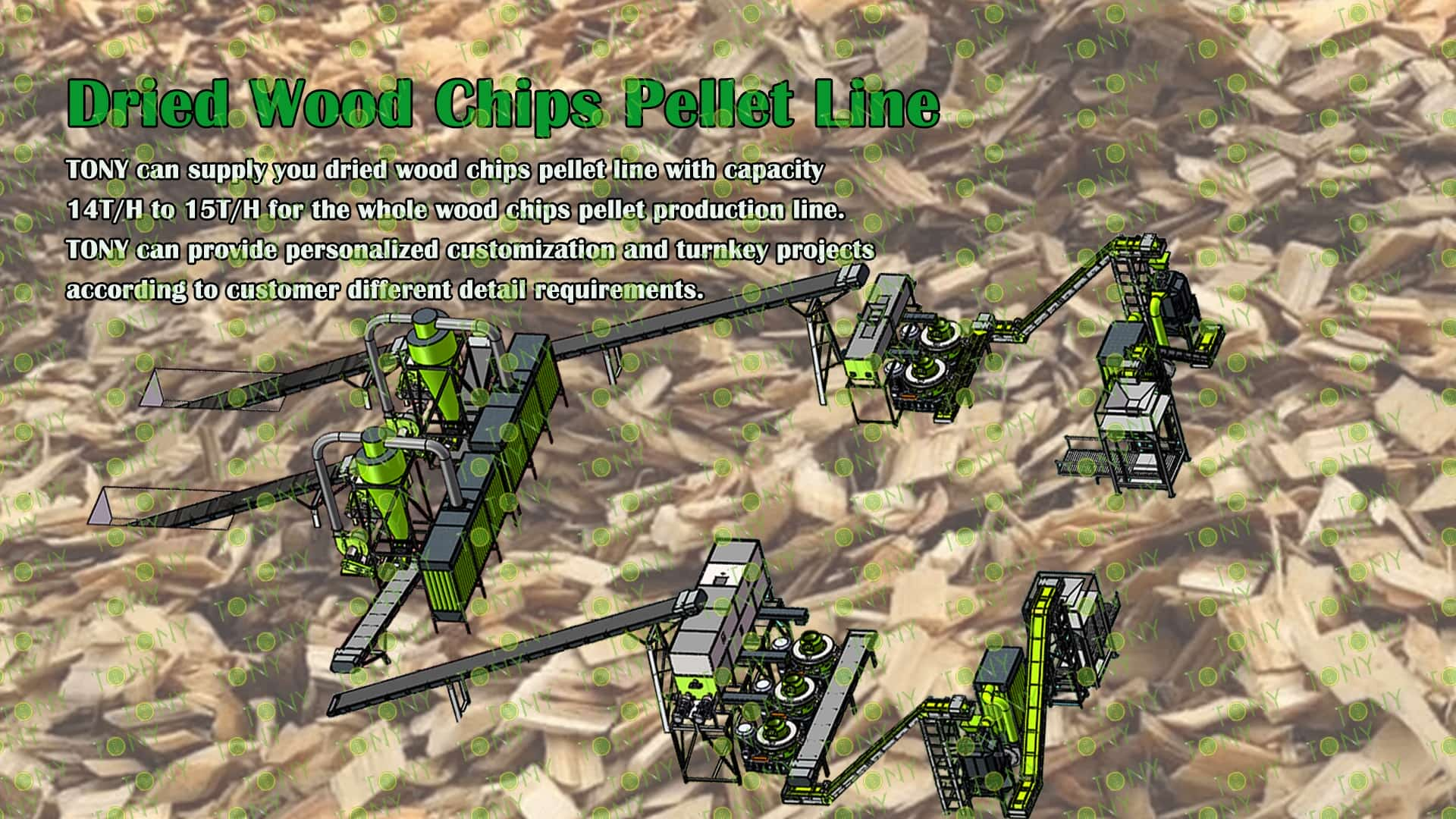

Project Brief Introduction:

