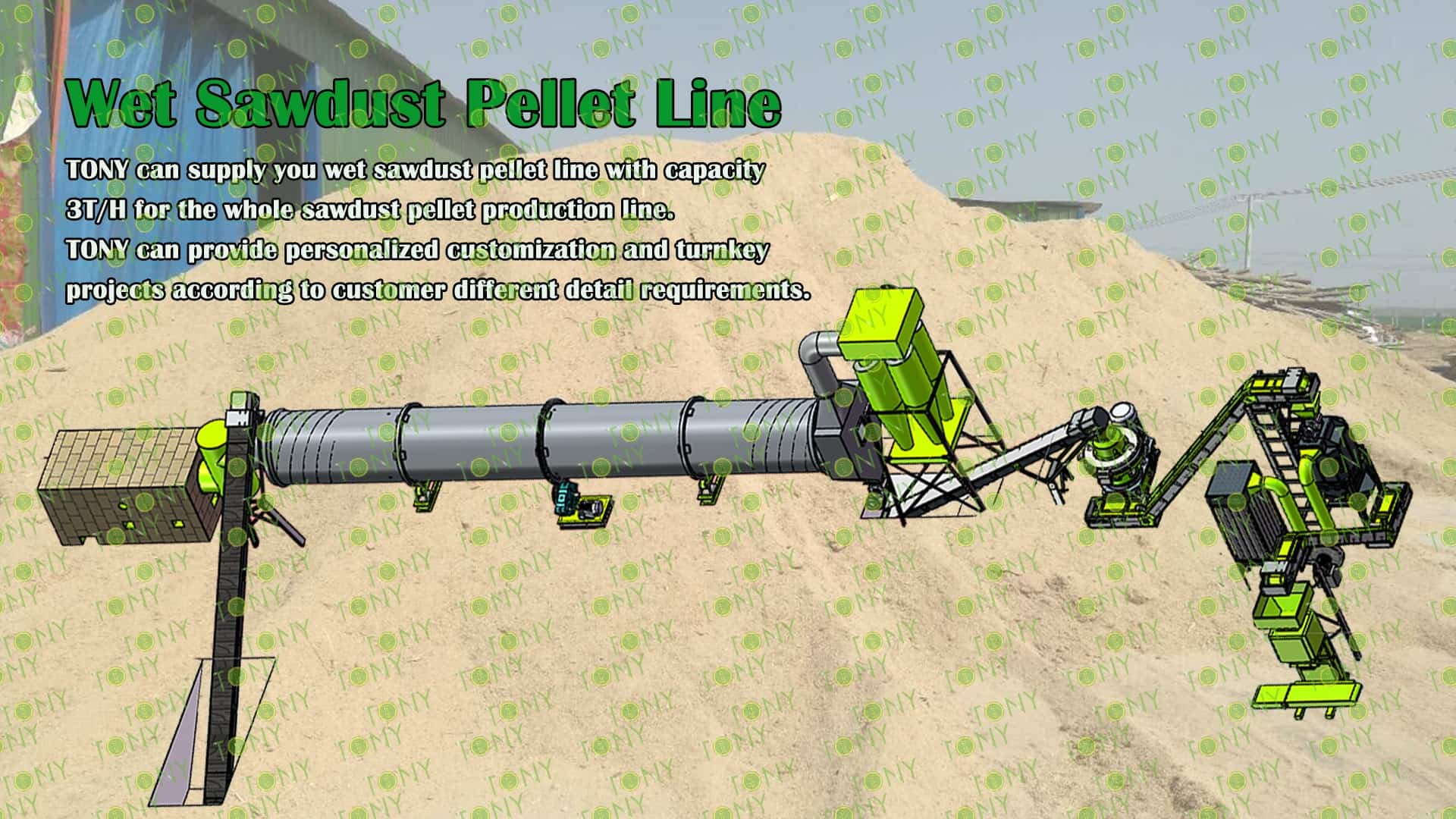

Project Brief Introduction:

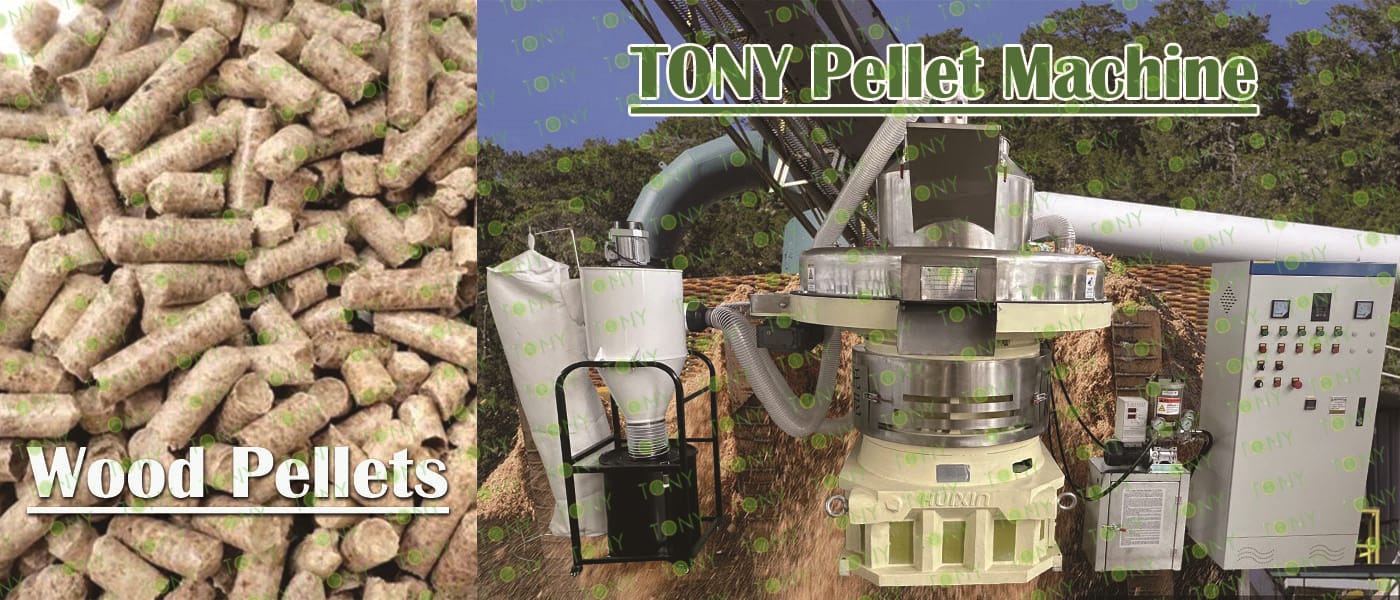

1.Product:Wet Sawdust Pellet Line

2.Capacity: 3T/Hour

3.TONY Brand 3Ton /Hour Wet Sawdust Pellet Line Project Process

4.Main Machine: Rotary Drum Dryer,TONY Pellet Machine TYJ760-Ⅲ-200KW,Pellets Cooler,Packing Machine And Belt Conveyors

5.Total Power: About 295KW

6.Need Area: About ㎡ L: M W: M H: M

Project Layout For Customer:

三维图

1.The working principle of wet sawdust biomass pellet processing equipment

Wet sawdust pellet processing equipment is key to converting damp sawdust into uniform, dry, and storable wood pellets. Its operating principle generally includes three core stages: drying, compression molding, and cooling. The entire process is designed to increase the density of the raw material, reduce its moisture content, and enhance its performance as a biomass fuel or other applications.

2.Characteristics of wet sawdust biomass pellet processing equipment

(1)Strong adaptability to raw materials: It can process a variety of wet sawdust and biomass raw materials, including wood processing waste such as eucalyptus, birch, and poplar, as well as crop straw, bamboo chips, etc. Through pre-treatment steps such as drying and screening, wet sawdust is converted into raw materials that meet the requirements of pelletizing.

(2)Integrated processing flow: The equipment is usually equipped with integrated production lines such as drying, pelletizing, cooling, and packaging to ensure the continuous processing of wet sawdust from raw materials to finished pellets.

(3)Key technologies in the drying process: Some equipment integrates drying functions to quickly reduce the moisture content of wet sawdust and meet the moisture content requirements of raw materials before pelletizing.

