1.图片

Project Brief Introduction:

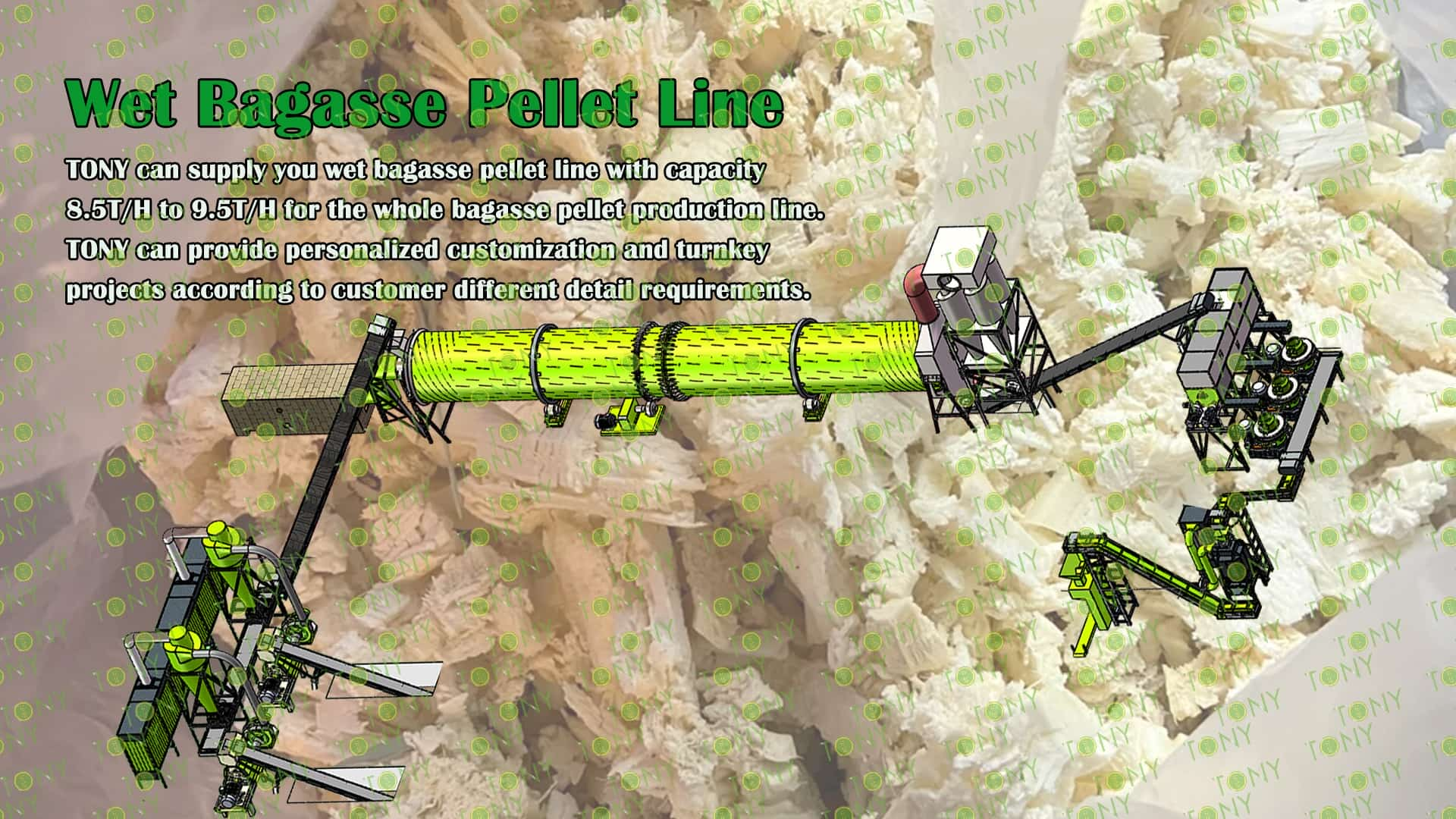

1.Product:Wet Bagasse Pellet Line

2.Capacity: 8.5-9.5T/Hour

3.TONY Brand 8.5-9.5 Ton /Hour Wet Bagasse Pellet Line Project Process

4.Main Machine:Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ760-III-185KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1040kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

图片

1. The working principle of wet bagasse biomass pellet processing equipment

After the pre-treated bagasse enters the pellet machine, high-pressure extrusion + thermal effect triggers the transformation of component properties to achieve densification of the loose material.

