Project Brief Introduction:

1.Product:Dried Wood Chips Pellet Line

2.Capacity: 18T/Hour

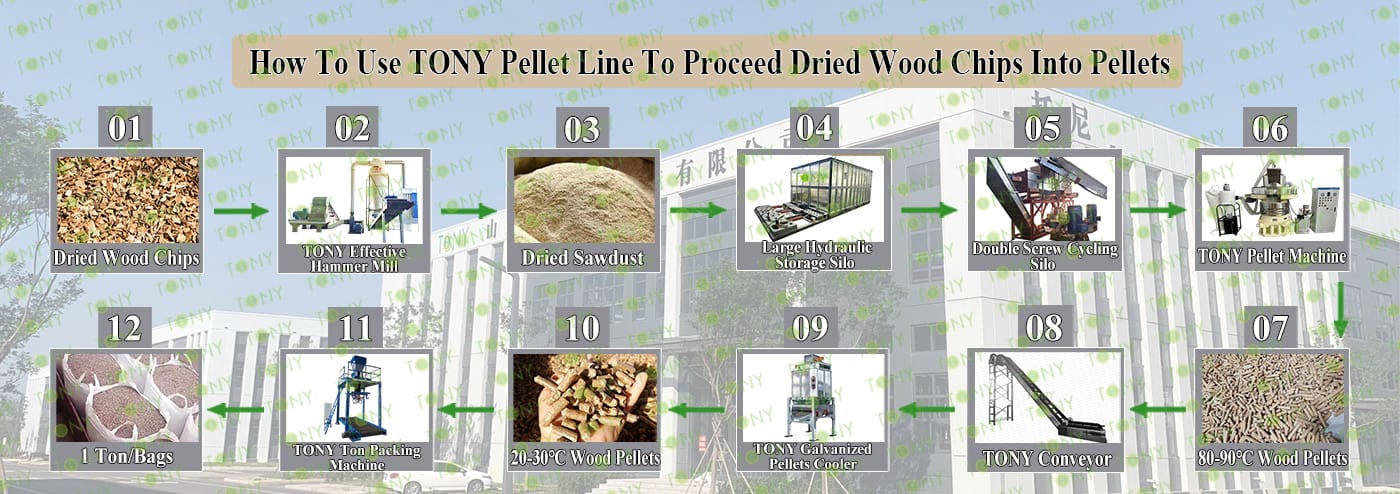

3.TONY Brand 18Ton /Hour Dried Wood Chips Pellet Line Project Process

4.Main Machine: Hammer Mill, Large Hydraulic Storage Silo,TONY Pellet Machine TYJ760-III-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1920KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of dried wood chips biomass pellet processing equipment

(1)Raw Material Pretreatment Stage

First, dry wood chips are crushed to an appropriate particle size (usually 3-5 mm) to ensure uniformity for subsequent compression.

(2)Mechanical Compression Molding Stage

The pretreated raw material is fed through a screw feeder between the rollers and the die of the molding machine. Under high pressure (usually 50-150 MPa), the wood chip pellets are squeezed into the die channels. During this process, the cellulose and hemicellulose components within the raw material soften under pressure and frictional heat (temperatures can reach 100-180°C), creating intermolecular bonding and forming continuous, columnar pellets.

(3)Cutting and Cooling Stage

The pellets extruded from the die are cut by a fixed blade into a desired length (usually 5-30 mm). They are then cooled to room temperature by air cooling to prevent the pellets from sticking due to residual heat. The result is a biomass pellet fuel with high hardness and density.

2.Characteristics of dried wood chips biomass pellet processing equipment

(1)Strong adaptability:

The biomass pellet machine can adapt to various raw materials, including dry wood chips.

(2)High-efficiency pelletizing:

The centrifugal force is used to make the material continuously move in a circular motion and adhere to the inner wall of the die, forming a uniform annular material layer. The roller continuously rotates and squeezes the material, forcing it into the ring die hole for molding.

