1.The working principle of dried sawdust biomass pellet processing equipment

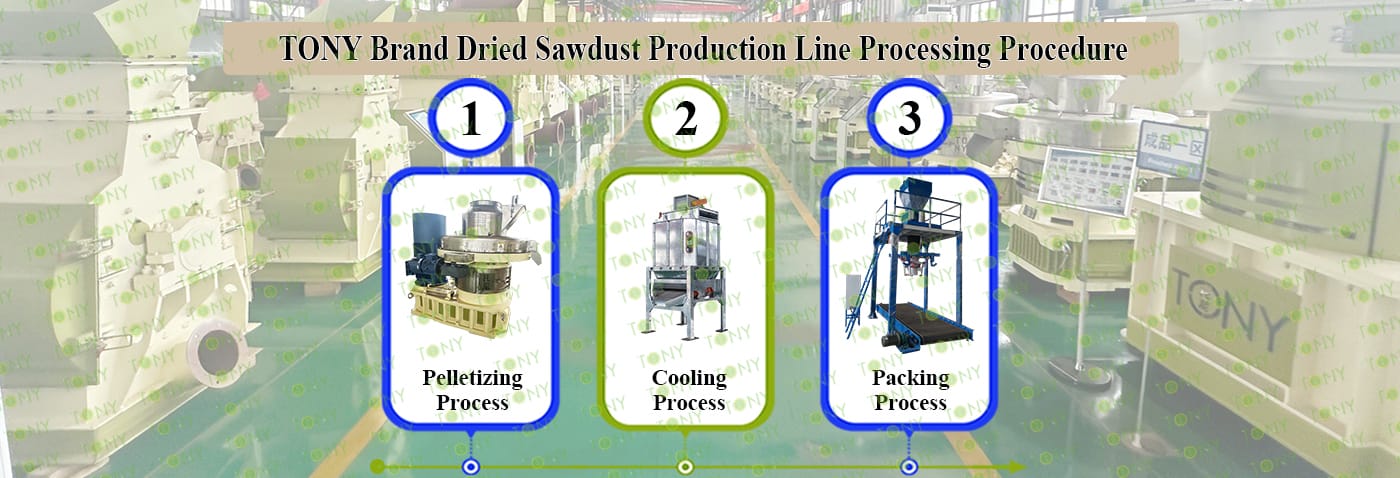

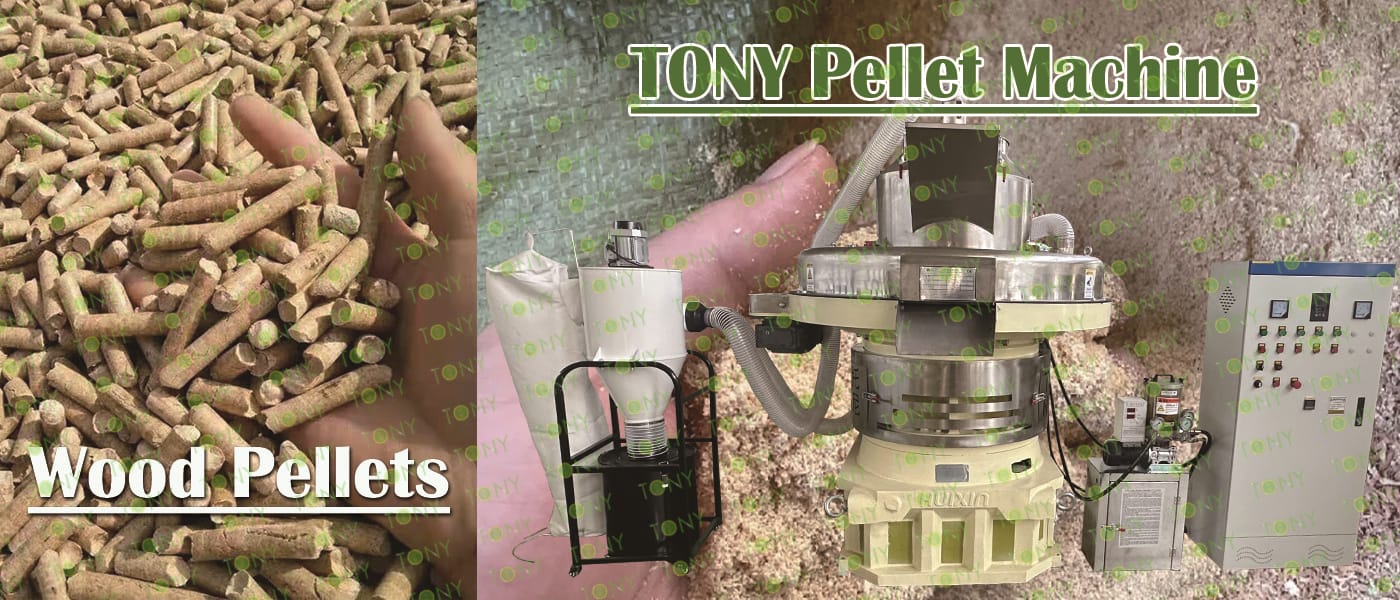

The dry sawdust biomass pellet process transforms loose agricultural and forestry waste (such as wood chips, straw, and rice husks) into high-density, regularly shaped pellet fuel through a series of physical and mechanical processes. The core process consists of three key steps: forming, cooling, and packaging. Each step requires specialized equipment to change the material's physical state.

2.Characteristics of dried sawdust biomass pellet processing equipment

(1)High efficiency and energy saving: The dried sawdust pellet machine can process waste materials such as wood chips into pellet fuel, which not only reduces environmental pollution but also realizes the recycling of resources and greatly improves energy utilization efficiency.

(2)Multifunctionality: In addition to being able to process biomass fuel, the dried sawdust pellet machine can also process animal feed, organic fertilizer, etc., and is widely used in agriculture, breeding and other fields.

(3)Advanced pelletizing technology: The dried sawdust pellet machine adopts advanced pelletizing technology, which can automatically control parameters such as feed amount and temperature during the pelletizing process, greatly reducing production costs and making the production process more economical and environmentally friendly.

(4)High-quality components: The main shaft and the connected hollow shaft of the dried sawdust pellet machine are made of alloy structural steel imported from Germany through water forging, rough turning, heat treatment, fine turning and fine grinding. The reasonable structure and uniform hardness improve the fatigue resistance and wear resistance of the components, providing more reliable guarantee for safe operation.

