Project Brief Introduction:

1.Product:Dried Wood Chips Pellet Line

2.Capacity: 6-7.5T/Hour

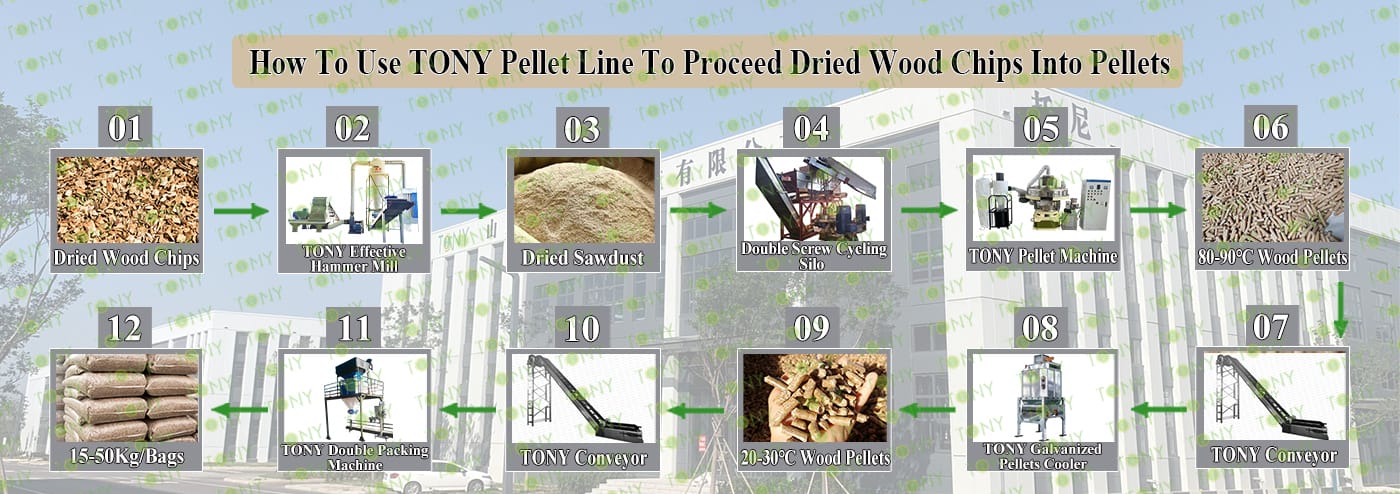

3.TONY Brand 6-7.5Ton /Hour Dried Wood Chips Pellet Line Project Process

4.Main Machine: Hammer Mill,TONY Pellet Machine TYJ551-III-132KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 825KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of dried wood chips biomass pellet processing equipment

The process of processing dry wood chips into biomass pellets is mainly completed by biomass pellet molding equipment. Its core principle is to crush and compress dry wood chips and other biomass raw materials into high-density pellet fuel. This process requires key steps such as raw material pretreatment, mechanical compression, and thermal curing. The densification of the raw materials is achieved through the combined action of pressure and temperature.

2.Characteristics of dried wood chips biomass pellet processing equipment

(1)Wide adaptability of raw materials: It can process 40 to 50 kinds of waste materials such as dry wood chips, sawdust, straw, rice husks, etc., and compress them into pellets of different specifications after pretreatment. For raw materials such as dry wood chips with high crude fiber content, light weight and loose texture, some equipment adopts mechanical forced feeding to solve the feeding problem.

(2)Excellent product performance: The density of the processed pellet fuel is greater than 1.1 (the density of the raw material is usually 0.6-0.8), with the advantages of high calorific value, complete combustion, low cost, etc., and it is easy to store and transport, and can replace traditional energy sources such as coal and natural gas.

(3)Environmental protection and energy saving characteristics: The fuel combustion efficiency is over 90%, and the staged combustion technology is used to reduce pollutant emissions and reduce dependence on petrochemical energy, which is in line with the low-carbon and environmentally friendly development direction.

3.Application scenarios of dried wood chips biomass pellet processing equipment

(1)Biomass power generation: Biomass pellets can be used as fuel in biomass power plants to produce electricity.

(2)Boilers and fireplaces: Biomass pellets can be used in industrial boilers and home fireplaces to provide heat.

(3)Household appliances: Biomass pellets can be used as fuel for home heating equipment to provide a clean heat source.

(4)Replacement of traditional fossil fuels: Biomass pellets, as a renewable biomass clean energy, can reduce dependence on traditional energy sources such as coal, oil, and natural gas, helping to significantly reduce greenhouse gas emissions, reduce carbon emissions, and reduce air pollution.

