Project Brief Introduction:

1.Product:Wet Wood Pallets Pellet Line

2.Capacity: 5-6T/Hour

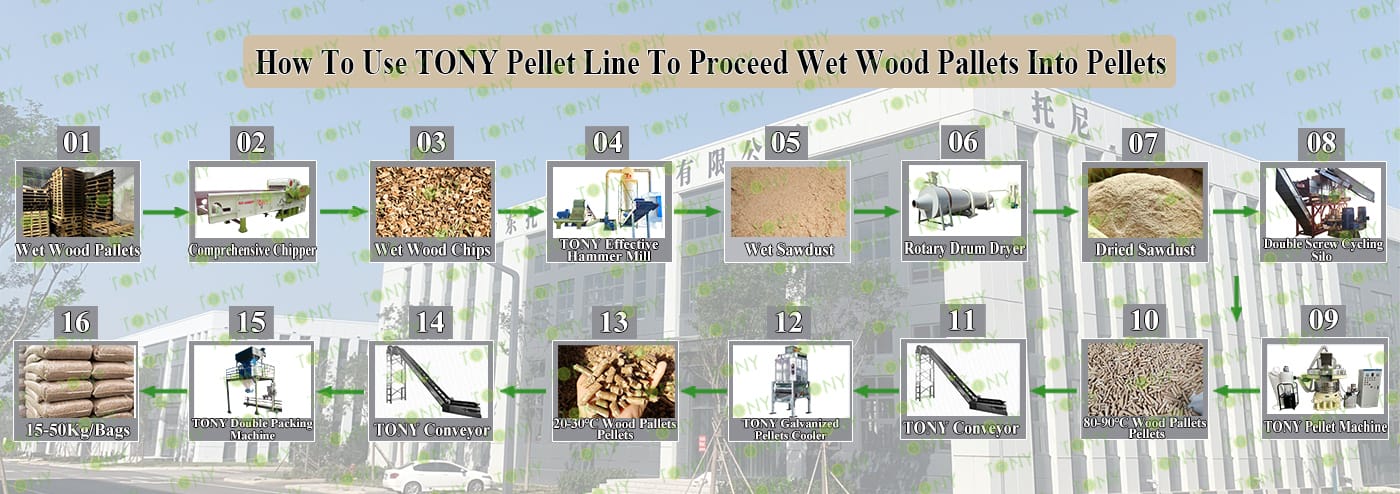

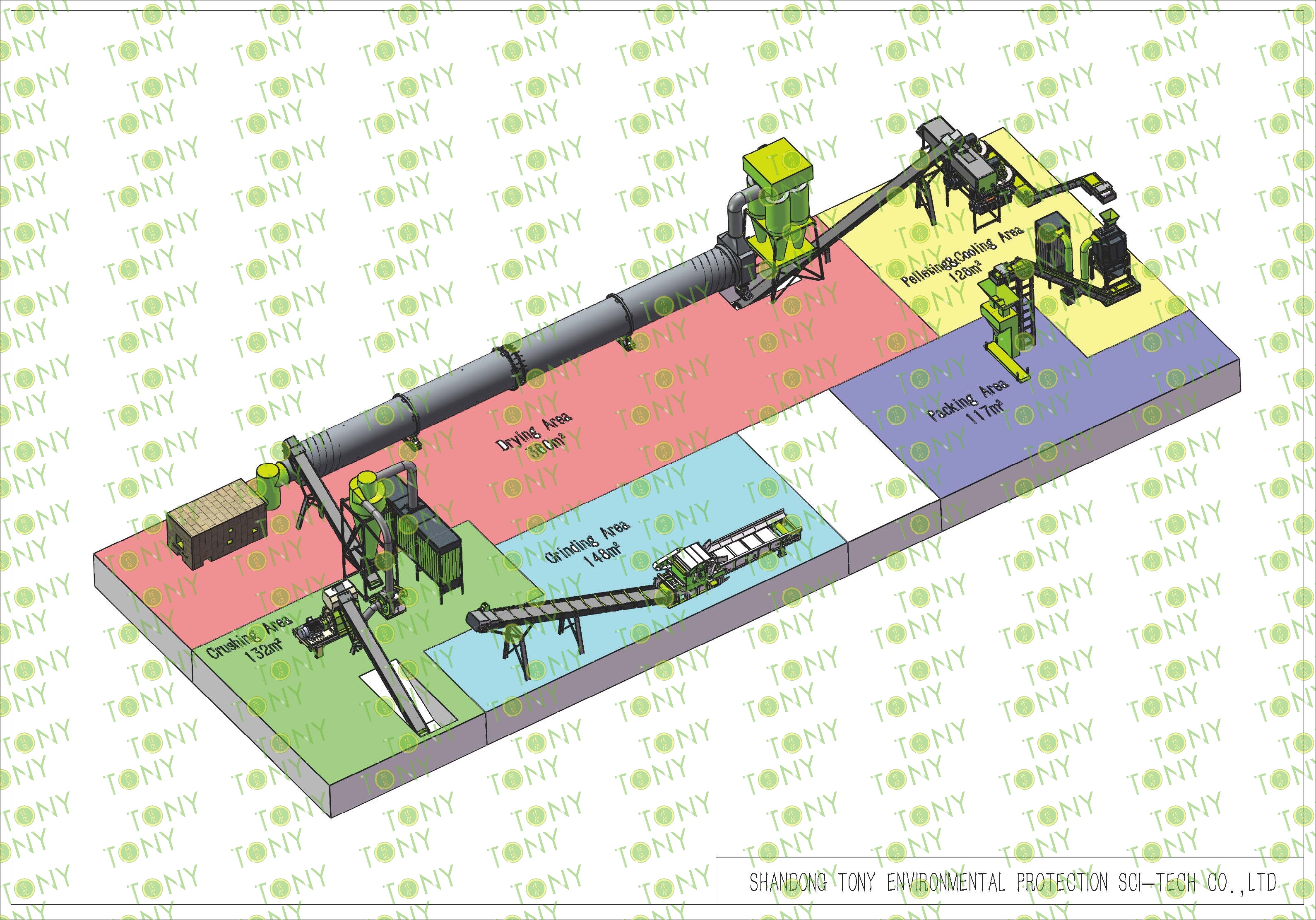

3.TONY Brand 5-6Ton /Hour Wet Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-160KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 680KW