(3)Environmental protection and energy saving:

The pellet fuel produced by the biomass pellet machine has the advantages of high density, high calorific value, good combustion, low cost, convenient use, clean and hygienic, easy to store and transport, etc. It can replace firewood, coal, natural gas, liquefied gas, etc. and is widely used in domestic stoves, heating stoves, hot water boilers, drying furnaces, industrial boilers, etc.

(4)High degree of automation:

The TONY biomass pellet machine has a fully automatic lubrication function and can work 24 hours a day, reducing manual intervention and improving production efficiency.

(5)Low maintenance cost:

Some biomass pellet machine equipment has low maintenance cost, no need to add grease, the wearing parts are practical and durable, and the roller bearings are international brands and are not easy to damage.

(6)Compact process:

The biomass pellet machine has compact process, small footprint, good dust removal effect, low noise and good production environment.

3.Application scenarios of dried wood chips biomass pellet processing equipment

(1)Biomass energy field

As a clean fuel: The processed wood pellets have high calorific value and high combustion efficiency, and their sulfur, ash and nitrogen content are much lower than fossil fuels such as coal and oil. They can be directly used for fireplaces and boiler heating, or as fuel for biomass power plants, achieving energy substitution and emission reduction goals.

Energy conversion advantages: Compared with traditional fuels, wood pellets are smokeless and odorless when burned, with low pollutant emissions, which meets the needs of modern green energy, especially in Europe and America where the demand for biomass energy is relatively high.

(2)Animal feed field

Feed pellet production: Wood pellets processed by wood pellet machines can be used as high-quality feed for poultry and livestock breeding, improving feed utilization and animal production efficiency. Some equipment is specially designed for feed pellets to meet the process requirements of feed processing.

(3)Environmental protection and resource recycling field

Wood waste processing: The equipment uses wood chips, sawdust, branches and other wood processing waste as raw materials, converting waste that might have been discarded into high-value pellet products, realizing resource recycling and reducing environmental pollution.

TONY Brand 18Ton/Hour Dried Wood Chips Pellet Manufacturing Plant can take dried wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried wood chips is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 18Ton/Hour

2. Raw materials: Dried wood chips

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of wood chips or more waste wood raw materials

Suitable customers: Solid wood furniture production, artificial board processing (plywood, fiberboard, particleboard), wood component processing, construction and decoration, packaging and logistics, such as pallets and wooden boxes, will generate a large amount of waste wood chips due to repeated use, size mismatch or changes in cargo transportation needs. Paper and pulp production.Where waste wood chip resources are advantageous.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

