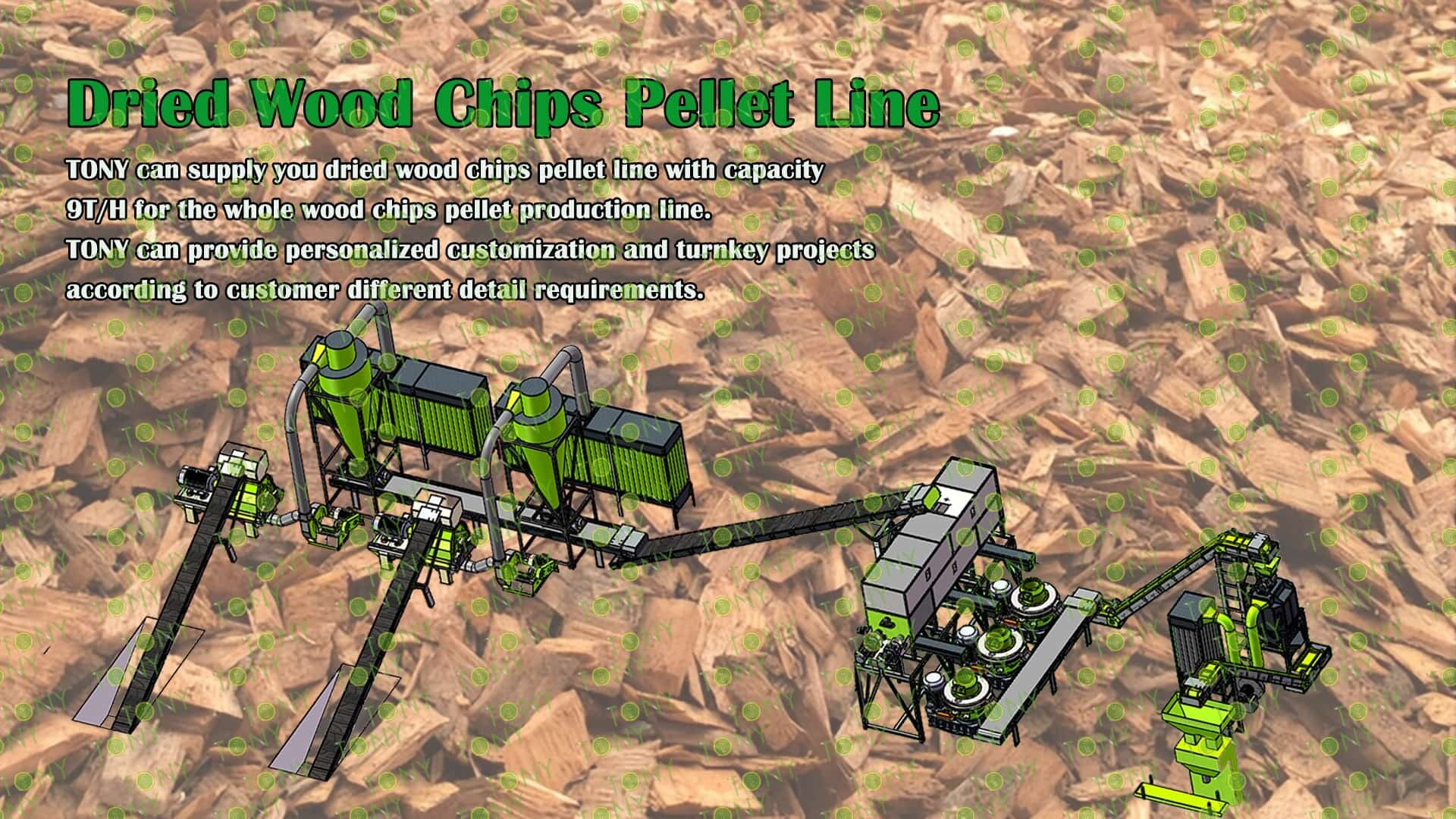

Project Brief Introduction:

1.Product:Dried Wood Chips Pellet Line

2.Capacity: 9T/Hour

3.TONY Brand 9Ton /Hour Dried Wood Chips Pellet Line Project Process

4.Main Machine: Hammer Mill,TONY Pellet Machine TYJ760-Ⅲ-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 980KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of dried wood chips biomass pellet processing equipment