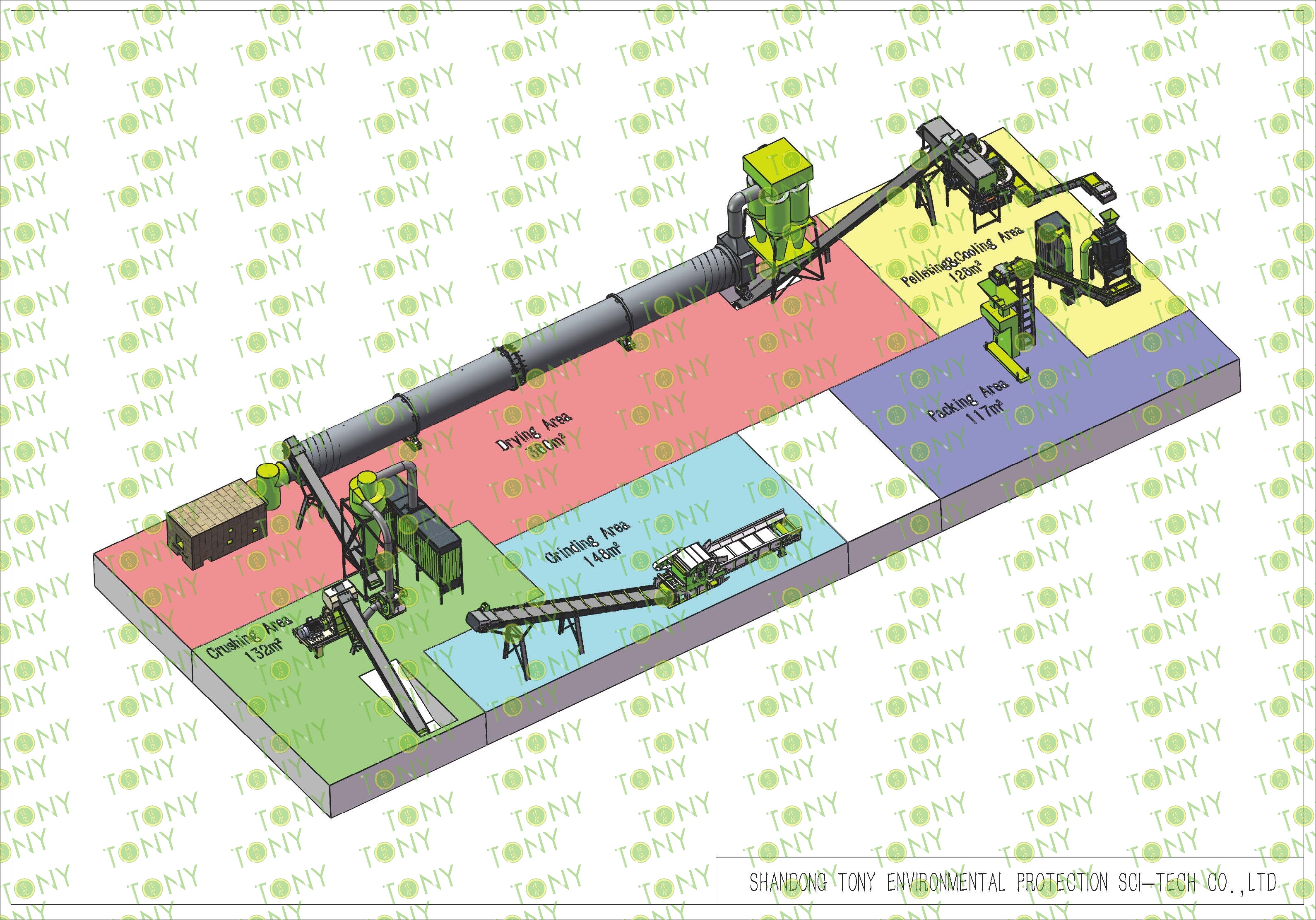

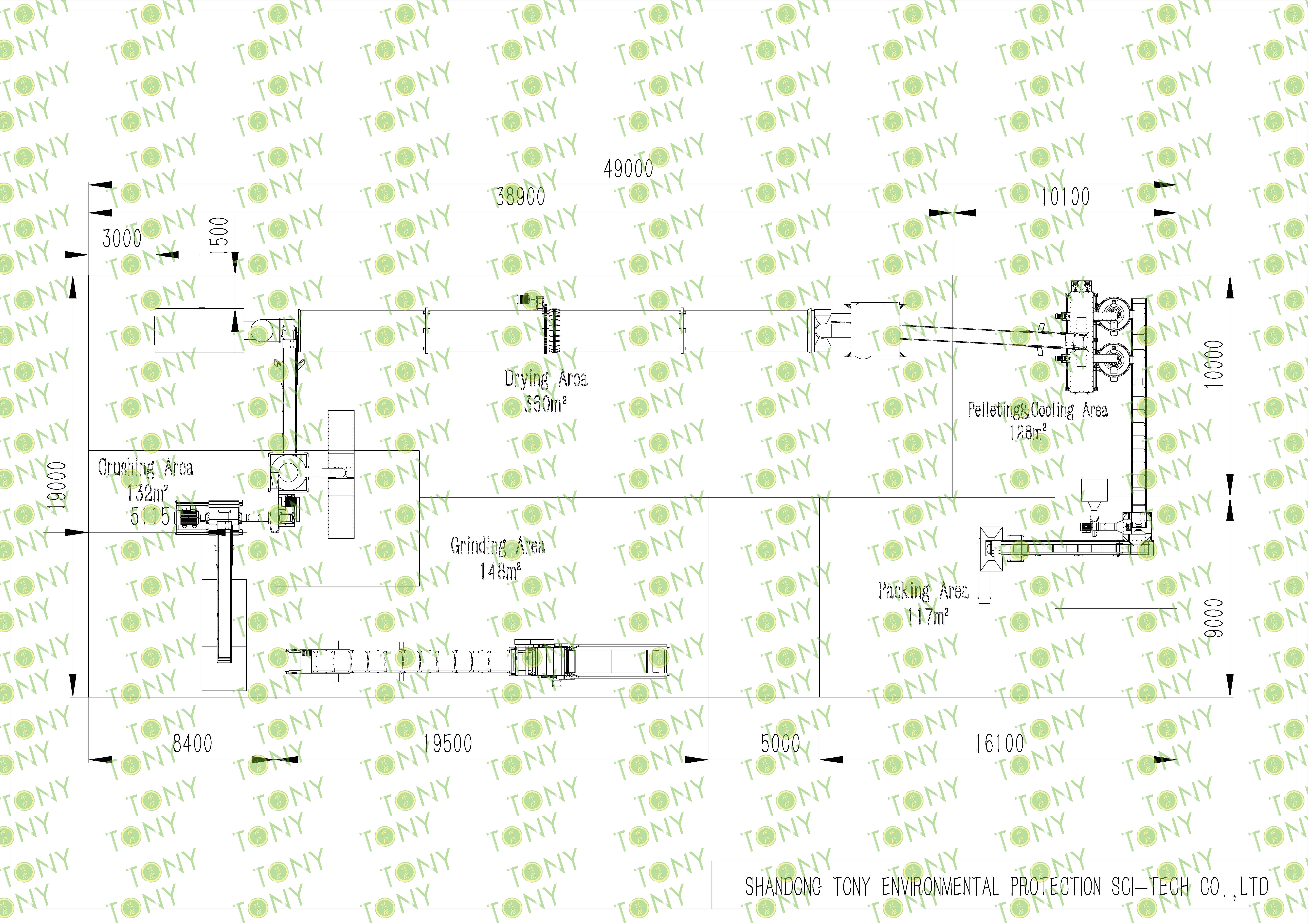

6.Need Area: About 931 ㎡ L: 49 M W: 19 M H: 7.065 M

Project Layout For Customer:

1.The working principle of wet wood pallets biomass pellet processing equipment

The wet pallet biomass pellet processing equipment is used to remove nails from wet pallets and other biomass materials, shred them, and compress them into pellet fuel. Its working principle is to first crush the wet pallets to remove nails, then grind them into sawdust in a pulverizer. The dryer dries the wood to a moisture content of 10-15%, and then presses it into pellets in a pelletizer, ultimately producing biomass fuel pellets that meet quality standards.

2.Characteristics of wet wood pallets biomass pellet processing equipment

(1)Strong adaptability of raw materials, compatible with a variety of biomass

Wide processing capacity: Processable raw materials include wet wooden pallets, old furniture, demolition materials, etc. By adjusting the crushing and pulverizing equipment, it can adapt to raw materials of different hardness and fiber content.

Clear requirements for raw material pretreatment: The moisture content of the raw materials must be controlled at 10%-15% (too high a moisture content will easily cause adhesion and mold clogging, and too low a moisture content will result in insufficient pellet strength), and the particle size is usually required to be 1-3mm.

(2)Modularization of core equipment and continuous production process

Modular combination: A typical production line consists of "crushing equipment (coarse crushing) → crushing equipment (fine crushing) → drying equipment (humidification) → pelletizing equipment (molding) → cooling equipment (cooling) → screening equipment (screening) → packaging equipment". Each module can be flexibly increased or decreased according to production capacity requirements (for example, for small production lines, some auxiliary equipment can be omitted).

Continuous operation: Through the connection of various links such as conveyor belts and screw feeders, automated continuous production from raw material input to finished product output is achieved.

3.Application scenarios of wet wood pallets biomass pellet processing equipment

Processing equipment provides fuel for factory boilers and kilns (replacing coal and oil), such as steam boilers in textile and food processing plants, and heating kilns in the ceramics and building materials industries. Stable pellet production ensures energy supply.

