Project Brief Introduction:

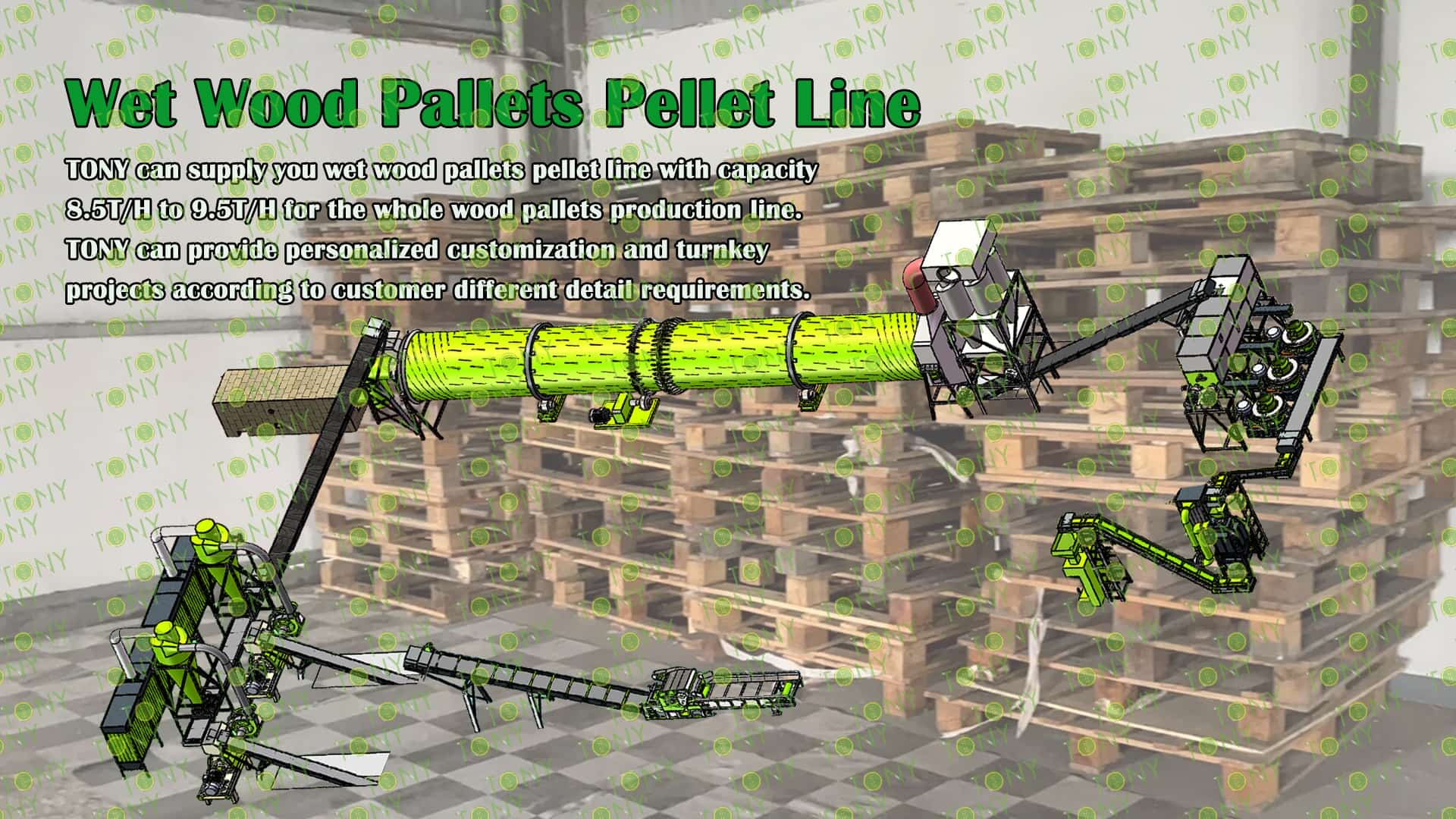

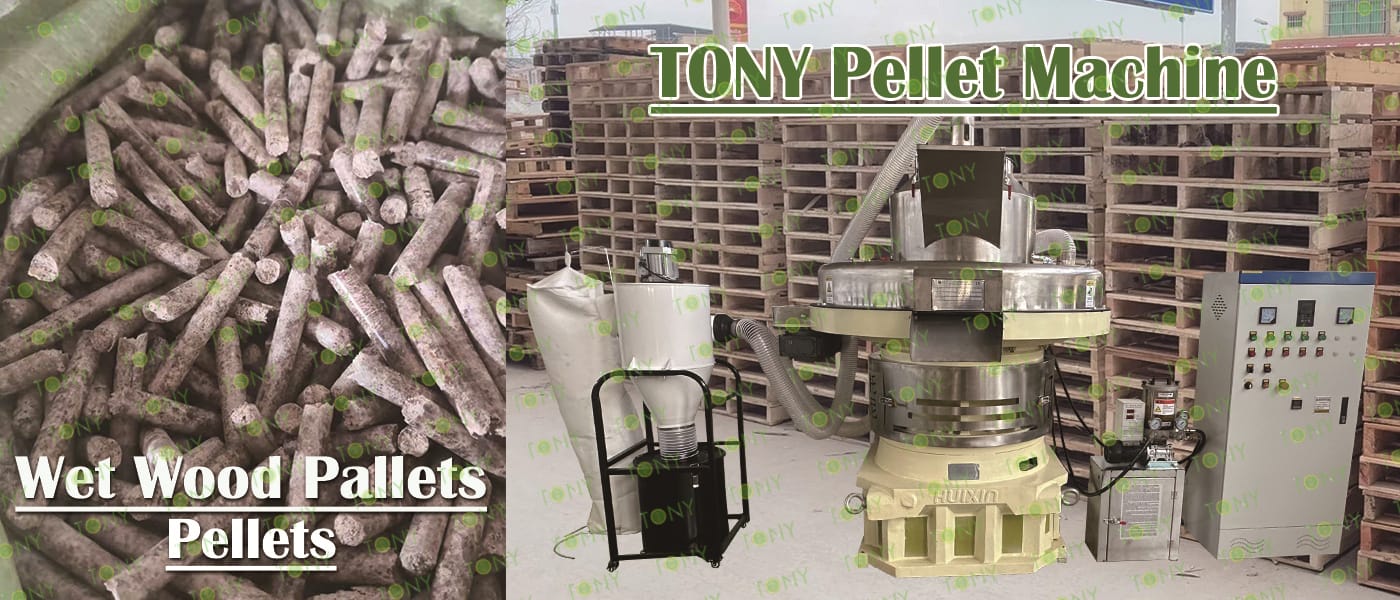

1.Product:Wet Wood Pallets Pellet Line

2.Capacity: 8.5-9.5T/Hour

3.TONY Brand 8.5-9.5Ton /Hour Wet Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-185KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1200KW