Hot pressing molding: the natural bonding effect of lignin. The core of this path is to use about 19% of lignin (a natural thermoplastic component) in sugarcane bagasse as an "endogenous binder". The specific principle can be divided into three steps:

(1) Pre-pressing and densification: After entering the pelletizing chamber, the material is first compacted by the pre-pressing device to reduce the gap and accumulate force for high-pressure extrusion;

(2) High-pressure friction heating: The ring die and the pressing wheel (rotation speed 300-500 rpm) generate a pressure of 50-150MPa, and the friction between the materials causes the temperature to rise to 100-180℃. When the temperature reaches above 120°C, the lignin begins to soften and melt, and at 180°C it is completely plasticized, forming a sticky "natural glue."

(3) Fiber bonding and solidification: The plasticized lignin tightly bonds the cellulose and hemicellulose (which serve as the "skeleton"), while some of the water evaporates, further enhancing the plasticity. The material is squeezed through the small holes of the ring die to form a rod. After being cut by the cutter, the lignin hardens again as the temperature drops, fixing the particle shape.

2. Characteristics of wet bagasse biomass pellet processing equipment

(1) The main parts are made of wear-resistant materials with special treatment: so it can be pressed continuously and durable.

(2) Suitable for pressing and forming various biomass raw materials: low energy consumption and high production efficiency.

(3) Increased machine stability and durability: automatic lubrication system

(4) Increased pitch and feed rate: thus significantly increasing production.

(5) Improved mold structure: reduced friction between the machine and the raw material, and increased particle density

3. Application scenarios of wet bagasse biomass pellet processing equipment

(1) Energy sector: biomass energy plants, industrial boiler renovation projects, and household pellet fuel production workshops;

(2) Agriculture sector: livestock farms (producing feed pellets), organic fertilizer plants (producing carrier pellets);

(3) Forestry sector: Sugarcane product plants,ethanol plant (processing bagasse).

2.图片

TONY Brand 8.5-9.5 Ton/Hour Wet Bagasse Pellet Manufacturing Plant can take wet bagasse as the main raw material. After pretreatment and processing, it is solidified into high - density Bagasse pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bagasse resources.

1. Capacity: 8.5-9.5 Ton/Hour

2. Raw materials: Wet bagasse

3. Moisture: Wet type, about 40%.

4. Application: All kinds of bagasse materials suitable for pellet production.

Suitable customers: Sugarcane processing factories are the direct output of bagasse, such as sugar mills, sugarcane ethanol factories, sugarcane pulping factories, etc.; centralized storage and transit places, such as sugar mills, ethanol factories, agricultural product processing parks, where multiple sugarcane processing factories often gather to form a park. The storage and transit areas of bagasse are uniformly planned within the park, and the resource concentration is extremely high.and other places where bagasse raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3.图片

图片

1. Project Name: Wet Bagasse Pellet Production Line

2. Raw Material: All kinds of wet bagasse

3. Moisture Content of Raw Material: 40%

4. Capacity: 8.5-9.5 tons per hour

5. Process: Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD75*132-132kw, Rotary Drum Dryer-2.5*24m, TONY Pellet Machine- TYJ760-Ⅲ-185kw, Galvanized Pellets Cooler, Double Packing Machine and Belt Conveyors