(1)Power Generation:Biomass power plants require large quantities of standardized pellets as fuel. Large-scale processing equipment can meet the power plant's stringent requirements for pellet calorific value and density, ensuring efficient combustion and stable power generation.

(2)Residential Heating:For pellets used in home fireplaces and space heaters, processing equipment must control pellet size and hardness to accommodate residential combustion equipment. The equipment's refined production capabilities directly impact the user experience of these pellets.

(3)Environmental Protection and Waste Management:In waste and sewage treatment plants, processing equipment converts organic waste (such as sludge and food waste) into fuel pellets for resource recovery. Corrosion-resistant and clogging-resistant designs are crucial.

TONY Brand 5-6Ton/Hour Wet Wood Pallets Pellet Manufacturing Plant can take wet wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity:5-6Ton/Hour

2. Raw materials: Wet wood pallets

3. Moisture: Wet type, about 40%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Pallets Pellet Production Line

2. Raw Material: All kinds of wet wood pallets

3. Moisture Content of Raw Material: 40%

4. Capacity: 5-6 tons per hour

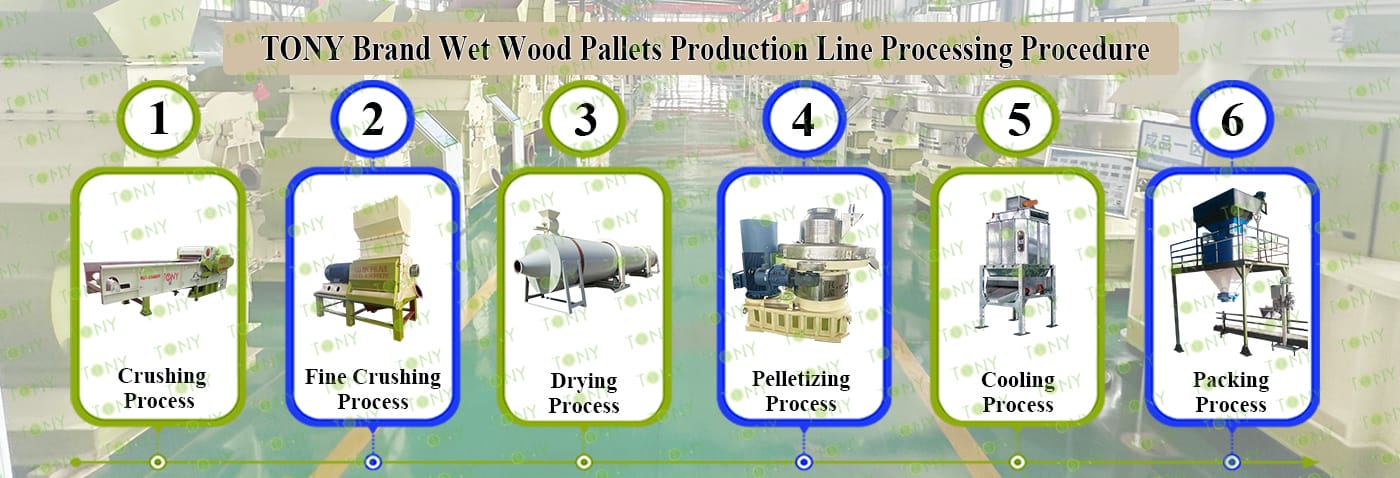

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer Mill--TFD75*160-160KW, Rotary Drum Dryer-1.8*24m, TONY Pellet Machine TYJ760-Ⅲ-160KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

