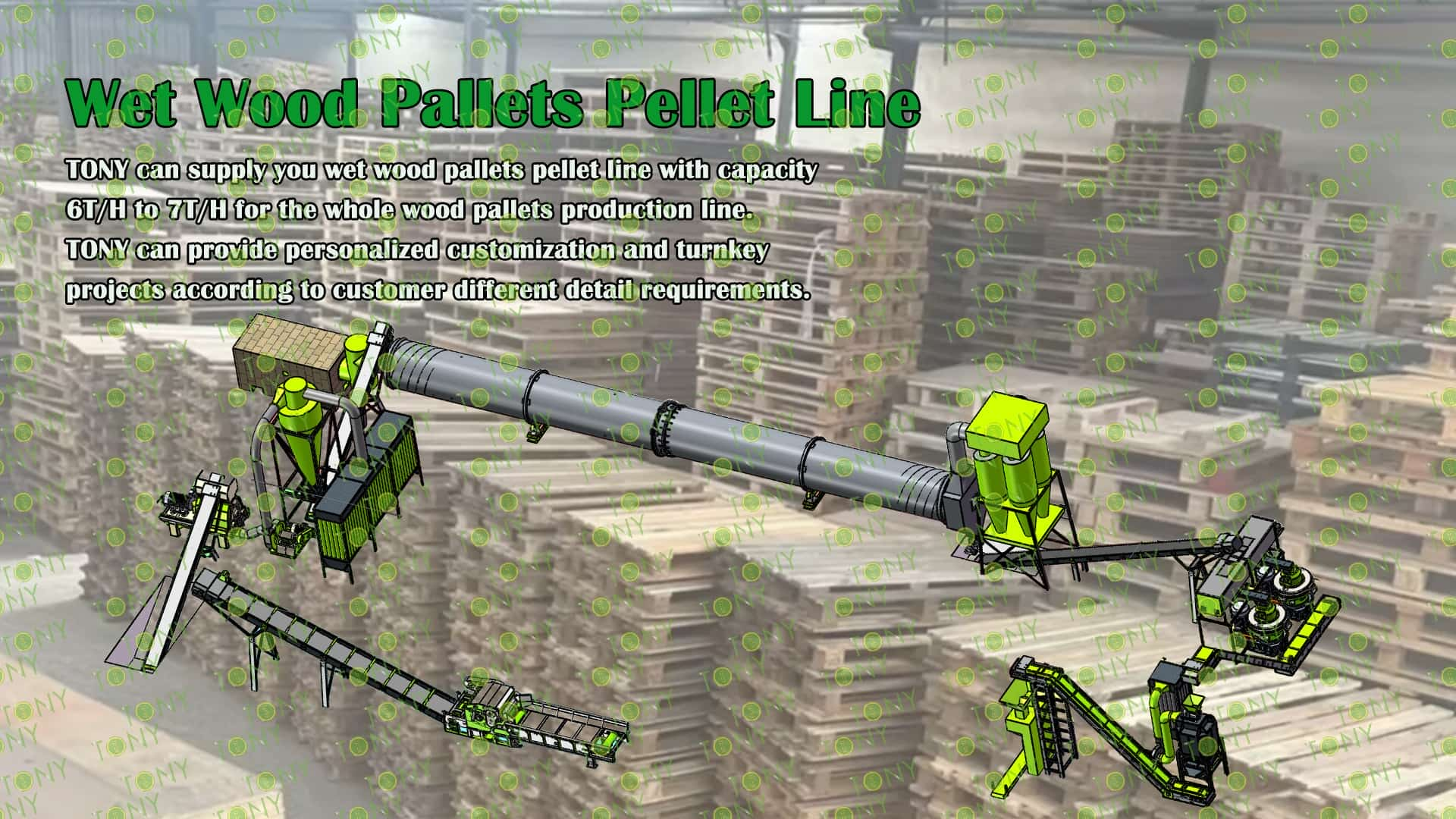

Project Brief Introduction:

1.Product:Wet Wood Pallets Pellet Line

2.Capacity: 6-7T/Hour

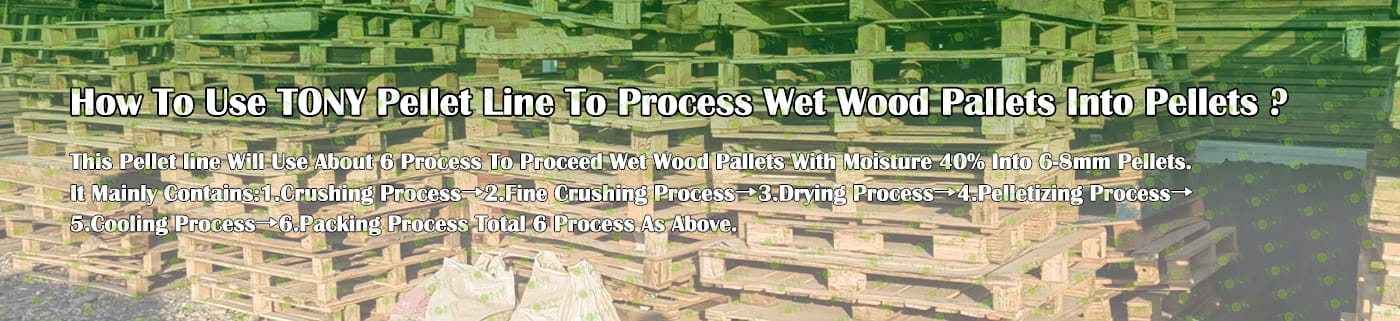

3.TONY Brand 6-7Ton /Hour Wet Wood Pallets Pellet Line Project Process

4.Main Machine: Comprehensive Chipper,Hammer Mill, Rotary Drum Dryer,TONY Pellet Machine TYJ860-Ⅲ-220KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 1000KW

