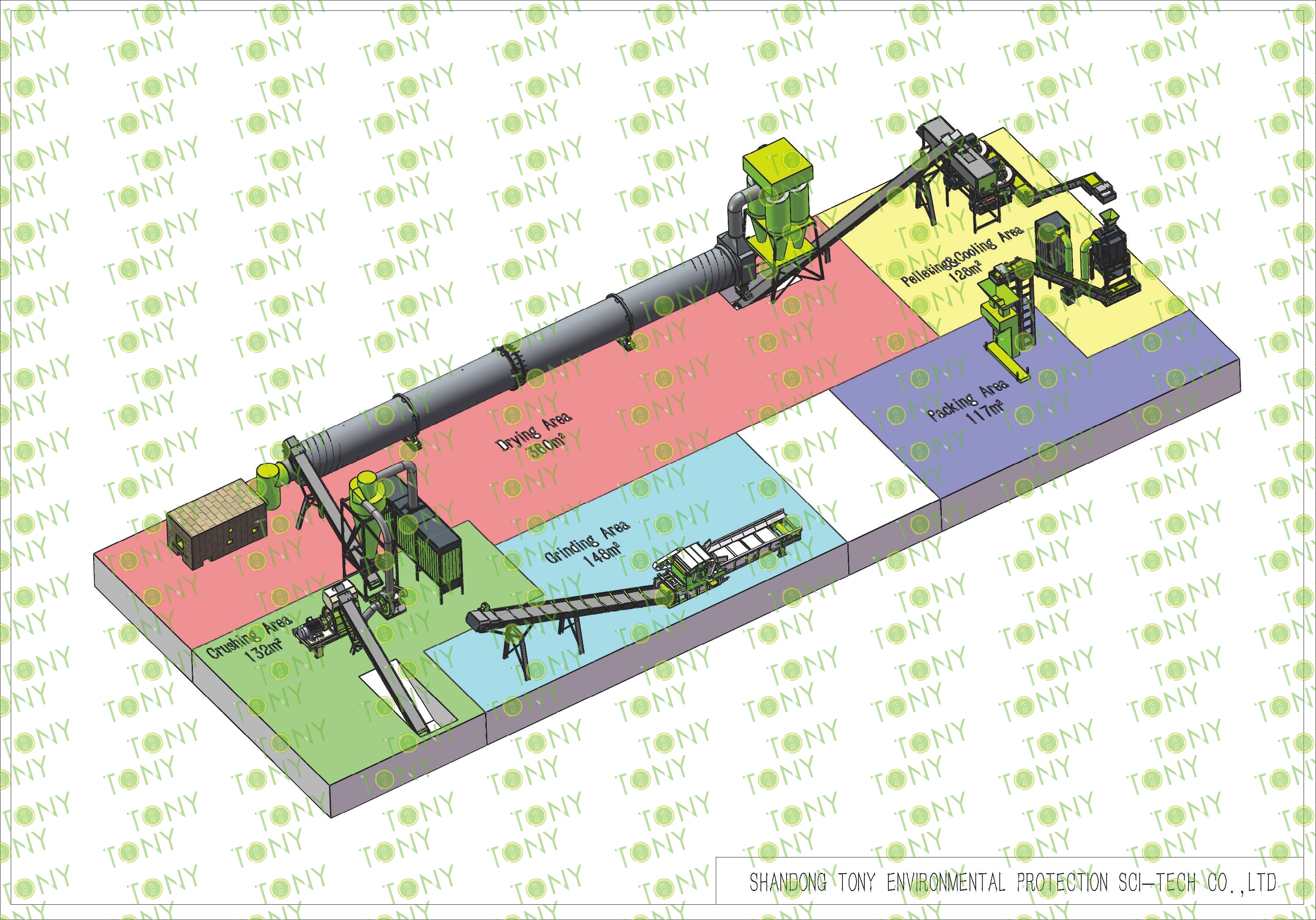

Project Brief Introduction:

1.Product:Wet Wood Pallets Pellet Line

2.Capacity: 6T/Hour

3.TONY Brand 6Ton /Hour Wet Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 910KW