4.图片

|

How to use the TONY pellet production line to make pellets from wet bagasse? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the slightly larger bagasse into 8-14 mm bagasse.If customer has enough Investment budget,he can also chose TONY Special Cutting Machine for bagasse which will be more expensive than the hammer mill. 2. Use TONY rotary drum dryer to dry the bagasse with a 40% moisture content down to a moisture content of 10%-15%. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

图片

图片

5.图片

图片

图片

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

| 图1 | 图2 | 图3 |

| Effective Hammer Mill | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Crush Larger Bagasse Into 8-14mm Baggase. 2.Model: TFD75*132-132KW*2 sets 3.Capacity: 4-5 Ton/Hour/Set |

1.To Dry The 40% Bagasse Into 10-15% Bagasse. 2.Model: THGD2.5*24*1set 3.Capacity:8.5-9.5 Ton/Hour/Set |

1.To Stroage Bagasse Before Pellet Machine; Adjust The Speed Of Bagasse Entering The Pellet Machine 2.Model: TLC-10*1set 3.Capacity:8.5-9.5 Ton/Hour/Set |

| 图4 | 图5 | 图6 |

| Vertical Ring Die Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine |

| 1.To Press Dry Bagasse Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-185KW*3 sets 3.Capacity:2.8-3.3 Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-4*1set 3.Capacity:8.5-9.5 Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TPZ-50*1set 3.Capacity: 8.5-9.5 Ton/Hour |

三维图

5.1图片

图片

1.Bagasse Fine Crushing Process:

A.This process is mainly used to crush larger bagasse into 8-14mm bagasse.

B.Capacity:8-10 Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132kw*2 sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.2图片

图片

2.Wet Bagasse Drying Process:

A.This process is mainly used to dry the bagasse from 40% to 10-15%.

B.Capacity:8.5-9.5 Ton/Hour.

C.TONY use 1 set of 2.5*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.3图片

图片

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:8.5-9.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-Ⅲ-185kw*3 sets

D.Double Screw Cycling Silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

5.4图片

图片

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:8.5-9.5 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.5图片

图片

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50KG/Bags.

B.Capacity:8.5-9.5 Ton/Hour.

C.TONY brand double packing machine*1 set

Main Parts:

(1)TONY Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

6.图片

图片

7.图片

图片

Raw material advantages of the wet sugarcane bagasse biomass pellet project—significant cost advantages and a stable and easily accessible supply.

1. Nearly zero raw material cost:

Wet sugarcane bagasse is a waste product left by sugar mills after sugar production. Most mills provide this waste material free of charge or at a low price for disposal. This eliminates the high cost of raw material procurement and only requires a small transportation fee.

2. Guaranteed supply:

Large sugar mills in major sugarcane-producing areas can produce hundreds of tons of wet sugarcane bagasse daily. The project can sign long-term cooperation agreements with these mills to ensure a stable year-round raw material supply (it can be stored in silage or storage sheds during the off-season).

3. Highly adaptable raw material processing:

Wet sugarcane bagasse has a complete fiber structure. After crushing and drying, it can be formed without the addition of additional binders, reducing auxiliary material costs and ensuring that no harmful additives are released during pellet combustion.

8.图片

图片

Environmental Advantages: Low Pollution, Recyclable

1. Clean Combustion:

Sulfur dioxide and nitrogen oxide emissions during combustion are extremely low, far lower than those from fossil fuels such as coal, significantly reducing air pollution and complying with environmental protection policies.

2. Carbon Neutral:

As a biomass fuel, the carbon dioxide absorbed during its growth is nearly balanced by the carbon dioxide released during combustion, achieving "zero carbon emissions" and contributing to the dual carbon goals.

3. Waste Reuse:

The raw material is derived from sugarcane residue, eliminating the environmental pollution caused by the indiscriminate disposal or incineration of sugarcane residue and enabling the recycling of agricultural waste.

9.图片

图片

10.图片

图片

11.图片

图片

2025 Tony Machinery - All Rights Reserved. Map