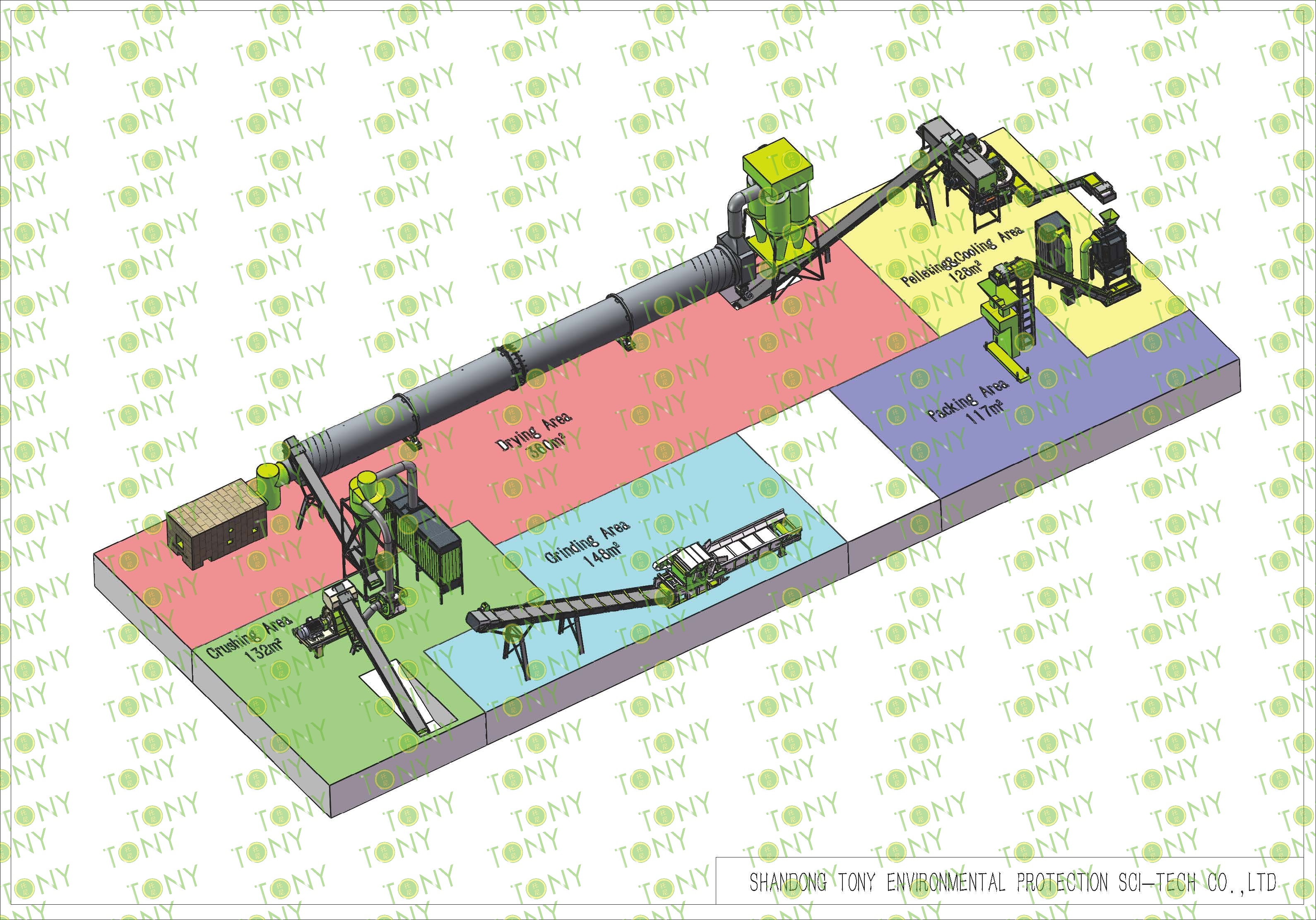

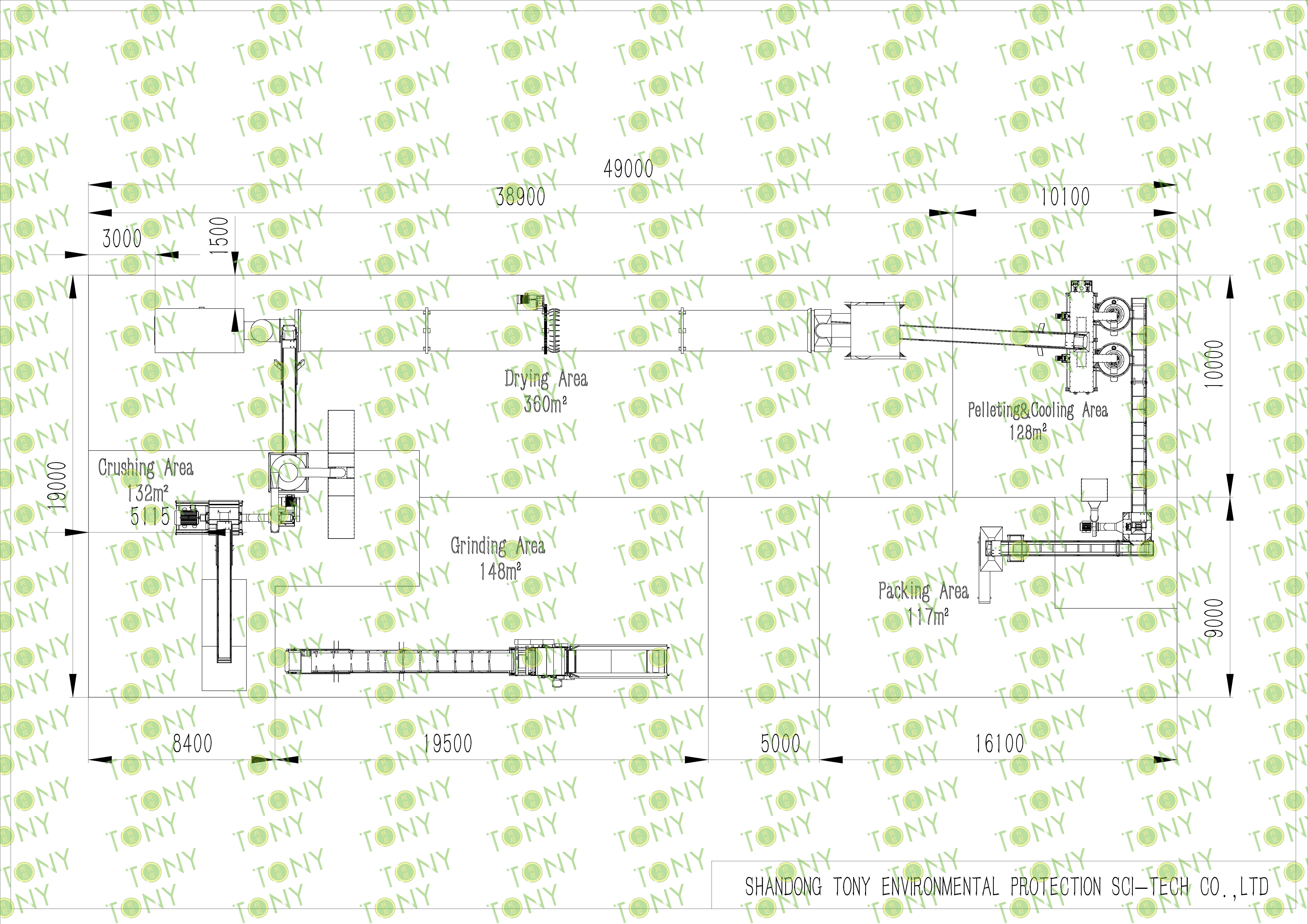

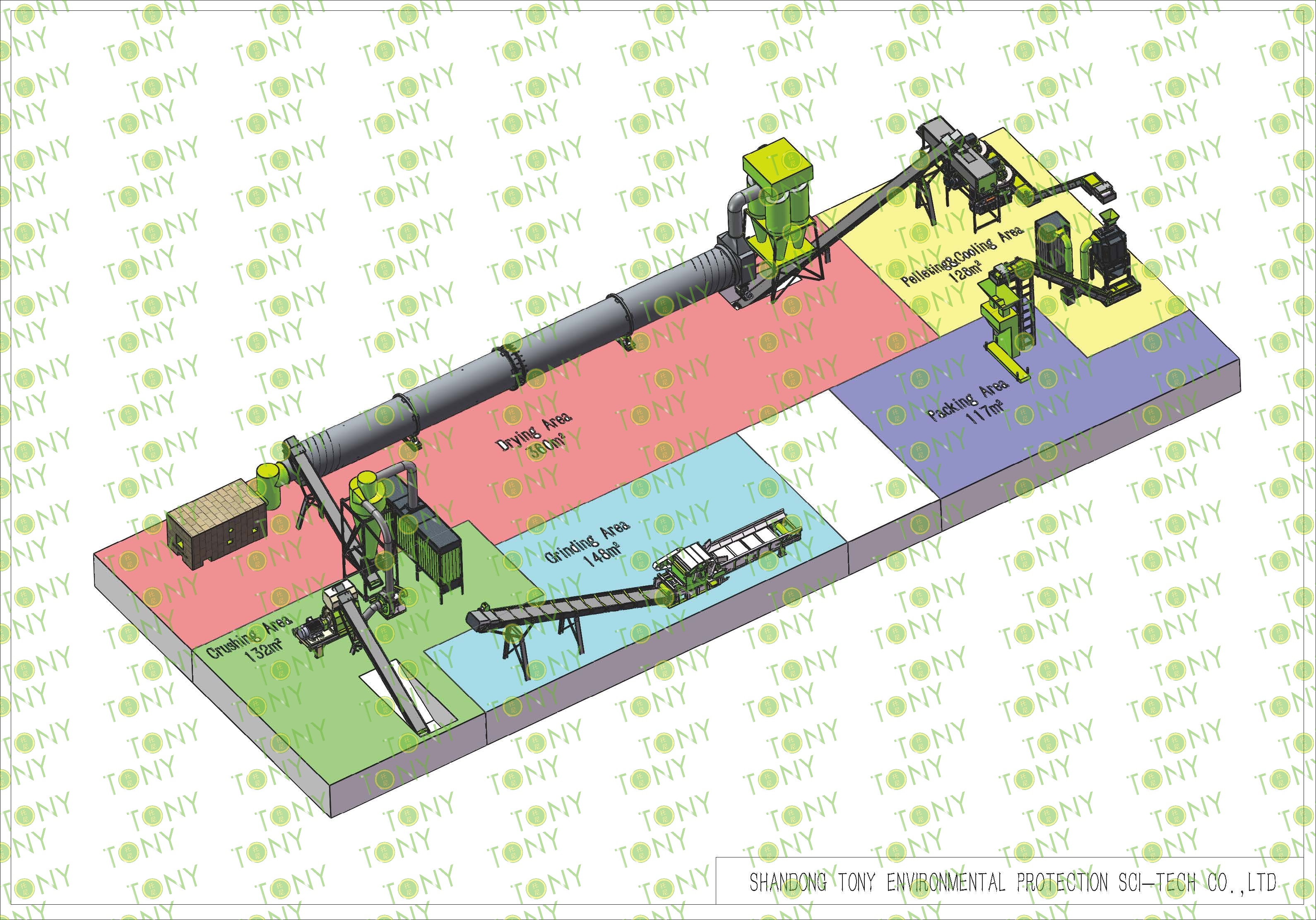

6.Need Area: About 931㎡ L: 49 M W: 19 M H: 7.065 M

Project Layout For Customer:

1.The working principle of wet wood pallets biomass pellet processing equipment

The core principle of the wood pallet pellet processing equipment is to convert waste wood pallets (including wood body, a small amount of metal connectors and other impurities) into biomass pellets with high density and stable combustion performance through continuous processes such as crushing → fine crushing → drying → pelletizing → cooling and screening

2.Characteristics of wet wood pallets biomass pellet processing equipment

The wood pallet pellet processing equipment is a complete set of processing equipment designed specifically for waste wood pallets (including complex raw materials such as metal nails, plywood, and wood with different moisture contents). Its characteristics revolve around four core requirements: raw material adaptability, process adaptability, performance stability, and environmental compliance. It not only solves the "pain points" of wood pallet recycling (such as impurity removal and uneven material quality), but also ensures the efficiency and quality of pellet production.