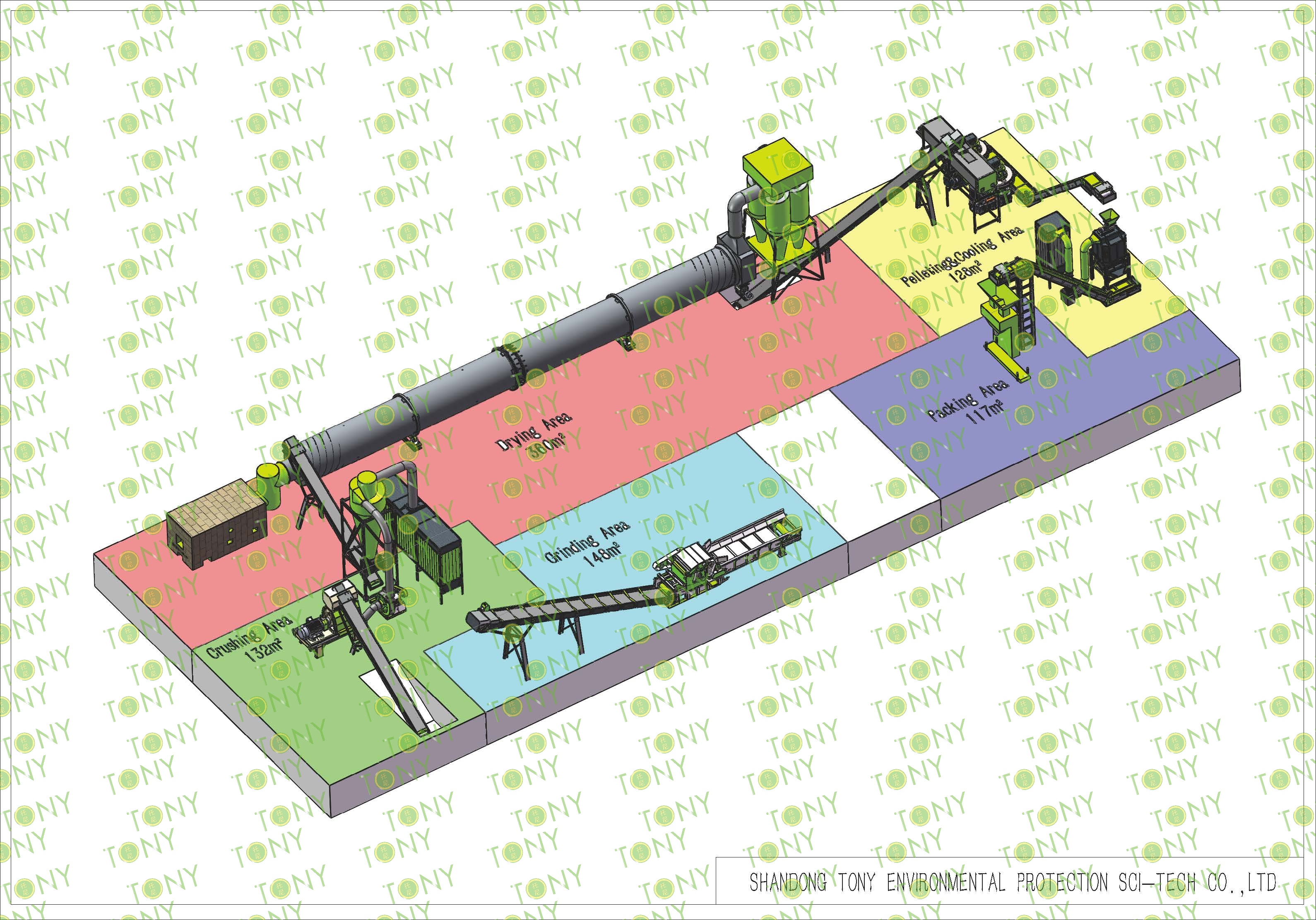

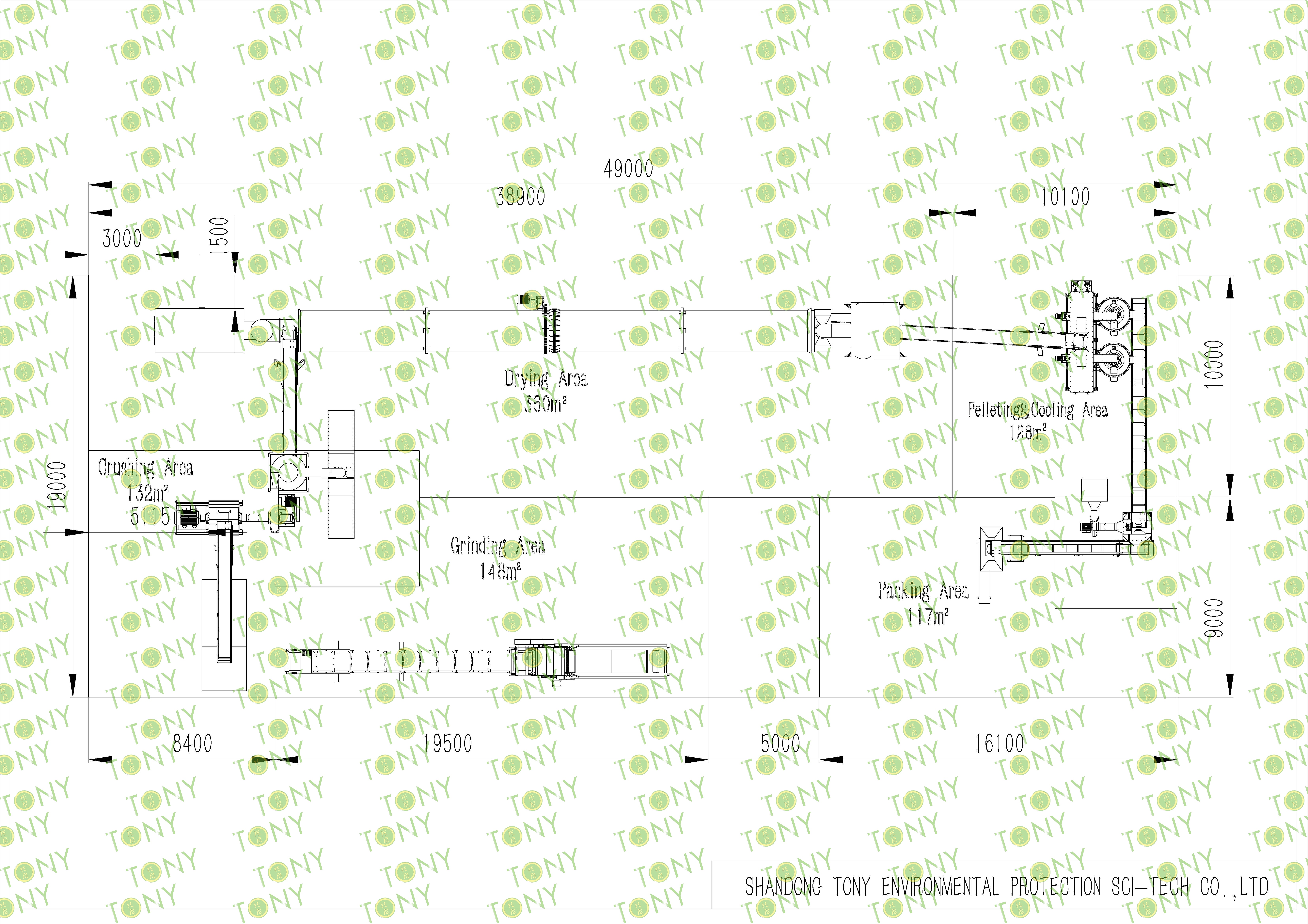

6.Need Area: About 931㎡ L: 49 M W: 19 M H: 7.065M

Project Layout For Customer:

1.The working principle of wet wood pallets biomass pellet processing equipment

The core equipment in pallet pellet processing is the biomass ring die pelletizer, which utilizes a combination of mechanical extrusion, frictional heating, and fiber self-bonding. The specific process is as follows:

During the extrusion process, rollers exert a pressure of up to 50-150 MPa on the powder, forcing it from its loose state (density 0.15-0.3 g/cm³) into the die's forming hole, forming a cylindrical column.

As the powder moves through the hole, it creates intense friction with the hole walls. Frictional heating raises the column temperature to 100-120°C, completely melting the softened lignin and hemicellulose, forming a natural adhesive that tightly binds the surrounding wood fiber particles together.

At the same time, the high temperature and pressure also remove some free moisture from the material (reducing the final pellet moisture content to 10%-15%) and rearranges the wood fiber structure, forming a high-density, high-strength column (density increased to 0.8-1.2 g/cm³).

2.Characteristics of wet wood pallets biomass pellet processing equipment

The pallet pellet processing equipment is a production line specifically designed for waste pallets (containing nails, metal connectors, and wood with uneven moisture and hardness). Its core features are tailored to the raw material characteristics, ensuring production efficiency, and optimizing finished product quality.

The crushing stage processes the pallets into 25-55mm wood chips. The equipment design balances crushing efficiency with impurity tolerance.

The fine crushing stage processes pre-treated wood segments/chips into 2-5mm sawdust (the optimal particle size for pelletization).

The drying stage controls moisture content and ensures pellet formation efficiency.

The pelletizing stage forms the core and presses the powder into high-density pellets. The cooling and screening stages stabilize pellet properties and eliminate substandard products.

The equipment in each stage works synergistically to transform raw materials into finished products.

3.Application scenarios of wet wood pallets biomass pellet processing equipment

Wood pallet pellet processing equipment is mainly used to convert waste wood pallets into renewable resources. Its application scenarios are concentrated in the fields of biomass energy production and environmentally friendly recycling.

Specific application scenarios and functions

(1)Biomass energy production:The processed wood pallet pellets can be used as fuel for fireplaces, boilers and biomass power plants, replacing traditional non-renewable energy such as coal and reducing environmental pollution.