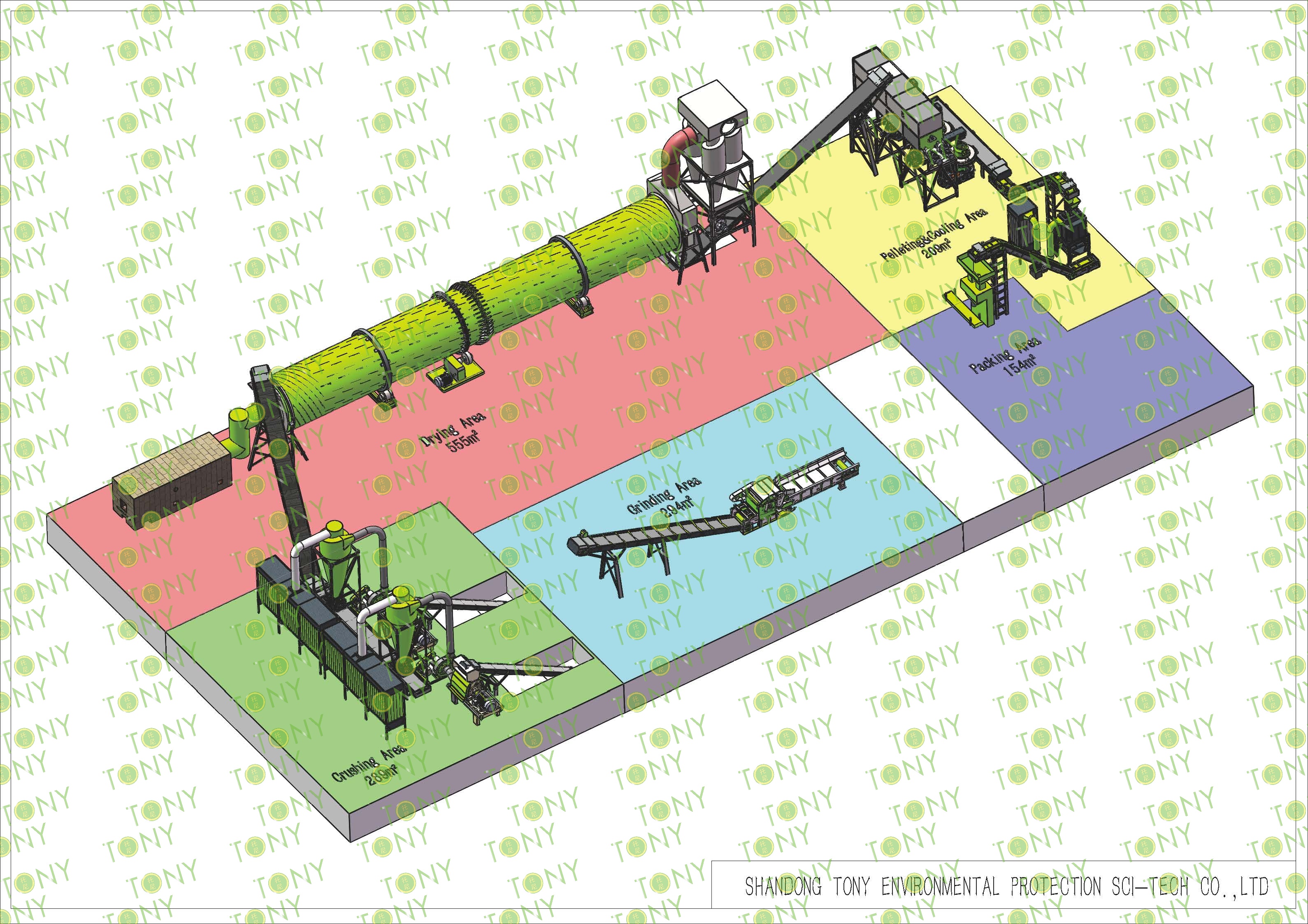

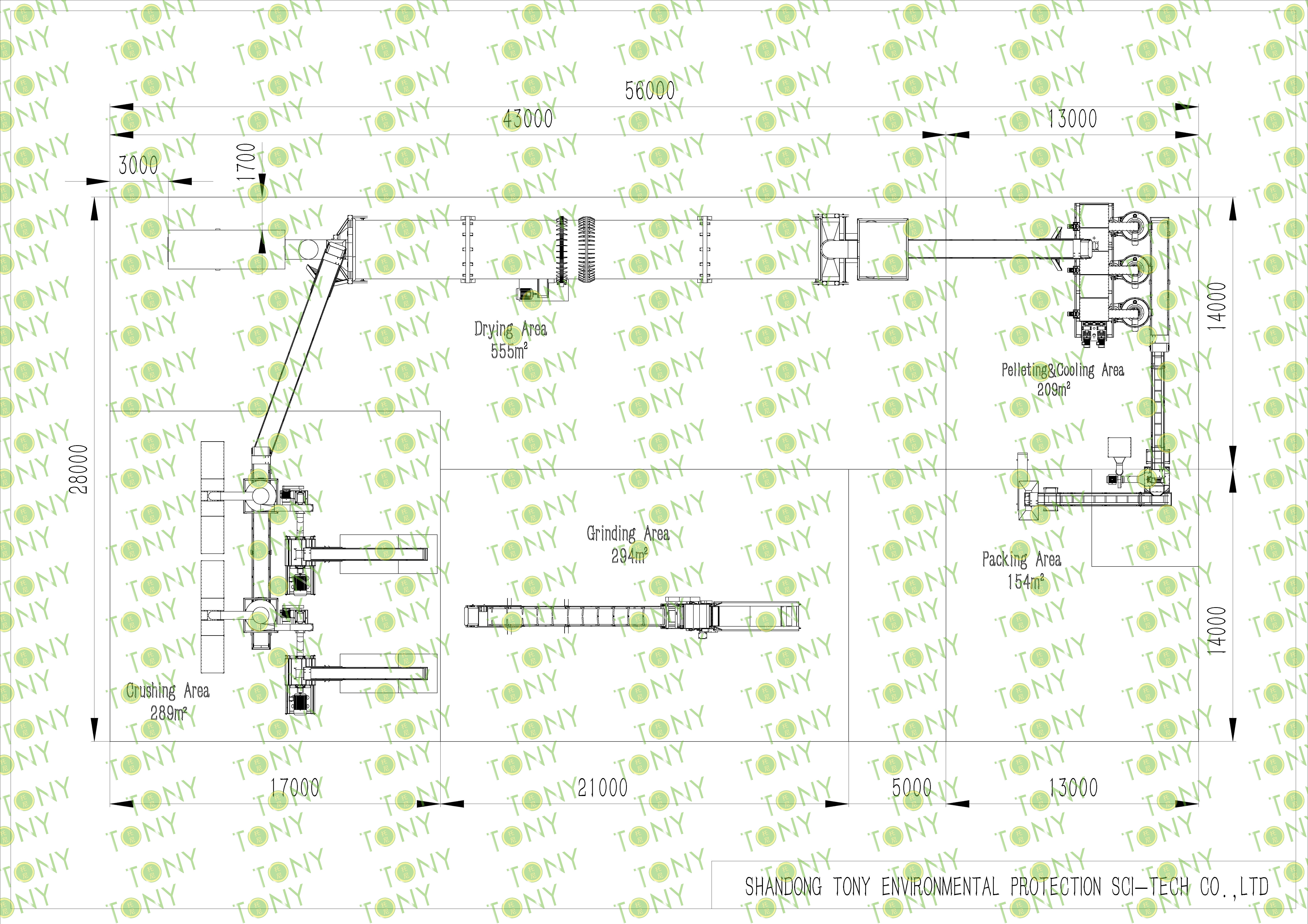

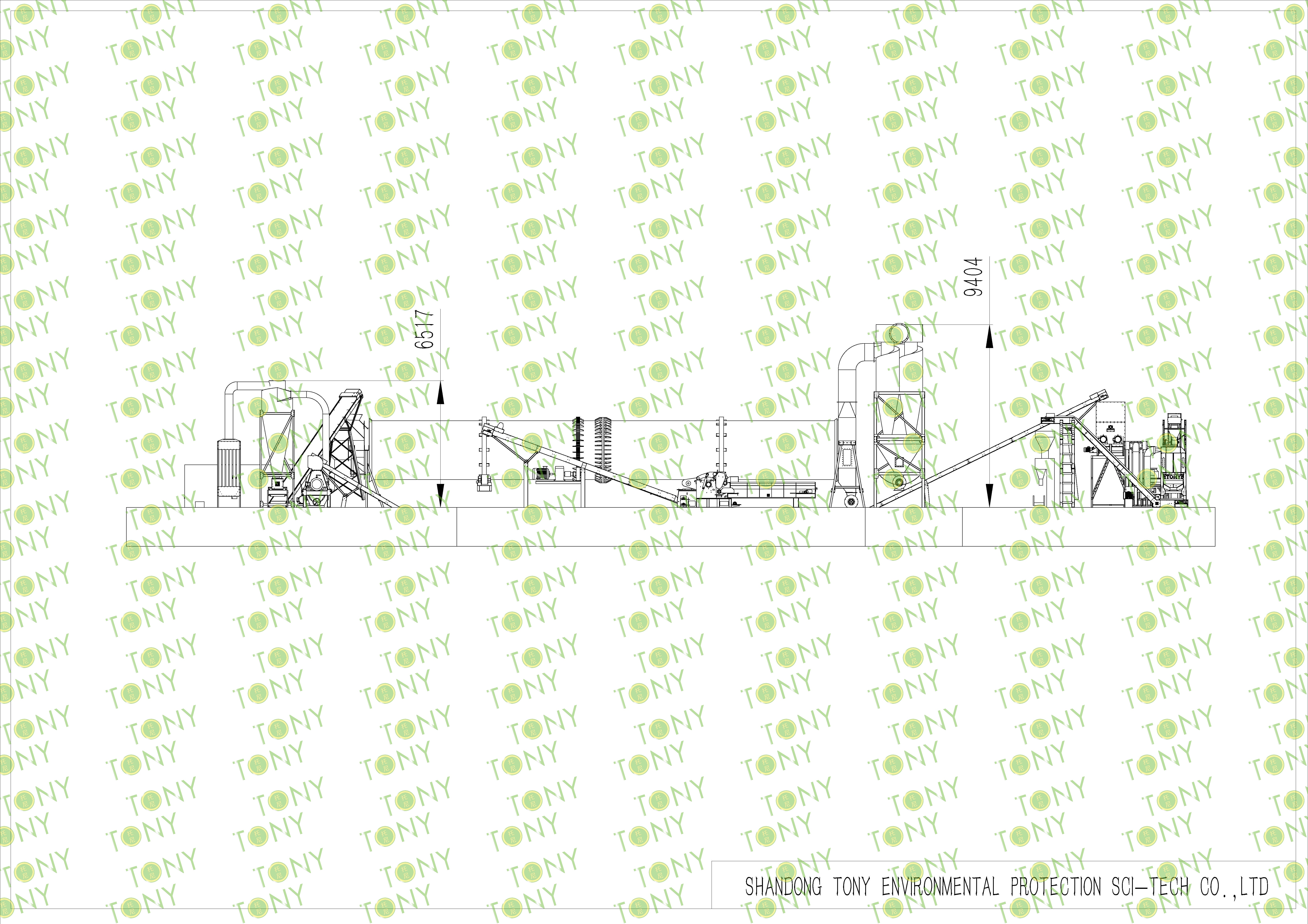

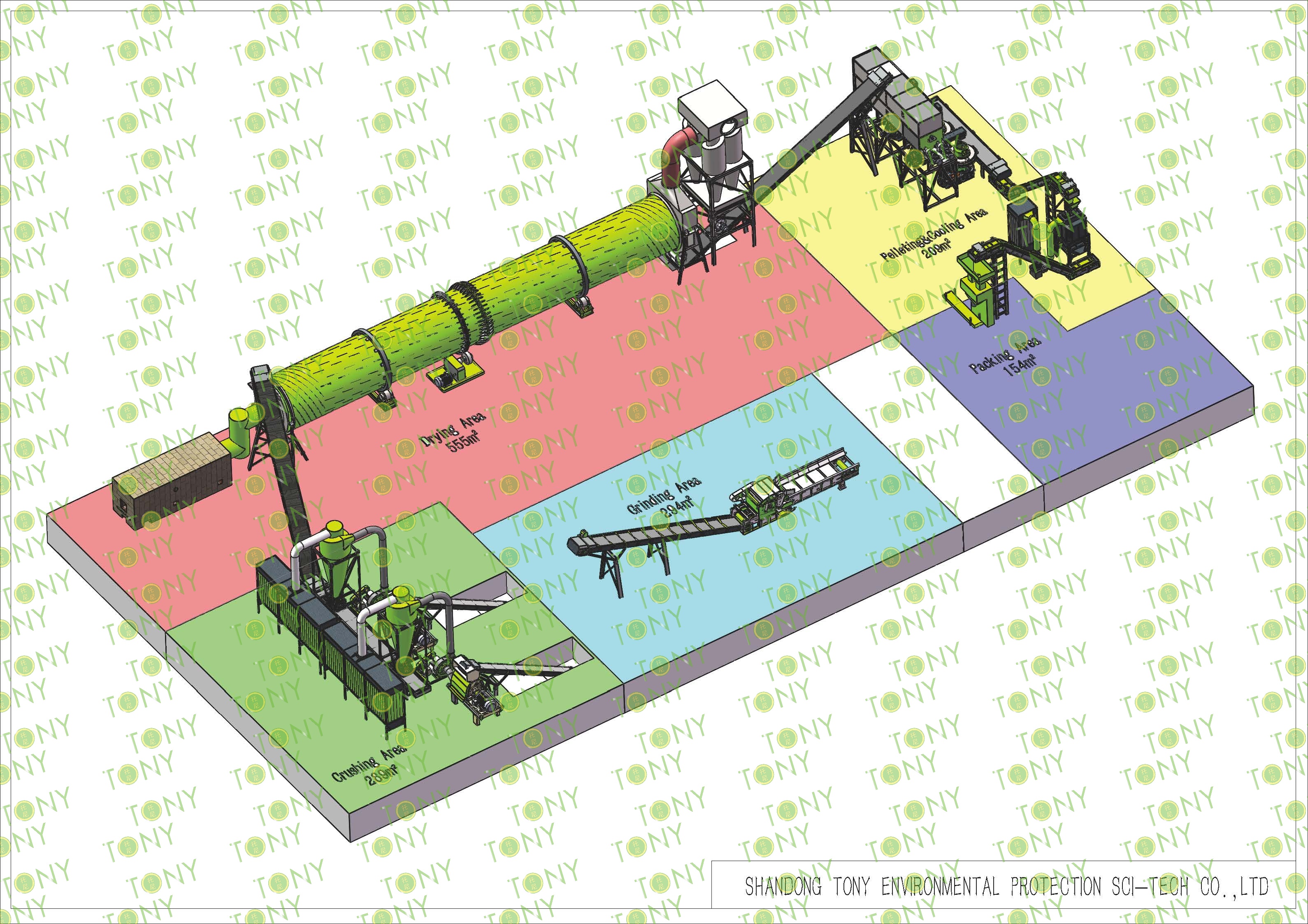

6.Need Area: About 1568㎡ L: 56 M W: 28 M H: 9.404 M

Project Layout For Customer:

1.The working principle of wet wood pallets biomass pellet processing equipment

The core equipment in pallet pellet processing is the biomass ring die pelletizer, which utilizes a combination of mechanical extrusion, frictional heating, and fiber self-bonding. The specific process is as follows:

During the extrusion process, rollers exert a pressure of up to 50-150 MPa on the powder, forcing it from its loose state (density 0.15-0.3 g/cm³) into the die's forming hole, forming a cylindrical column.

As the powder moves through the hole, it creates intense friction with the hole walls. Frictional heating raises the column temperature to 100-120°C, completely melting the softened lignin and hemicellulose, forming a natural adhesive that tightly binds the surrounding wood fiber particles together.

At the same time, the high temperature and pressure also remove some free moisture from the material (reducing the final pellet moisture content to 10%-15%) and rearranges the wood fiber structure, forming a high-density, high-strength column (density increased to 0.8-1.2 g/cm³).