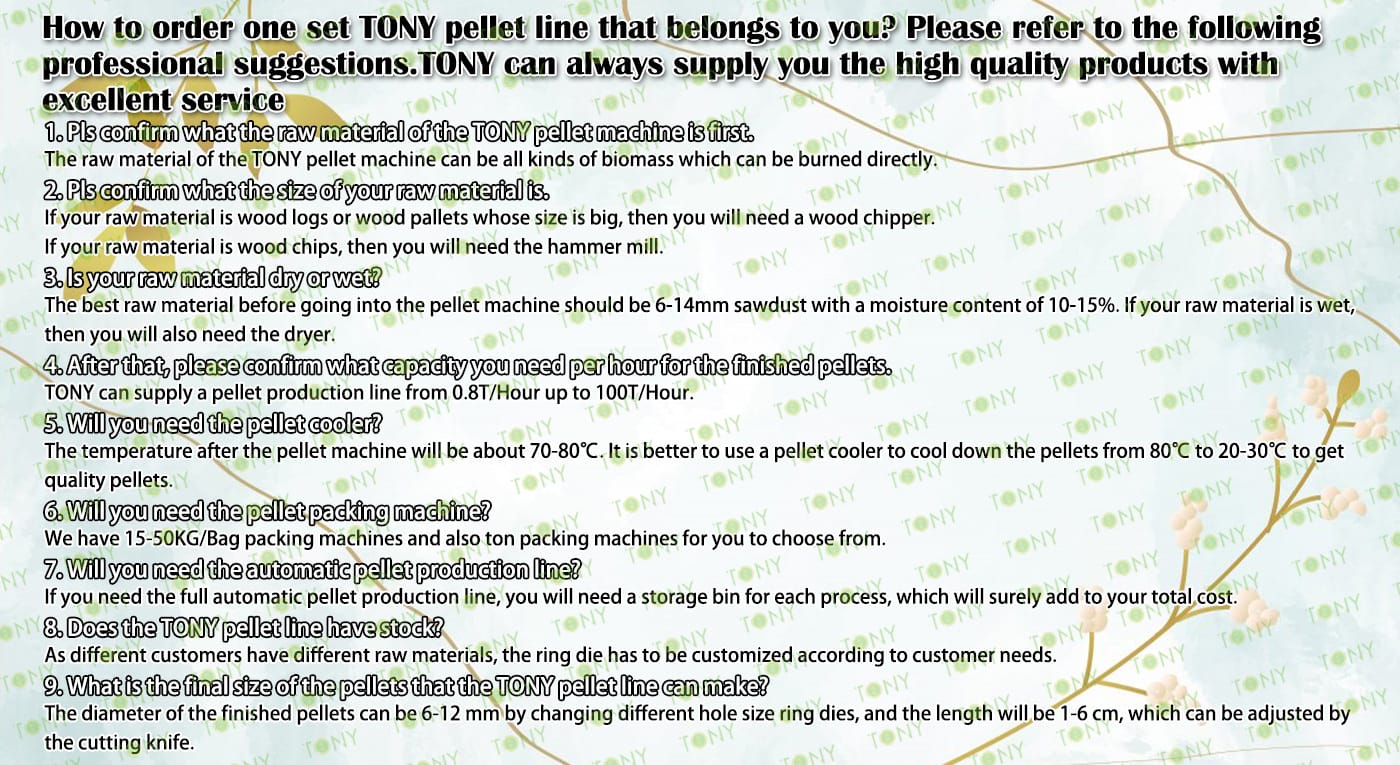

How to use the TONY pellet production line to make pellets from wet wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind wet wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. |