1.Product:Dried Wood Chips Pellet Line

2.Capacity: 14-15T/Hour

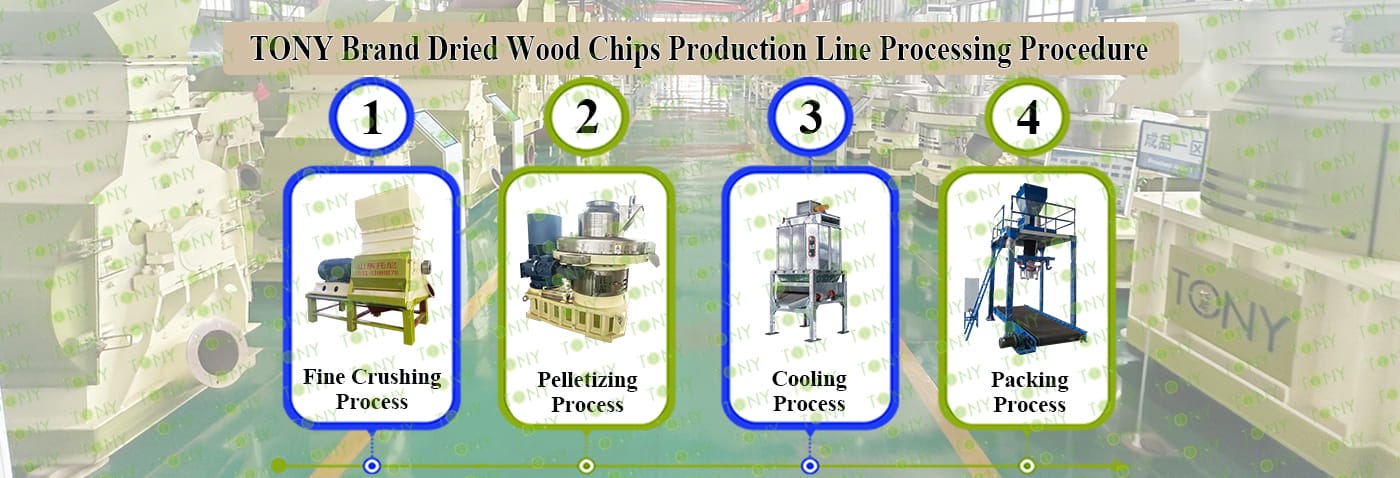

3.TONY Brand 14-15Ton /Hour Dried Wood Chips Pellet Line Project Process

4.Main Machine: Hammer Mill,TONY Pellet Machine TYJ760-Ⅲ-185KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1550KW