2.Characteristics of wet wood pallets biomass pellet processing equipment

(1)High-strength crushing/smashing system to cope with "large block + hard" raw materials

Wood pallets are mostly whole boards (usually 1.2m×1.0m, 1.1m×1.1m in size), and some are plywood and solid wood hard materials. The crusher needs to have high torque and wear resistance

(2)High-efficiency impurity removal device to accurately separate "metal + non-metal" impurities

The key pain point of wood pallet processing is "containing metal nails and plastic accessories". The equipment usually integrates a multi-stage impurity removal system to ensure the purity of the particles

(3)Wide range of moisture content adaptation to reduce drying energy consumption

Wood pallets have different storage environments and large differences in moisture content (15%-30%). The drying system of the equipment (mostly a drum hot air dryer) can achieve precise temperature control (80-120℃) and humidity adjustment, stabilizing the moisture content of wood chips at 10%-15% (the optimal humidity for pelletizing)

(4)Wood pallet pellet processing requires multiple steps: crushing → impurity removal → pulverization → drying → pelletizing → cooling → screening. Equipment typically comes in the form of a complete production line, with core features including a consistent process flow and a high degree of automation.

(5)Wood pallet raw materials (especially plywood and hardwood) subject equipment components to significant wear and tear, making durability a key feature.

(6)Wood pallet processing is prone to dust and noise, and poses significant risks to mechanical safety. Therefore, the equipment features specific environmental and safety design features.

(7)Wood pallet pellet production equipment can be flexibly adjusted based on the user's production capacity, site, and intended use of the finished product, meeting diverse needs.

3.Application scenarios of wet wood pallets biomass pellet processing equipment

Wood pallet pellets are processed through crushing, drying, extrusion molding and other processes. Waste wood pallets are processed into pellet fuel or recycled materials to achieve resource recycling.

Equipment applicable industries and user groups

(1)Wood processing and furniture manufacturing:Processing wood pallet scraps and sawdust generated during the production process, converting them into internal energy or pellet fuel for export.

