Project Brief Introduction:

1.Product:Dried Wood Chips Pellet Line

2.Capacity:1.5-2T/Hour

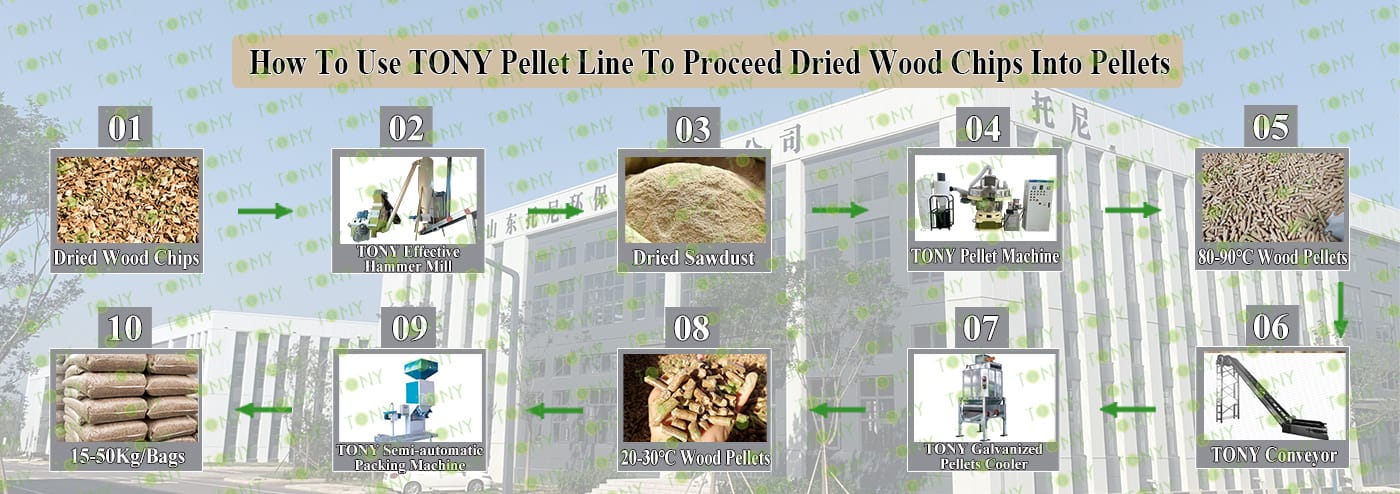

3.TONY Brand 1.5-2Ton /Hour Dried Wood Chips Pellet Line Project Process

4.Main Machine: Hammer Mill,TONY Pellet Machine TYJ551-III-110KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 200KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3D

1.The working principle of dried wood chips biomass pellet processing equipment

The process of processing dry wood chips into biomass pellets is mainly completed by biomass pellet molding equipment. Its core principle is to crush and compress dry wood chips and other biomass raw materials into high-density pellet fuel. This process requires key steps such as raw material pretreatment, mechanical compression, and thermal curing. The densification of the raw materials is achieved through the combined action of pressure and temperature.

2.Characteristics of dried wood chips biomass pellet processing equipment

(1)Combination of forced extrusion and high-temperature shaping:The pellet machine uses a high-pressure roller-die system (the die speed is usually 150-300r/min and the extrusion pressure can reach 50-100MPa) to force the material to extrude. At the same time, the friction heat generated by the extrusion (raising the material temperature to 80-120℃) can soften the lignin in the dry wood chips. Lignin, as a natural adhesive, can melt at high temperatures and bond the fibers together, solving the problem of dry wood chips being "difficult to shape and easy to loosen", ensuring that the pellet density reaches 1.1-1.3g/cm³ (in line with industrial fuel standards).

