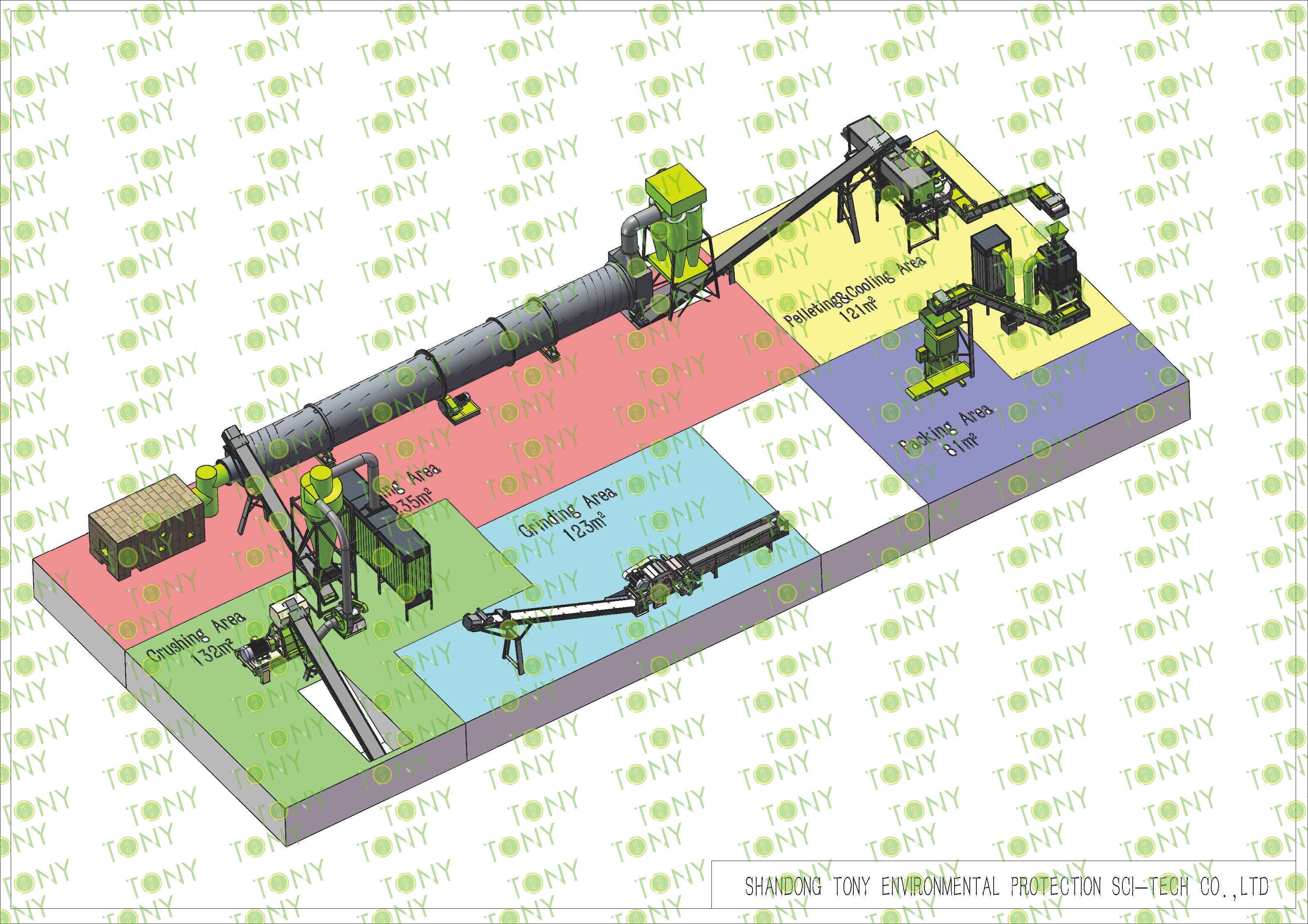

6.Need Area: About 735㎡ L: 42 M W: 17.5 M H: 6.517 M

Project Layout For Customer:

1.The working principle of wet wood pallets biomass pellet processing equipment

The core goal of the wet wood pallet biomass pellet processing equipment is to solve the problems of dehydration, impurity removal and molding of wet wood pallets. Its working principle revolves around the three core links of "pretreatment → drying and dehydration → pelletizing and molding". The various equipment work together to convert high-humidity and impurity wood pallets into qualified biomass pellets.

2.Characteristics of wet wood pallets biomass pellet processing equipment

Strong Adaptability to Wet Materials: Addressing the high moisture content of wet pallets, a high-power hot air drying system is equipped to quickly reduce the raw material moisture content to the optimal molding range of 10%-20%, while preventing wet material from sticking to the equipment and clogging the conveyor.