(2)Biomass energy companies:Using wood pallets and other wood waste as raw materials, large-scale production of pellet fuel is carried out to supply power plants or industrial boilers.

(3)Environmental recycling companies:The equipment realizes the resource processing of waste wood pallets, meets the needs of sustainable development, and reduces the environmental pressure caused by landfill or incineration

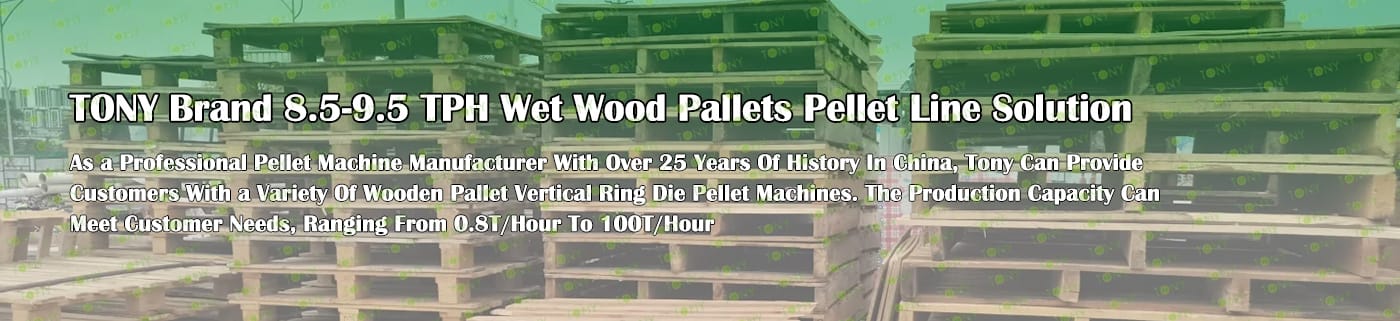

TONY Brand 8.5-9.5Ton/Hour Wet Wood Pallets Pellet Manufacturing Plant can take wet wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 8.5-9.5Ton/Hour