(1)Crushing Equipment: Refines Dry Wood Chips to Suitable Particle Size

Dry wood chips cannot be fed directly into the pelletizing machine and must be refined into wood pellets using a hammer mill. The principle is as follows:

The core component of the hammer mill is a high-speed rotating rotor (800-1500 rpm) with 2-4 rows of manganese steel hammers evenly distributed across it. Once the dry wood chips enter the crushing chamber, they are repeatedly struck and sheared by the high-speed hammers, while rubbing against the toothed plates on the chamber's inner wall, ultimately breaking them into fine wood chips. The crushed material is then screened through a bottom screen, leaving unqualified coarse material within the chamber for further crushing.

(2)Core Molding Equipment: Converts Wood Chips into High-Density Pellets

The molding equipment is the core of the entire production line. Currently, the mainstream equipment is the ring die pelletizer, which operates on a continuous "extrusion - forming - cutting" process.

The ring die is the core component of the pelletizer and is an annular steel die (mostly made of 40Cr or alloy steel) with evenly distributed forming holes (diameter 6-12mm, adjusted according to pellet size). As the pre-pressed pellets rotate with the rollers toward the inside of the ring die, the extrusion pressure between the rollers and the die increases dramatically (to a pressure of 50-150 MPa). Simultaneously, friction between the pellets and the die's inner wall and forming holes generates high temperatures (up to 80-120°C).

Under these high temperatures and pressures, the cellulose and hemicellulose components in the sawdust soften, forming a sticky "binder" that tightly binds the pellets together. Simultaneously, the pellets are forced into the die's forming holes, forming a continuous column of pellets that are extruded from the outside.

(3)Finished Product Post-Processing Equipment: Ensuring Stable Pellet Quality

Newly formed biomass pellets are hot and have a slightly higher moisture content. They require cooling and screening in post-processing equipment to ensure storage stability and uniformity.

2.Characteristics of dried wood chips biomass pellet processing equipment

(1)Automatic lubrication and intelligent control:

The pellet machine is equipped with an automatic lubrication system and variable frequency speed regulation function, which can adjust the speed according to the characteristics of the raw materials, avoid machine blockage problems, and reduce energy consumption.

(2)High efficiency and energy saving and cost control Dry-in and dry-out process:

When the moisture content of the raw materials is 10-15%, there is no need to dry them and they can be processed directly, which significantly reduces energy consumption costs. Low maintenance design: The equipment's vulnerable parts (such as molds and rollers) are made of high-strength materials. Combined with regular lubrication and maintenance (such as gear oil replacement and metal impurity cleaning), they can extend their service life and reduce downtime.

(3)Environmental protection and resource recycling Zero additives and pollution-free:

The processing process does not require adhesives and relies on the softening and bonding of lignin itself. When the finished product is burned, there is no harmful emission such as sulfur dioxide, which meets the requirements of energy conservation and emission reduction. Waste resource utilization: Agricultural and forestry waste such as dry wood chips and waste wood can be converted into high-value pellet fuel, realizing "waste to treasure" and contributing to the circular economy.

(4)Application scenarios and market adaptability:

The equipment is widely used in industrial boilers, biomass power plants, civil heating and other fields. With the advancement of environmental protection policies, equipment is extending from traditional energy replacement to diversified fields such as feed and fertilizer, and market demand continues to grow.

3.Application scenarios of dried wood chips biomass pellet processing equipment

(1)Biomass energy field

As a clean fuel: The processed wood pellets have high calorific value and high combustion efficiency, and their sulfur, ash and nitrogen content are much lower than fossil fuels such as coal and oil. They can be directly used for fireplaces and boiler heating, or as fuel for biomass power plants, achieving energy substitution and emission reduction goals.

Energy conversion advantages: Compared with traditional fuels, wood pellets are smokeless and odorless when burned, with low pollutant emissions, which meets the needs of modern green energy, especially in Europe and America where the demand for biomass energy is relatively high.

(2)Animal feed field

Feed pellet production: Wood pellets processed by wood pellet machines can be used as high-quality feed for poultry and livestock breeding, improving feed utilization and animal production efficiency. Some equipment is specially designed for feed pellets to meet the process requirements of feed processing.