3.Application scenarios of dried sawdust biomass pellet processing equipment

Processing equipment provides fuel for factory boilers and kilns (replacing coal and oil), such as steam boilers in textile and food processing plants, and heating kilns in the ceramics and building materials industries. Stable pellet production ensures energy supply.

(1)Power Generation:Biomass power plants require large quantities of standardized pellets as fuel. Large-scale processing equipment can meet the power plant's stringent requirements for pellet calorific value and density, ensuring efficient combustion and stable power generation.

(2)Residential Heating:For pellets used in home fireplaces and space heaters, processing equipment must control pellet size and hardness to accommodate residential combustion equipment. The equipment's refined production capabilities directly impact the user experience of these pellets.

(3)Environmental Protection and Waste Management:In waste and sewage treatment plants, processing equipment converts organic waste (such as sludge and food waste) into fuel pellets for resource recovery. Corrosion-resistant and clogging-resistant designs are crucial.

TONY Brand 80-100Ton/Hour Dried Sawdust Pellet Manufacturing Plant can take dried sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, dried sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 80-100Ton/Hour

2. Raw materials: Dried sawdust

3. Moisture: Dry type, about 10%-15%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Dried Sawdust Pellet Production Line

2. Raw Material: All kinds of dried sawdust

3. Moisture Content of Raw Material: 10%-15%

4. Capacity: 80-100 tons per hour

5. Process: Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: TONY Pellet Machine TYJ860-Ⅲ-280kw, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

