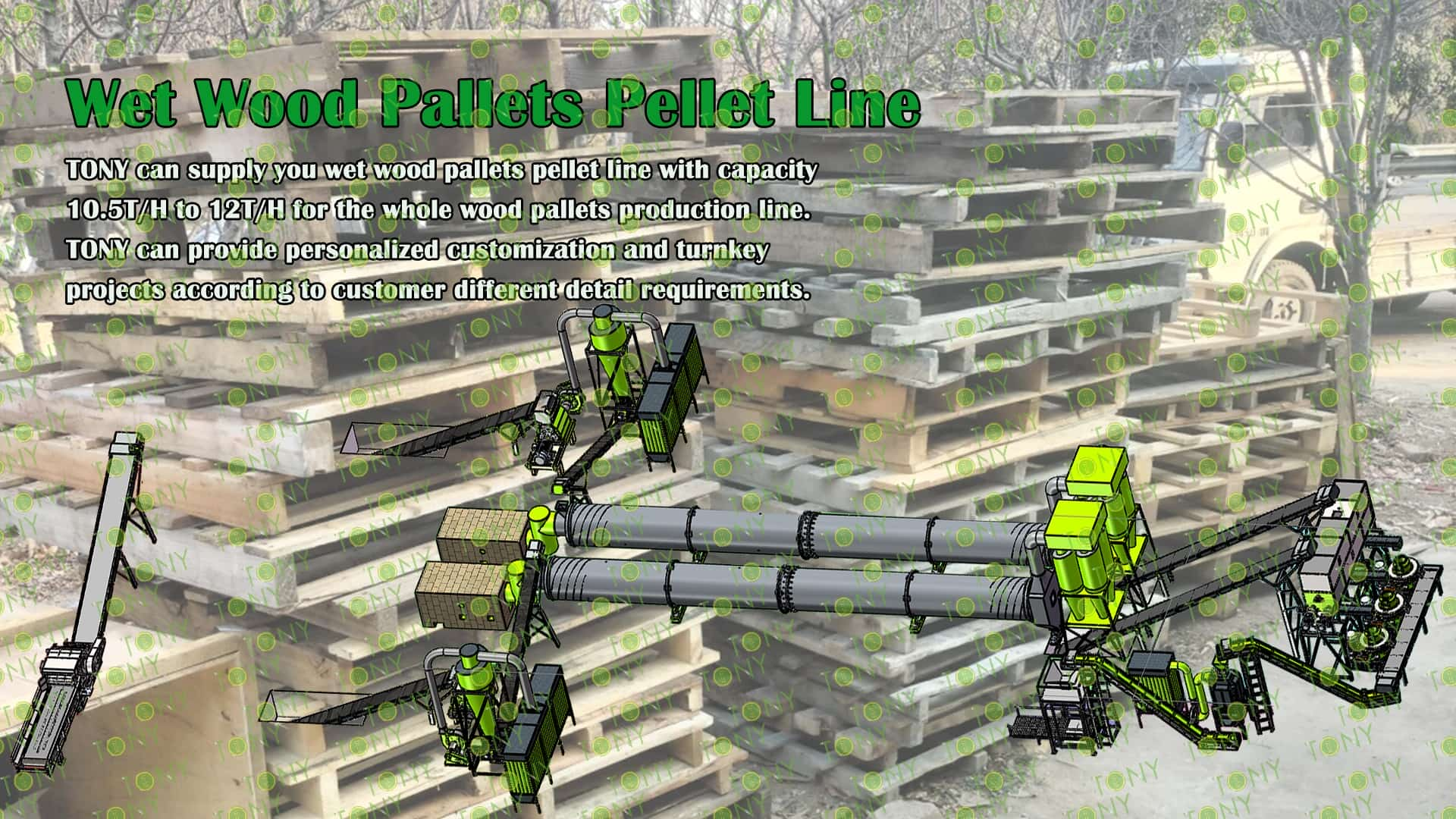

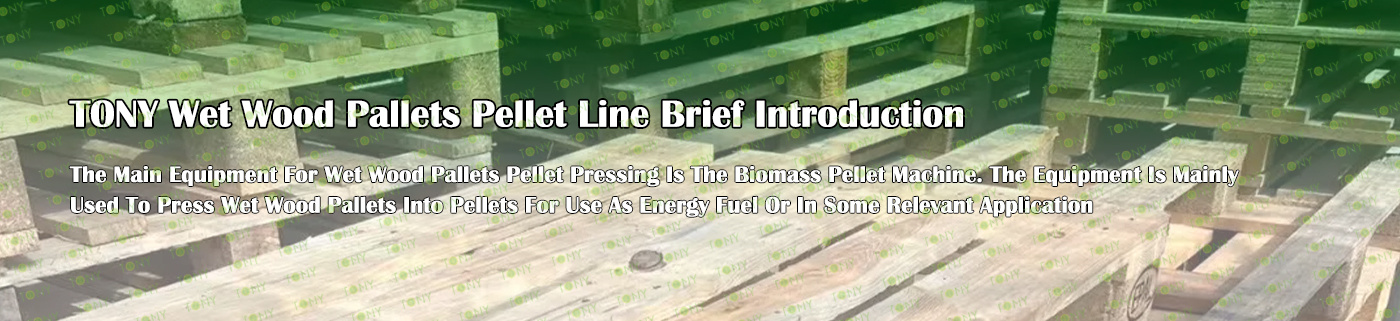

Project Brief Introduction:

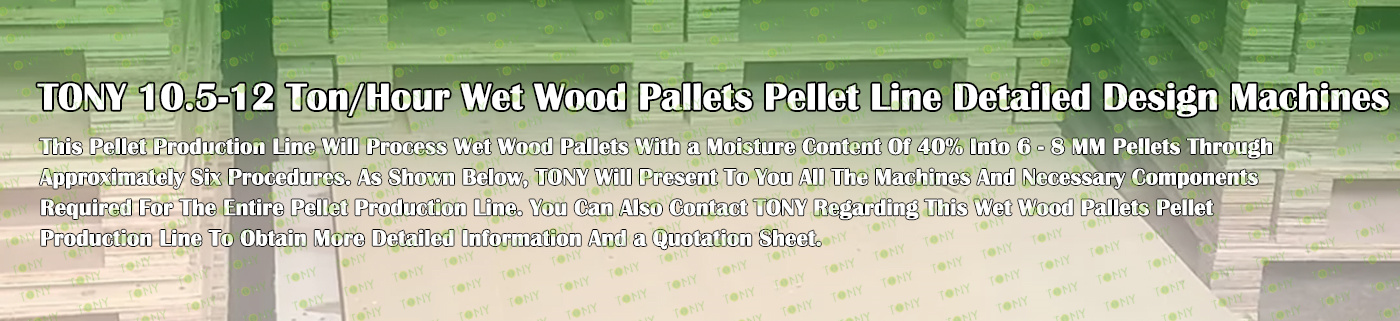

1.Product:Wet Wood Pallets Pellet Line

2.Capacity: 10.5-12T/Hour

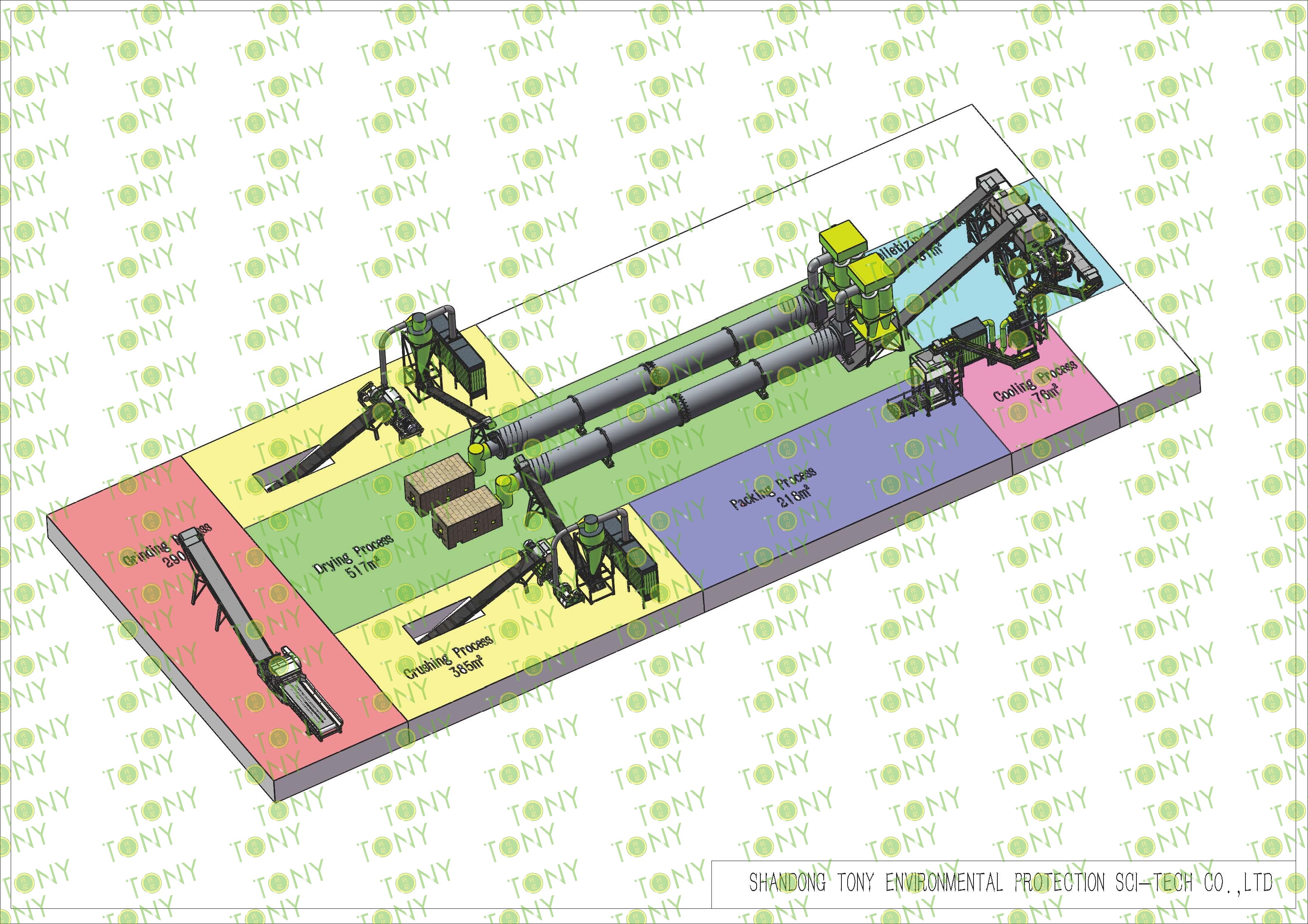

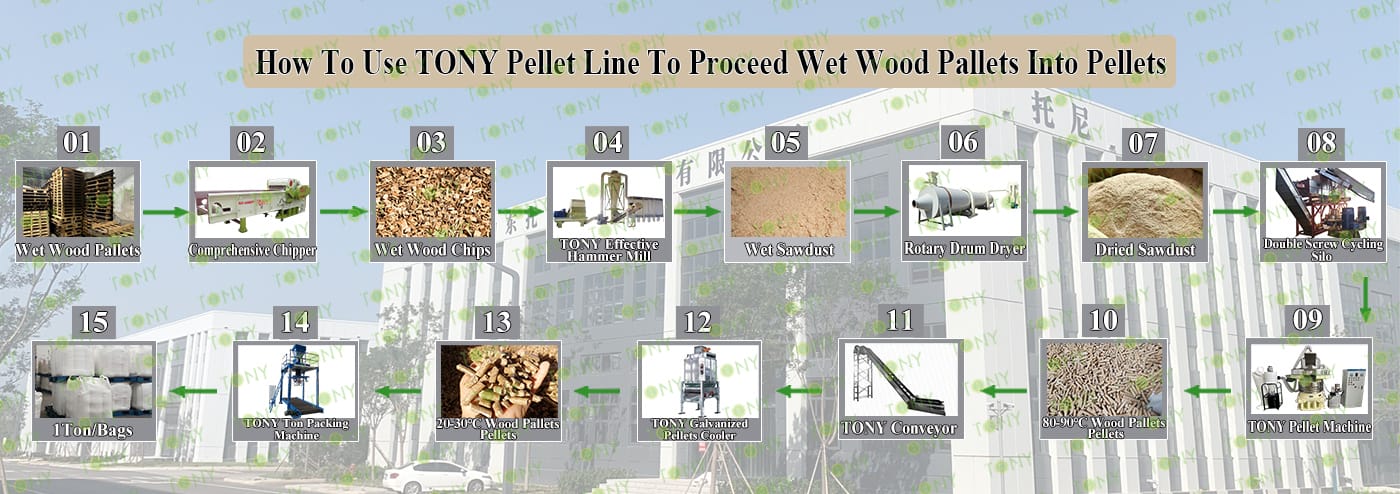

3.TONY Brand 10.5-12Ton /Hour Wet Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ860-Ⅲ-250KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1600KW