Efficient Impurity Removal and Protection: Built-in metal detection and magnetic separation modules precisely separate metal impurities such as nails and wire from the pallets. The crushing and forming components are constructed of wear-resistant materials to prevent impurities from scratching the molds or damaging the transmission mechanism, extending the equipment's service life.

Flexible Raw Material Processing: Adaptable to the irregular shapes of waste pallets, the pre-processing stage uses a shredder to break down large pieces into smaller pieces. An adjustable-speed pulverizer then refines the material into uniform 3-5mm chips. This system is compatible with pallets of varying thicknesses and materials, such as pine and poplar.

High Forming Stability: Utilizing a ring die/flat die dual-roller structure, coupled with extrusion friction heating (70-100°C), the high temperature softens wood fibers and improves pellet adhesion. The adjustable pressure system adapts to varying sawdust moisture levels, minimizing pellet cracking and loosening. Finished product density can reach 1.1-1.3g/cm³.

Environmentally Friendly and Energy-Saving: The drying process utilizes waste heat from biomass fuel generated during the forming process for auxiliary heating, reducing external energy consumption. The entire machine is equipped with a sealed dust collection device to reduce sawdust pollution, complying with environmental emission requirements and enabling the recycling of waste wooden pallets.

3.Application scenarios of wet wood pallets biomass pellet processing equipment

Logistics/Warehousing Companies Build Their Own Recycling Lines:Large logistics parks and e-commerce warehouses generate thousands to tens of thousands of pieces of waste wet pallets annually. This equipment allows for on-site processing: Instead of sending the waste pallets for drying, the wet pallets are directly crushed into wood chips. The equipment's built-in drying system reduces the moisture content to pelletizing requirements, ultimately producing fuel pellets for the company's own forklifts and boilers, or for external sales. This reduces waste disposal costs and generates additional revenue.

Professional Waste Wood Pallet Recycling Companies:For companies specializing in the recycling and reuse of wood pallets, traditional methods only allow for the disassembly and reassembly of dry pallets. Wet pallets, prone to mold and deformation, are often treated as waste. This type of equipment can expand their business scope by processing recycled wet pallets into biomass pellets, addressing the problem of unusable wet materials and forming a complete "recycling-processing-sales" industry chain. This equipment is particularly suitable for locations near ports and industrial parks (near concentrated sources of wood pallets).

Wood Processing/Furniture Factory Ancillary Processing:Wood processing and furniture factory operations generate wet pallets (for transporting finished products) and scraps. This equipment can process these wet pallets and scraps together, eliminating the need for separate handling of different materials. This allows one device to process multiple wet materials, improving resource utilization.

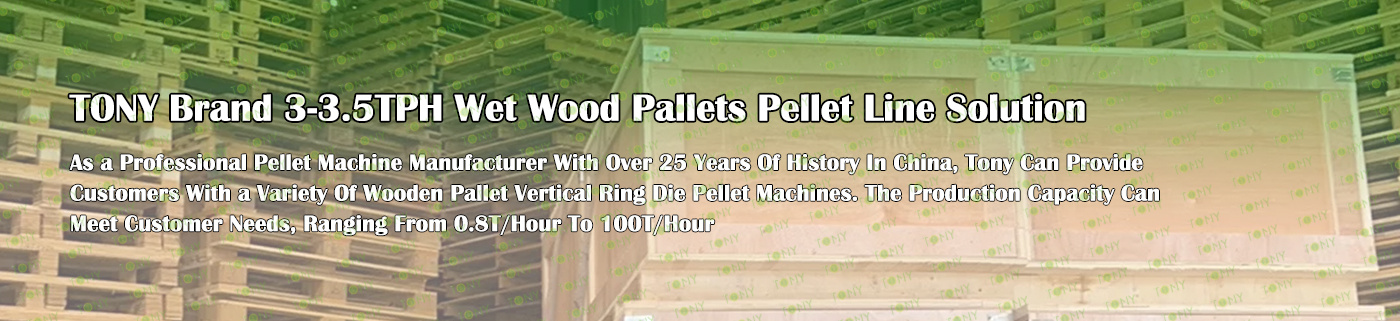

TONY Brand 3-3.5Ton/Hour Wet Wood Pallets Pellet Manufacturing Plant can take wet wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 3-3.5Ton/Hour