(2)Agricultural and industrial waste treatment:The equipment can collaboratively process a variety of agricultural and industrial waste, such as rice husks, straw, building formwork scraps, etc., and process them together with wood pallets into pellet fuel, which is widely used in feed mills, fertilizer plants, chemical plants and other scenarios.

(3)Environmentally friendly recycling industry chain:Waste wood pallets are turned into treasure after being crushed and formed, reducing the waste of wood resources. This recycling model is not only suitable for damaged pallets eliminated by the logistics and warehousing industry, but can also integrate wood waste in urban garbage to form a closed loop of "recycling-processing-reuse".

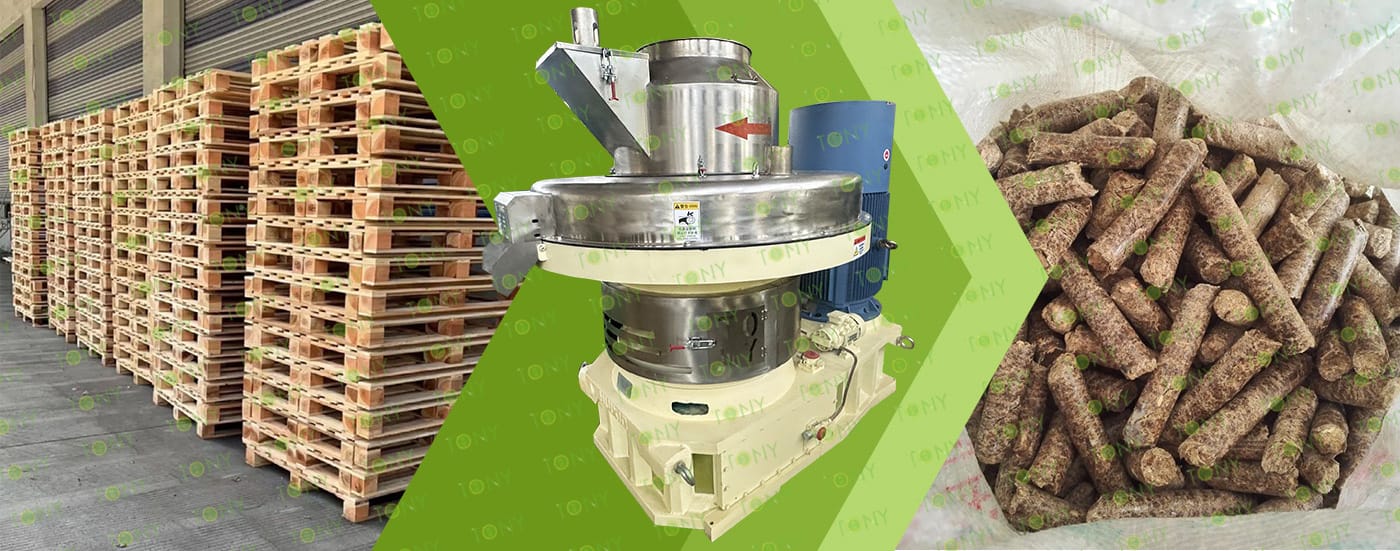

TONY Brand 6Ton/Hour Wet Wood Pallets Pellet Manufacturing Plant can take wet wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 6Ton/Hour