3.Application scenarios of wet sawdust biomass pellet processing equipment

(1)Wood processing and furniture manufacturing industry clusters

Typical scenarios: solid wood furniture factories, plywood factories, wood flooring factories, and woodworking machinery factories;

Equipment function: converts wet sawdust, which originally required payment for transportation, into biomass pellets that can be used for self-use or export (for example, furniture factories use pellets instead of natural gas to heat and dry wood, reducing energy costs).

(2)Forestry felling and timber storage and transportation sites

Typical scenarios: forest farms, log purchasing stations, and timber transshipment terminals;

Equipment function: prevents wet sawdust from becoming moldy and deteriorating during storage and transportation (especially in the rainy season). After being processed into pellets, the volume is reduced to 1/3-1/4 of the original size, reducing transportation costs by more than 60%, and can be sold directly to biomass power plants.

(3)Construction and renovation waste wood processing sites

Typical scenarios: building demolition sites, renovation waste treatment stations, and waste wood recycling plants;

Equipment function: Solve the problem of "wet sawdust being difficult to degrade and easily polluted" (traditional treatment methods are mostly incineration or landfill, which pollute the environment) and convert it into clean pellet fuel, in line with the "construction waste resource utilization" policy requirements.

TONY Brand 3Ton/Hour Wet Sawdust Pellet Manufacturing Plant can take wet sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, wet sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 3Ton/Hour

