1.图片

Project Brief Introduction:

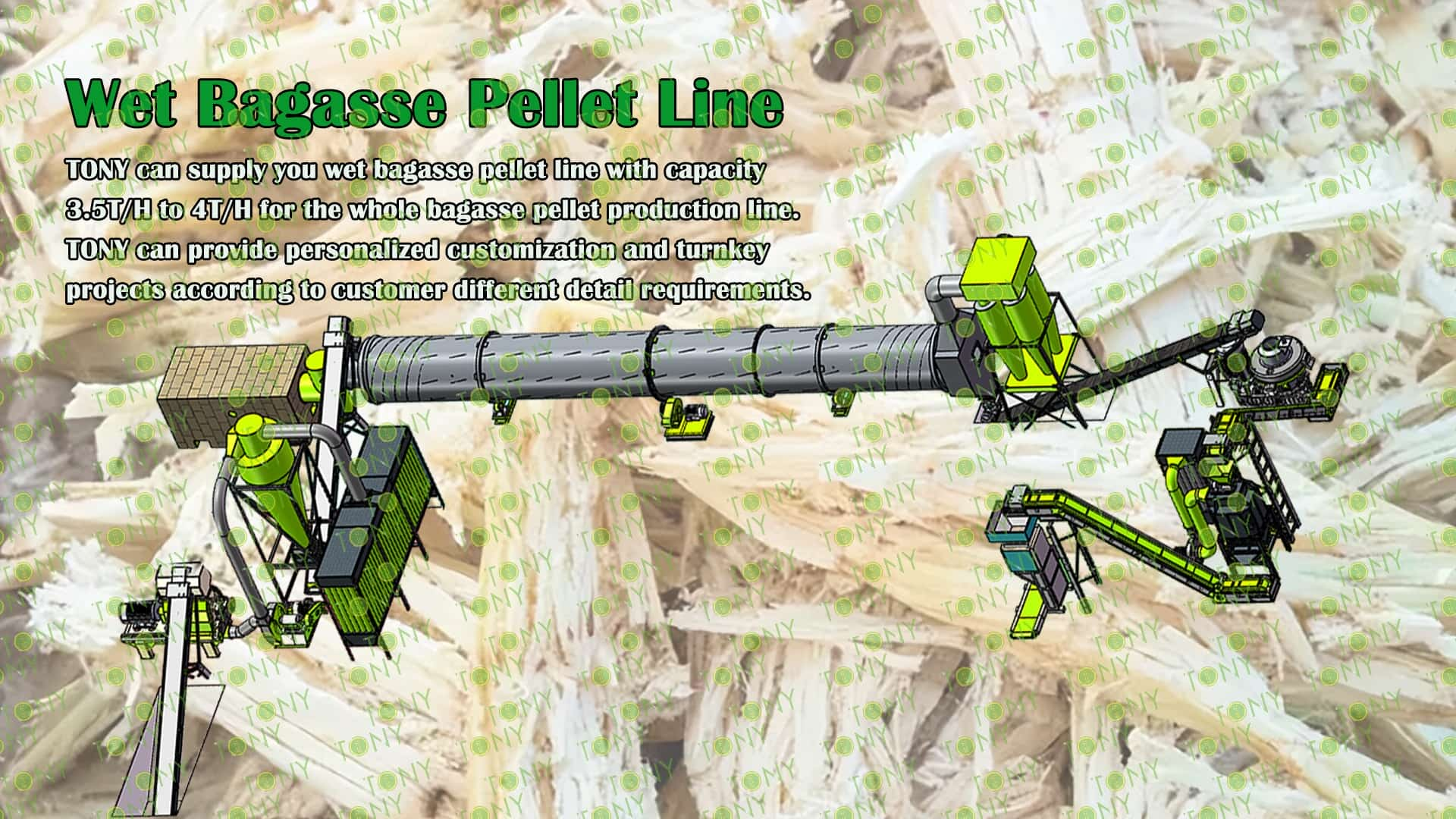

1.Product:Wet Bagasse Pellet Line

2.Capacity:3.5-4 T/Hour

3.TONY Brand 3.5-4Ton /Hour Wet Bagasse Pellet Line Project Process

4.Main Machine:Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ860-Ⅲ-250KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 440kw

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

3维图

原材料图+颗粒机图片

1. The working principle of wet bagasse biomass pellet processing equipment

Wet bagasse pellet processing equipment uses wet bagasse as raw material and processes it into pellet fuel through a series of processes, including crushing, drying, and pelletizing. During processing, the raw material is pulverized into fine particles that meet the requirements of subsequent processing. Next, it enters the drying process to reduce the moisture content to a range suitable for pelletization. Finally, it enters the pelletizing stage, where it is formed into pellets through the extrusion and other processes of the equipment.