2. Raw materials: Wet wood pallets

3. Moisture: Wet type, about 40%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Pallets Pellet Production Line

2. Raw Material: All kinds of wet wood pallets

3. Moisture Content of Raw Material: 40%

4. Capacity: 6 tons per hour

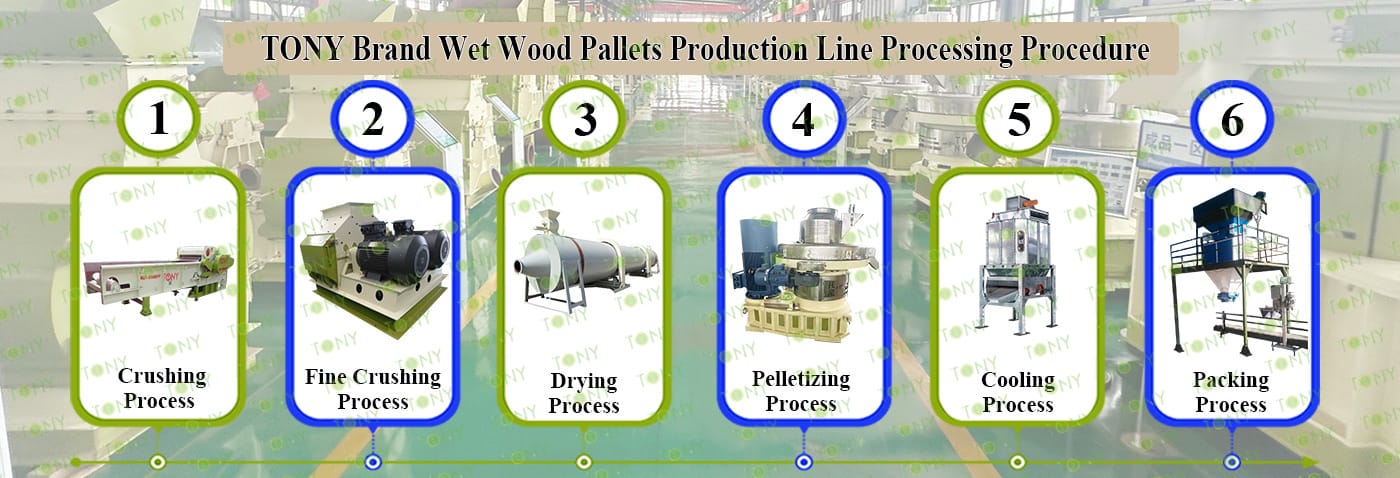

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Dual Shaft Hammer Mill--TFS65*100-110*2KW, Rotary Drum Dryer-2*24m, TONY Pellet Machine TYJ760-Ⅲ-200KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

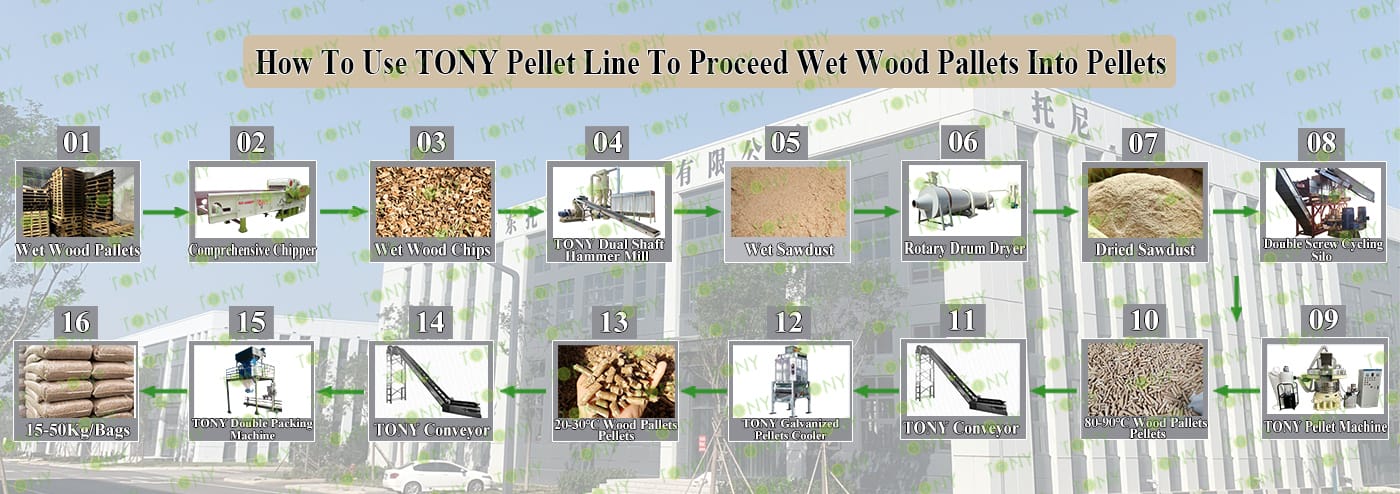

How to use the TONY pellet production line to make pellets from wet wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind wet wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY dual shaft hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Comprehensive Chipper | Dual Shaft Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 16 Hammer Heads*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFS65*100-110*2KW*1set 3.Capacity: 6Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2*24*1set 3.Capacity:6Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-6*1set 3.Capacity: 6Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*2sets 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:6Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*6sets 3.Capacity:Designed With The Whole Line |

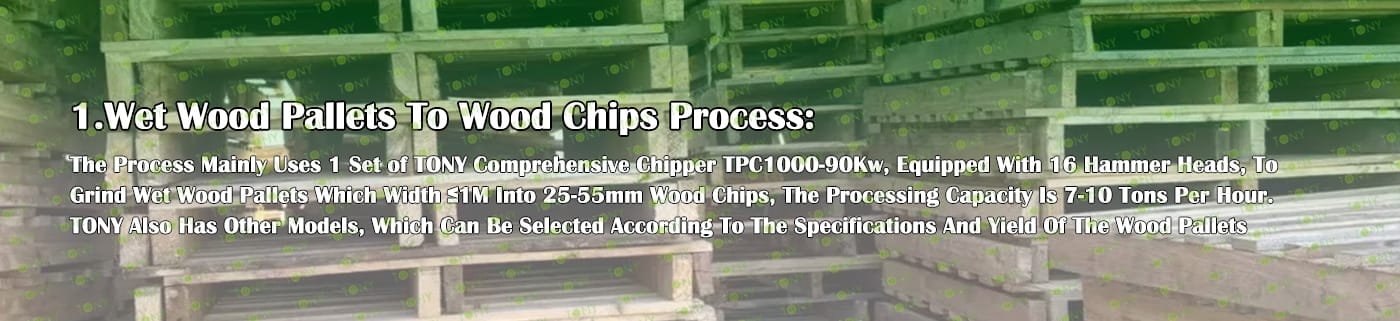

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY Brand comprehensive chipper TPC1000-90kw model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