(1)Strong adaptability to raw materials: Targeted solution to the "difficulties" of wood pallet processing

(2)High process integration: Achieve One-Stop Continuous Production

(3)Durable Core Components: Suitable for high-load, high-wear scenarios.

(4)Environmental and Safety Considerations: Compliance with Industrial Production Standards.

(5)High Flexibility: Adaptable to diverse needs.

3.Application scenarios of wet wood pallets biomass pellet processing equipment

Wood pellets (also known as "biomass pellet fuel") are a key alternative to traditional fossil fuels like coal and heavy oil due to their high combustion efficiency, low pollution emissions, and convenient storage and transportation. They are also the most popular application for wood pallet pellet processing equipment, including:

(1)Industrial Boiler/Kiln Fuel:Small and medium-sized boilers (steam boilers and hot water boilers) in the food processing, textile, chemical, and building materials industries, as well as heating equipment such as ceramic and glass kilns, can directly use wood pallet pellets (with a calorific value of approximately 4200-4800 kcal/kg, similar to medium-quality coal).

(2)Residential Heating/Household Energy:Wood pallet pellets can be used as fuel for household biomass heating stoves and fireplaces. The pellets burn stably (no black smoke or odor) and are automatically fed through a dedicated hopper, eliminating the need for frequent refills. Furthermore, some catering businesses (such as small restaurants) use them to replace liquefied petroleum gas for heating, reducing energy costs.

(3)Power Plant Supplemental Fuel:Some biomass power plants mix wood pallet pellets with other biomass fuels, such as straw and sawdust, for power generation or combined heat and power (cogeneration) (generating both electricity and steam). The high density of wood pallet pellets (0.8-1.2 g/cm³) reduces transportation and storage space, lowering raw material storage costs for power plants. Furthermore, the high purity of the wood fiber (free of sand and impurities found in straw) reduces the risk of boiler slagging.

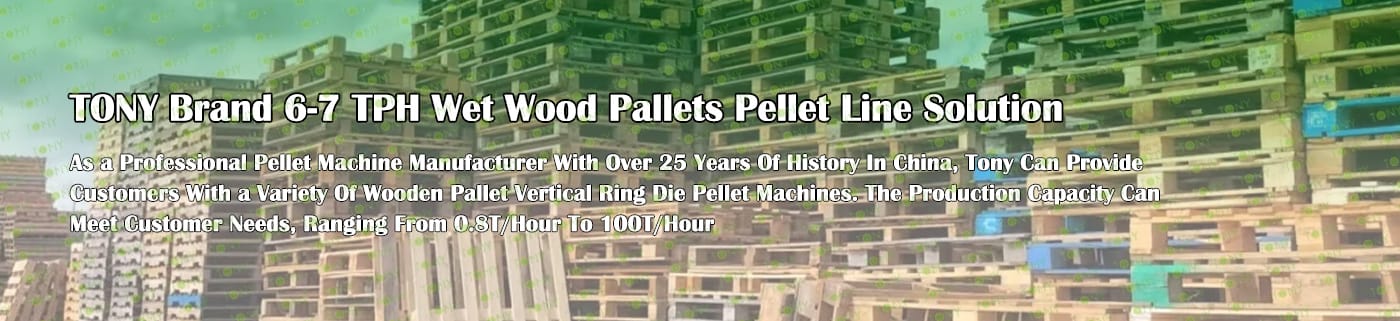

TONY Brand 6-7Ton/Hour Wet Wood Pallets Pellet Manufacturing Plant can take wet wood pallets, various types of wood - related biomass materials, such as branches, small - diameter logs, and wood shavings, with wet wood as the main raw material. After pretreatment and processing, it is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction. At present, it has been widely used in regions rich in wood resources.