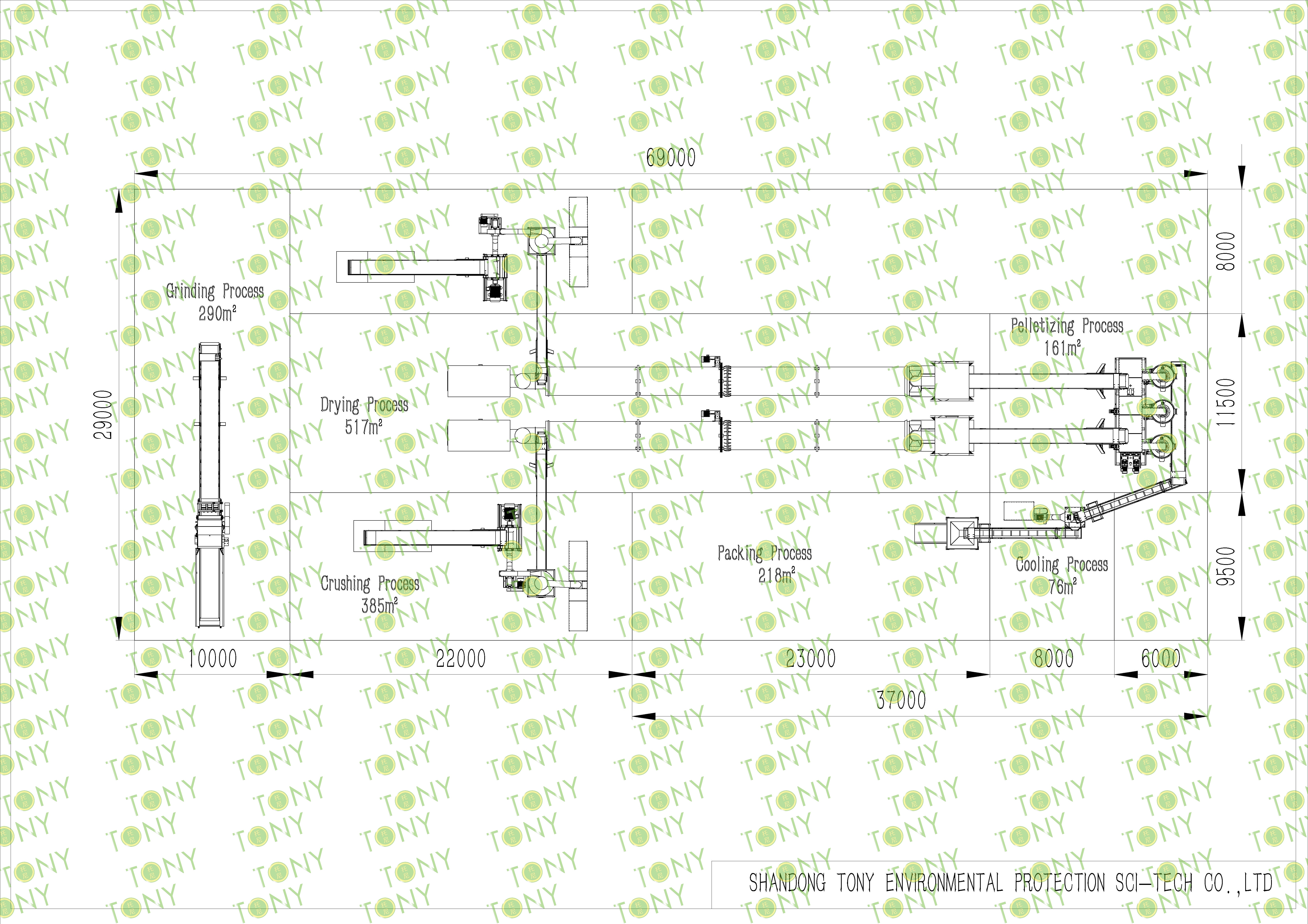

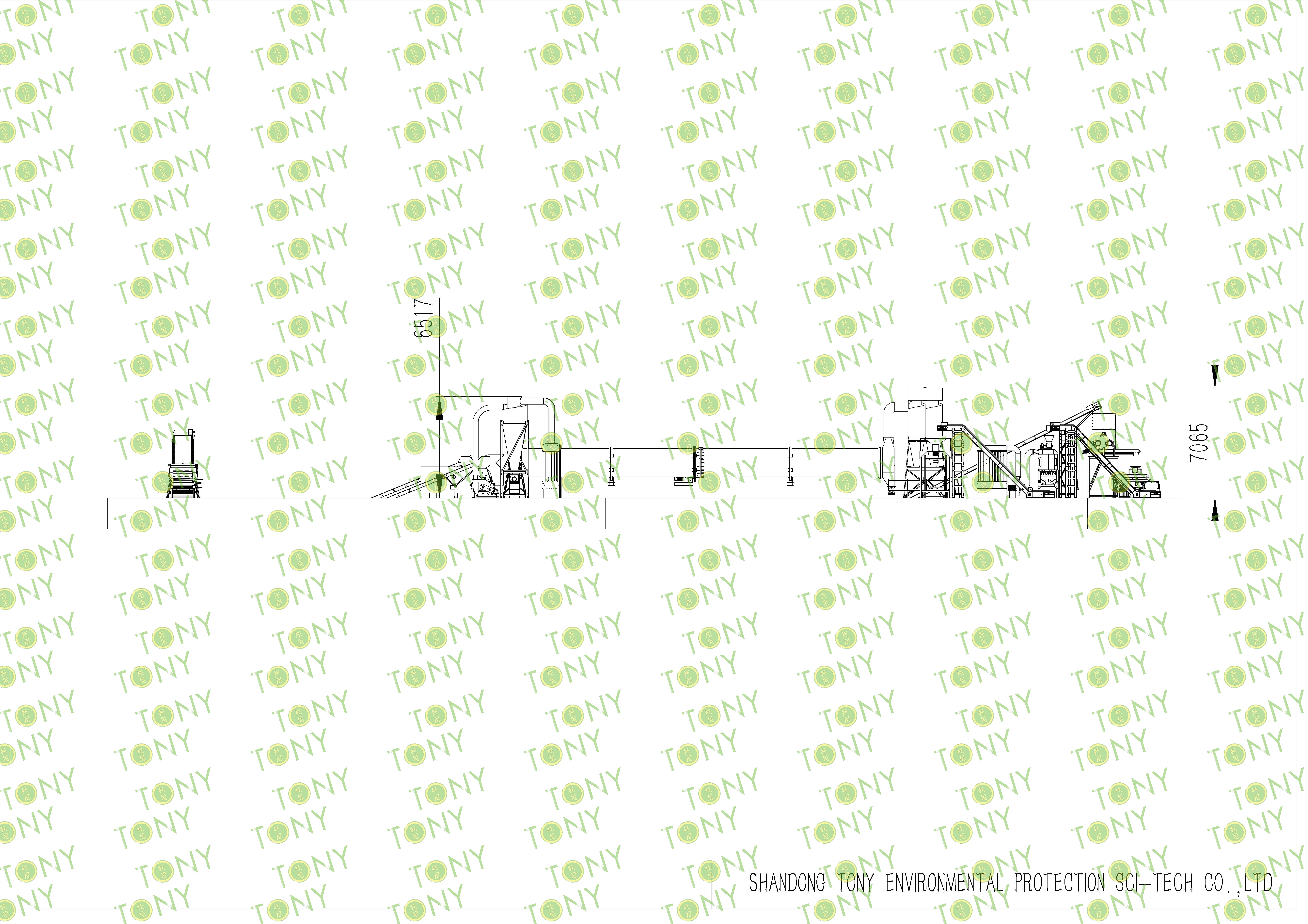

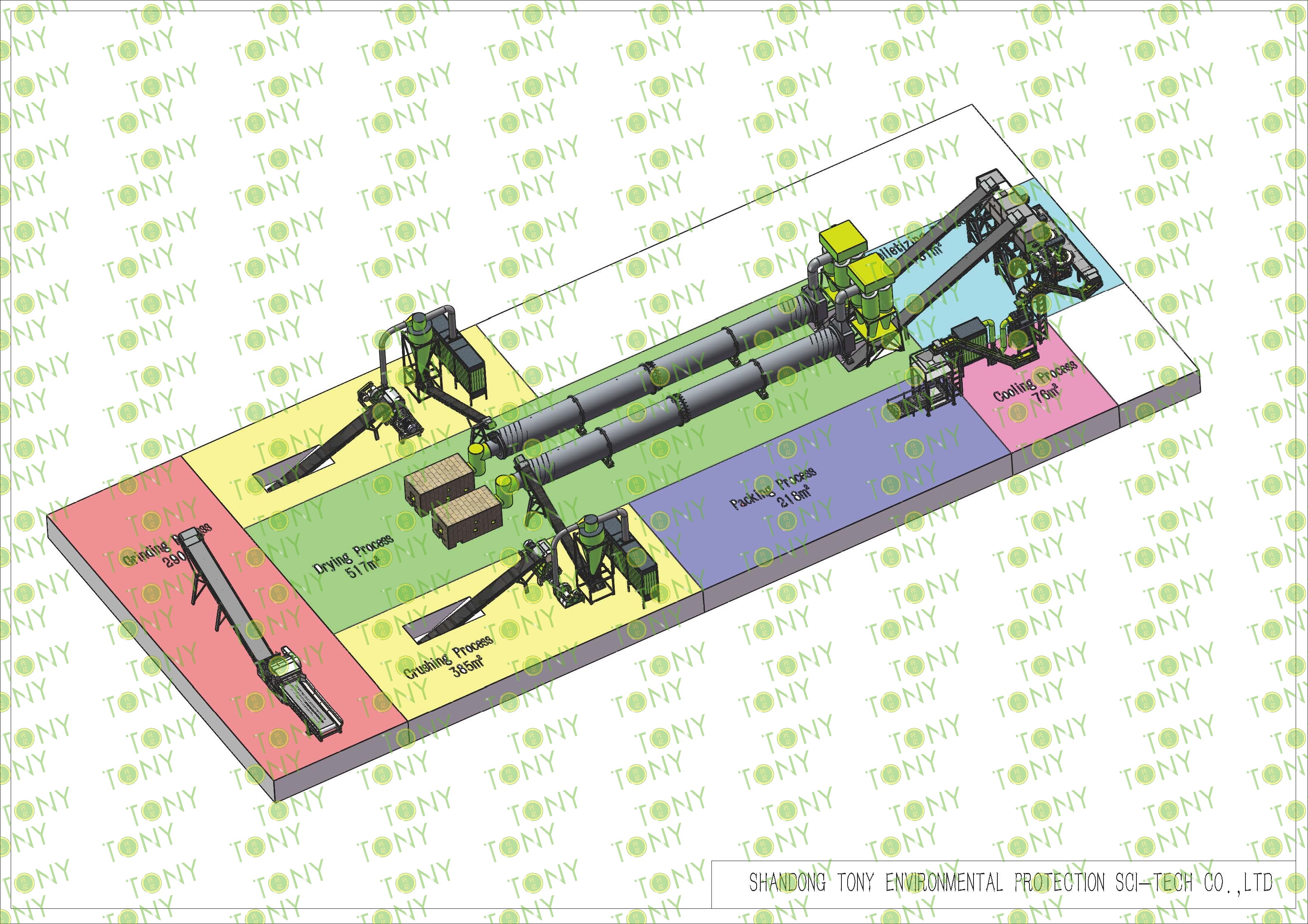

6.Need Area: About 2001㎡ L: 69 M W: 29 M H: 7.065 M

Project Layout For Customer:

1.The working principle of wet wood pallets biomass pellet processing equipment

(1)Mechanical shearing and impact force break the wood fiber structure, converting irregular raw materials into uniform fine particles, providing a "surface area maximization" raw material basis for subsequent dehydration and pelletizing (the larger the surface area, the higher the dehydration efficiency).