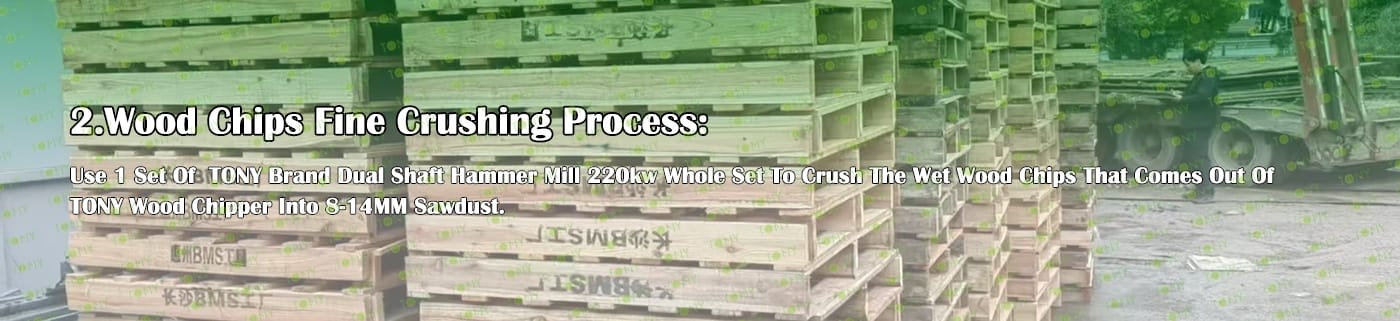

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:6Ton/Hour.

C.TONY brand dual shaft hammer mill TFS65*100-110KW*2*1set

Main Parts:

(1)TONY Dual Shaft Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

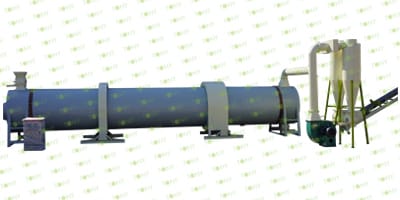

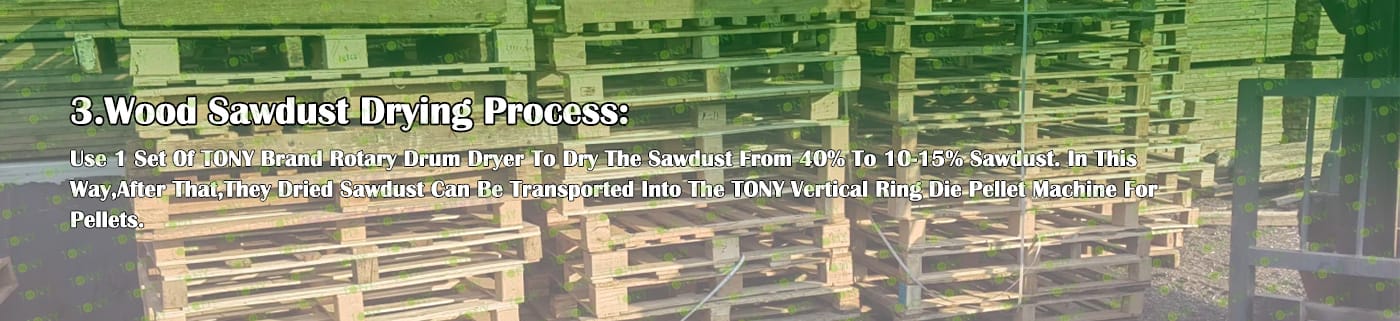

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:6Ton/Hour.