1. Capacity: 6-7Ton/Hour

2. Raw materials: Wet wood pallets

3. Moisture: Wet type, about 40%.

4. Application: All kinds of waste wood pallets or more waste wood raw materials

Suitable customers: Logistics and warehousing companies, various manufacturing plants, ports and airports, construction sites, large supermarkets and shopping malls, and other places where waste wood pallets have advantages

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Wood Pallets Pellet Production Line

2. Raw Material: All kinds of wet wood pallets

3. Moisture Content of Raw Material: 40%

4. Capacity: 6-7 tons per hour

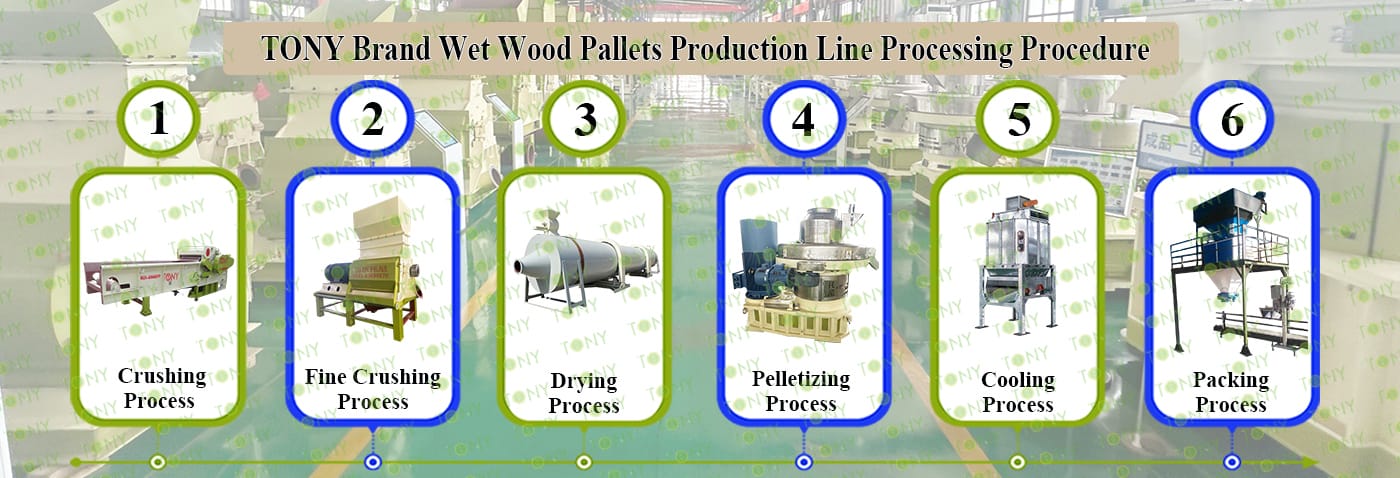

5. Process: Crushing Process - Fine Crushing Process - Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Comprehensive Chipper TPC1000-90KW, Effective Hammer mill-TFD85*250-250KW, Rotary Drum Dryer-2.2*24m, TONY Pellet Machine TYJ860-Ⅲ-220KW, Pellet Cooler, Double Packing Machine and Belt Conveyors