|||

|

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Silo |

|

1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. |

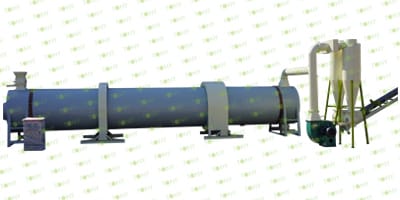

1.To Dry The 40% Sawdust Into 10-15% Sawdust. |

1.To Stroage Sawdust Before Pellet Machine; |

|

|

|

|

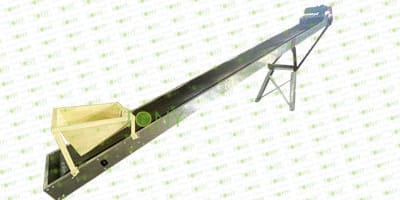

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets |

1.To Cool Pellets From 80-90℃ Into 20-30℃ |

1.To Pack Pellets Into 15-50KG/Bags. |

1.To Transport Wood Chips,Sawdust,Pellets. |

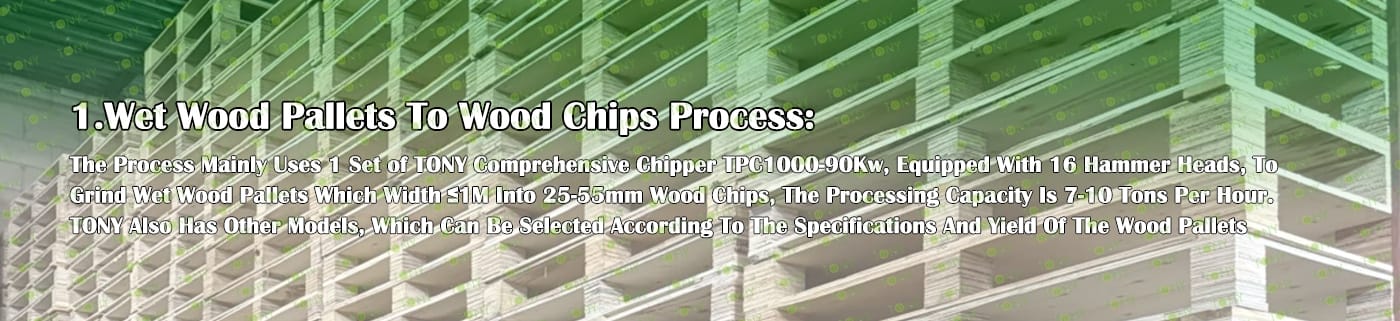

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1000-90kw model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:5-6Ton/Hour.

C.TONY brand effective hammer mill TFD75*160-160KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