C.TONY use 1set of 2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

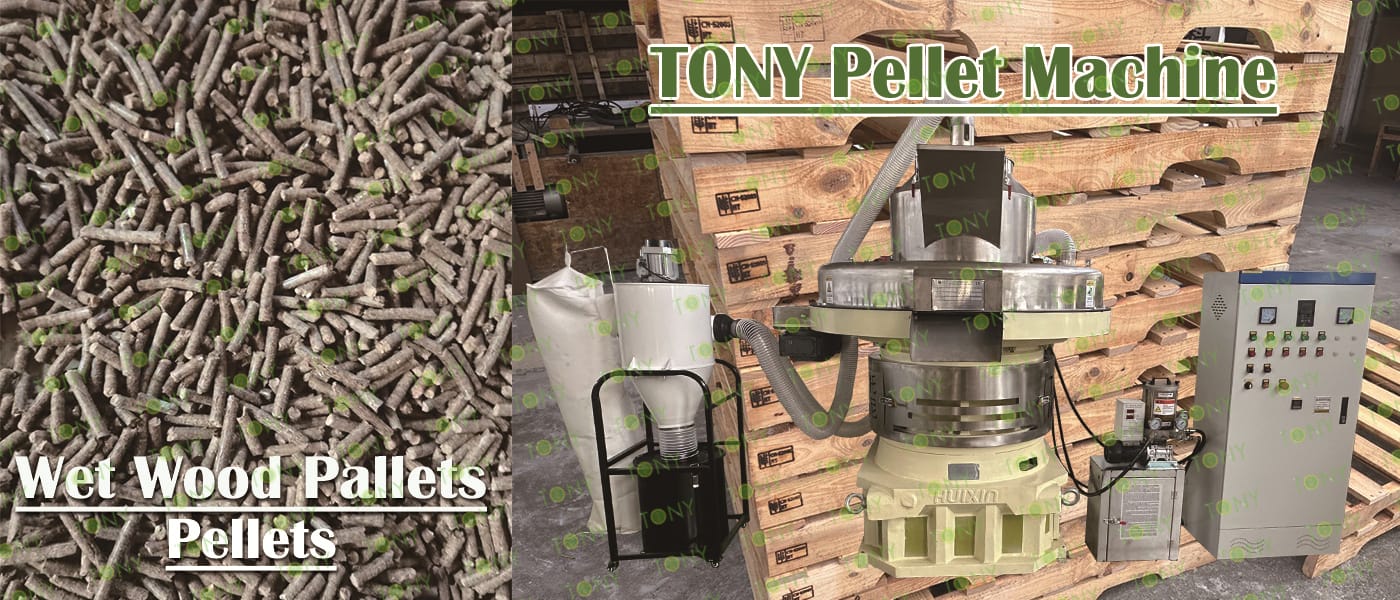

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity: 6Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-200KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:6Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:6Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