TONY Brand 6-7.5Ton/Hour Dried Wood Chips Pellet Manufacturing Plant can take dried wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried wood chips is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 6-7.5Ton/Hour

2. Raw materials: Dried wood chips

3. Moisture: Dry type, about 10-15%.

4. Application: All kinds of wood chips or more waste wood raw materials

Suitable customers: Solid wood furniture production, artificial board processing (plywood, fiberboard, particleboard), wood component processing, construction and decoration, packaging and logistics, such as pallets and wooden boxes, will generate a large amount of waste wood chips due to repeated use, size mismatch or changes in cargo transportation needs. Paper and pulp production.Where waste wood chip resources are advantageous.

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Wood Chips Pellet Production Line

2. Raw Material: All kinds of dried wood chips

3. Moisture Content of Raw Material: 10-15%

4. Capacity: 6-7.5 tons per hour

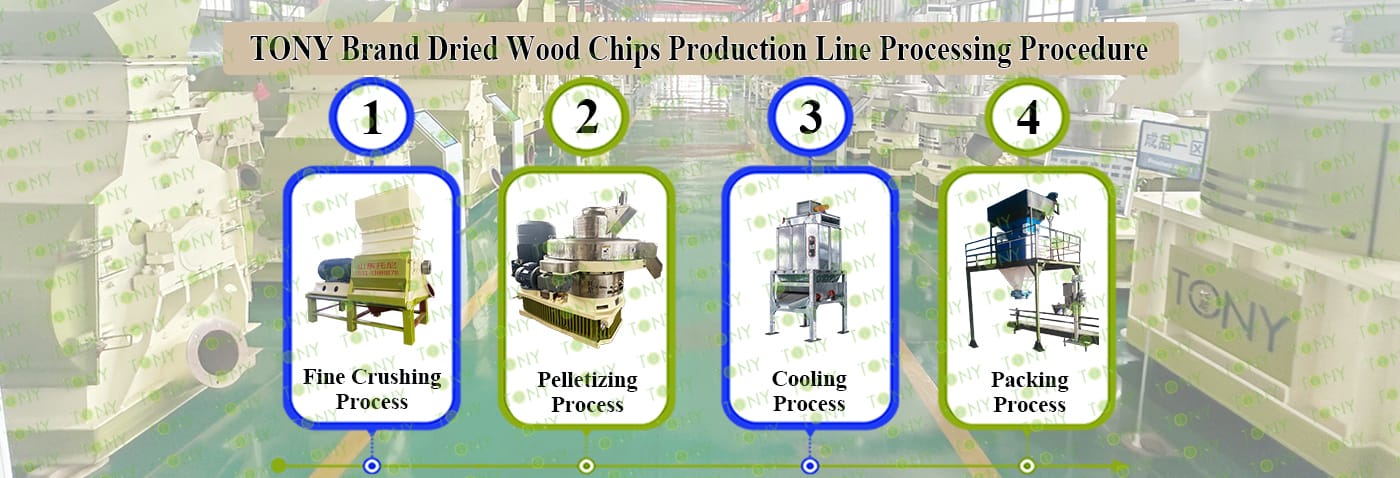

5. Process: Fine Crushing Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD85*250-250KW, TONY Pellet Machine TYJ551-Ⅲ-132KW, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