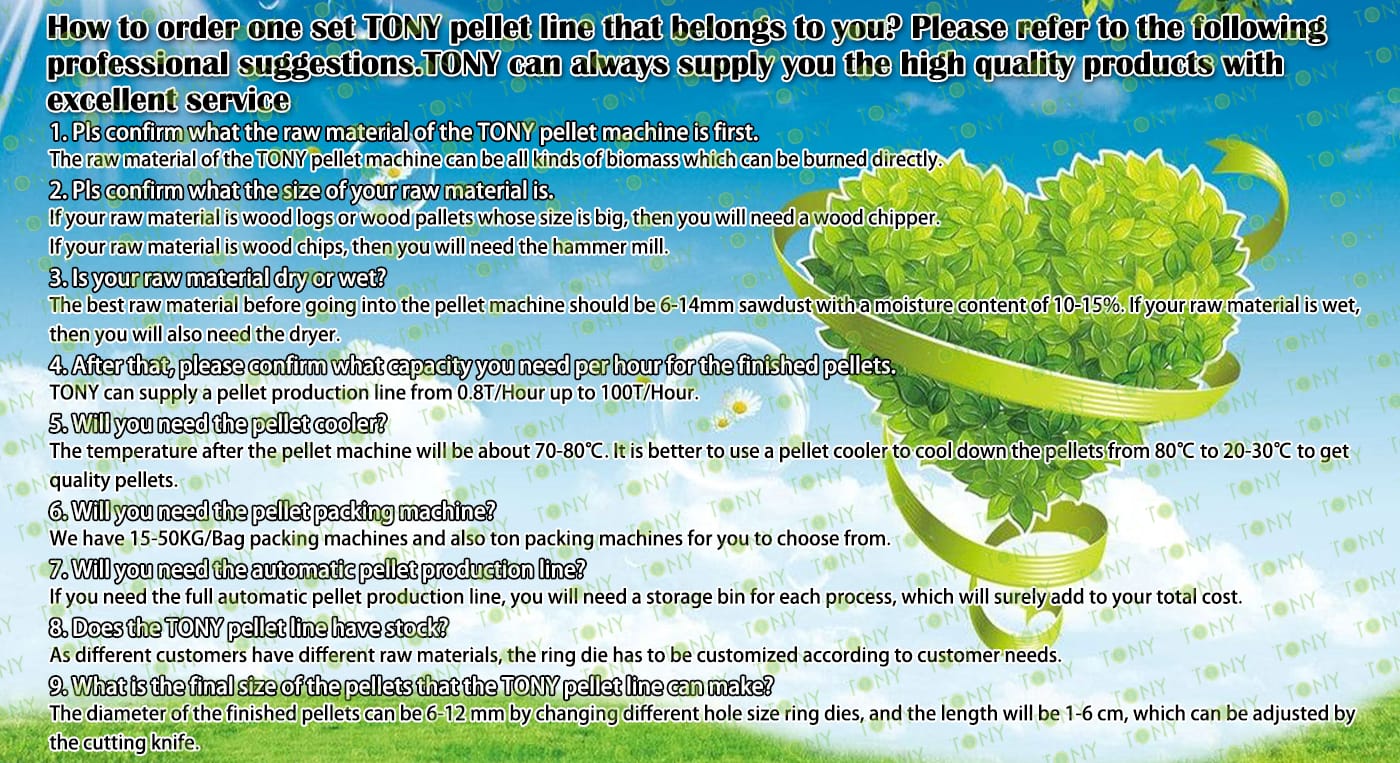

1. Project Name: Dried Wood Chips Pellet Production Line

2. Raw Material: All kinds of dried wood chips

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 18 tons per hour

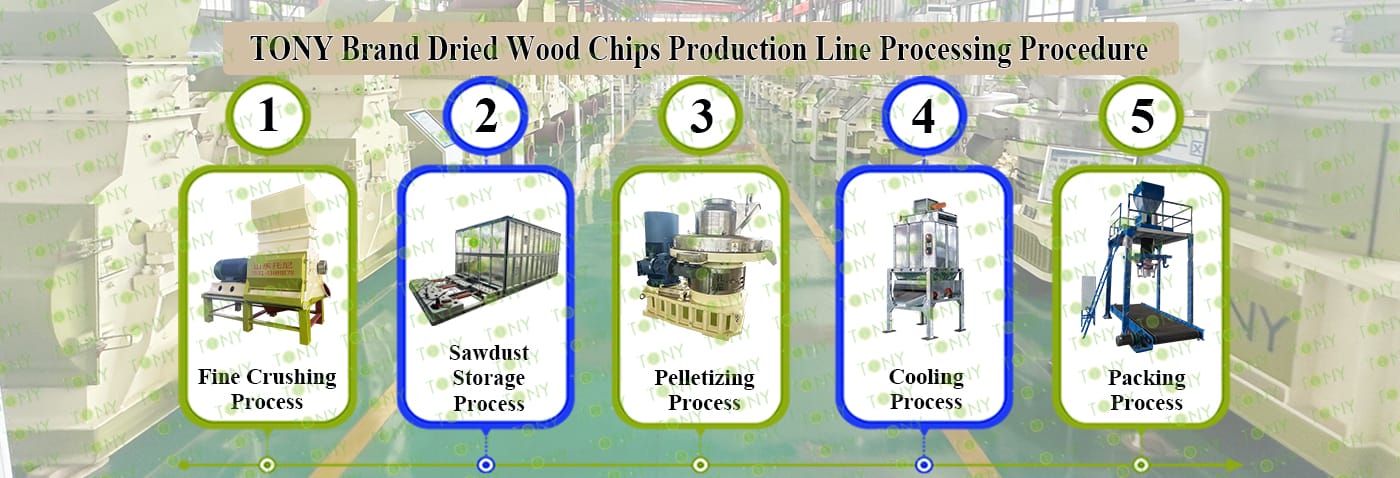

5. Process: Fine Crushing Process -Sawdust Storage Process- Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD75*132-132KW, TONY Large Hydraulic Storage Silo, TONY Pellet Machine TYJ760-Ⅲ-200KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