2. Raw materials: Wet sawdust

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

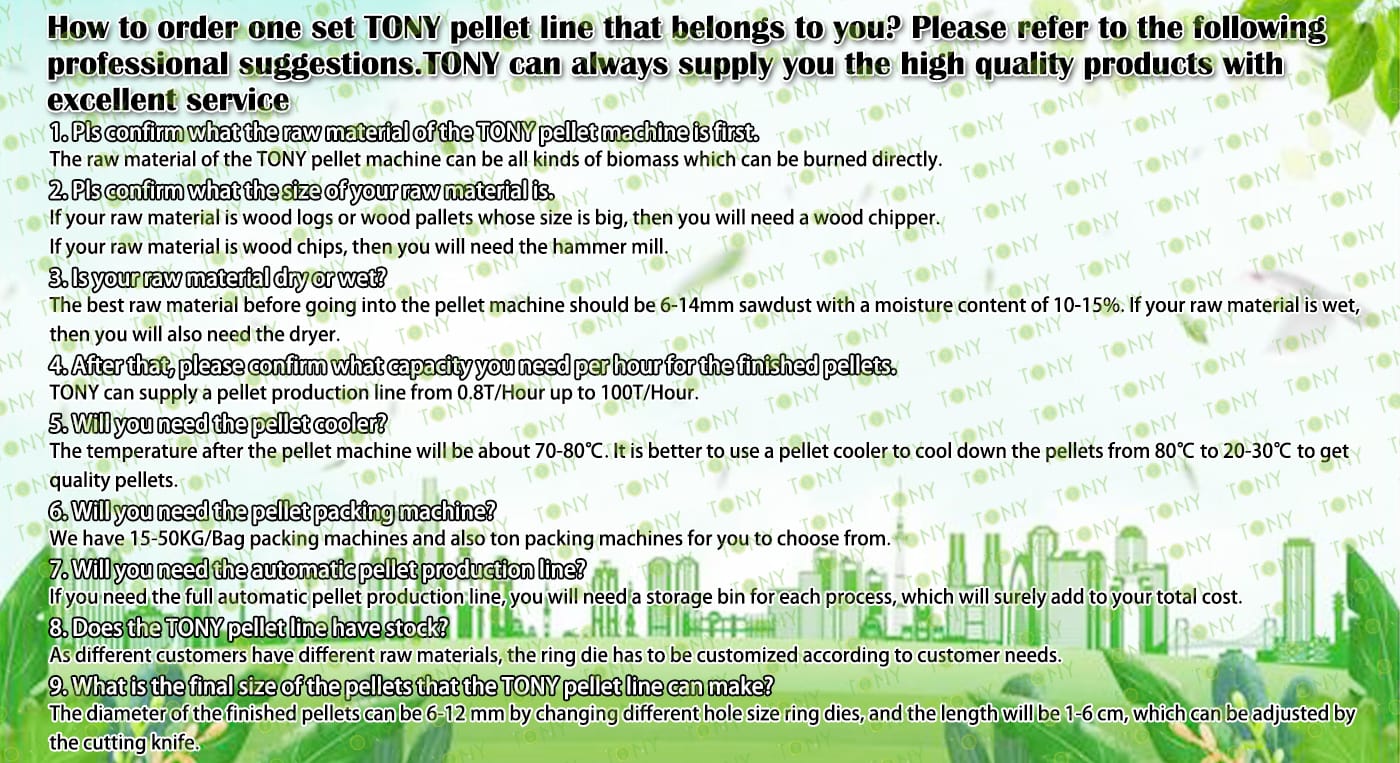

1. Project Name: Wet Sawdust Pellet Production Line

2. Raw Material: All kinds of wet sawdust

3. Moisture Content of Raw Material: 40%

4. Capacity: 3 tons per hour

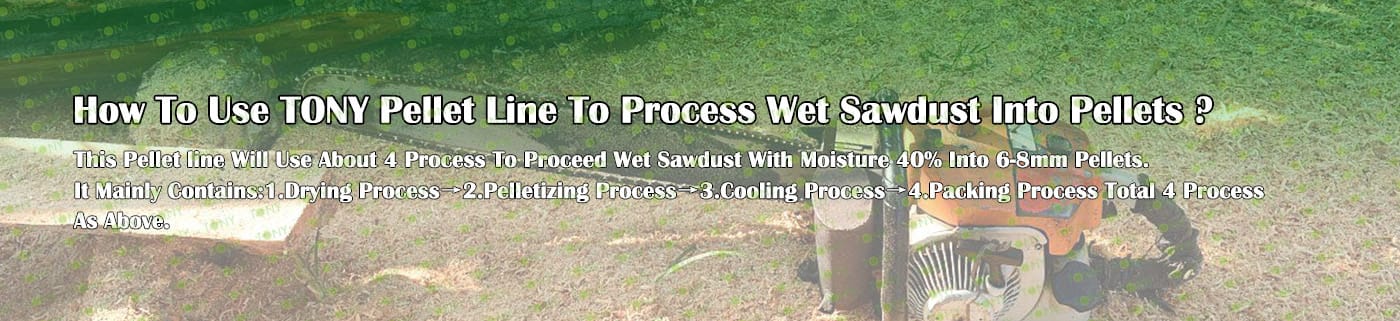

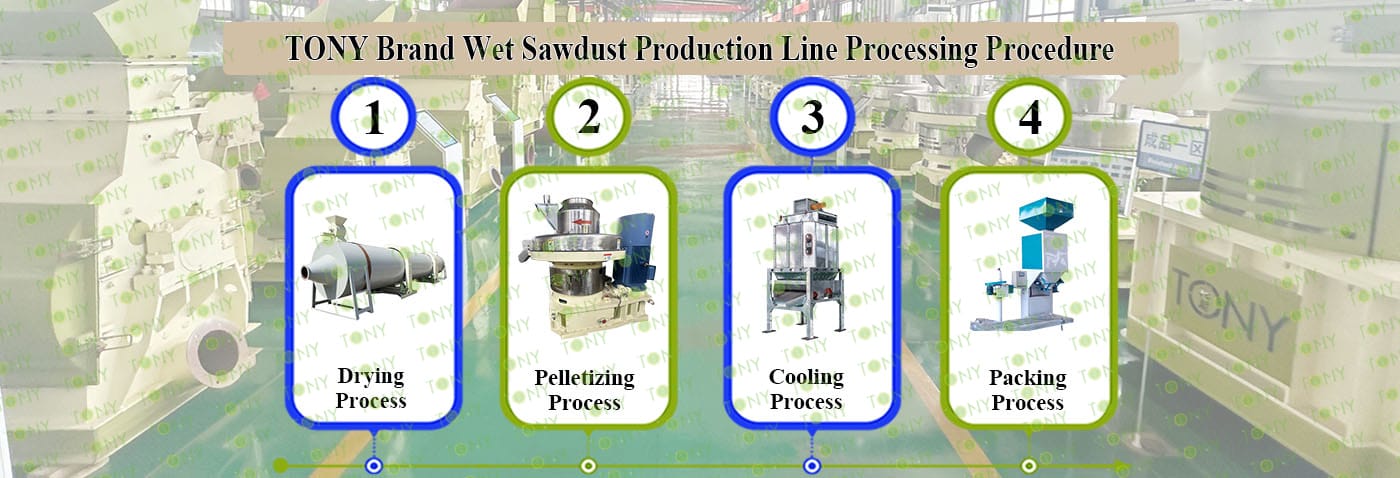

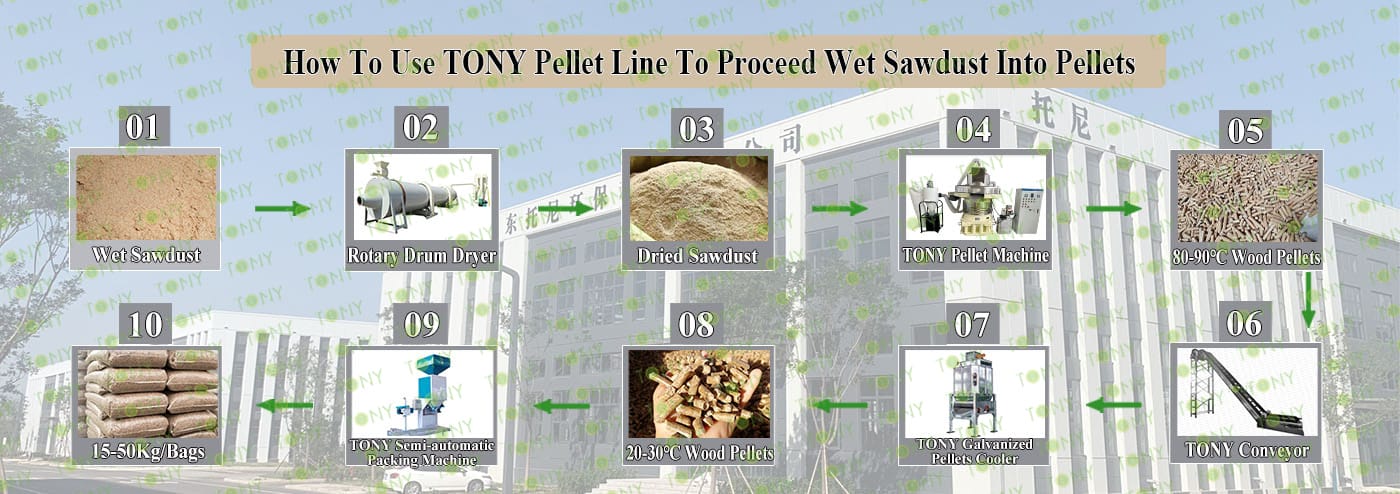

5. Process: Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Rotary Drum Dryer-1.8*15m, TONY Pellet Machine TYJ760-Ⅲ-200KW, Galvanized Pellets Cooler, Semi-automatic Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet sawdust? The process mainly includes the following steps and equipment: 1. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a moisture content of 10%-15%. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY semi - automatic packing machine to pack the pellets into bags, each weighing 15-50 kg. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

三维图

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | |||

|

|

|

|

| Rotary Drum Dryer | Vertical Ring Die Pellet Machine | Galvanized Pellets Coole | Semi-automatic Packing Machine |

| 1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD1.8*15*1set 3.Capacity:3Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ760-III-200KW*1set 3.Capacity:3-3.5Ton/Hour/Set 4.New 304SS Type |

1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-2.5*1set 3.Capacity:3Ton/Hour |

1.To Pack Pellets Into 15-50Kg/Bags. 2.Model: TBF-50*1set 3.Capacity:3Ton/Hour |

三维图

1.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:3Ton/Hour.

C.TONY use 1set of 1.8*15m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:3-3.5Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ760-III-200KW*1set

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity: 3Ton/Hour.