(2)When the moisture content is too high, the raw material is easy to adhere to the inner wall of the mold during the pelletizing process, causing blockage; when the moisture content is too low, the wood fiber becomes more brittle and is easy to break after molding. Therefore, the pretreatment needs to accurately control the moisture content to "pave the way" for pelletizing.

(3)The wood chips are forced into the "conditioning chamber" of the pelletizer through a screw feeder (with a stirring device). The stirring device continuously stirs the raw materials to ensure that the raw materials enter the pressing chamber evenly.

(4)The viscosity of the wet material is "utilized" in this link - the viscosity of the softened lignin just makes up for the problem of the wet material being easy to loosen, and the high temperature and high pressure solve the problem of the difficulty in molding the wet material.

(5)The cutter (adjustable distance) on the outside of the ring die rotates synchronously with the extruded strips, cutting the strips into pellets of uniform length (usually 1.5-3 times the diameter, such as 6mm). The particle size corresponds to a length of 9-18mm), and the initial forming is completed.

(6)Cooling is performed to avoid "stagnation" when the high-temperature particles are piled up, and at the same time, the softened lignin is re-solidified to make the particle structure harder.

(7)The cooled particles are passed through a vibrating screen to remove broken fine powder and unqualified oversized/ultra-small particles (the fine powder can be returned to the pelletizing stage for reuse), and finally the wet wood pallet biomass particles that meet the standards are obtained.

2.Characteristics of wet wood pallets biomass pellet processing equipment

The pallet pellet processing equipment is a production line specifically designed for waste pallets (containing nails, metal connectors, and wood with uneven moisture and hardness). Its core features are tailored to the raw material characteristics, ensuring production efficiency, and optimizing finished product quality.

The crushing stage processes the pallets into 25-55mm wood chips. The equipment design balances crushing efficiency with impurity tolerance.

The fine crushing stage processes pre-treated wood segments/chips into 2-5mm sawdust (the optimal particle size for pelletization).

The drying stage controls moisture content and ensures pellet formation efficiency.

The pelletizing stage forms the core and presses the powder into high-density pellets. The cooling and screening stages stabilize pellet properties and eliminate substandard products.

The equipment in each stage works synergistically to transform raw materials into finished products.

3.Application scenarios of wet wood pallets biomass pellet processing equipment

Wood pallet pellets are processed through crushing, drying, extrusion molding and other processes. Waste wood pallets are processed into pellet fuel or recycled materials to achieve resource recycling.

Equipment applicable industries and user groups

(1)Wood processing and furniture manufacturing:Processing wood pallet scraps and sawdust generated during the production process, converting them into internal energy or pellet fuel for export.

(2)Biomass energy companies:Using wood pallets and other wood waste as raw materials, large-scale production of pellet fuel is carried out to supply power plants or industrial boilers.

(3)Environmental recycling companies:The equipment realizes the resource processing of waste wood pallets, meets the needs of sustainable development, and reduces the environmental pressure caused by landfill or incineration

TONY Brand 10.5-12Ton/Hour Wet Wood Pallets Pellet Manufacturing Plant can take wet wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 10.5-12Ton/Hour

