1.The working principle of dried wood pallets biomass pellet processing equipment

(1)Crushing equipment: This addresses the issue of raw material suitability. Dry pallets (mostly solid or compressed wood) are large and may contain metallic impurities (such as nails and screws), requiring pre-treatment equipment to pave the way for subsequent processes.

(2)Fine crushing equipment: This converts the raw material into a pelletizable fine powder/wood chips. The dry pallet wood must be crushed into uniform, fine wood chips (typically 2-5mm in size) to meet the pelletizing equipment's feed requirements. The core process is to achieve material refinement through shearing, impact, and grinding.

(3)Pelletizing equipment: This is the core process, compressing fine wood chips into high-density pellets. The pelletizing equipment is the core of the entire production line. Its principle is to compress loose, fine sawdust into high-density pellets with a circular cross-section (6-12mm in diameter, 8mm is common) and a length of 3-10mm using a combination of mechanical extrusion and lignin softening. The key lies in the ring die pelletizer.

(4)Cooling Equipment: This equipment reduces pellet temperature to prevent mold and loosening. Pellets fresh from the ring die are at temperatures of 80-90°C and contain approximately 10%-12% moisture. Direct storage can lead to cracking due to thermal expansion and contraction, and mold growth due to high temperature and humidity. Therefore, cooling equipment is required to cool pellets to room temperature (±5°C) and stabilize the moisture content.

2.Characteristics of dried wood pallets biomass pellet processing equipment

(1)Flexibility in raw material processing:The wood pellet machine is suitable for processing various wooden pallets, density boards, artificial boards and other different products.

(2)Low energy consumption and environmental protection:The equipment adopts a spiral feeding device, with an energy utilization rate of 85%; The fully enclosed structure reduces dust and noise pollution.

(3)Durability and easy maintenance:The key components are made of special steel and specially treated, which ensures a long service life of the equipment. The whole machine has a compact structure and a small footprint, and can be put into production after installation and commissioning.

(4)Easy maintenance and cost control:The pellet machine adopts an automatic refueling system to save maintenance costs; the equipment troubleshooting is simple, and no professional personnel are required for daily maintenance.

(5)Resource recycling:The waste of wooden pallets is converted into recycled products such as pellet fuel to achieve efficient recycling of wood resources.

3.Application scenarios of dried wood pallets biomass pellet processing equipment

Wood pallet pellet processing equipment is mainly used to convert waste wood pallets into renewable resources. Its application scenarios are concentrated in the fields of biomass energy production and environmentally friendly recycling.

Specific application scenarios and functions

(1)Biomass energy production:The processed wood pallet pellets can be used as fuel for fireplaces, boilers and biomass power plants, replacing traditional non-renewable energy such as coal and reducing environmental pollution.

(2)Agricultural and industrial waste treatment:The equipment can collaboratively process a variety of agricultural and industrial waste, such as rice husks, straw, building formwork scraps, etc., and process them together with wood pallets into pellet fuel, which is widely used in feed mills, fertilizer plants, chemical plants and other scenarios.

(3)Environmentally friendly recycling industry chain:Waste wood pallets are turned into treasure after being crushed and formed, reducing the waste of wood resources. This recycling model is not only suitable for damaged pallets eliminated by the logistics and warehousing industry, but can also integrate wood waste in urban garbage to form a closed loop of "recycling-processing-reuse".