C.TONY brand galvanized pellets cooler *1set

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 15-50Kg/Bags.

B.Capacity:3Ton/Hour.

C.TONY semi-automatic packing machine*1set

Main Parts:

(1)TONY's Semi-Automatic Packing Machine.

(2)Sew Machine, Buyer Can Also Choose Hot Seal Machine For Chosen,To Confirm With Tony For The Price Difference.

(3)Bags Transportation Conveyors.

(4)Feeding Inlet Silo.

(5)Electrical Cabinets.

Benefit Analysis of Sawdust Processing Biomass Pellets Project

1.Economic Benefit Advantages:

Fast Return on Investment, Stable Profit Margin The project belongs to the “light asset, fast turnover” type, with flexible investment threshold, clear profit margin, and strong risk resistance. The price of raw materials (sawdust) fluctuates slightly (annual fluctuation is usually less than 10%), and the price of products (biomass pellets) is driven by the energy market (for example, when coal and natural gas prices rise, pellet prices rise simultaneously). “The cost side is stable, and the selling price side is linked to the energy price”, and the ability to resist market risks is better than most processing industries.

2.Environmental Protection and Social Benefit Advantages:

Taking into account both commercial value and social responsibility The project can not only bring economic benefits, but also generate significant environmental protection and social benefits, and enhance the brand value of enterprises:

(1)Significant environmental benefits: The carbon emissions of biomass pellets during combustion are much lower than those of traditional energy - compared with coal, burning 1 ton of pellets can reduce CO₂ emissions by about 1.5 tons and SO₂ emissions by about 0.08 tons, which is in line with the “dual carbon” goal. Enterprises can further obtain additional income through carbon trading (great potential in the future).

(2)Outstanding social benefits: The project can stimulate local employment (such as positions in raw material recycling, production operations, and logistics distribution), utilize local wood processing waste, contribute to rural revitalization, and easily obtain support from local governments, creating a good environment for the company's subsequent development.

In summary, the sawdust processing biomass pellet project is a high-quality investment direction with low risk and stable returns in the current new energy and environmental protection fields. It is particularly suitable for deployment in areas with concentrated wood processing industries and a large number of industrial boilers.

The physical and chemical properties of sawdust biomass pellets are key to their combustion efficiency, which surpasses that of loose sawdust and approaches that of traditional fossil fuels. This is primarily reflected in the following three key aspects:

1.Stable calorific value and high energy density

The lower calorific value of sawdust pellets is typically 4200-4800 kcal/kg (this varies slightly depending on the wood type; hardwood sawdust pellets have a higher calorific value, reaching 4600-4800 kcal/kg), approaching that of Class II bituminous coal (4500-5500 kcal/kg). Furthermore, due to the "drying (moisture content controlled at 10%-15%) + compression" process during processing, the calorific value is evenly distributed, avoiding the "calorific value loss" associated with excessive moisture content in loose sawdust (which often exceeds 20%) (each 1% increase in moisture reduces the calorific value by approximately 50 kcal/kg).

2.Excellent combustion completeness and low heat loss

The pellets have a regular shape (6-10mm diameter, 20-30mm length) and a dense structure. This allows for sufficient air contact with the pellet surface during combustion. The combustion process does not cause "coking" like coal (the ash content of sawdust pellets is only 2%-5%, far lower than the 10%-20% of coal), nor does it cause "accumulation and smoldering" like loose sawdust. The final burnout rate can reach over 95% (coal burnout rates are approximately 85%-90%, loose sawdust approximately 80%-85%), with minimal unburned "charcoal residue" and significantly reduced heat loss.

3.Fast ignition and stable combustion, reducing startup losses.

The pellets have a low moisture content and a moderate surface area (smaller than pulverized coal, making them less prone to deflagration; larger than lump wood, making them easier to ignite). Ignition takes only 3-5 minutes (loose sawdust takes 10-15 minutes, and wet coal can be difficult to ignite). Furthermore, the combustion process is stable, with minimal temperature fluctuations (the furnace temperature can remain stable at 800-1000°C), avoiding excessive heat loss caused by repeated ignition or fluctuating fires.

2025 Tony Machinery - All Rights Reserved. Map