1.图片

Project Brief Introduction:

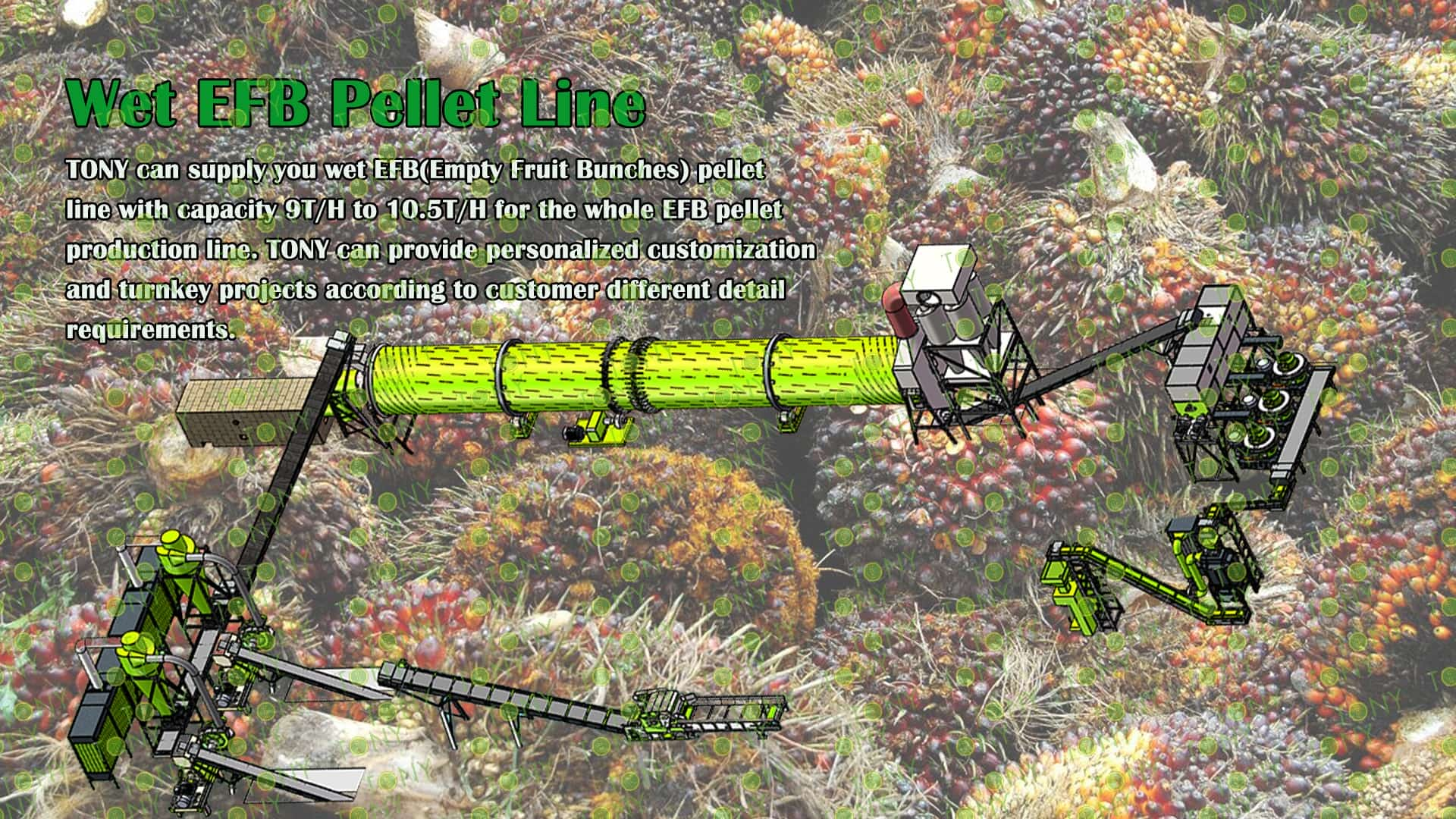

1.Product:Wet EFB Pellet Line

2.Capacity: 9-10.5T/Hour

3.TONY Brand 9-10.5Ton /Hour Wet EFB Pellet Line Project Process

4.Main Machine:Comprehensive Chipper, Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ860-Ⅲ-220kw,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1380 kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

原材料图+颗粒机图片

1. The working principle of wet EFB biomass pellet processing equipment

The principles of EFB biomass pellet processing equipment always revolve around the two core elements of "adapting to raw material characteristics" and "improving pellet quality":

(1) For EFB "high moisture", hot air/drum drying is used to achieve precise dehumidification;

(2) For "coarse fiber", hammer coarse crushing + blade fine crushing is used to achieve uniform particle size;

(3) For "forming needs", ring die extrusion friction heat is used to activate the natural bonding properties of lignin, without the need for artificial additives;

The entire process is through impurity removal, cooling, and screening to ensure equipment safety and the density, hardness, and stability of the finished pellets.