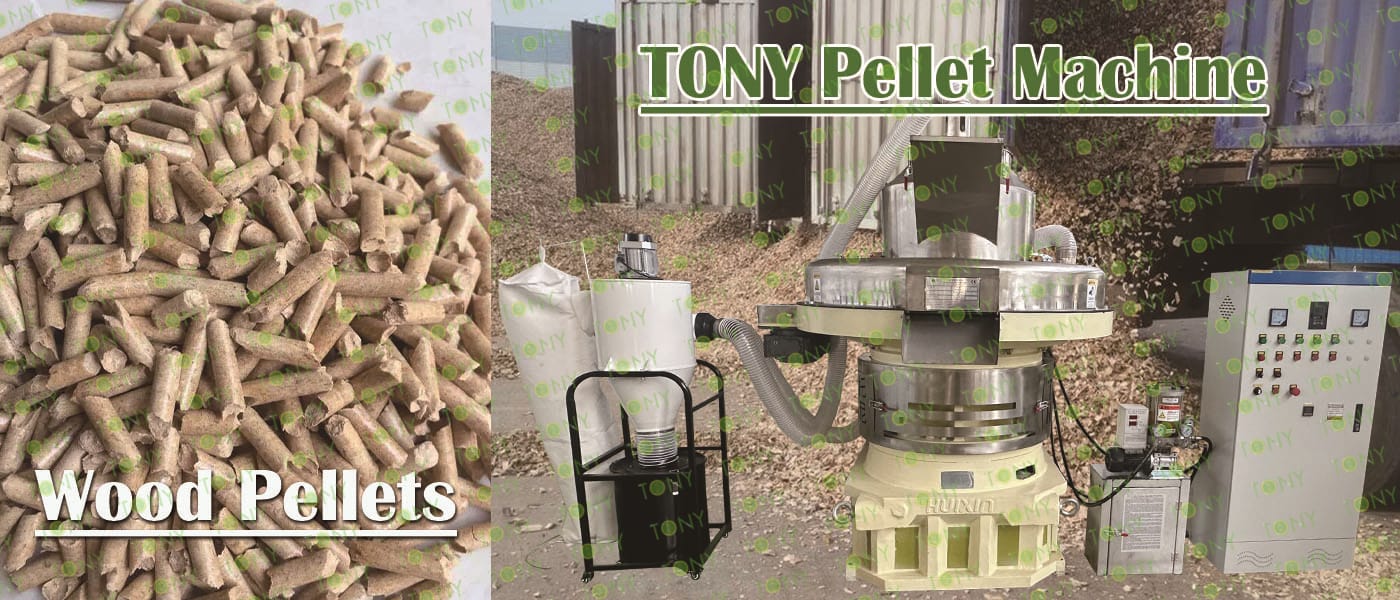

How to use the TONY pellet production line to make pellets from dried wood chips? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 2.Use TONY large hydraulic storage silo to storage 8-14 mm sawdust 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Effective Hammer Mill | Large Hydraulic Storage Silo | Vertical Ring Die Pellet Machine |

| 1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*132-132KW*4sets 3.Capacity: 4-5Ton/Hour/Set |