6.Need Area: About ㎡ L: M W: M H: M

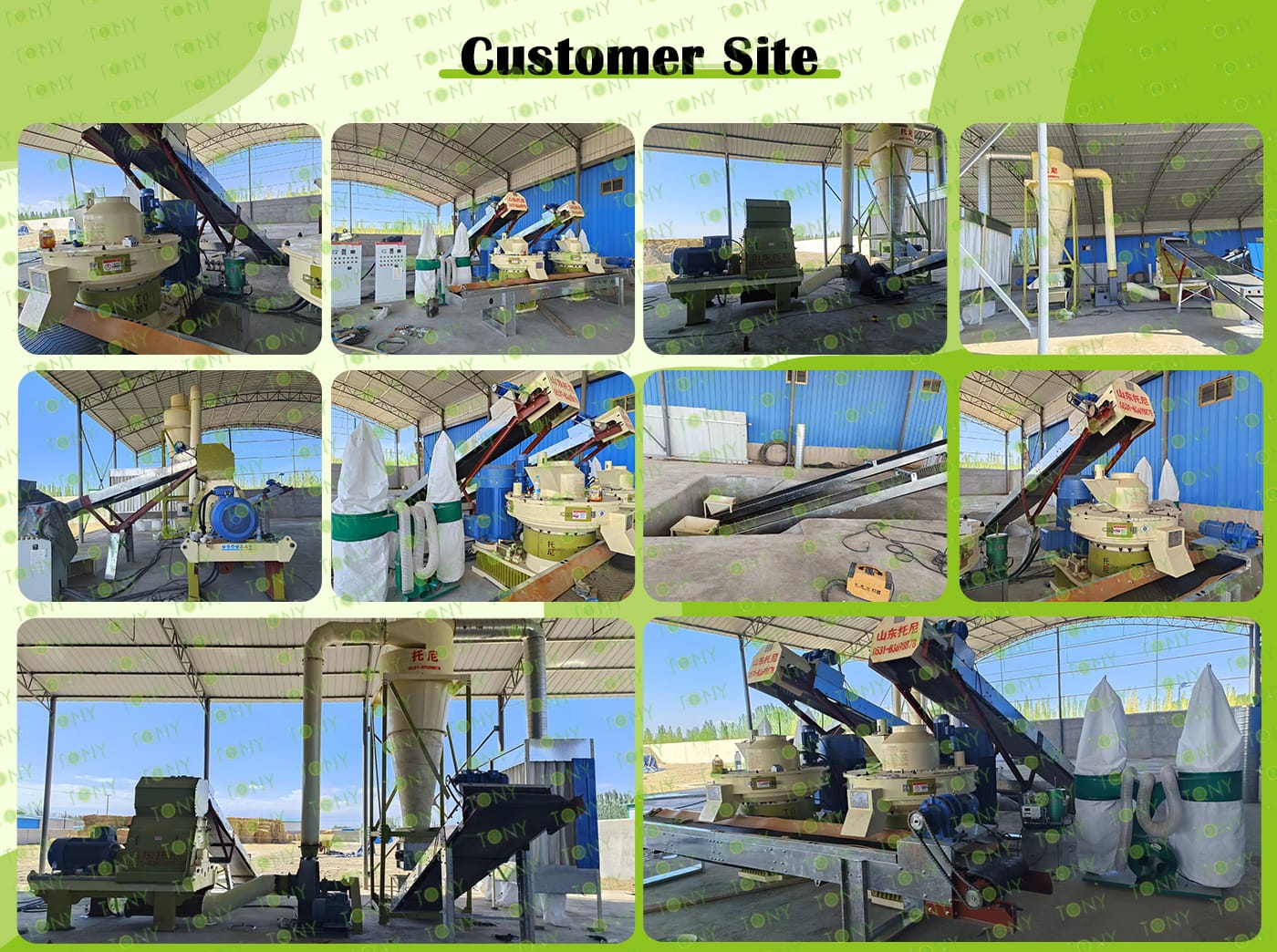

Project Layout For Customer:

三维图

1.The working principle of dried wood chips biomass pellet processing equipment

The process of processing dry wood chips into pellets is essentially a process of "raw material adaptation → physical shaping → stable shaping". Three key stages determine the quality of the pellets:

(1)Raw material pretreatment: Make the dry wood chips meet the "extrudability"

The initial state of the dry wood chips (particle size, moisture content) directly affects the molding effect. The core of pretreatment is to solve two problems

(2)Extrusion molding: Rely on "friction heat + pressure" to achieve bonding

This is the core link of the entire equipment. The principle can be summarized as "pressure compaction + lignin bonding"

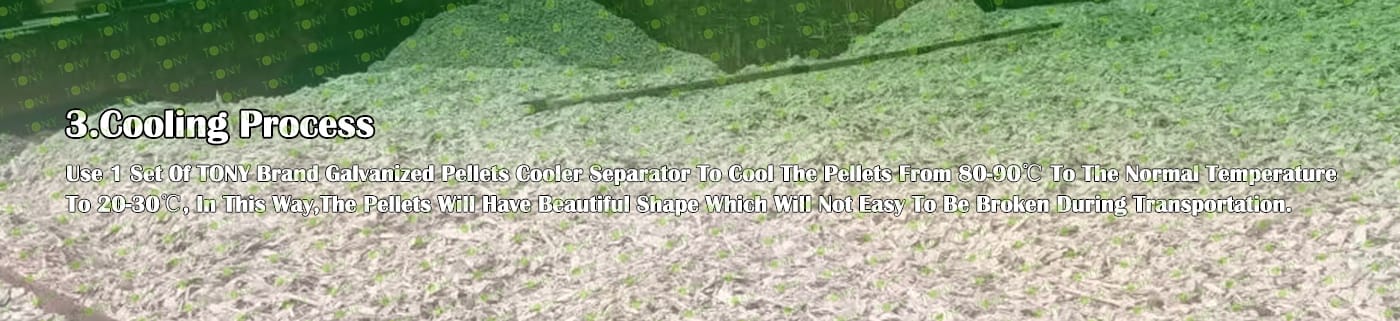

(3)Cooling and shaping: Make the pellets maintain "structural stability"

There are two problems with freshly extruded pellets: ① The temperature is high (80-100℃), and the lignin is not completely solidified; ② A small amount of hot air may remain inside. If stored directly, it is easy to cause: the pellets to stick to each other (lignin has not cooled and hardened); the hot air inside shrinks when it cools, causing the pellets to crack; high temperature accelerates moisture absorption, increasing the risk of mold. Therefore, the cooling system uses "air cooling + vibrating screen" to quickly cool down (to room temperature) and release the internal stress of the particles, ultimately forming biomass particles with "high hardness (compressive strength ≥ 150N), no agglomeration, and easy storage".