(3)Environmental protection and resource recycling field

Wood waste processing: The equipment uses wood chips, sawdust, branches and other wood processing waste as raw materials, converting waste that might have been discarded into high-value pellet products, realizing resource recycling and reducing environmental pollution.

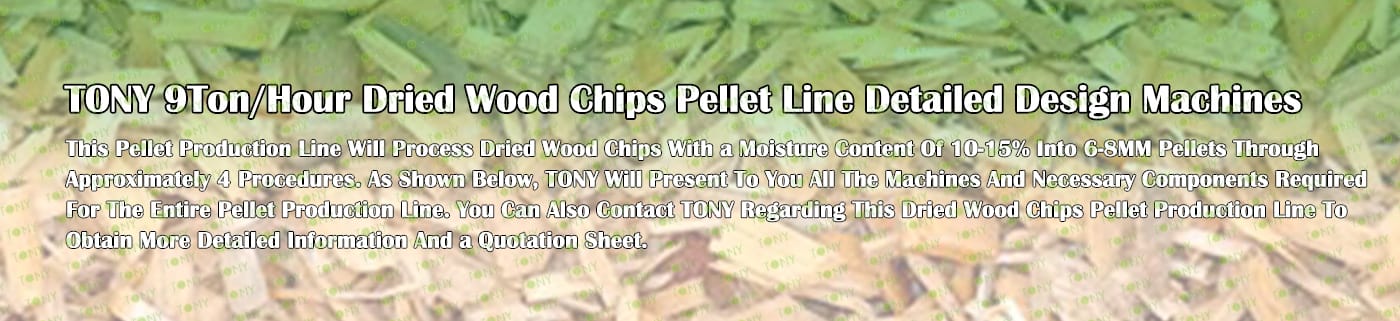

TONY Brand 9Ton/Hour Dried Wood Chips Pellet Manufacturing Plant can take dried wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried wood chips is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 9Ton/Hour

2. Raw materials: Dried wood chips

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of wood chips or more waste wood raw materials

Suitable customers: Solid wood furniture production, artificial board processing (plywood, fiberboard, particleboard), wood component processing, construction and decoration, packaging and logistics, such as pallets and wooden boxes, will generate a large amount of waste wood chips due to repeated use, size mismatch or changes in cargo transportation needs. Paper and pulp production.Where waste wood chip resources are advantageous.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Chips Pellet Production Line

2. Raw Material: All kinds of dried wood chips

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 9 tons per hour

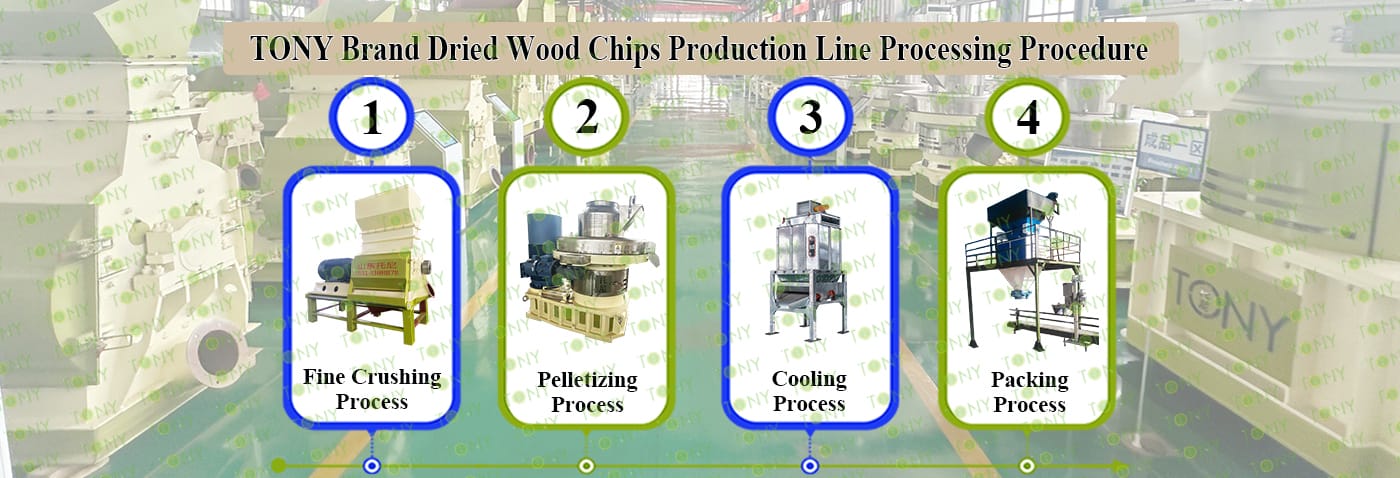

5. Process: Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD75*132-132KW, TONY Pellet Machine TYJ760-Ⅲ-200KW, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