(2)Customized die hole and roller parameters:According to the fiber length and hardness of dry wood chips, the ring die hole is designed as a conical inlet + cylindrical channel (the inlet cone angle is 15°-30°, which facilitates the entry of dry wood chip fibers and reduces clogging of the hole). The die hole diameter is mostly 6-10mm (adapting to the mainstream specifications of dry wood chip particles); the roller surface adopts spiral teeth or diamond patterns to enhance the grip of dry wood chips, avoid "slipping" caused by material drying, and improve feeding uniformity.

(3)Wear-resistant materials extend service life:Dry wood chips (especially hardwood) cause greater wear on the equipment. The ring die and roller are made of high chromium alloy (such as Cr26) or carburized quenched steel, with a surface hardness of HRC58-62, strong wear resistance, and a single service life of up to 1000-3000 hours (depending on the hardness of the wood chips), reducing the cost of frequent replacement of parts.

(4)Automation control: Equipped with a PLC control system to automatically adjust the equipment's operating status (e.g., automatically reduce feed when pellet machine pressure is too high), reducing manual intervention.

(5)Continuous production: Each device is connected through a conveyor belt and a screw conveyor, and can achieve "one-button start, continuous operation" from dry wood chip feeding to finished pellet packaging, adapting to industrial-scale processing needs.

(6)Dust control: The crushing and screening process of dry wood chips easily generates dust. The equipment is equipped with a bag dust collector (dust removal efficiency ≥ 99%), and sealing devices are installed at the feed and discharge ports to reduce dust overflow.

(7)Safety protection: Pellet machines, crushers and other high-speed running equipment are equipped with "emergency stop buttons + protective covers" to prevent safety accidents caused by equipment overload and overheating;

3. Application scenarios of dried wood chips biomass pellet processing equipment

(1)Biomass power generation: Biomass pellets can be used as fuel in biomass power plants to produce electricity.

(2)Boilers and fireplaces: Biomass pellets can be used in industrial boilers and home fireplaces to provide heat.

(3)Household appliances: Biomass pellets can be used as fuel for home heating equipment to provide a clean heat source.

(4)Replacement of traditional fossil fuels: Biomass pellets, as a renewable biomass clean energy, can reduce dependence on traditional energy sources such as coal, oil, and natural gas, helping to significantly reduce greenhouse gas emissions, reduce carbon emissions, and reduce air pollution.