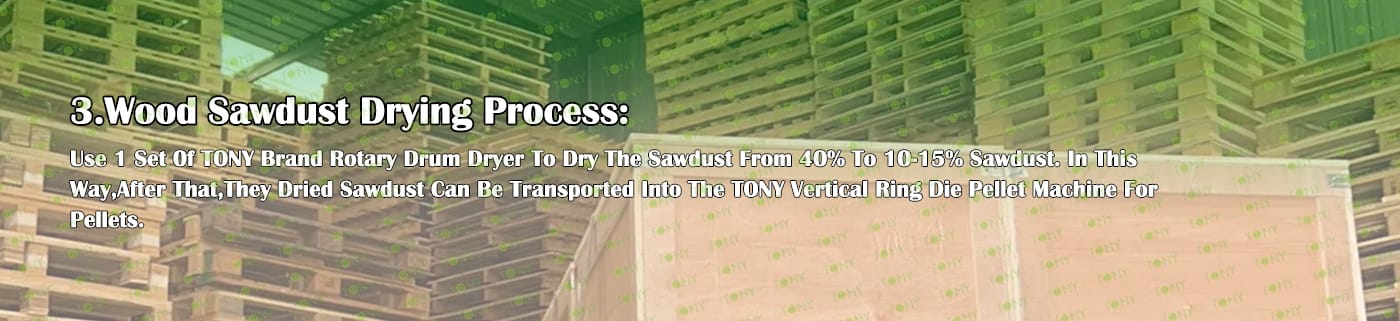

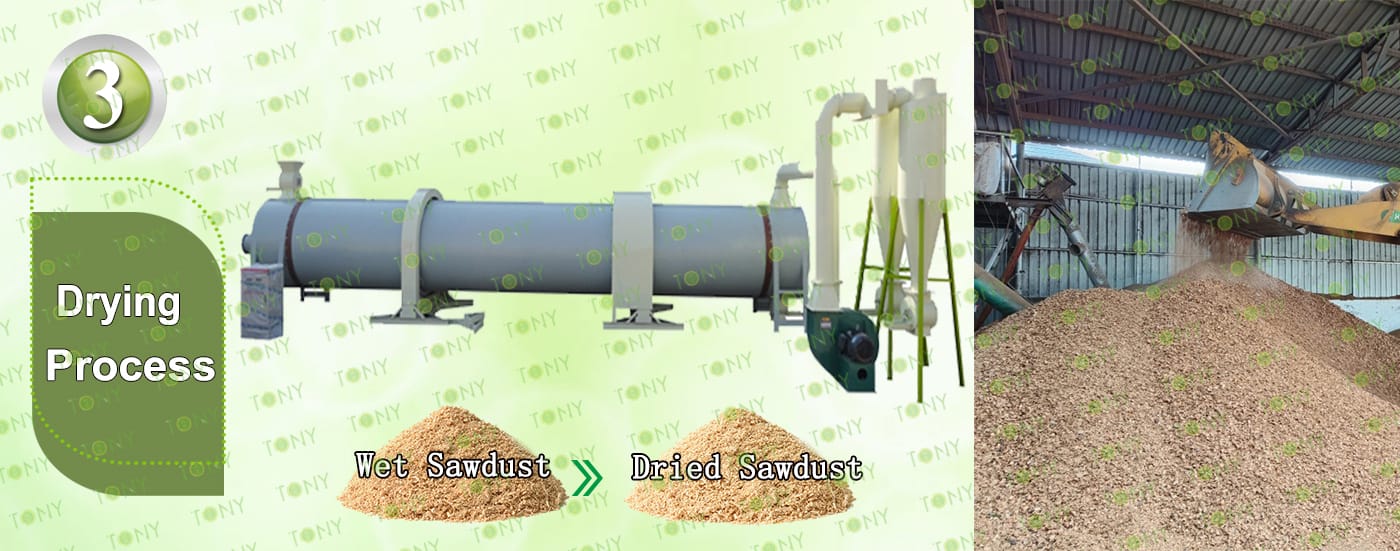

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:5-6Ton/Hour.

C.TONY use 1set of 1.8*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:5-6Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-160KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:5-6Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity5-6Ton/Hour.

C.TONY double packing machine*1set.

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

For investors, it is better to give priority to regions with abundant raw materials and strong policy support. By locking in raw material supply, improving production capacity utilization and expanding high-end markets (such as exports and civilian use), the return cycle can be further shortened and rapid profits can be achieved.

Wood Pellet Processing Investment Costs

1.Equipment Investment:

Equipment investment varies significantly depending on the project scale and equipment selected. A small semi-automatic production line may cost only tens to hundreds of thousands of yuan, while a large fully automated production line can cost millions or even more.

2.Plant and Site Costs:

You need to select an appropriate plant and site based on your production scale. Rental or construction costs vary by region.

Raw Material Procurement and Transportation Costs: Raw material costs are affected by factors such as region, season, and raw material type, while transportation costs are related to the raw material sourcing radius and product sales range.

3.Environmental and Other Expenses:

These include the investment and operating costs of environmental protection equipment, utilities, and employee salaries.

1.Environmentally friendly features

(1)Low pollution emissions: The sulfur and phosphorus content during combustion is extremely low, and the concentration of SO₂ and NOx in the flue gas is much lower than that of coal. It will not produce acid rain, and CO₂ emissions are zero (because plants absorb CO₂ during growth)

(2)Ash utilization: Ashes after combustion are rich in organic potassium and can be recycled as high-efficiency organic fertilizer

2.Economical

(1)Wide range of raw materials: waste such as wood processing waste and crop straw can be used, and the production cost is lower than traditional fossil fuels.

(2)Substitution benefits: Replacing coal can save about 20% to 30% of fuel costs

3.Wide range of application scenarios

(1)Industrial applications: Widely used in boiler heating, power generation and industrial production, such as textile factories, food factories, etc.

(2)Civil heating and living energy: Wood pellets have high combustion efficiency, are easy to store and use, and are safe and hygienic.

(3)Biomass industrial boiler: As the main fuel for industrial boilers, it replaces coal, heavy oil and natural gas to solve environmental pollution problems.

2025 Tony Machinery - All Rights Reserved. Map