|

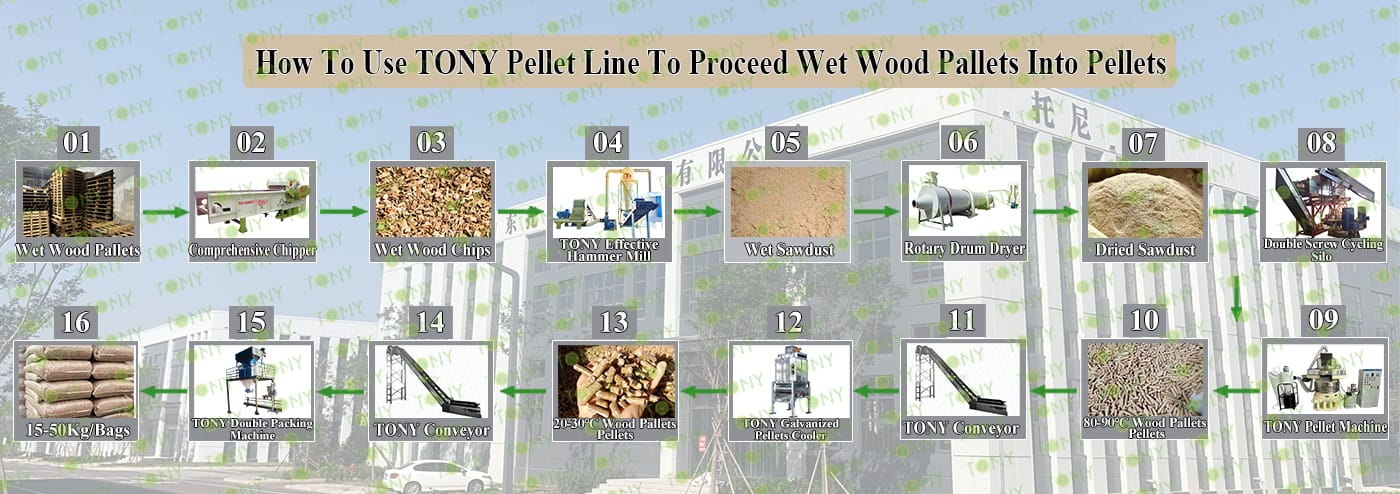

How to use the TONY pellet production line to make pellets from wet wood pallets? The process mainly includes the following steps and equipment: 1. Use TONY comprehensive chipper to grind wet wood pallets with width 1m into wood chips 25 - 55 mm in length. 2. Use TONY effective hammer mill to crush the 25-55 mm wood chips into 8-14 mm sawdust. 3. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 4. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 5. Use TONY galvanized cooler to cool the pellets from 80-90°C to 20-30°C. 6. Use TONY double packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Comprehensive Chipper | Effective Hammer mill | Rotary Drum Dryer | Double Screw Cycling Silo |

| 1.To Grind Wood pallets Width ≤1m Into25-55mm Wood Chips. 2.Model: TPC1000-90KW With 16 Hammer Heads*1set 3.Capacity: 7-10Ton/Hour. |

1.To Crush 25-55mm Wood Chips Into 8-14mm Sawdust. 2.Model: TFD85*250-250KW*1set 3.Capacity:6-8Ton/Hour/Set |

1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2.2*24*1set 3.Capacity:6-7 Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-7*1set 3.Capacity: 6-7 Ton/Hour/Set |

|

|

|

|

| Vertical Ring Die Sawdust Pellet Machine | Galvanized Pellets Cooler | Double Packing Machine | Belt Conveyor |

| 1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-220KW*2sets 3.Capacity:3-4Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:6-7Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TPZ-50*1set 3.Capacity: 6-7Ton/Hour |

1.To Transport Wood Chips,Sawdust,Pellets. 2.Width: 80cm*6sets 3.Capacity:Designed With The Whole Line |

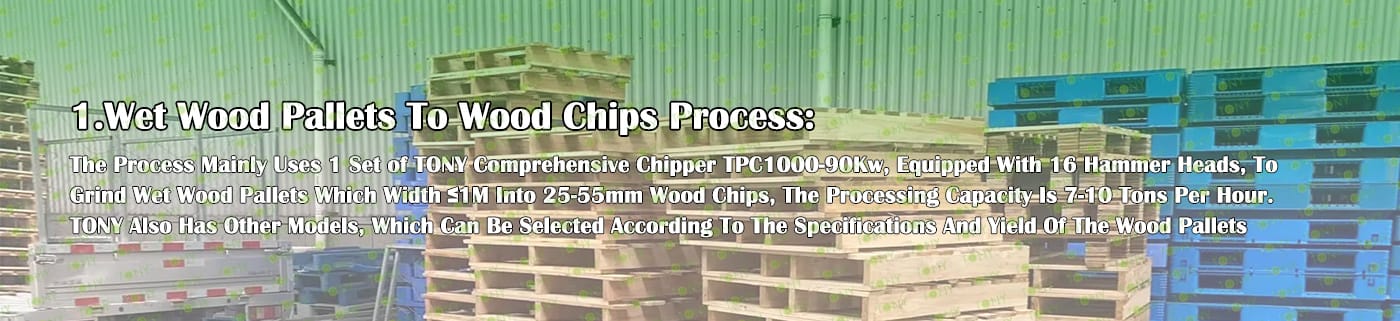

1.Wood Pallets Chipping Process:

A. This process is mainly used to grind wooden pallets with nails less than 1 m in width into wood chips with a size of 25-55 mm. The final size of the wood chips can be adjusted by replacing the screen with different sizes and replacing or adjusting the hammer heads with different specifications.

B.TONY brand comprehensive chipper TPC1000-90KW model with 16 hammer heads*1set

C.Capacity:7-10Ton/Hour.

Main Parts:

(1)TONY's Comprehensive Chipper.

(2)Feed And Discharge Belt Frequency Control To Prevent Card Material

(3)Hydraulic System Control Can Be Used For Thicker Materials

(4)Electronic Control System Allows The Equipment To Be Used Normally

Contact Tony For More Details With Quotation

2.Wood Chips Fine Crushing Process:

A.This process is mainly used to crush 25-55mm wood chips into 8-14mm sawdust.

B.Capacity:6-7Ton/Hour.

C.TONY brand effective hammer mill TFD85*250-250KW*1set

Main Parts:

(1)TONY Effective Hammer Mill.

(2)Galvanized Dust Collector.

(3)Sawdust Transportation Fan Blower.