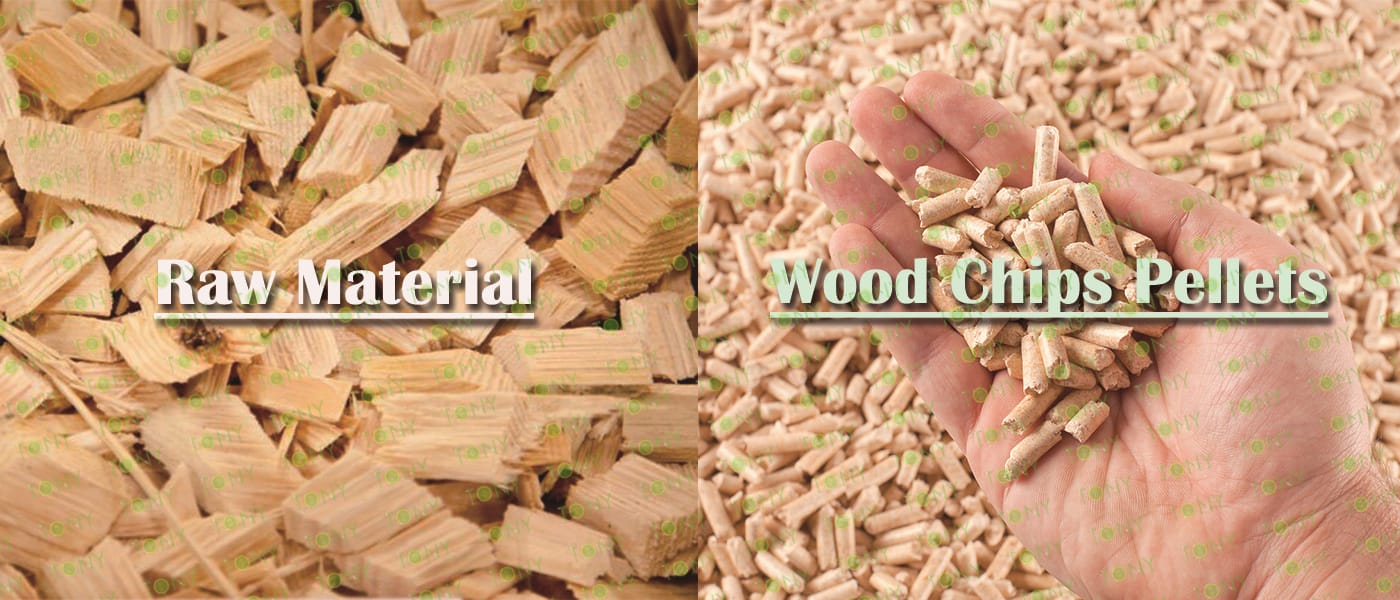

TONY Brand 1.5-2Ton/Hour Dried Wood Chips Pellet Manufacturing Plant can take dried wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried wood chips is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 1.5-2Ton/Hour

2. Raw materials: Dried wood chips

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of wood chips or more waste wood raw materials

Suitable customers: Solid wood furniture production, artificial board processing (plywood, fiberboard, particleboard), wood component processing, construction and decoration, packaging and logistics, such as pallets and wooden boxes, will generate a large amount of waste wood chips due to repeated use, size mismatch or changes in cargo transportation needs. Paper and pulp production.Where waste wood chip resources are advantageous.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Chips Pellet Production Line

2. Raw Material: All kinds of dried wood chips

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 1.5-2 tons per hour

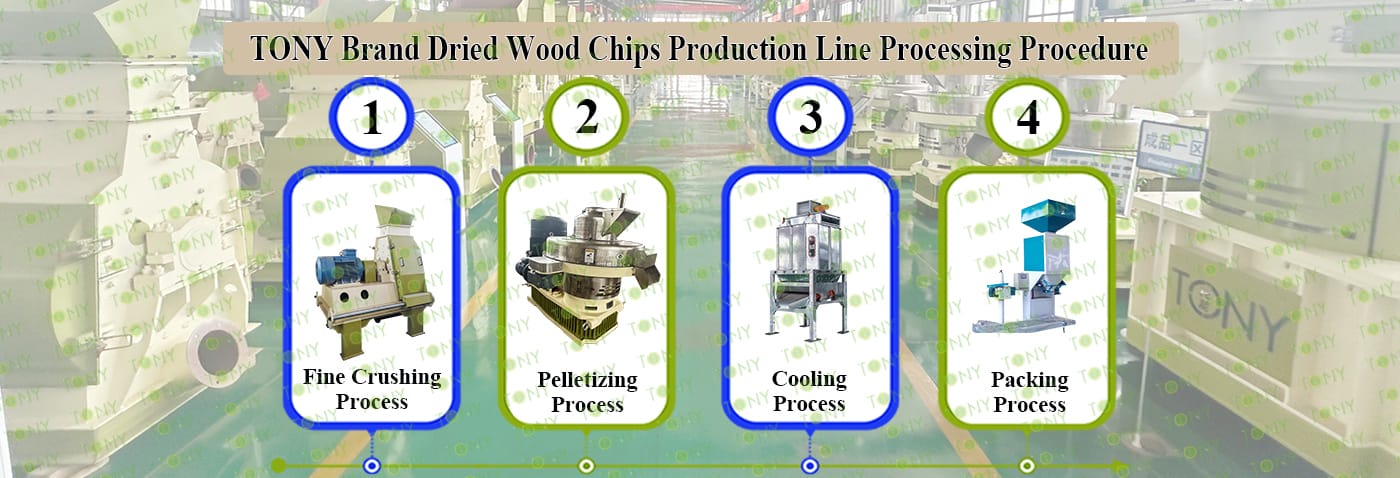

5. Process: Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD65*55-45KW, TONY Pellet MachineTYJ551-Ⅲ-110KW, Galvanized Pellets Cooler, Semi-automatic Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from dried wood chips? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4 Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Effective Hammer Mill | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Semi-automatic Packing Machine |