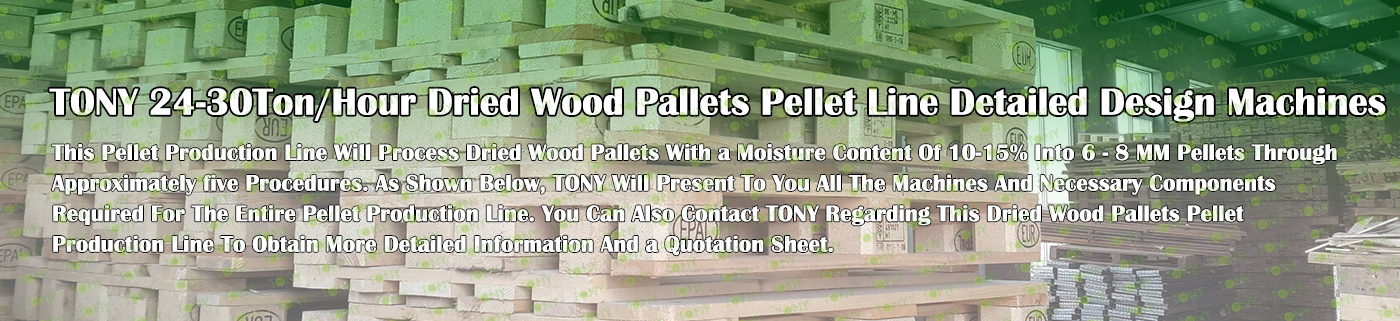

TONY Brand 24-30Ton/Hour Dried Wood Pallets Pellet Manufacturing Plant can take dried wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings. After pretreatment and processing, dried wood pallets is solidified into high - density wood pellet fuel.The content of pollutants such as sulfur dioxide and nitrogen oxides produced by biomass pellets during combustion is extremely low, and the dust emission is also low, which can effectively reduce air pollution. Moreover, the raw material sources of biomass pellets are very wide, and the combustion efficiency is high. Compared with traditional fossil energy, it reduces the production and use costs and has higher economic efficiency. It has received a lot of attention and promotion.

1. Capacity: 24-30Ton/Hour

2. Raw materials: Dried wood pallets

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Pallets Pellet Production Line

2. Raw Material: All kinds of dried wood pallets

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 24-30 tons per hour

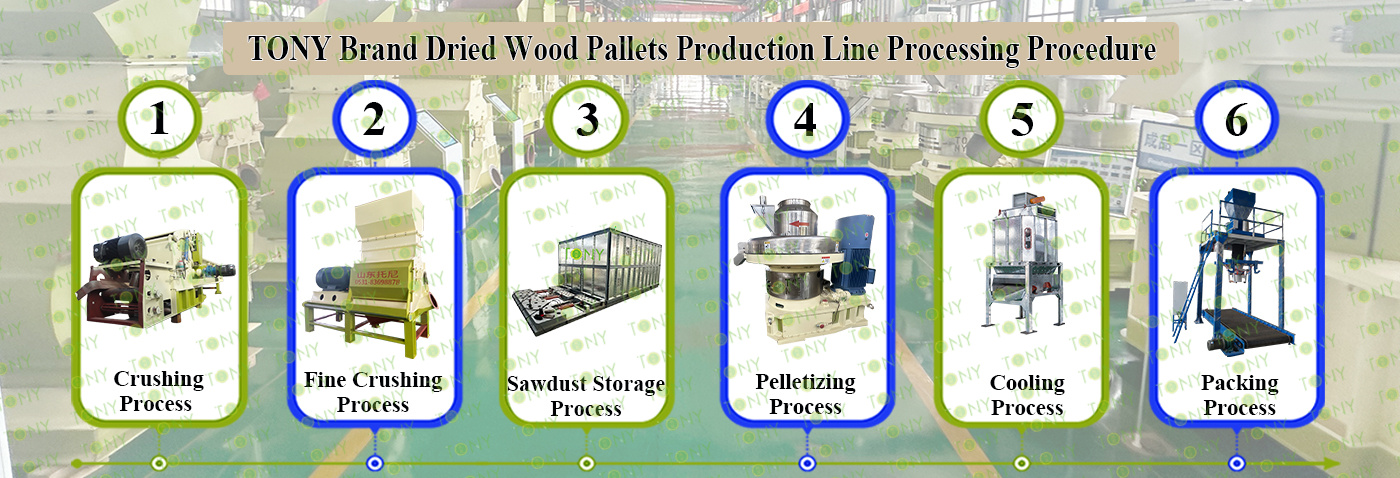

5. Process: Crushing Process - Fine Crushing Process -Sawdust Storage Process- Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1400-600-200KW, Effective Hammer Mill-TFD85*220-220KW, TONY Large Hydraulic Storage Silo,TONY Pellet Machine TYJ860-Ⅲ-280KW, Pellet Cooler, Ton Packing Machine and Belt Conveyors