2. Raw materials: Wet wood pallets

3. Moisture: Wet type, about 40%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Pallets Pellet Production Line

2. Raw Material: All kinds of wet wood pallets

3. Moisture Content of Raw Material: 40%

4. Capacity: 3-3.5 tons per hour

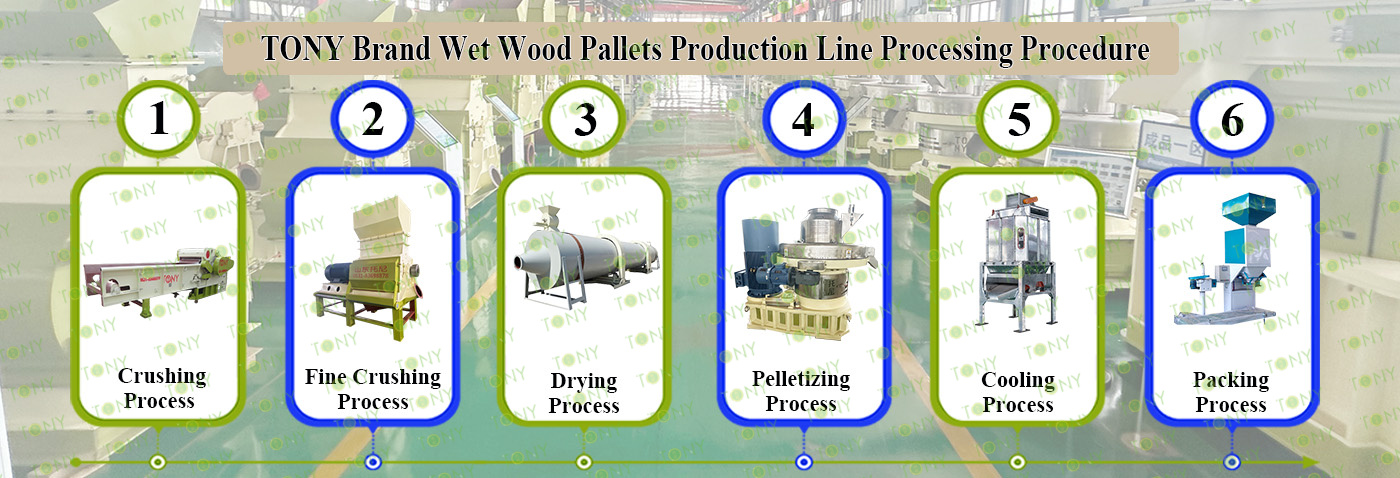

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer Mill-TFD75*100-110KW, Rotary Drum Dryer-1.8*18m, TONY Pellet Machine TYJ860 - Ⅲ - 220KW, Pellet Cooler, Semi-automatic Packing Machine and Belt Conveyors

|

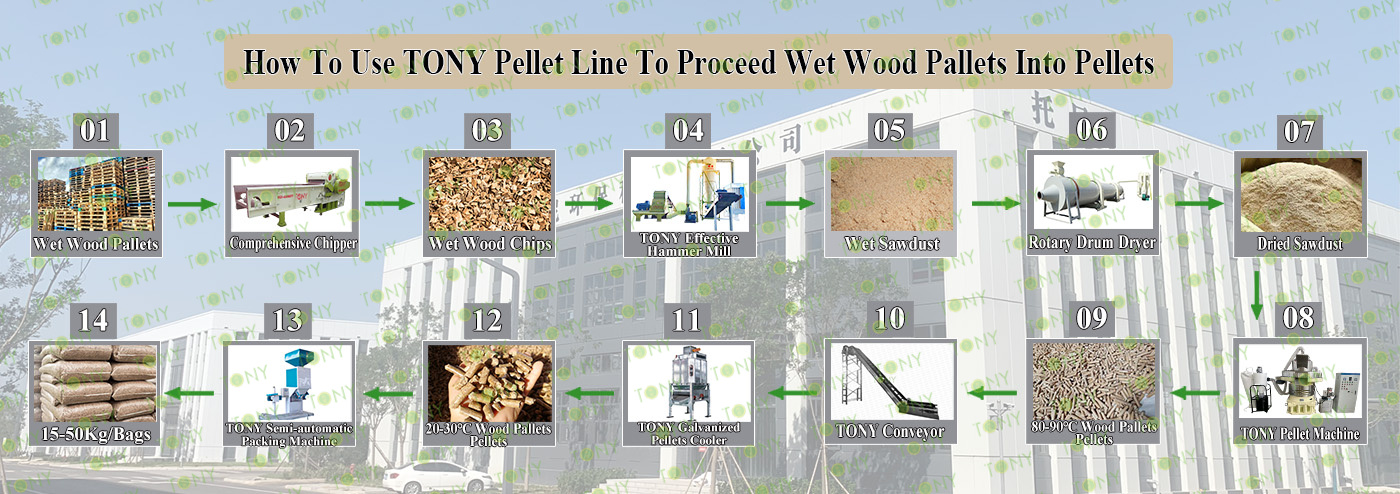

How to use the TONY pellet production line to make pellets from wet wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind wet wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer mill | Rotary Drum Dryer |

| 1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With16 hammer heads*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*100-110KW*1set 3.Capacity: 3-3.5Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD1.8*18*1set 3.Capacity:3-3.5Ton/Hour/Set |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*1set 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3-3.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity:3-3.5Ton/Hour |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY Brand comprehensive chipper TPC1000-90KW model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:3-3.5Ton/Hour.