|

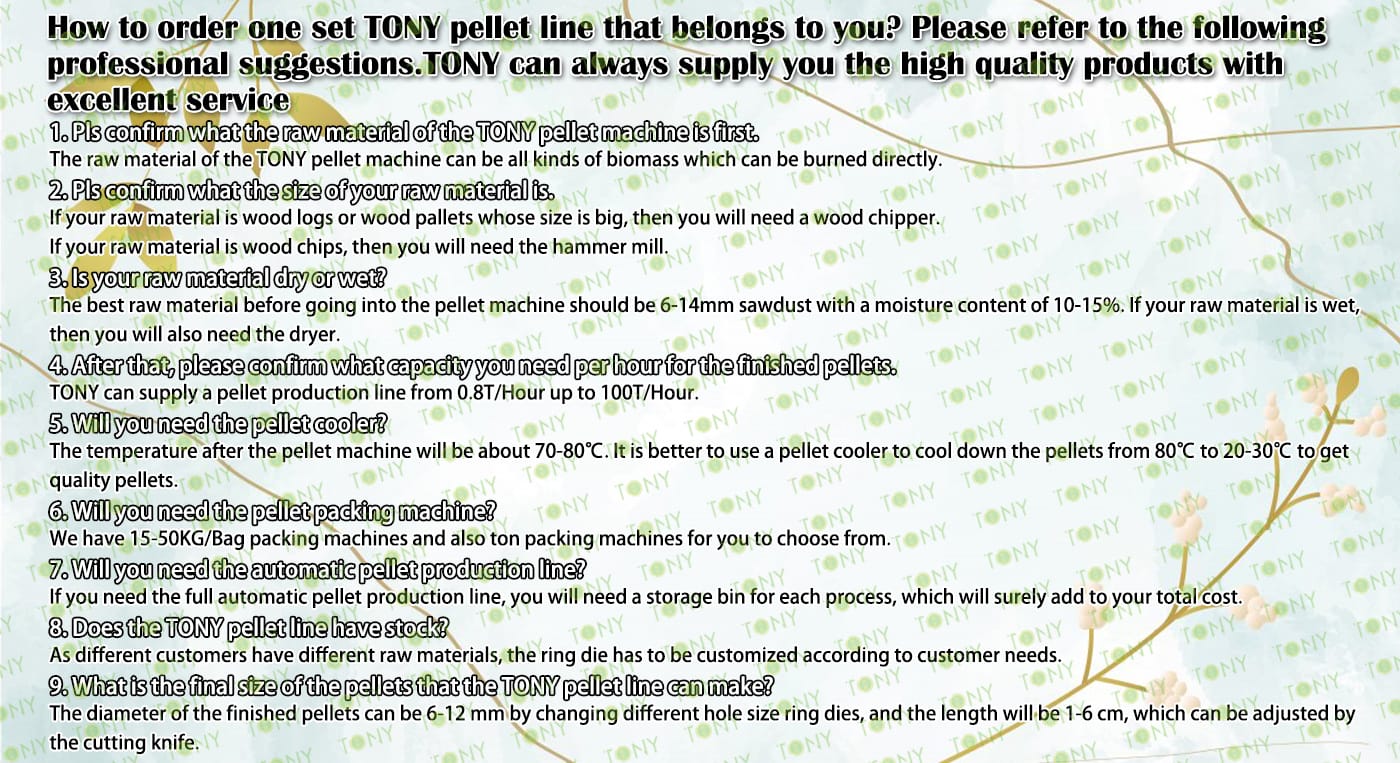

How to use the TONY pellet production line to make pellets from dried wood chips? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4 Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Effective Hammer Mill | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

| 1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*1set 3.Capacity: 8-10Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-7*1set 3.Capacity:6-7.5Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ551-Ⅲ-132KW*3sets 3.Capacity:2-2.5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Double Packing Machine | BelteyorConv |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*1set 3.Capacity:6-7.5Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6-7.5Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*5sets 3.Capacity:Designed With The Whole Line |

三维图

1.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:6-7.5Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:6-7.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ551-Ⅲ-132KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:6-7.5Ton/Hour.

C.TONY brand galvanized pellets cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:6-7.5Ton/Hour.

C.TONY brand double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

The Significance of the Dry Wood Chip Biomass Pellet Project

The dry wood chip to biomass pellet project is of great significance. Biomass pellets offer numerous advantages as a fuel.

From a cost perspective, the associated biomass burners, when used in conjunction with boilers, are 50%-60% cheaper than natural gas, saving users significant annual costs. This makes biomass pellets competitive in the energy market and can generate economic benefits for both businesses and users.

Furthermore, as a renewable energy source, the dry wood chip to biomass pellet project aligns with environmental trends, helping to reduce reliance on traditional fossil fuels and optimize the energy mix. Furthermore, the project's construction and operation are expected to create local employment opportunities and promote the development of related industries.

1.Application scenarios and ease of use

(1)Multi-scenario adaptability:

It is widely used in residential heating (intelligent temperature control, automatic feeding), biomass power generation, industrial boilers and other fields, especially in the Nordic region where it has become the main heating source. The EU uses combined heat and power to improve energy utilization.

(2)Intelligent operation experience:

Compared with traditional coal burning, pellet fuel can realize automatic feeding and temperature control, reduce manual operation intensity, and improve ease of use.

(3)Policy support and market recognition:

It complies with environmental protection policies, enjoys renewable energy subsidies, and has high public acceptance.

2.Technological innovation and comprehensive benefits

(1)Diversification of conversion technologies:

Through gasification and carbon sequestration polygeneration technology, pellets can be further converted into combustible gas, biochar and liquid fertilizer, achieving "full utilization" and increasing the added value of resource utilization

(2)Optimization of regional energy structure:

In areas rich in forestry resources, biomass pellets can replace natural gas and coal, ensuring energy supply security, while reducing sulfide and nitrogen oxide emissions and improving air quality

In summary, biomass pellets processed from wood chips have become an important direction for the global renewable energy transformation due to their multiple advantages such as environmental protection, high efficiency and economy. Especially in the context of policy drive and technological upgrading, their market potential will continue to be released.

2025 Tony Machinery - All Rights Reserved. Map