|

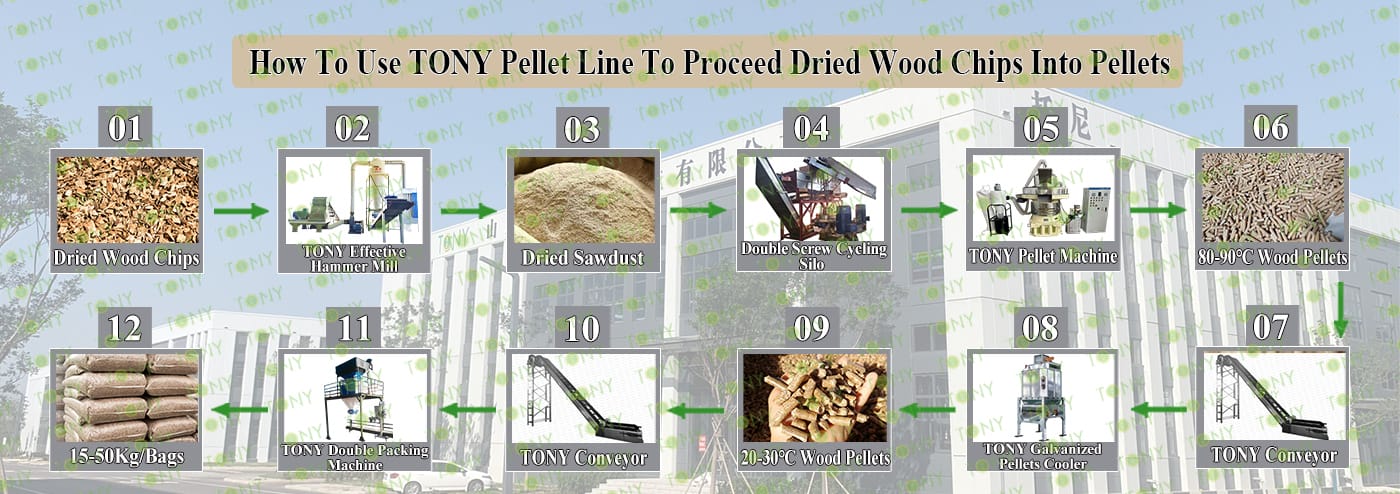

How to use the TONY pellet production line to make pellets from dried wood chips? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Effective Hammer Mill | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

|

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD75*132-132KW*2sets 3.Capacity: 4-5 Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-9*1set 3.Capacity:9Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-Ⅲ-200KW*3sets 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

|

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*1set 3.Capacity:9Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 9Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*7sets 3.Capacity:Designed With The Whole Line |

三维图

1.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:9Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132KW*2sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:9Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-Ⅲ-200KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:9Ton/Hour.

C.TONY brand galvanized pellets cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