2. Raw materials: Wet wood pallets

3. Moisture: Wet type, about 40%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

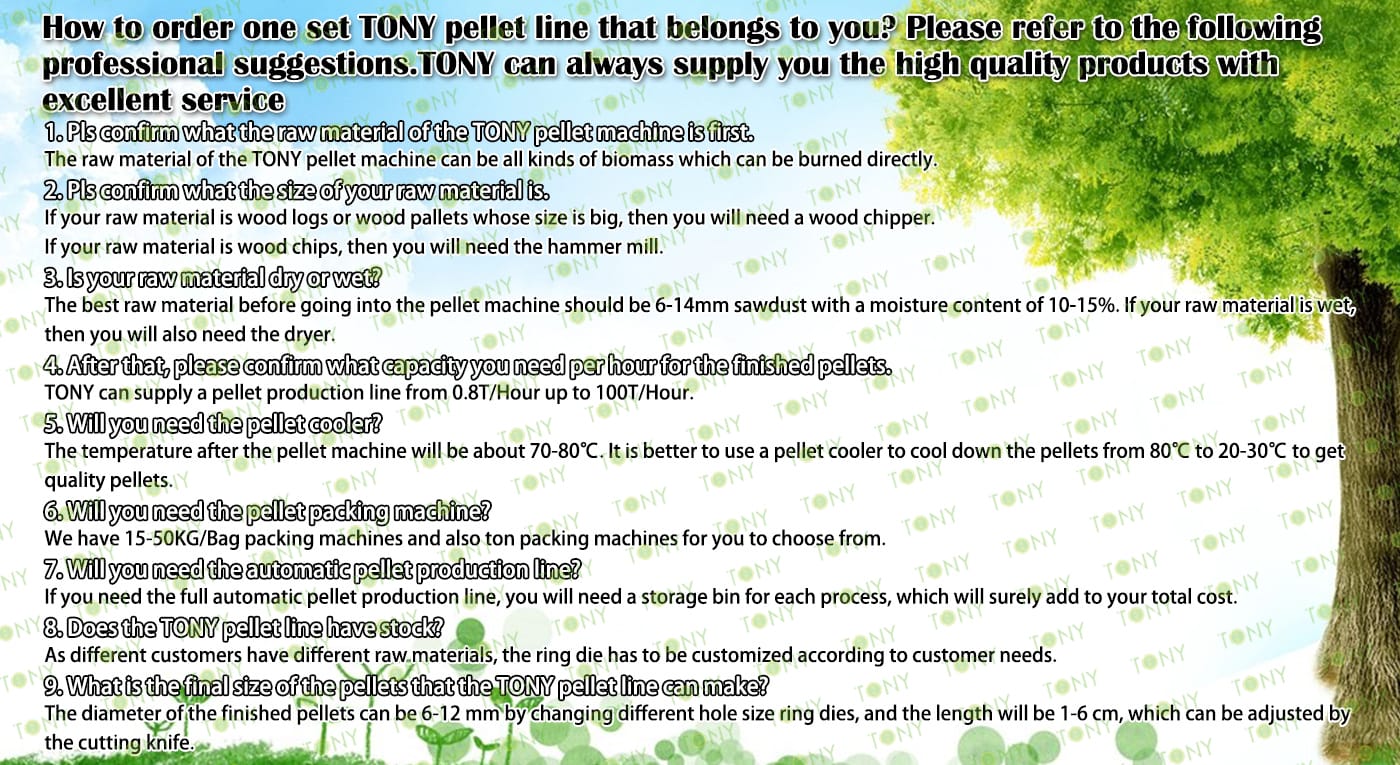

1. Project Name: Wet Wood Pallets Pellet Production Line

2. Raw Material: All kinds of wet wood pallets

3. Moisture Content of Raw Material: 40%

4. Capacity: 8.5-9.5 tons per hour

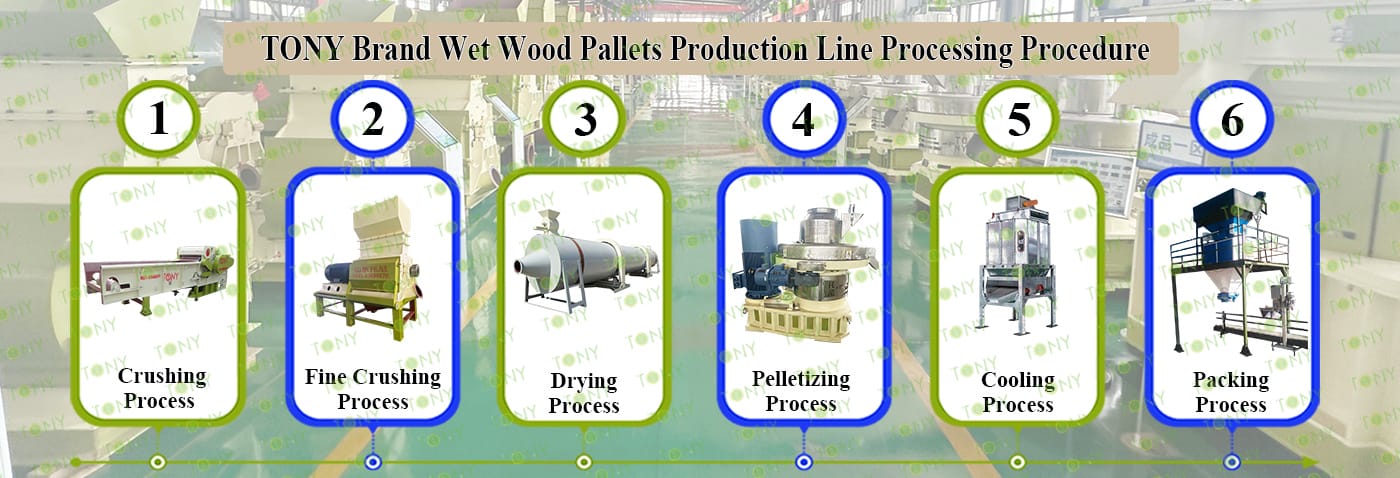

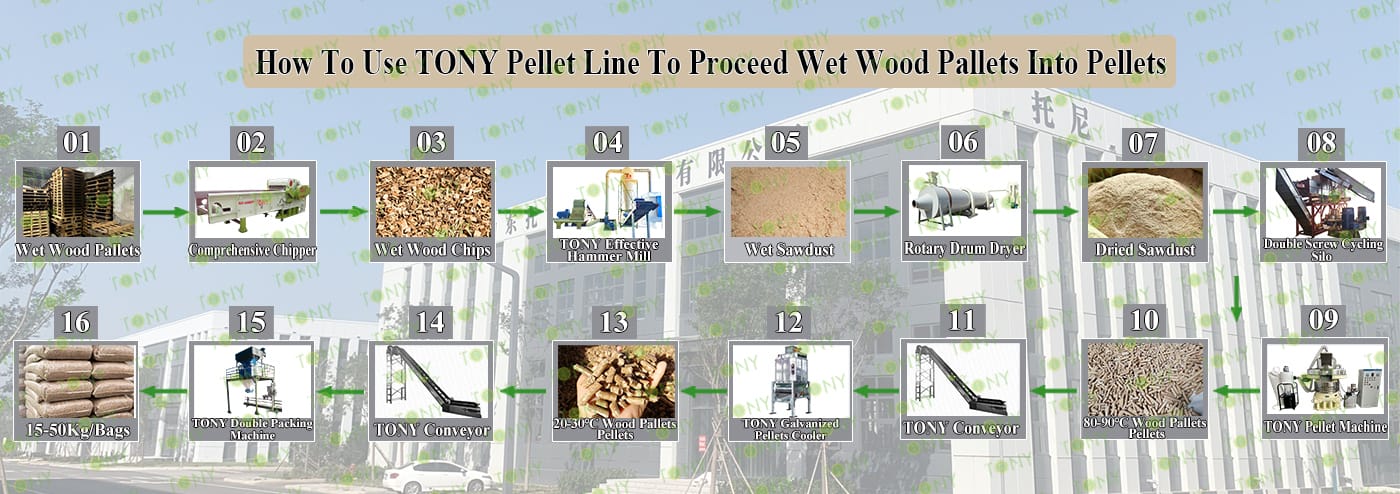

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1300-600-132KW, Effective Hammer Mill-TFD75*132-132KW, Rotary Drum Dryer-2.5*24m, TONY Pellet Machine TYJ760-Ⅲ-185KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind wet wood pallets with width 1.3m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

|

Comprehensive Chipper |

Effective Hammer mill |

Rotary Drum Dryer |

Double Screw Cycling Silo |

|

1.To Grind Wood pallets Width ≤1.3m Into25-55mm Wood Chips. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. |