C.TONY brand effective hammer mill TFD75*100-110KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

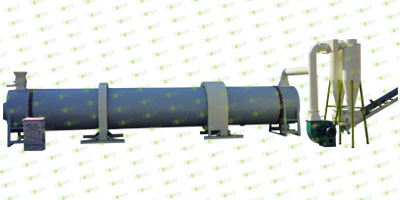

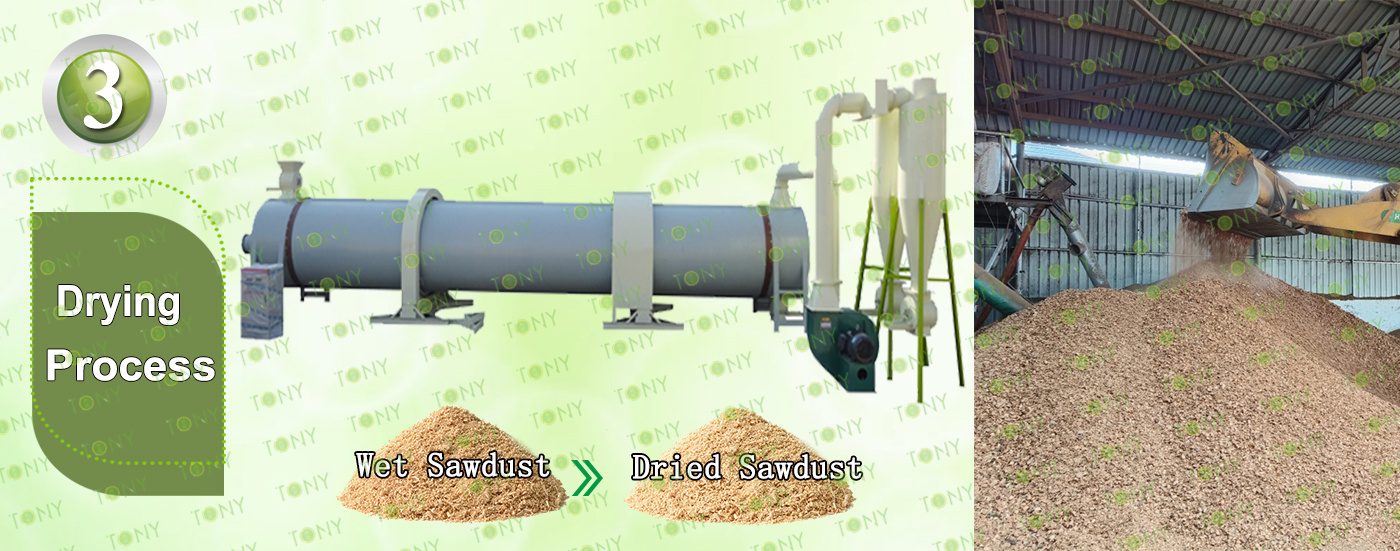

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:3-3.5Ton/Hour.

C.TONY use 1set of 1.8*18m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:3-3.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-220KW*1set

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:3-3.5Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:3-3.5Ton/Hour.

C.TONY Semi-Automatic Packing Machine*1set.

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

For industrial boilers, research the number, scale, and fuel consumption of industrial enterprises in the local and surrounding areas that are using biomass pellets to replace traditional fuels like coal and natural gas. For example, analyze the potential demand for biomass pellets from food processing plants, wood processing plants, and other enterprises, and analyze their requirements for quality indicators such as pellet calorific value and density.

For the heating market, focus on investigating the willingness and market size of urban centralized heating companies, small heating stations, and rural areas in cold northern regions to adopt biomass pellets. Understand the price acceptance of pellets among different customer groups. For example, decentralized heating users in rural areas may be more price-sensitive, while urban commercial heating users have higher requirements for product quality and supply stability.

Study the application of biomass pellets in power generation, focusing on biomass power plant construction plans, fuel supply conditions for existing power plants, and the potential for sourcing biomass pellets processed from wooden pallets. For example, if a region plans to build a new biomass power plant, establish early contact with the project to understand its fuel demand and potential for cooperation.

Strong market demand and guaranteed sales

With stricter environmental protection policies (such as the expansion of "coal-free zones" and the conversion of industrial boilers from coal to gas or coal to biomass), the market demand for biomass pellets as a clean alternative fuel continues to grow. Its downstream customers include:

1.Industrial sector:

boiler heating in the food processing, textile, chemical and other industries;

2.Commercial sector:

central heating in hotels, hospitals, and residential areas;

3.Energy sector:

small biomass power stations and biomass gasification projects;Some regions can also export to countries with high demand for biomass fuels, such as Europe, Japan, and South Korea, to expand the international market.

2025 Tony Machinery - All Rights Reserved. Map