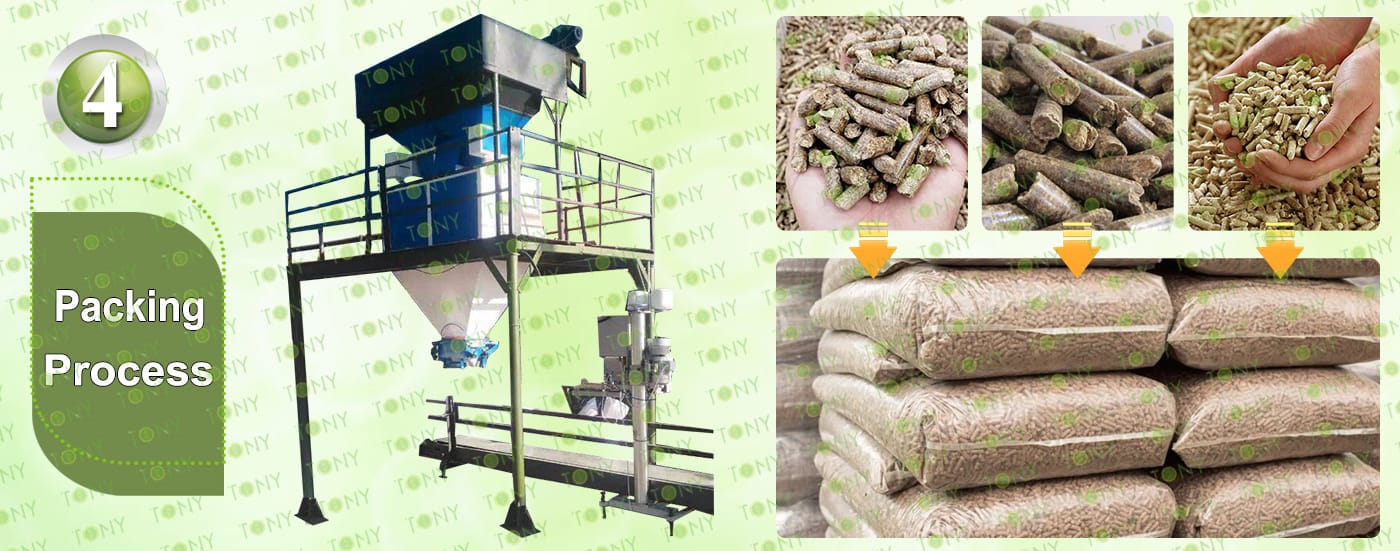

4.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:9Ton/Hour.

C.TONY brand double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Risk Control and Operation Recommendations for Dry Wood Chip Processing Biomass Pellets Project

1.Core Risks and Countermeasures

(1)Raw Material Risk: Raw material shortage and price increase

Sign long-term agreements with 3-5 suppliers to lock in price and supply;

Expand raw material sources (e.g., cooperate with forestry departments to recycle logging residues);

Reserve 15-30 days of raw material inventory

(2)Quality Risk: Pellet density does not meet standards and yield is low

Establish a raw material testing system (measure moisture and impurities for each batch);

Regularly maintain the pellet machine (clean the ring die weekly and check the rollers monthly);

Train operators and familiarize them with parameter adjustments (e.g., pressure, temperature)

(3)Market Risk: Pellet price drop and demand reduction

Binding long-term customers (e.g., signing a 1-3 year supply agreement with a power plant);

Expanding multi-scenario customers (industrial + civil + export);

Improving product quality (entering the high-end market)

(4)Environmental Risk: Exceeding dust emission standards and failing environmental inspections

Maintain the dust removal system regularly (replace filter bags monthly);

Install online monitoring equipment (real-time monitoring of dust concentration);

Reserve environmental emergency funds (to cope with unexpected inspections)

2.Operational optimization suggestions

(1)Optimize raw material pretreatment:

For dry wood chips containing impurities (such as scrap wood with nails), add a "magnetic separation + manual sorting" step to avoid damage to the equipment;

(2)Equipment maintenance plan:

Establish a "daily inspection (check screws, lubrication), weekly inspection (clean mold holes, filter bags), monthly inspection (replace wearing parts)" system to extend the life of the equipment;

(3)Cost control details:

Reuse of scrap materials (can reduce raw material loss by 5%-10%), staggered electricity use (use off-peak electricity hours for production to reduce electricity costs), and recycling packaging materials (woven bags can be reused 2-3 times).

Processed biomass pellets have the following characteristics:

1.High density and high energy:

Volume density can reach 1.1-1.3 tons/cubic meter, with a calorific value of approximately 4,000-4,500 kcal/kg, making them easy to store and transport.

2.Environmentally friendly and renewable:

Combustion produces near-zero CO₂ emissions, and the sulfur and nitrogen content are low, making them a viable alternative to coal or natural gas for industrial boilers, hot air furnaces, and other equipment.

3.Fuel cost advantage:

Compared to natural gas, fuel costs are 30%-50% lower, and the raw material source is broad (such as wood processing waste and crop straw).

This technology not only enables the resourceful utilization of agricultural and forestry waste but also provides a low-carbon solution for industrial heating, making it a key development direction in the renewable energy sector.

2025 Tony Machinery - All Rights Reserved. Map