2. Characteristics of wet EFB biomass pellet processing equipment

(1) Multifunctional design: EFB pellet processing equipment may have a multifunctional design, which can not only press EFB, but also press wood chips, bamboo, and straw.

(2) Energy saving and environmental protection: EFB pellet processing equipment may use energy-saving materials and energy-saving technologies, which reduces the operating cost of the equipment and reduces the impact on the environment, achieving the goal of green production.

(4) Easy to operate and maintain: EFB pellet processing equipment may be simple and easy to operate, and even non-professionals can quickly get started. At the same time, the equipment is also easy to maintain, reducing maintenance costs and downtime.

(5) Strong adaptability: EFB pellet processing equipment may be highly adaptable, whether it is different types of raw materials or different specifications of feed pellets, the equipment can easily cope with

3. Application scenarios of wet EFB biomass pellet processing equipment

(1) Supporting production lines within palm oil mills

Application scenario: To achieve the goal of "using waste to feed the factory", large palm oil mills build EFB pellet processing workshops within the factory area, directly processing the EFB they produce into pellets, which are used as boiler fuel in the factory (for steam supply for palm fruit cooking and oil extraction), and the remaining pellets are sold to the outside world.

(2) Processing factories around palm industry clusters

In palm industry clusters, some companies build large-scale EFB pellet processing plants in the middle of multiple palm oil mills, uniformly purchase EFB from surrounding small and medium-sized palm oil mills, and supply them to industrial customers or biomass power plants in the area after processing into pellets.

2.图片

TONY Brand 9-10.5 Ton/Hour Wet EFB Pellet Manufacturing Plant can take wet EFB as the main raw material. After pretreatment and processing, it is solidified into high - density EFB pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in EFB resources.

1. Capacity: 9-10.5 Ton/Hour

2. Raw materials: Wet EFB

3. Moisture: Wet type, about 40%.

4. Application: All kinds of EFB materials suitable for pellet production.

Suitable customers: Palm plantation owners or related agricultural enterprises have abundant EFB resources. For example, palm oil mills generate a large amount of EFB waste during the production process. Energy companies, EFB biomass pellets as a clean energy, can be used in industrial heating, power generation and other fields, and have synergy with the existing business of energy companies. Environmental investors, investors with financial strength, technology investors, etc.and other places where EFB raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3.图片

图片

原材料--成品图

1. Project Name: Wet EFB Pellet Production Line

2. Raw Material: All kinds of wet EFB

3. Moisture Content of Raw Material: 40%

4. Capacity: 9-10.5 tons per hour

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper -TPC1300-600-132kw, Effective Hammer Mill-TFD75*132-132kw, Rotary Drum Dryer-3*24m, TONY Pellet Machine- TYJ860-Ⅲ-220kw, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

4.图片

|

How to use the TONY pellet production line to make pellets from wet EFB? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind EFB Into 25-55mm palm fiber. 2. Use TONY effective hammer mill to crush the 25-55 mm palm fiber into 8-14 mm palm dust.If customer has enough Investment budget,he can also chose TONY special cutting machine for palm silk which will be more expensive than the hammer mill. 3. Use TONY rotary drum dryer to dry the palm dust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

流程图1

流程图.

5.图片

原材料+颗粒图

颗粒+机器图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

| Comprehensive Chipper | Effective Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Grind EFB Into25-55mm Palm Fiber. 2.Model: TPC1300-600-132KW With 6 Baldes*1set 3.Capacity: 10-15 Ton/Hour. |

1.To Crush 25-55mm Palm Fiber Into 8-14mm Palm Dust. 2.Model: TFD75*132-132KW*2 sets 3.Capacity: 4-5 Ton/Hour/Set |

1.To Dry The 40% Palm Dust Into 10-15% Palm Dust. 2.Model: THGD3*24*1 set 3.Capacity:9-10.5 Ton/Hour/Set |