1.To Storage Sawdust Before Pellet machine 2.Model: TCY-25*2sets 3.TONY Uses Galvanized Material |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*6sets 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*2sets 3.Capacity:18Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*2sets 3.Capacity: 18Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*18sets 3.Capacity:Designed With The Whole Line |

三维图

1.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:18Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132KW*4sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

2.Sawdust Storage Process:

A. This process is mainly used to storage the sawdust that comes out of the hammer mill.It is hydraulic galvanized storage bin which is more stalbe and sawdust in it is not easy to be blocked.

B.TONY brand sawdust storage to storage the sawdust that comes out of the hammer mill.This process can be optional by customer.If customer do not chose the storage bin,he can storage the sawdust on the ground directly which may need some labour.

Main Parts:

(1)TONY's New Sawdust Storage Bin.

(2)With Screws Inside The Storage Bin To Prevent Sawdust Blocked.

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:18Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-Ⅲ-200KW*6sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:18Ton/Hour.

C.TONY brand galvanized pellets cooler separator*2sets

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

5.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:18Ton/Hour.

C.TONY brand ton packing machine*2sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Risk Control and Operation Recommendations for Dry Wood Chip Processing Biomass Pellets Project

1.Core Risks and Countermeasures

(1)Raw Material Risk: Raw material shortage and price increase

Sign long-term agreements with 3-5 suppliers to lock in price and supply;

Expand raw material sources (e.g., cooperate with forestry departments to recycle logging residues);

Reserve 15-30 days of raw material inventory

(2)Quality Risk: Pellet density does not meet standards and yield is low

Establish a raw material testing system (measure moisture and impurities for each batch);

Regularly maintain the pellet machine (clean the ring die weekly and check the rollers monthly);

Train operators and familiarize them with parameter adjustments (e.g., pressure, temperature)

(3)Market Risk: Pellet price drop and demand reduction

Binding long-term customers (e.g., signing a 1-3 year supply agreement with a power plant);

Expanding multi-scenario customers (industrial + civil + export);

Improving product quality (entering the high-end market)

(4)Environmental Risk: Exceeding dust emission standards and failing environmental inspections

Maintain the dust removal system regularly (replace filter bags monthly);

Install online monitoring equipment (real-time monitoring of dust concentration);

Reserve environmental emergency funds (to cope with unexpected inspections)

2.Operational optimization suggestions

(1)Optimize raw material pretreatment:

For dry wood chips containing impurities (such as scrap wood with nails), add a "magnetic separation + manual sorting" step to avoid damage to the equipment;

(2)Equipment maintenance plan:

Establish a "daily inspection (check screws, lubrication), weekly inspection (clean mold holes, filter bags), monthly inspection (replace wearing parts)" system to extend the life of the equipment;

(3)Cost control details:

Reuse of scrap materials (can reduce raw material loss by 5%-10%), staggered electricity use (use off-peak electricity hours for production to reduce electricity costs), and recycling packaging materials (woven bags can be reused 2-3 times).

Processed biomass pellets have the following characteristics:

1.High density and high energy:

Volume density can reach 1.1-1.3 tons/cubic meter, with a calorific value of approximately 4,000-4,500 kcal/kg, making them easy to store and transport.

2.Environmentally friendly and renewable:

Combustion produces near-zero CO₂ emissions, and the sulfur and nitrogen content are low, making them a viable alternative to coal or natural gas for industrial boilers, hot air furnaces, and other equipment.

3.Fuel cost advantage:

Compared to natural gas, fuel costs are 30%-50% lower, and the raw material source is broad (such as wood processing waste and crop straw).

This technology not only enables the resourceful utilization of agricultural and forestry waste but also provides a low-carbon solution for industrial heating, making it a key development direction in the renewable energy sector.

2025 Tony Machinery - All Rights Reserved. Map