2.Characteristics of dried wood chips biomass pellet processing equipment

(1)Wide adaptability of raw materials: It can process 40 to 50 kinds of waste materials such as dry wood chips, sawdust, straw, rice husks, etc., and compress them into pellets of different specifications after pretreatment. For raw materials such as dry wood chips with high crude fiber content, light weight and loose texture, some equipment adopts mechanical forced feeding to solve the feeding problem.

(2)Excellent product performance: The density of the processed pellet fuel is greater than 1.1 (the density of the raw material is usually 0.6-0.8), with the advantages of high calorific value, complete combustion, low cost, etc., and it is easy to store and transport, and can replace traditional energy sources such as coal and natural gas.

(3)Environmental protection and energy saving characteristics: The fuel combustion efficiency is over 90%, and the staged combustion technology is used to reduce pollutant emissions and reduce dependence on petrochemical energy, which is in line with the low-carbon and environmentally friendly development direction.

3.Application scenarios of dried wood chips biomass pellet processing equipment

(1)Biomass power generation: Biomass pellets can be used as fuel in biomass power plants to produce electricity.

(2)Boilers and fireplaces: Biomass pellets can be used in industrial boilers and home fireplaces to provide heat.

(3)Household appliances: Biomass pellets can be used as fuel for home heating equipment to provide a clean heat source.

(4)Replacement of traditional fossil fuels: Biomass pellets, as a renewable biomass clean energy, can reduce dependence on traditional energy sources such as coal, oil, and natural gas, helping to significantly reduce greenhouse gas emissions, reduce carbon emissions, and reduce air pollution.