1.To Stroage Palm Dust Before Pellet Machine; Adjust The Speed Of Palm Dust Entering The Pellet Machine 2.Model: TLC-11*1set 3.Capacity:9-10.5 Ton/Hour/Set |

| Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

| 1.To Press Dry Palm Dust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*3 sets 3.Capacity:3-3.5 Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*1 set 3.Capacity:9-10.5Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TPZ-50*1 set 3.Capacity: 9-10.5Ton/Hour |

1.To Transport Palm Fiber, Palm Dust,Pellets. 2.Width: 80cm*8 sets 3.Capacity:Designed With The Whole Line |

三维图

5.1图片

TPC1300-600-132KW机器图

带原材料-成品图

1.Wet EFB To Palm Fiber Process:

A.This process is mainly used to grind the EFB into palm fiber with size 25-55mm. The finish palm fiber size can be adjustable by changing different sizes of screeners and adding flying knives inside the wood chipper.

B.TONY brand comprehensive chipper TPC1300-600-132kw with 6 flying blades type*1 set

C.Capacity:10-15 Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

5.2图片

高效粉碎机

带锯末图

2.Palm Fiber Fine Crushing Process:

A.This process is mainly used to crush 25-55mm palm fiber into 8-14mm palm dust.

B.Capacity:9-10.5 Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132kw*2 sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.3图片

烘干机

带锯末图

3.Wet Palm Dust Drying Process:

A.This process is mainly used to dry the palm dust from 40% to 10-15%.

B.Capacity:9-10.5 Ton/Hour.

C.TONY use 1 set of 3*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.4图片

颗粒机四件套带 原材料,颗粒图

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:9-10.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-Ⅲ-220kw*3 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.5图片

镀锌冷却仓加颗粒图

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:9-10.5 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.6图片

双胞包装机

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50KG/Bags.

B.Capacity:9-10.5 Ton/Hour.

C.TONY brand double packing machine*1 set

Main Parts:

(1)TONY Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

6.图片

客户生产线案例图

7.图片

图 湿EFB+颗粒 颗粒机

EFB Biomass Pellet Project Benefit Analysis: Triple Economic, Environmental, and Social Benefits

The core competitiveness of the EFB biomass pellet project lies in "low investment, stable returns, and strong environmental protection." These three significant benefits align with policy guidance and market demand.

1. Economic Benefits: Controllable costs and stable returns

2. Environmental Benefits: Solid waste reduction + carbon emissions reduction

Addressing solid waste pollution: 1 ton of fresh EFB pellets can be converted into 0.6 tons of pellets after processing, reducing methane emissions (a greenhouse gas with a greenhouse effect 28 times that of CO₂) from EFB storage and preventing soil and water pollution caused by rainwater erosion.

Fossil Energy Replacement: 1 ton of EFB pellets has a low calorific value of 16-18 MJ/kg, equivalent to 0.6-0.7 tons of standard coal. When burned, SO₂ emissions are less than 50 mg/m³ (compared to approximately 2000 mg/m³ for coal combustion) and NOₓ is less than 200 mg/m³. Annual processing of 10,000 tons of EFB can reduce CO₂ emissions by approximately 5,000 tons, meeting the "dual carbon" goals.

Solid Waste Recycling: The ash (containing potassium and calcium) from pellet combustion can be used as fertilizer for palm plantations, achieving the "EFB - pellets - Ash - Palm Oil Planting" closed loop.

3. Social Benefits: Employment Creation + Energy Transition Support

Job Creation: A medium-sized production line can provide 5-10 stable positions (operation, maintenance, and sales), driving local employment in major palm oil-producing areas (mostly rural or suburban areas);

Energy Security: Reduce dependence on imported coal and natural gas. Biomass pellets can serve as a stable alternative energy source, especially in regions with volatile energy prices (such as Europe);

Industrial Upgrading: Help the palm oil industry transition from a "sole oil extraction" model to a diversified "oil extraction + waste resource utilization" model, thereby increasing added value.

8.图片

湿EFB图 颗粒图

1. Environmentally friendly and clean:

Carbon neutrality and low pollutant emissions align with global carbon reduction needs.

2. Low cost:

Zero raw material cost and low processing energy consumption, with a cost-effectiveness far exceeding that of fossil fuels.

3. Stable performance:

High density, high hardness, and low hygroscopicity make it easy to store, transport, and burn.

4. Flexible application:

Suitable for industrial, residential, and power generation applications, offering a wide range of alternatives.

5. Resource attributes:

Promoting the recycling of the palm oil industry and realizing waste resource utilization.

9.图片

绿色地球+原材料+颗粒图

10.图片

11.图片

公司认证图

2025 Tony Machinery - All Rights Reserved. Map