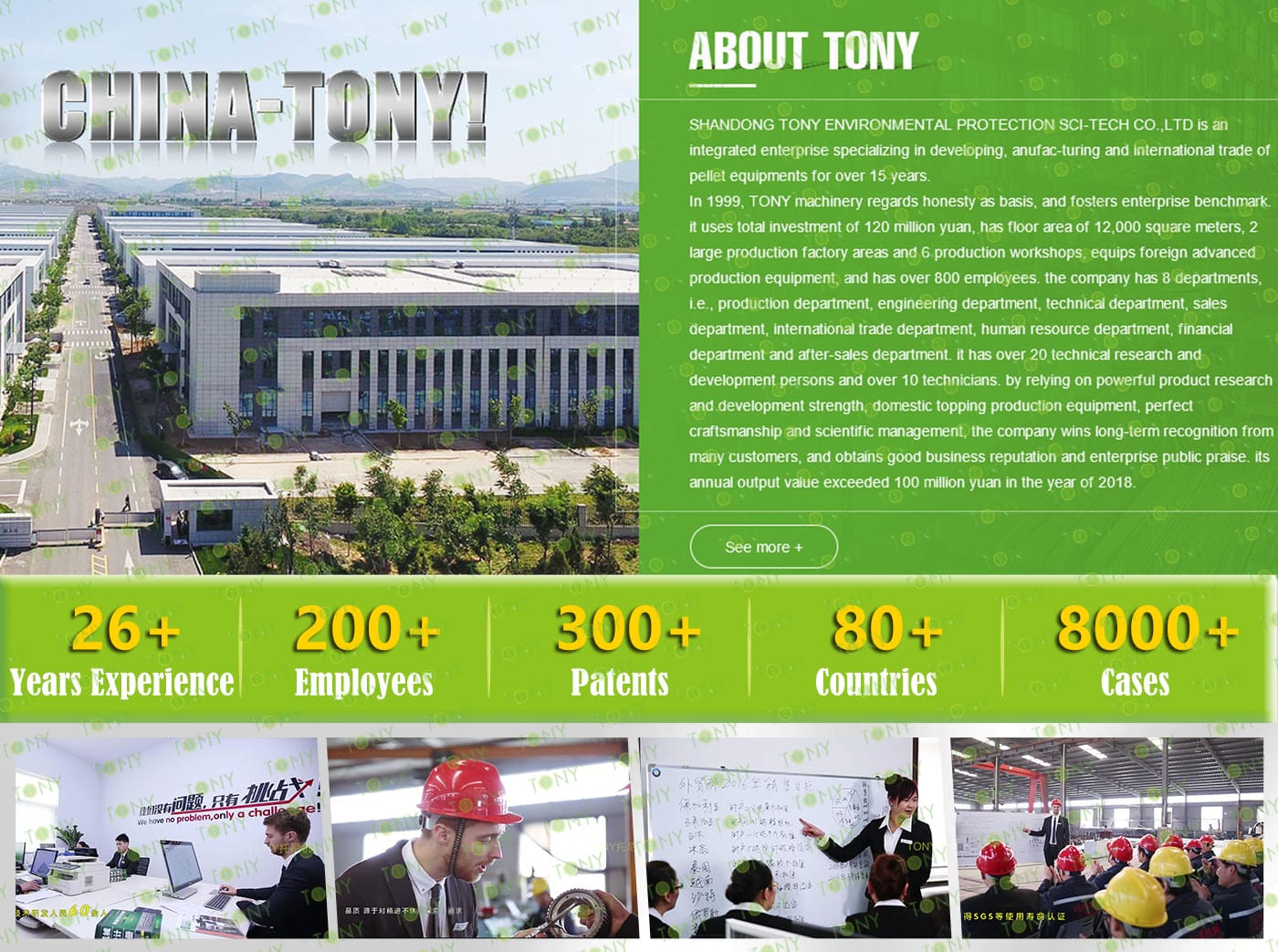

Competitive advantages and challenges of the wood pallet processing biomass pellet project

1.Core competitive advantages

(1)Raw material cost advantage: Wood pallet waste has a wide range of sources (such as logistics companies and manufacturing scraps), low recycling costs, and can be efficiently processed through wood crushers.

(2)Policy and environmental protection dividends: Wood pallets are renewable resources, and the biomass pellets processed from them are in line with the "circular economy" policy orientation and are easy to obtain subsidies or tax incentives.

(3)High technological maturity: Existing wood crushing and pelletizing equipment can achieve large-scale production and reduce unit costs.

2.Potential challenges

(1)Fierce market competition: The global wood pellet market is dominated by leading companies, and new entrants need to compete with differentiation.

(2)Raw material supply stability: Wood pallet recycling is affected by fluctuations in the logistics industry, and it is necessary to establish diversified recycling channels to avoid raw material shortages5.

(3)Upgraded environmental standards: Some regions have higher requirements for carbon emissions and ash content of biomass pellets, and investment in technology upgrades is needed to meet compliance.

3.Market demand trends and corporate strategy recommendations

(1)Future demand trends

With the upgrading of environmental protection technology, the penetration rate of wood pallet pellets in high-end industrial fields will increase, becoming the fastest-growing sub-category.

In addition to traditional power generation and industrial furnaces, the demand for biomass pellets in civil heating (such as home fireplaces) and agricultural greenhouse heating will gradually emerge.

(2)Regional layout is accelerating:

mature markets such as Europe and North America are highly competitive, and emerging markets (such as Southeast Asia and South America) may become new growth points for demand

4.Corporate strategy recommendations

Raw material side: Sign long-term recycling agreements with logistics companies and manufacturing parks to ensure a stable supply of wood pallet waste, and explore diversified raw material supplements such as straw and sawdust.

Product side: Focus on the high-growth pellet market, reduce ash content and improve combustion efficiency through technological research and development, and meet the needs of high-end customers.

Market side: Prioritize layout in regions with strong policy support such as Europe and China, and use cross-border e-commerce or local cooperation to expand sales channels.

1.Resource Recycling: Solving the "Solid Waste Problem"

Waste-to-Resource: Used wooden pallets are a common source of solid waste in the logistics and warehousing industries. If they are discarded or incinerated without proper treatment, they can lead to resource waste and environmental pollution. Pallet pellets transform them into high-value products.

2.Excellent performance: Suitable for multiple scenarios and easy to use.

As biomass pellet fuel or industrial auxiliary materials, pallet pellets offer stable physical and chemical properties, providing a superior user experience compared to traditional bulk wood, coal, and other materials.

3.Outstanding environmental performance: Low pollution.

The clean nature of pallet pellets is a core competitive advantage.

4.Significant economic value: Low cost and stable returns.

From production to application, the economic advantages of pallet pellets permeate the entire supply chain. Demand for biomass pellets is strong, and revenue is stable.

The core advantages of pallet pellets are their triple combination of environmental protection, cost-effectiveness, and practicality. They solve the solid waste disposal problem of used pallets and provide a clean and efficient alternative energy source. They balance low production costs with convenient application. Therefore, they have broad application prospects in logistics waste recycling, biomass energy, and clean heating. They are also a "circular economy + green energy" project encouraged by current policies.

2025 Tony Machinery - All Rights Reserved. Map