1.The working principle of wet sawdust biomass pellet processing equipment

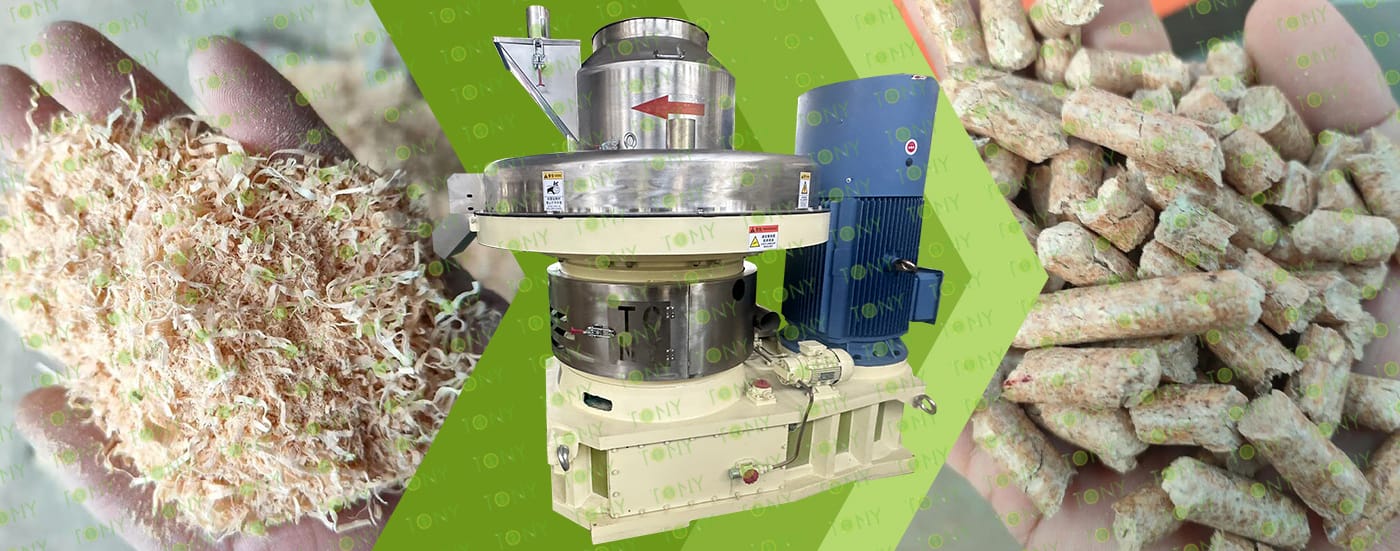

Wet sawdust pelletizing equipment works by mechanically compressing pre-treated sawdust, wood chips, and other biomass materials into solid fuel pellets.

The specific process is as follows: The material is first dried to meet the required pelletizing and moisture standards.

The material is then fed into the pelletizer, where centrifugal force forms a circular layer on the inner wall of the die. The material is then continuously compressed by rollers, forced into the die and extruded.

The extruded material then maintains pressure within the die for a certain period of time. Pellets that have reached the desired density and strength are then extruded out of the die and cut into the desired length by a cutter.

Finally, the finished pellets are cooled, dust-removed, and packaged for transportation and use.

2.Characteristics of wet sawdust biomass pellet processing equipment

(1)Strong adaptability: It can directly process high-moisture wet sawdust without the need for complex pre-drying processes, thus reducing initial processing costs.

(2)Good molding effect: Through high-pressure extrusion, wet sawdust particles have high density and strength, are not easy to break, and are easy to store and transport.

(3)High integration: Some equipment integrates crushing, conveying, granulation, cutting and other functions into one, realizing integrated processing and saving operation steps.

(4)Relatively reasonable energy consumption: Designed according to the characteristics of wet materials, the material's own moisture can be used to assist in molding during the extrusion process. Compared with equipment that processes dry materials, it has more energy consumption advantages under certain conditions.

(5)Convenient operation: Most of them use automated control systems, which can easily adjust parameters such as particle size and output, making them suitable for continuous production.

3.Application scenarios of wet sawdust biomass pellet processing equipment

After pre-treatment such as drying, wet sawdust pellets can be used as biomass fuel. Compared with traditional fossil fuels, it has the advantages of being renewable and having relatively low carbon dioxide emissions. In some regional heating systems, the heat generated by the combustion of wet sawdust pellets can be used for heating residents, heating in industrial production processes, etc. For example, in parts of Northern Europe, biomass pellet heating systems are widely used, and wet sawdust pellets are used as one of the raw materials to provide local residents with a warm winter living environment. This is because it has good combustion performance, can effectively release heat, and has a relatively wide source and relatively low cost.