2. Raw materials: Wet wood pallets

3. Moisture: Wet type, about 40%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Pallets Pellet Production Line

2. Raw Material: All kinds of wet wood pallets

3. Moisture Content of Raw Material: 40%

4. Capacity: 10.5-12 tons per hour

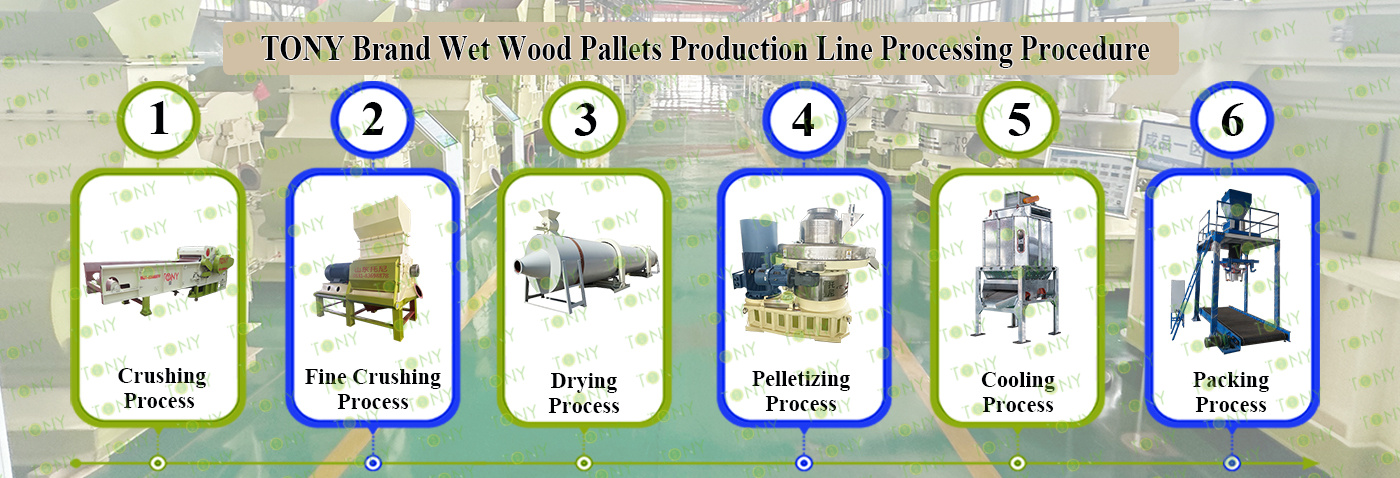

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1300-600-160KW, Effective Hammer Mill-TFD75*160-160KW, Rotary Drum Dryer-1.8*24m, TONY Pellet Machine TYJ860-Ⅲ-250KW, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

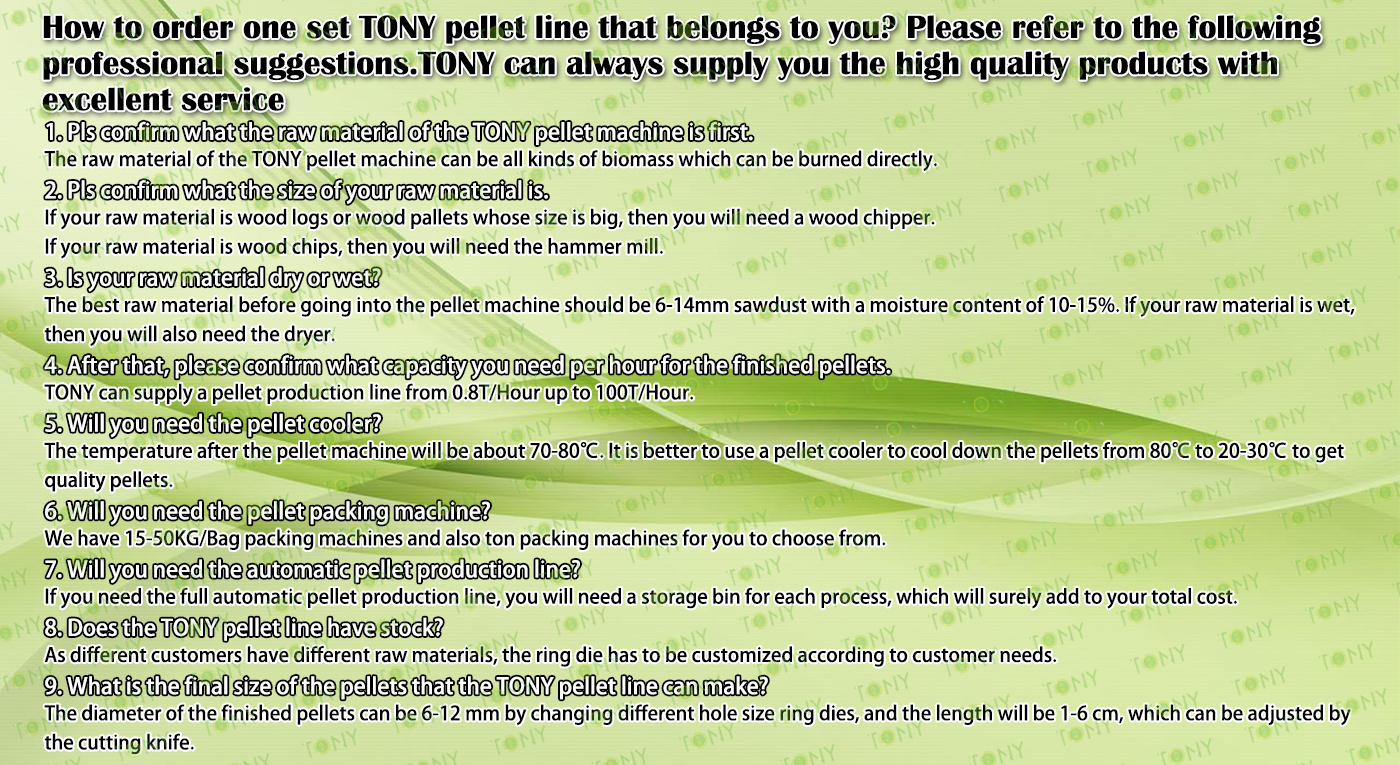

How to use the TONY pellet production line to make pellets from wet wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind wet wood pallets with width 1.3m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Comprehensive Chipper | Effective Hammer mill | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Grind Wood pallets Width ≤1.3m Into25-55mm Wood Chips. 2.Model: TPC1300-600-160KW With 24 Hammer Heads*1set 3.Capacity: 12-15Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*160-160KW*2sets 3.Capacity: 5-6Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD1.8*24*2sets 3.Capacity:5-6Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-12*1set 3.Capacity:10.5-12Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-250KW*3sets 3.Capacity:3.5-4.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:10.5-12Ton/Hour |

1.To Pack Pellets Into 1 Ton/Bags. 2.Model: TBD* 1set 3.Capacity: 10.5-12Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*9sets 3.Capacity:Designed With The Whole Line |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1.3 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1300-600-160KW model with 24 hammer heads*1set

C.Capacity:12-15Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:10.5-12Ton/Hour.