|

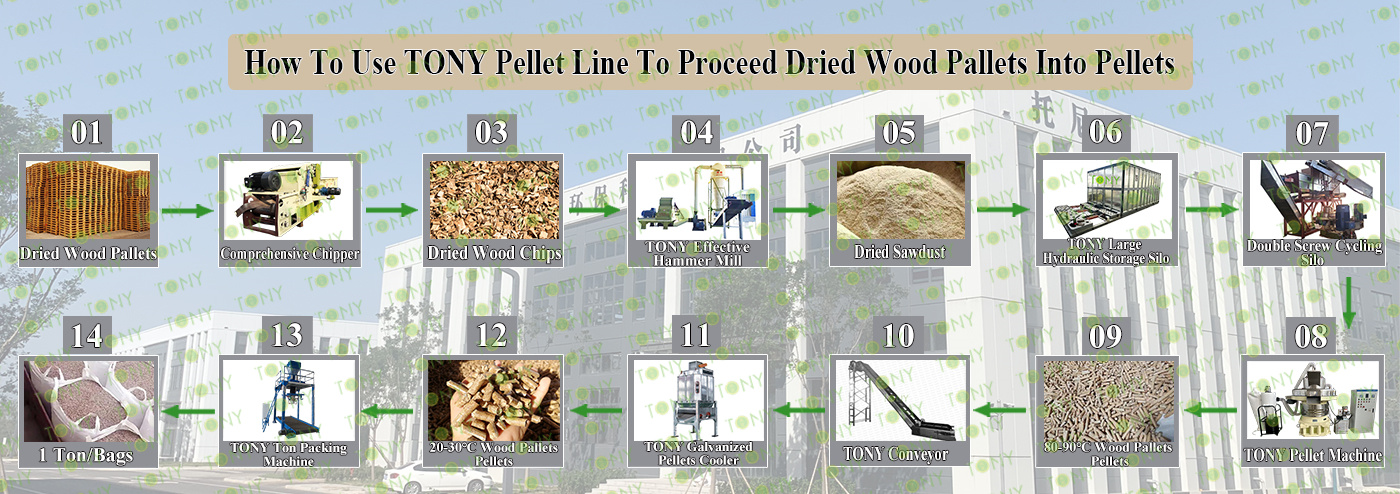

How to use the TONY pellet production line to make pellets from dried wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind dried wood pallets with width 1.4m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Comprehensive Chipper | Effective Hammer Mill | Large Hydraulic Storage Silo |

| 1.To Grind Wood pallets Width ≤1.4m Into25-55mm Wood Chips. 2.Model: TPC1400-600-200KW With 24 Hammer Heads*2sets 3.Capacity: 24-30 Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*220-220KW*4sets 3.Capacity: 6-8Ton/Hour/Set |

1.To Storage Sawdust Before Pellet machine 2.Model: TCY-40*2sets 3.TONY Uses Galvanized Material |

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*6sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*2sets 3.Capacity:24-30Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*2sets 3.Capacity: 24-30Ton/Hour |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1.4 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1400-600-200kw model with 24 hammer heads*2sets

C.Capacity:24-30Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

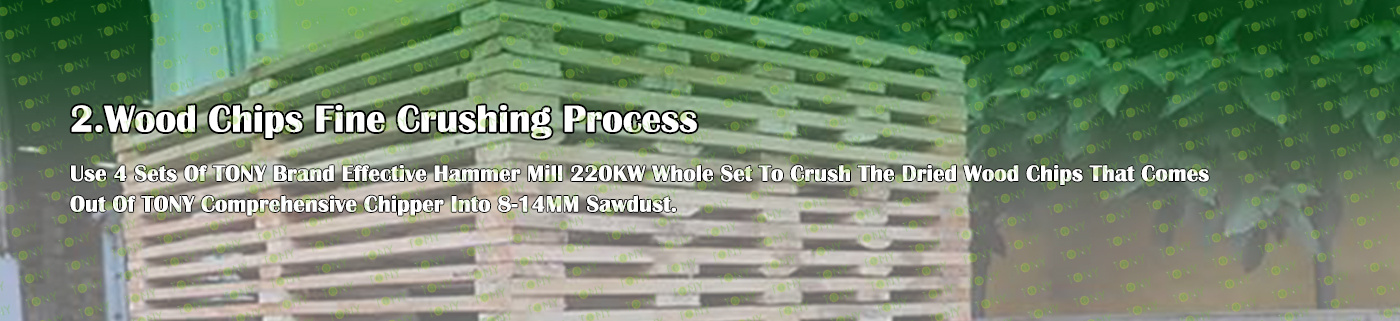

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:24-30Ton/Hour.