| 1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD65*55-45KW*1set 3.Capacity: 1.5-2Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-Ⅲ-110KW*1set 3.Capacity:1.5-2Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-1.5*1set 3.Capacity:1.5-2Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity:1.5-2Ton/Hour |

1.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:1.5-2Ton/Hour.

C.TONY brand effective hammer mill TFD65*55-45KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:1.5-2Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-Ⅲ-110KW*1set

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:1.5-2Ton/Hour.

C.TONY brand galvanized pellets cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:1.5-2Ton/Hour.

C.TONY brand semi-automatic packing machine*1set

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

The dry wood chip processing biomass pellet project has significant advantages in terms of environmental protection, economy and social benefits, as follows:

1.Environmental advantages

(1)Reduce waste: By processing agricultural and forestry waste (such as waste wood, sawdust, etc.) into biomass pellet fuel, the pollution of these wastes to the environment can be effectively reduced and the recycling of resources can be promoted.

(2)Reduce pollutant emissions: Biomass pellet fuel produces less smoke, dust and harmful gases during the combustion process. Compared with traditional coal burning, it can significantly reduce air pollution and help improve air quality.

2.Economic advantages

(1)Low cost and high profit: The production cost of biomass pellet fuel is relatively low, while its sales price is high, so it has a higher profit margin. In addition, due to its relatively low price, high calorific value and good combustion efficiency, it has a wide market demand and can bring good economic benefits.

(2)Cost savings: For enterprises or individuals using biomass pellet fuel, biomass pellet fuel can significantly reduce fuel costs compared with traditional fuels.

3.Social Benefit Advantages

(1)Promoting employment: The construction and operation of biomass pellet fuel projects can drive local employment, increase farmers' income, and promote rural economic development.

(2)Supporting sustainable development: Biomass pellet fuel projects are in line with the national policy orientation on environmental protection and renewable energy development and have good development prospects. Investing in such projects can not only generate economic benefits, but also contribute to the realization of sustainable development.

1. Environmental protection and sustainable development value

(1)Renewable energy attribute: The raw materials come from biomass waste such as wood chips, which are renewable resources. Replacing fossil fuels such as coal can reduce dependence on non-renewable energy and conform to the concept of circular economy

(2)Low carbon emission characteristics: The carbon dioxide emissions during combustion are much lower than those of fossil fuels, and the carbon absorbed by biomass during growth can offset the carbon released by combustion, achieving "carbon neutrality" and helping to slow down global climate change

(3)Solid waste resource utilization: Converting urban wood waste such as construction wood waste and garden branches into energy solves the environmental pollution problems caused by traditional incineration treatment, and has both biomass and sustainable development value. Ecological and social benefits

2.Energy utilization and economic advantages

(1)High calorific value and combustion efficiency: processed biomass pellets have high calorific value, long combustion time, and complete combustion. The energy conversion efficiency is comparable to that of wood chips with the same calorific value, which can meet the diverse needs of industrial production, power generation, and residential heating.

(2)Optimized storage and transportation costs: pellets have regular shape and high density, and the volume is only 1/5-1/3 of wood chips, which significantly reduces storage space occupation and transportation costs, making it suitable for large-scale distribution.

(3)High maturity of processing technology: small investment in production equipment, low energy consumption, and energy saving of 30%-50% in the drying process. The industry chain is well-equipped and economically feasible.

2025 Tony Machinery - All Rights Reserved. Map