2. Characteristics of wet bagasse biomass pellet processing equipment

(1) The motor shaft and the gear shaft are directly connected, which provides stronger power transmission, greater torque resistance, higher stability and lower maintenance rate.

(2) The bearing chamber has been improved, the sealing method has been changed, and forged tempered wear-resistant materials are used to prevent dust from falling into the bearing chamber.

(3) The gearbox body is larger, the gears are larger, the output power is higher, and the power consumption is lower.

(4) The bearings use genuine heavy-duty Harbin shafts, which have longer bearing life and lower maintenance rate for the whole machine.

(5) The ring die adopts a vertical double-layer structure, with both upper and lower layers used, which improves utilization, reduces costs and increases efficiency.

(6) The pressure wheel rotates, the material is centrifuged, and the surrounding material is evenly distributed.

(7) High efficiency and energy saving, automatic timed oil supply and lubrication ensure that the bearings are fully lubricated and the operation is safer and more reliable.

(8) High-pressure filtration and clean and smooth independent frequency conversion device ensure the output of particles.

3. Application scenarios of wet bagasse biomass pellet processing equipment

Wet bagasse pellet processing equipment has a wide range of applications. Its core function is to convert high-moisture, difficult-to-process sugar production waste into standardized, high-energy-density biomass fuel. Sugar mills generate large quantities of wet bagasse (moisture content >40%) during the crushing season. This is converted into fuel pellets through a pellet production line (including crushing, drying, and pressing). The pressed pellets can be directly fed into the sugar mill's own boilers, replacing coal or natural gas. By meeting the sugar mill's steam and electricity needs, it can achieve 100% energy self-sufficiency

2图

TONY Brand 3.5-4 Ton/Hour Wet Bagasse Pellet Manufacturing Plant can take wet bagasse as the main raw material. After pretreatment and processing, it is solidified into high - density Bagasse pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in bagasse resources.

1. Capacity: 3.5-4 Ton/Hour

2. Raw materials: Wet bagasse

3. Moisture: Wet type, about 40%.

4. Application: All kinds of bagasse materials suitable for pellet production.

Suitable customers: Sugarcane processing factories are the direct output of bagasse, such as sugar mills, sugarcane ethanol factories, sugarcane pulping factories, etc.; centralized storage and transit places, such as sugar mills, ethanol factories, agricultural product processing parks, where multiple sugarcane processing factories often gather to form a park. The storage and transit areas of bagasse are uniformly planned within the park, and the resource concentration is extremely high.and other places where bagasse raw materials have advantages

5. Finished Pellets Markets: Large power plants, domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

3图

图片

原材料--成品图

1. Project Name: Wet Bagasse Pellet Production Line

2. Raw Material: All kinds of wet bagasse

3. Moisture Content of Raw Material: 40%

4. Capacity: 3.5-4 tons per hour

5. Process: Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Effective Hammer Mill-TFD75*100-110kw, Rotary Drum Dryer-1.8*18m, TONY Pellet Machine- TYJ860-Ⅲ-250kw, Galvanized Pellets Cooler, Semi-automatic Packing Machine and Belt Conveyors

4图

|

How to use the TONY pellet production line to make pellets from wet bagasse? The process mainly includes the following steps and equipment: 1. Use TONY effective hammer mill to crush the slightly larger bagasse into 8-14 mm bagasse.If customer has enough Investment budget,he can also chose TONY Special Cutting Machine for bagasse which will be more expensive than the hammer mill. 2. Use TONY rotary drum dryer to dry the bagasse with a 40% moisture content down to a moisture content of 10%-15%. 3. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 4. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 5. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

|||||||||||||||||||||||||||||||||||||||||||||

流程图1

流程图.