TONY Brand 32-40Ton/Hour Wet Sawdust Pellet Manufacturing Plant can take wet sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, wet sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 32-40Ton/Hour

2. Raw materials: Wet sawdust

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

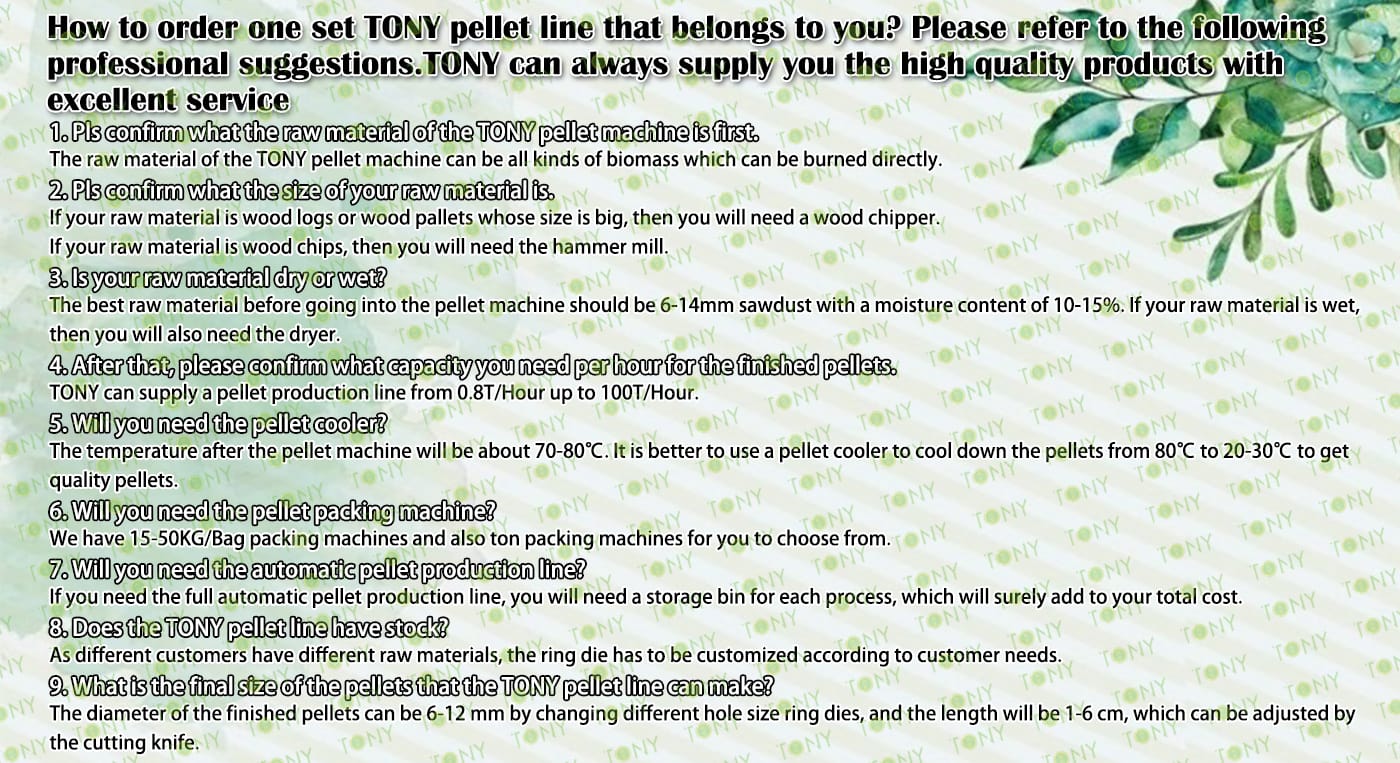

1. Project Name: Wet Sawdust Pellet Production Line

2. Raw Material: All kinds of wet sawdust

3. Moisture Content of Raw Material: 40%

4. Capacity: 32-40 tons per hour

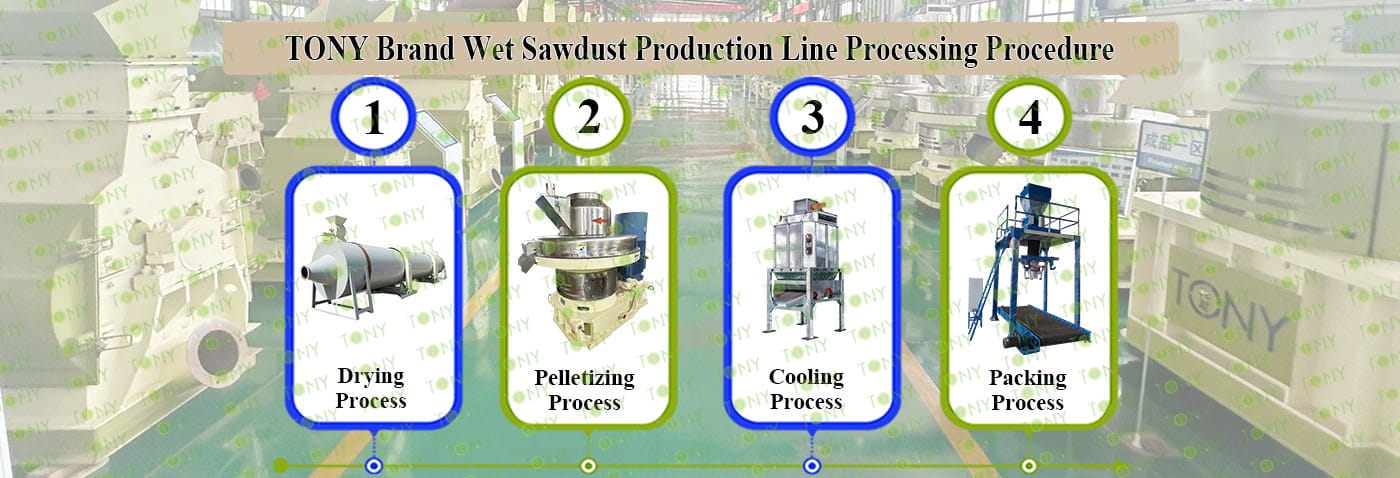

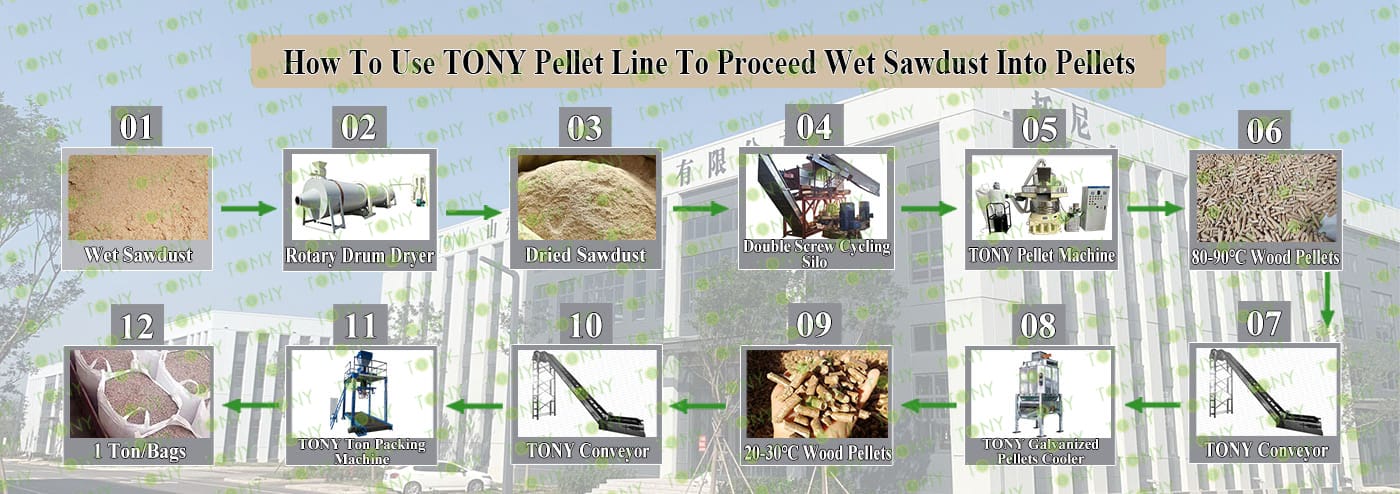

5. Process: Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Rotary Drum Dryer-2.5*24m, TONY Pellet Machine TYJ860-Ⅲ-280KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet sawdust? The process mainly includes the following steps and equipment: 1. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Rotary Drum Dryer | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

| 1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2.5*24*6sets 3.Capacity:6-8Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-20*2sets 3.Capacity:16-20Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets |

|

|

|

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*2sets 3.Capacity:32-40Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD* 2sets 3.Capacity:32-40Ton/Hour |

1.To Transport Sawdust,Pellets.

|

1.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:32-40Ton/Hour.