C.TONY brand effective hammer mill TFD85*220-220KW*4sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B. TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's New Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:24-30Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-280KW*6sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:24-30Ton/Hour.

C.TONY brand galvanized cooler separator*2sets

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 1ton/bags.

B.2 sets of TONY ton packing machine

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

How to build a stable and scalable market system for wood pallet pellets?

The market is the foundation for a sustainable project. Long-term profitability must be achieved through "customer lock-in + market expansion + brand building":

1.Target "strong-demand customers" and sign long-term supply agreements.

Prioritize your partnership with industrial boiler users (such as food factories, chemical plants, and textile mills), heating companies (rural centralized heating, residential heating), and livestock farms (for greenhouse heating and livestock and poultry insulation). These customers have stable demand (usually exceeding 1,000 tons per year). One- to three-year supply contracts can be signed with a price adjustment mechanism (e.g., in line with coal/natural gas price fluctuations) to ensure consistent sales.

2.Expand high-value-added applications to break through "low-end competition"

Develop "specialty pellets": Targeted at different customer needs, we produce high-calorific value pellets (e.g., pure dry tray pellets with a calorific value of approximately 4200-4500 kcal/kg, suitable for high-load industrial boilers), low-ash pellets (for small household fireplaces, with an ash content ≤3%), or add combustion aids (e.g., biomass tar inhibitors) to improve combustion efficiency. These products offer price premiums of over 20%.

3.Connect with "green energy projects"

These include biomass cogeneration and biomass gasification power generation projects. These clients have high pellet quality requirements (e.g., ash content ≤5%, sulfur content ≤0.05%), but also have large order volumes and stable payment cycles. These clients can be long-term strategic partners.

4.Branded operations: Enhance market resilience

Establish a product quality traceability system: Each batch of pellets is labeled with the raw material source, production date, and quality indicators (calorific value, ash content, moisture content) to enhance customer trust (industrial clients, in particular, demand high quality consistency).

1.Resource Recycling:

Addressing the "Waste" Pain Point, Reducing Costs, and Protecting the Environment.Pallets (especially wooden pallets) are common consumables in the logistics and warehousing industries. The indiscriminate disposal or incineration of large quantities of used pallets (such as damaged or obsolete wooden pallets) can lead to resource waste and environmental pollution.

Pallet pellet fuel converts this waste into high-value energy through recycling and reprocessing. This not only solves the problem of waste pallet disposal (reducing landfill volume) but also reduces the raw material cost of pellet fuel. Compared to directly purchasing raw materials such as logs and straw, used pallets are more affordable to acquire (in some cases, they can be recycled at a low price or even free of charge), forming a "waste to energy" cycle.

2.Outstanding environmental attributes:

Low carbon emissions, in line with policy orientation As a type of biomass energy, pallet pellet fuel has significant environmental advantages and is in line with the global trend of low-carbon energy transformation:

(1)Low carbon emissions: The carbon dioxide released when biomass fuel is burned is essentially the "carbon" absorbed by plants during growth, which can achieve "carbon cycle balance" as a whole. Compared with coal (carbon emissions of about 2400g/kg) and natural gas (carbon emissions of about 1600g/kg), its net carbon emissions are only 1/10~1/5 of fossil energy, which can effectively reduce greenhouse gas emissions.

(2)Low pollutant emissions: If the raw materials (pallets) are pre-treated (removing metal nails, oil stains and other impurities), the sulfide, nitrogen oxide and dust emissions generated during combustion are extremely low - for example, sulfide emissions are much lower than coal (the sulfur content of coal is usually 0.5%~3%, and the sulfur content of wooden pallets is almost negligible), and no complex desulfurization and denitrification equipment is required, reducing air pollution.

(3)No harmful residue: The ash content of high-quality pallet pellet fuel after combustion is low (usually ≤3%), and the ash can be returned to the field as organic fertilizer, achieving "zero waste" and avoiding the pollution of soil and water sources by coal slag (containing heavy metals and other harmful substances) produced after coal combustion.

2025 Tony Machinery - All Rights Reserved. Map