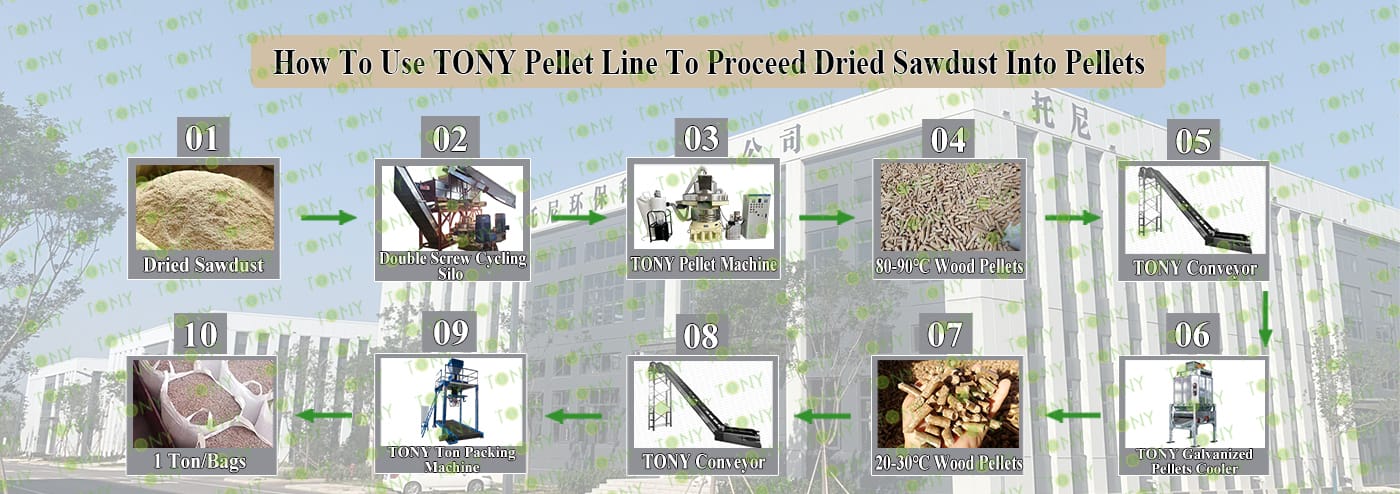

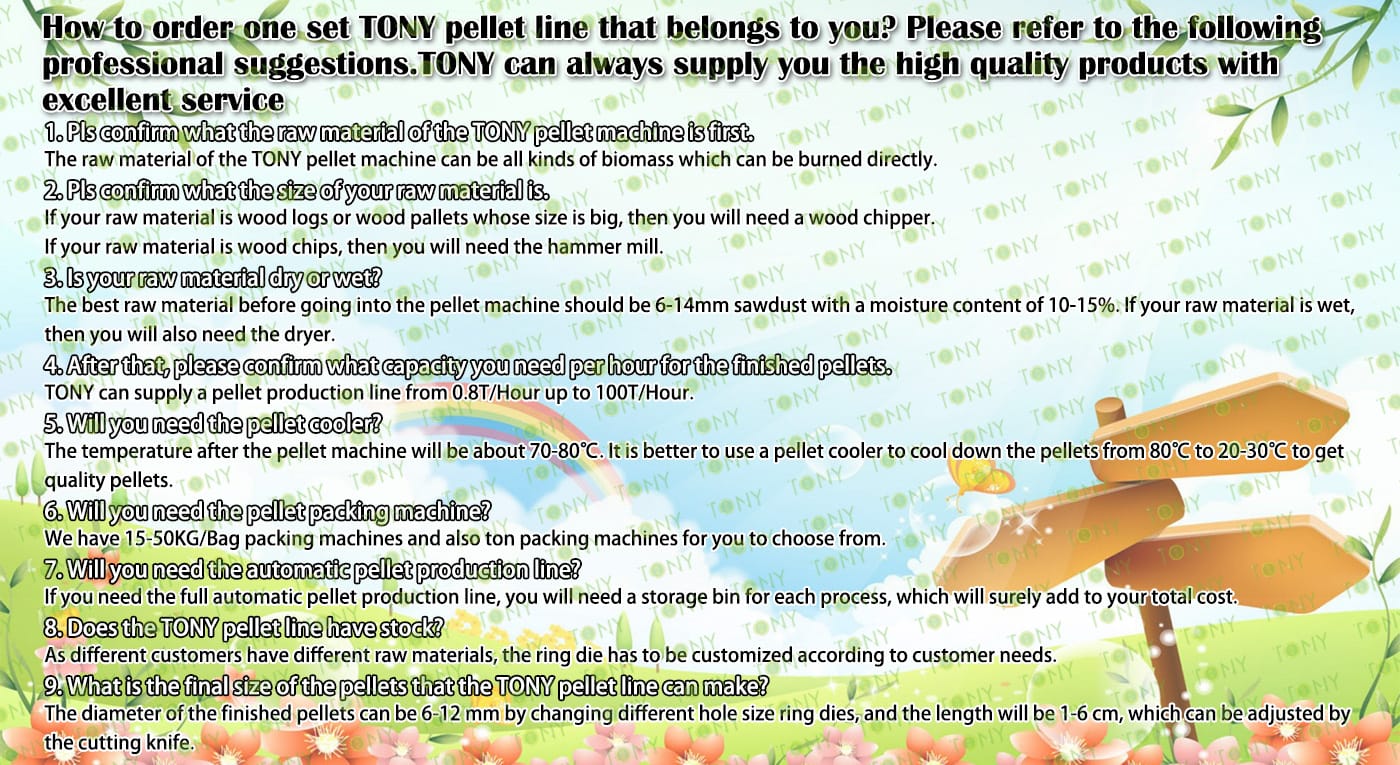

How to use the TONY pellet production line to make pellets from dried sawdust? The process mainly includes the following steps and equipment: 1. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 2. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 3. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Double Screw Cycling Silo | Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Ton Packing Machine |

| 1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-25*4sets 3.Capacity:20-25Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*20sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*4sets 3.Capacity:80-100 Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD* 4sets 3.Capacity:80-100 Ton/Hour |

1.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:80-100Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-280KW*20sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

2.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:80-100Ton/Hour.

C.TONY brand galvanized pellets cooler *4 sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

3.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:80-100Ton/Hour.

C.TONY band ton packing machine*4 sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

Project Startup Recommendations

1.Preliminary Research:

First, visit local wood processing plants and furniture factories to confirm monthly sawdust supply (the raw material quantity must meet the "production capacity x 1.2" requirement to avoid idle capacity). Also, contact two or three potential customers (such as nearby food factories and heating companies) and sign letters of intent for supply.

2 Pilot Operation:

If funding is limited, start with a small-scale project (1 ton per hour) and spend 6 to 12 months verifying raw material supply, customer stability, and profit margins before gradually expanding production.

3.Long-Term Planning:

Once the project is operating stably, you can expand your supply chain. For example, establishing a dedicated logistics fleet (to reduce transportation costs), developing customized pellets (for example, offering "low-ash pellets" for fireplace users to increase unit prices), or building a small-scale biomass heating station (to directly supply heat to surrounding factories and increase profits).

In summary, the pallet-based biomass pellet fuel project is suitable for entrepreneurs or small and medium-sized enterprises with local resources (raw materials/customers) and moderate capital. The key lies in controlling raw material costs, securing stable customers, and ensuring environmental compliance to achieve sustainable profitability.

1.Environmentally friendly features

(1)Low pollution emissions: The sulfur and phosphorus content during combustion is extremely low, and the concentration of SO₂ and NOx in the flue gas is much lower than that of coal. It will not produce acid rain, and CO₂ emissions are zero (because plants absorb CO₂ during growth)

(2)Ash utilization: Ashes after combustion are rich in organic potassium and can be recycled as high-efficiency organic fertilizer

2.Economical

(1)Wide range of raw materials: waste such as wood processing waste and crop straw can be used, and the production cost is lower than traditional fossil fuels.

(2)Substitution benefits: Replacing coal can save about 20% to 30% of fuel costs

3.Wide range of application scenarios

(1)Industrial applications: Widely used in boiler heating, power generation and industrial production, such as textile factories, food factories, etc.

(2)Civil heating and living energy: Wood pellets have high combustion efficiency, are easy to store and use, and are safe and hygienic.

(3)Biomass industrial boiler: As the main fuel for industrial boilers, it replaces coal, heavy oil and natural gas to solve environmental pollution problems.

2025 Tony Machinery - All Rights Reserved. Map