5.图片

原材料+颗粒图

颗粒+机器图

三维图

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

| 图1 | 图2 | 图3 |

| Effective Hammer Mill | Rotary Drum Dryer | Vertical Ring Die Pellet Machine |

| 1.To Crush Larger Bagasse Into 8-14mm Baggase. 2.Model: TFD75*100-110KW*1set 3.Capacity: 3-4 Ton/Hour/Set |

1.To Dry The 40% Bagasse Into 10-15% Bagasse. 2.Model: THGD1.8*18*1set 3.Capacity:3.5-4 Ton/Hour/Set |

1.To Press Dry Bagasse Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-250KW*1set 3.Capacity:3.5-4.5 Ton/Hour/Set 4.New 304SS Type |

| 图4 | 图5 | 图6 |

| Galvanized Pellets Cooler | Semi-automatic Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3.5-4 Ton/Hour |

1.To Pack Pellets Into 15-50KG/Bags. 2.Model: TBF-50*1set 3.Capacity: 3.5-4 Ton/Hour |

1.Transport Bagasse,Pellets. 2.Width: 50cm*5 Sets 3.Capacity:Designed With The Whole Line |

三维图

5.1图

高效粉碎机

带锯末图

1.Bagasse Fine Crushing Process:

A.This process is mainly used to crush larger bagasse into 8-14mm bagasse.

B.Capacity:3-4 Ton/Hour.

C.TONY brand effective hammer mill TFD75*100-110kw*1set

Main Parts:

(1)TONY Effective Hammer Milll.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

5.2图

烘干机

带锯末图

2.Wet Bagasse Drying Process:

A.This process is mainly used to dry the bagasse from 40% to 10-15%.

B.Capacity:3.5-4 Ton/Hour.

C.TONY use 1 set of 1.8*18m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

5.3图

颗粒机四件套带 原材料,颗粒图

3.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:3.5-4.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-250kw*1 set

Main Parts:

(1)TONY's new Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

5.4图

镀锌冷却仓加颗粒图

4.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:3.5-4 Ton/Hour.

C.TONY brand galvanized pellets cooler *1 set

Main Parts:

(1)TONY's new Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3) Fan Blower.

(4)Connect Pipes.

5.5图

包装机

5.Packing Process:

A.This process is mainly used to pack pellets into 15-50KG/Bags.

B.Capacity:3.5-4 Ton/Hour.

C.TONY brand semi-automatic packing machine*1 set

Main Parts:

(1)TONY Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

6图

客户生产线案例图

7图

图 湿甘蔗渣+颗粒 颗粒机

1. Transforming sugarcane bagasse, a "waste product," into a valuable energy product perfectly aligns with the circular economy principles of "reduction, reuse, and resource utilization."

This extends the value chain of the sugarcane crop and improves the resource utilization efficiency and sustainability of the entire industry chain.

2. Nutritious

Bagasse feed pellets are rich in nutrients such as protein, fat, and carbohydrates, meeting the growth and development needs of animals.

3. Easy to Store

Bagasse feed pellets can be stored for long periods of time, are not easily spoiled, and are easy to eat.

4. Easy to Digest

Bagasse feed pellets have a uniform particle size, making them easy for animals to digest and absorb.

5. Easy to Absorb

Bagasse feed pellets have a smooth surface, making them easily absorbed by animals.

8图

湿甘蔗渣图 颗粒图

As a solid biofuel :bagasse pellets can be directly burned in boilers, replacing coal, fuel oil, or natural gas to provide steam, heat, or electricity for sugar refineries, other industrial users, and district heating facilities.

2. Carbonization for Sale: The bagasse pellets produced by the biomass pellet machine can be further carbonized and processed in a charcoal machine to produce charcoal sticks or briquettes for sale.

3. Pollution-Free Combustion: Bagasse pellets produce no pollutants after combustion, and the resulting ash is an ideal organic fertilizer, making it a clean and sustainable biomass energy source.

4. Ease of Transportation and Storage: The solidified bagasse reduces its volume by over 85%, making it easier to transport and store. Its density, durability, and combustion characteristics are significantly improved, significantly increasing its value and potential applications.9图

绿色地球+原材料+颗粒图

10图

图片

11图

公司介绍图

2025 Tony Machinery - All Rights Reserved. Map