C.TONY brand effective hammer mill TFD75*160-160KW*2sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:10.5-12Ton/Hour.

C.TONY use 2 sets of1.8*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:10.5-12Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-250KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:10.5-12Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 1ton/bags.

B.Capacity:10.5-12Ton/Hour.

C.TONY brand ton packing machine*1set

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Products, market demand and social benefits of the pallet processing biomass pellet project:

1.Product side: excellent energy performance and high market acceptance

The biomass pellets processed from wooden pallets are much more competitive than straw and rice husk pellets due to the advantages of raw material materials (solid wood/high-density composite wood)

2.Market side: rigid demand growth and stable sales

The market demand for biomass pellets is shifting from "policy-driven" to "market rigid demand", and pellets processed from wooden pallets are easier to enter the market due to their quality advantages:

The core demand scenarios are clear:

(1)Industrial side: boiler heating in food processing, chemical industry, building materials and other industries (replacing coal and reducing environmental protection costs);

(2)Civilian side: winter heating (replacing loose coal and complying with the "clean heating" policy), home fireplace fuel;

(3)Commercial side: greenhouse heating, biomass power station raw materials (some power plants purchase them on a long-term basis and sign annual supply agreements);

(4)Strong price competitiveness: the gross profit margin of wooden pallet pellets is over 50%, and the price is only 10% of that of natural gas and diesel. 1/3-1/2, which is very attractive to corporate customers;

3.Social benefits: It has both environmental protection and employment value, which enhances project recognition

(1)In addition to economic benefits, the project can also generate significant social benefits and easily obtain support from local governments and communities:

Environmental value: Every 10,000 tons of waste wooden pallets processed can reduce about 8,000 tons of CO₂ emissions (replacing coal burning), avoid about 3,000 cubic meters of land occupation (replacing landfill), and reduce dioxins and other harmful gases produced by incineration;

Employment value: Small and medium-sized projects can drive 10-30 jobs (covering raw material recycling, production and processing, warehousing and logistics, etc.), especially suitable for landing around industrial parks, solving some local employment problems, and obtaining active support from local governments (such as giving priority to providing factory buildings and simplifying approval processes).

(2)Production: The processing threshold is moderate, and small and medium-sized projects are easy to implement.

The "implementability" of the project is the core concern of small and medium-sized investors. The project has the characteristics of "low threshold and high adaptability" in the production process:

Controllable equipment investment: The core equipment (crusher, pulverizer, dryer, pelletizer, cooling and screening machine) of small and medium-sized production lines (daily production capacity of 5-20 tons) has a moderate investment, does not require large-scale infrastructure, and has low financial pressure, which is suitable for individuals or small and medium-sized enterprises to start;

Mature technology and easy operation: The processing process is standardized, without complex technical barriers. Ordinary workers can take up their posts after 1-2 weeks of training, and the equipment failure rate is low (wood raw materials cause less wear and tear on equipment than straw and rice husks), and the maintenance cost is low;

High energy consumption and environmental compliance: During the production process, the drying process can utilize the waste heat generated by the combustion of some pellets (reducing energy consumption). 30%), and no wastewater discharge (only a small amount of equipment cooling water, which can be recycled), and the waste gas can meet the standard after simple bag dust removal.

1.Resource Recycling: Solving the "Solid Waste Problem"

Waste-to-Resource: Used wooden pallets are a common source of solid waste in the logistics and warehousing industries. If they are discarded or incinerated without proper treatment, they can lead to resource waste and environmental pollution. Pallet pellets transform them into high-value products.

2.Excellent performance: Suitable for multiple scenarios and easy to use.

As biomass pellet fuel or industrial auxiliary materials, pallet pellets offer stable physical and chemical properties, providing a superior user experience compared to traditional bulk wood, coal, and other materials.

3.Outstanding environmental performance: Low pollution.

The clean nature of pallet pellets is a core competitive advantage.

4.Significant economic value: Low cost and stable returns.

From production to application, the economic advantages of pallet pellets permeate the entire supply chain. Demand for biomass pellets is strong, and revenue is stable.

The core advantages of pallet pellets are their triple combination of environmental protection, cost-effectiveness, and practicality. They solve the solid waste disposal problem of used pallets and provide a clean and efficient alternative energy source. They balance low production costs with convenient application. Therefore, they have broad application prospects in logistics waste recycling, biomass energy, and clean heating. They are also a "circular economy + green energy" project encouraged by current policies.

2025 Tony Machinery - All Rights Reserved. Map