C.TONY use 6 sets of 2.5*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

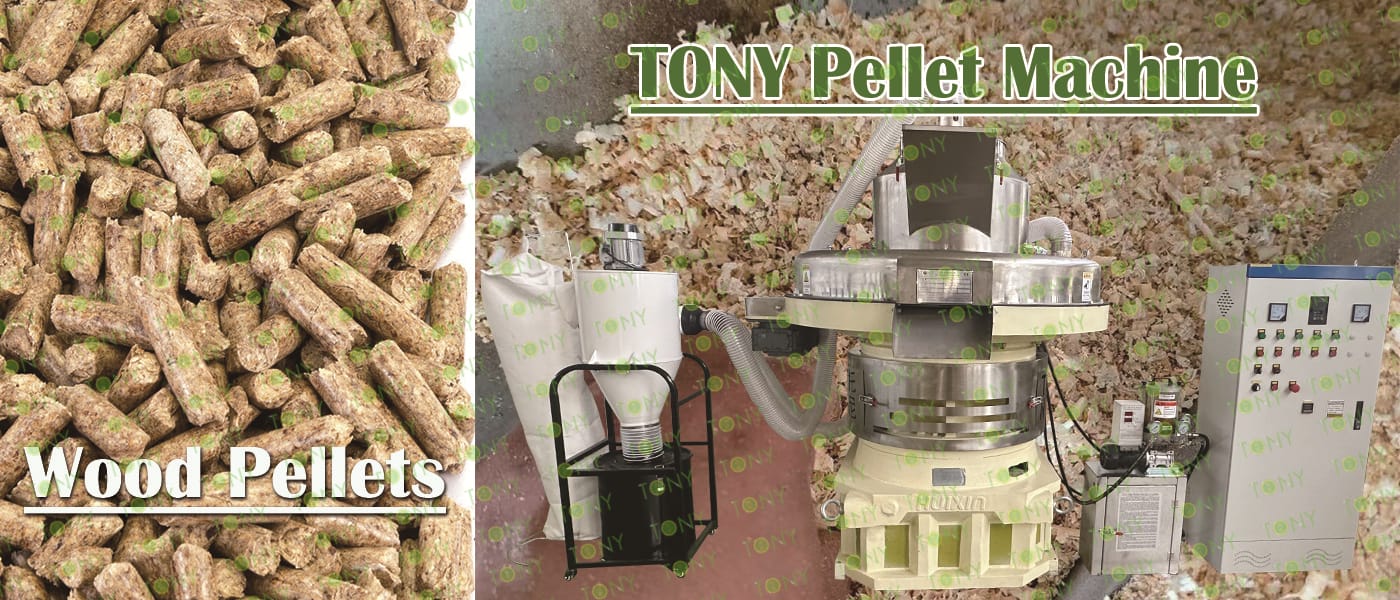

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:32-40Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-280KW*8 sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:32-40Ton/Hour.

C.TONY brand galvanized pellets cooler *2sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:32-40Ton/Hour.

C.TONY band ton packing machine*2sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

The wet sawdust biomass pellet project is an environmentally friendly industrial project focused on resource utilization of forestry waste. Using specialized equipment, wet sawdust with a moisture content of 40%-60% is converted into clean biomass pellet fuel. This not only addresses the pollution caused by sawdust disposal but also provides a new fuel alternative to fossil fuels, offering both environmental and economic benefits.

The project's raw material supply is stable and low-cost, primarily derived from wet sawdust waste generated by wood processing plants, furniture factories, and wood-based panel factories. Traditionally, this waste has been dumped or incinerated in the open air, which not only occupies land but also generates dust pollution and greenhouse gas emissions. The project, through long-term purchase agreements with upstream companies, offers a low price for wet sawdust and a transportation radius typically limited to 50 kilometers. This effectively reduces raw material costs and transportation losses, ensuring a stable supply of raw materials.

Sawdust biomass pellets, made from forestry waste, are a new fuel that combines environmental and practical benefits. Their core advantages are as follows:

1.Significant raw material advantages: a wide range of sources and low costs. Relying on waste from wood processing plants and furniture factories, they avoid occupying arable land and enjoy low procurement prices. They are chemical-free, relying on the sawdust's natural fibers bonded together under high temperature and high pressure, preserving their natural properties.

2.Their adaptable design allows for easy storage and transportation, significantly reducing storage space and transportation costs.

3.Their combustion performance far surpasses traditional fuels, offering high efficiency and low pollution: Their combustion efficiency exceeds 85%, significantly exceeding the 60% of coal, with rapid heat release and minimal pollutant emissions. They meet environmental standards and can directly replace fossil fuels.

4.Their application and economic value are outstanding, encompassing a wide range of scenarios and stable returns. They are suitable for industrial boilers, home heating, agricultural greenhouses, and other applications, eliminating the need to modify existing equipment. They also qualify for renewable energy subsidies, offering both environmental and economic benefits.

2025 Tony Machinery - All Rights Reserved. Map