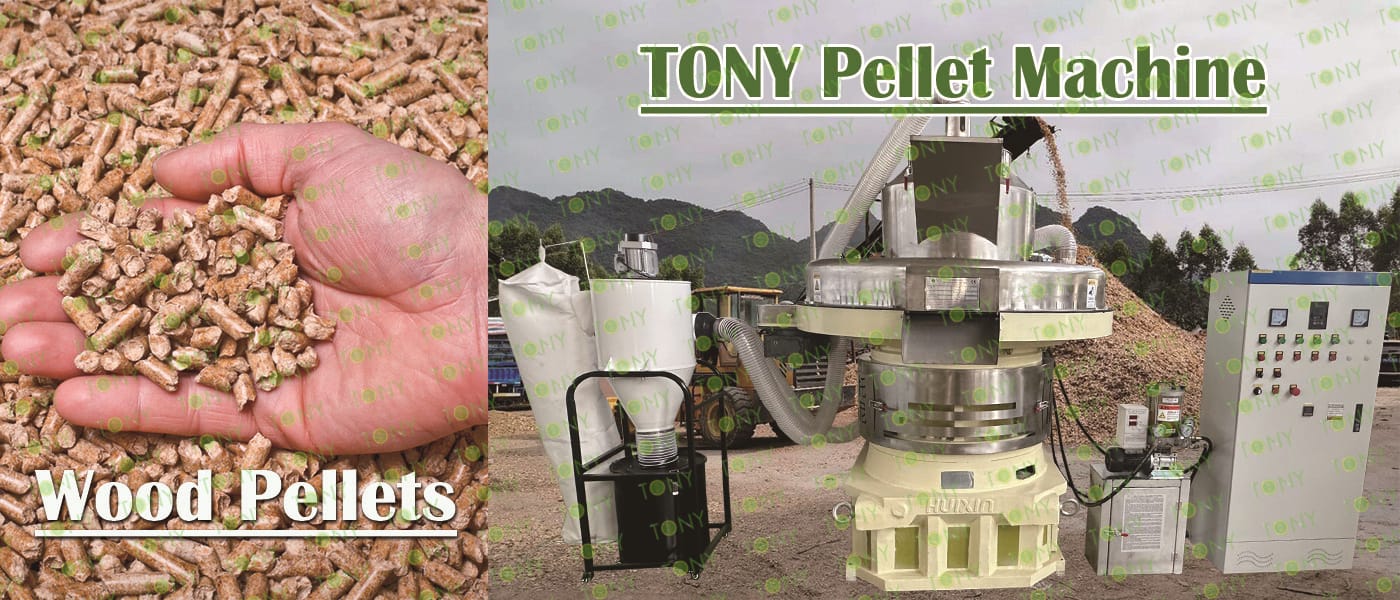

TONY Brand 14-15Ton/Hour Dried Wood Chips Pellet Manufacturing Plant can take dried wood chips, various types of wood - related biomass materials, such as wood pallets,branches, wood logs, and wood shavings. After pretreatment and processing, dried wood chips is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 14-15Ton/Hour

2. Raw materials: Dried wood chips

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of wood chips or more waste wood raw materials

Suitable customers: Solid wood furniture production, artificial board processing (plywood, fiberboard, particleboard), wood component processing, construction and decoration, packaging and logistics, such as pallets and wooden boxes, will generate a large amount of waste wood chips due to repeated use, size mismatch or changes in cargo transportation needs. Paper and pulp production.Where waste wood chip resources are advantageous.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Chips Pellet Production Line

2. Raw Material: All kinds of dried wood chips

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 14-15 tons per hour

5. Process: Fine Crushing Process- Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD85*220-220KW, TONY Pellet Machine TYJ760-Ⅲ-185KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

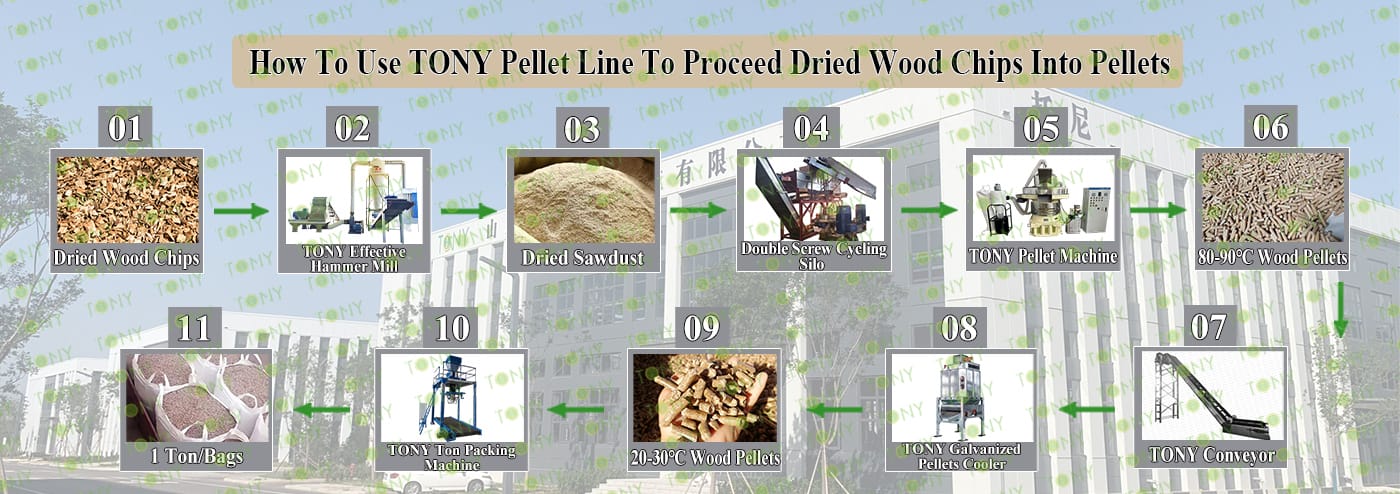

How to use the TONY pellet production line to make pellets from dried wood chips? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Effective Hammer Mill | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

|

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*220-220KW*2sets 3.Capacity: 7-8Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-15*1set 3.Capacity:14-15Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-185KW*5sets 3.Capacity:2.8-3.3Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

|

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1set 3.Capacity:14-15Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*1set 3.Capacity: 14-15Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*9sets 3.Capacity:Designed With The Whole Line |