1.To Stroage Sawdust Before Pellet Machine; |

|

|

|

|

|

Vertical Ring Die Sawdust Pellet Machine |

Galvanized Pellets Cooler |

Double Packing Machine |

Belt Conveyor |

|

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets |

1.To Cool Pellets From 80-90℃ Into 20-30℃ |

1.To Pack Pellets Into 15-50Kg/Bags. |

1.To Transport Wood Chips,Sawdust,Pellets. |

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1.3 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY Brand comprehensive chipper TPC1300-600-132KW model with 24 hammer heads*1set

C.Capacity:10-15Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:8.5-9.5Ton/Hour.

C.TONY brand effective hammer mill TFD75*132-132KW*2sets

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:8.5-9.5Ton/Hour.

C.TONY use 1set of 2.5*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity: 8.5-9.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-185KW*3sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:8.5-9.5Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:8.5-9.5Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Project Startup Suggestions

1.Preliminary Research:

First, visit local logistics parks and factories to confirm the monthly supply of discarded wood pallets (the raw material volume must meet "production capacity x 1.2" to avoid idle capacity). Simultaneously, contact two to three potential customers (such as nearby food factories and heating companies) and sign letters of intent for supply.

2.Pilot Operation:

If funding is limited, start with a "small-scale project" (1 ton per hour) and spend 6-12 months validating raw material supply, customer stability, and profit margins before gradually expanding production.

3.Long-Term Planning:

Once stable operations are achieved, the industry chain can be expanded—for example, by building a dedicated logistics fleet (to reduce transportation costs), developing customized pellets (such as "low-ash pellets" for fireplace users, which increase unit prices), or building a small biomass heating station (to directly supply steam to surrounding factories, resulting in higher profits). In summary, the project of processing wooden pallets into biomass pellet fuel is suitable for entrepreneurs or small and medium-sized enterprises with local resources (raw materials/customers) and medium-sized capital. The key is to control raw material costs, bind stable customers, and ensure environmental compliance to achieve sustainable profitability.

Biomass pellets made from recycled wooden pallets (referred to as "pallet pellets") are essentially wood-based biomass pellets. However, due to the unique nature of their raw material (waste pallets), they offer several advantages over other biomass pellets, such as straw, rice husks, sawdust, and bark:

1.Raw material stability: A single ingredient eliminates "mixed material defects"

The raw material composition of biomass pellets directly determines product consistency, and pallet pellets offer a distinct advantage in this regard. Pallet pellets are primarily made from discarded solid wood pallets (such as pine, fir, and poplar) or plywood pallets, with wood comprising over 95% of the raw material. They are free of crude fiber from straw, silica from rice husks, or high-ash impurities from bark. They are also free of pesticide residues (unlike farmland straw) and odor (unlike pellets derived from food waste).

2.Raw material cost efficiency: "Turning waste into treasure," the cost is significantly lower than conventional wood-based raw materials.

The raw material cost of biomass pellets accounts for 60%-70% of the total cost. The raw material advantages of pallet pellets significantly lower the investment threshold. Pallet pellets are made from discarded pallets, considered industrial solid waste. Procurement costs are extremely low (in some areas, they can even be recycled for free with a small transportation fee), and recycling channels are stable (logistics parks, manufacturing plants, and warehouses generate large quantities of discarded pallets annually). Furthermore, pallets are typically standardized in size (e.g., 1200×1000mm), making them highly efficient to disassemble and crush, eliminating the need for additional sorting (unlike loose sawdust).

3.Product Calorific Value: High wood density results in superior combustion efficiency compared to herbaceous/miscellaneous pellets.

Calorific value is a core performance metric for biomass pellets (determining the cost-effectiveness of replacing coal and natural gas). Pallet pellets, due to their high wood density, offer a significant calorific value advantage. Average Lower Calorific Value (MJ/kg): 18-20 Density (kg/m³): 1.1-1.3 Combustion Efficiency (compared to standard coal): 80%-85%

Pallets are typically made from "finished wood" (e.g., pine pallets have a higher density than log sawdust), resulting in a denser fiber structure. The resulting pellets are denser and more resistant to breakage (lower transportation loss). 3%, while straw pellets can reach 5%-8%), and the heat released during combustion is more stable, making it suitable for "high-load energy scenarios" such as industrial boilers and biomass power stations.

2025 Tony Machinery - All Rights Reserved. Map