(4)Cyclone With Airlock.

(5)Electrical Cabinets.

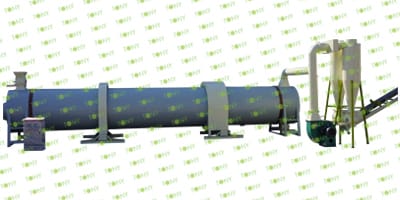

3.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:6-7Ton/Hour.

C.TONY use 1set of 2.2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

4.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity: 6-7Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-220KW*2sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

5.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:6-7Ton/Hour.

C.TONY brand galvanized cooler separator*1set

Main Parts:

(1)TONY's Galvanized Cooler Separator With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

6.Packing Process:

A.This process is mainly used to pack pellets into 15-50kg/bags.

B.Capacity:6-7Ton/Hour.

C.TONY double packing machine*1set

Main Parts:

(1)TONY's Double Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Three Fundamental Supports for the Feasibility of Processing Wooden Pallets into Biomass Pellets

The success of this project hinges critically on the maturity of three key factors: raw material supply, policy guidance, and market demand. These factors are also the core focus of preliminary research.

1.Raw Material Supply: Stable and low-cost raw material supply is a prerequisite.

The source, supply volume, and cost of discarded wooden pallets directly determine project profitability and require critical assessment:

(1)Raw Material Source Scenario:Core Channels: E-commerce logistics warehouses, manufacturing factories (auto parts, home appliances, machinery), ports/bonded areas (discarded IPPC pallets from cross-border trade), and pallet rental companies (damaged and retired pallets).

(2)Supply Characteristics: Discarded pallets in these scenarios are typically generated in bulk and are often recycled for free or at a low price, resulting in extremely low raw material costs.

(3)Suitability of Raw Material Processing:Wooden pallets (especially solid wood pallets) have a high wood fiber density, resulting in pellets with a calorific value of 4200-4800 kcal/kg (similar to medium-quality coal), surpassing agricultural waste such as straw and rice husks. Removal of metal (nails, clips) and minimal oil contamination is required, eliminating the need for complex pre-treatment and making them highly suitable for processing.

2.Policy Direction: Dual Benefits of Environmental and Energy Policies

Biomass pellets, as a compliant alternative fuel, have low market entry barriers. This project falls under the "solid waste resource utilization" category, meeting the "reduction and resource utilization" requirements.

3.Market Demand: Strong demand in both industrial and residential applications

The market demand for biomass pellet fuel has stabilized, eliminating the need to worry about "selling out":

(1)Industrial (Core Customers): Small and medium-sized boilers (1-10 tons) in food processing, textile, and building materials factories, ceramic kilns, and biomass power plants (for co-firing).

(2)Residential (Supplementary Customers): Home heating stoves, cooking energy in southern farmhouses and small restaurants, and home fireplace users.

As biomass pellet fuel or industrial auxiliary material, wood pallet pellets offer stable physical and chemical properties, and their user experience surpasses traditional loose wood and coal. Specifically, they demonstrate the following:

1.High energy density and excellent combustion efficiency

After compression molding, wood pallet pellets achieve a density of 1.1-1.3g/cm³ (much higher than the 0.4-0.6g/cm³ of loose wood), a volume reduction of 6-8 times, and a calorific value per unit volume of 4200-4800kcal/kg (similar to medium-quality coal). They also resist slagging during combustion (due to the low ash content of 1%-3% found in softwood, wood pallets are primarily made of softwood). Their thermal efficiency is over 30% higher than that of loose wood, making them suitable for use in boilers, fireplaces, hot air furnaces, and other equipment.

2.Convenient Storage and Transportation, Low Cost

The pellets have a regular shape (mostly cylindrical, 6-10mm in diameter and 10-30mm in length) and good fluidity. They can be transported in bags, silos, or conveyor belts, and are resistant to moisture and deformation. They require only one-fifth the storage space of bulk wood of the same thermal mass, and there's no concern for insect infestation or mildew (the high temperatures during the pelletizing process kill insect eggs and mold), reducing labor and space costs during storage and transportation.

3.Low Entry Points, Wide Adaptability

Wood pallet pellets can be directly used in automated biomass combustion equipment (such as pellet stoves and biomass boilers). No complex pre-processing (such as chopping or pulverizing) is required; simply feed the pellets at a constant rate through a feeder. Operation is simple, making them suitable for industrial heating, home heating, agricultural greenhouse insulation, and other applications. They can also serve as an auxiliary fuel in biomass power plants.

2025 Tony Machinery - All Rights Reserved. Map