三维图

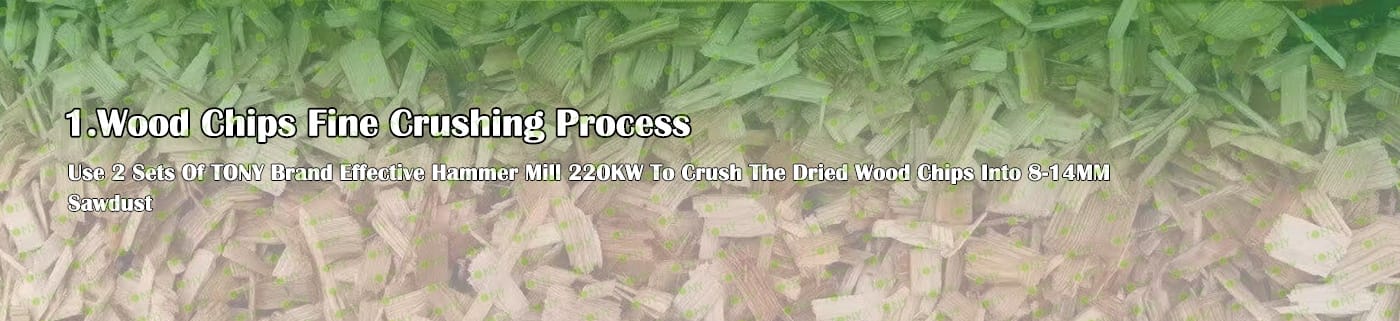

1.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:14-15Ton/Hour.

C.TONY brand effective hammer mill TFD85*220-220KW*2sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:14-15Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-Ⅲ-185KW*5sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:14-15Ton/Hour.

C.TONY brand galvanized pellets cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:14-15Ton/Hour.

C.TONY brand ton packing machine*1set

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Technical Advantages of Processing Biomass Pellets from Dry Wood Chips

The technology for processing biomass pellets from dry wood chips has been developed for over 20 years, resulting in highly mature equipment and processes, fundamentally reducing the project's "technical risk." Mature and reliable technology: Stable equipment and low production risk.

1.High equipment stability and low failure rate

Mainstream pellet mills (such as ring die pellet mills) are designed specifically for the characteristics of dry wood chips. Core components (rollers and ring dies) have a service life of 800-1500 hours, with a failure rate of less than 5% during continuous operation. Furthermore, equipment manufacturers all provide comprehensive after-sales service (such as free installation and commissioning, a one-year warranty, and lifetime technical support). Even if a malfunction does occur, it can be quickly resolved (with spare parts arriving within 1-3 days), avoiding production losses caused by equipment downtime.

2.The process is simple and easy to master, requiring no specialized technicians.

The production process consists of only four steps: raw material crushing → extrusion molding → cooling and screening → packaging and storage. Operators can begin operations after 1-2 weeks of training. Furthermore, most equipment is equipped with a PLC control system, automating the entire process and reducing human errors (such as raw material blockages and pressure imbalances). This ensures consistent pellet quality (density, hardness, length, and other indicators meet standards at ≥98%).

1.Environmental protection and sustainable development value

(1)Renewable energy attribute: The raw materials come from biomass waste such as wood chips, which are renewable resources. Replacing fossil fuels such as coal can reduce dependence on non-renewable energy and conform to the concept of circular economy

(2)Low carbon emission characteristics: The carbon dioxide emissions during combustion are much lower than those of fossil fuels, and the carbon absorbed by biomass during growth can offset the carbon released by combustion, achieving "carbon neutrality" and helping to slow down global climate change

(3)Solid waste resource utilization: Converting urban wood waste such as construction wood waste and garden branches into energy solves the environmental pollution problems caused by traditional incineration treatment, and has both biomass and sustainable development value. Ecological and social benefits

2.Energy utilization and economic advantages

(1)High calorific value and combustion efficiency: processed biomass pellets have high calorific value, long combustion time, and complete combustion. The energy conversion efficiency is comparable to that of wood chips with the same calorific value, which can meet the diverse needs of industrial production, power generation, and residential heating.

(2)Optimized storage and transportation costs: pellets have regular shape and high density, and the volume is only 1/5-1/3 of wood chips, which significantly reduces storage space occupation and transportation costs, making it suitable for large-scale distribution.

(3)High maturity of processing technology: small investment in production equipment, low energy consumption, and energy saving of 30%-50% in the drying process. The industry chain is well-equipped and economically feasible.

2025 Tony Machinery - All Rights Reserved. Map