1.The working principle of wet sawdust biomass pellet processing equipment

(1)Drying stage: Remove moisture to meet molding requirements

Wet sawdust usually has a high moisture content (up to 30%-50%) and must first be dried to a level suitable for pelleting (generally controlled below 10%-15%).

(2)Compression molding stage: High-pressure extrusion to form pellets The dried sawdust enters the compression system of the pellet machine and is extruded into pellets under high temperature and high pressure.

During the compression process, the natural lignin in the wood softens due to heat, acting as a binder, making the pellet structure more compact and stronger;

(3)Cooling and screening: Stabilizing pellet quality The newly made pellets are hot and loose in structure, so they need to be cooled and screened.

After cooling, the pellets become harder, less prone to breakage, and easier to transport and store;Screening can remove excessively fine powder or agglomerated particles, ensuring uniform particle size and stable quality of the final product.

2.Characteristics of wet sawdust biomass pellet processing equipment

(1)High efficiency and energy saving: For example, pellet machines have low energy consumption, high output, compact process, small footprint, good dust removal effect, low noise, and a good production environment. A production line only requires 2-3 workers and can be operated automatically, reducing labor costs.

(2)Low maintenance cost and easy operation: Sawdust pellet machines have low maintenance costs and do not require grease injection. Non-professionals do not need much time to complete maintenance. The wearing parts are practical and durable. The roller bearings are made of international brands and are not easy to damage. They are easy to operate and do not require professional operation.

(3)Raw material processing and environmental protection: The moisture content of the raw materials before pellet processing needs to be controlled at about 10-15%. Therefore, in actual production, drying equipment may be required. Sawdust pellets contain few harmful substances and the content of harmful gas components during combustion is extremely low. The ash after combustion can be used as potash fertilizer, which meets environmental protection requirements.

3.Application scenarios of wet sawdust biomass pellet processing equipment

The deployment of wet sawdust pellet processing equipment essentially adheres to the dual principles of "raw material proximity + product proximity"—needing proximity to both wet sawdust production sites (to reduce raw material transportation costs) and pellet demand (to reduce product transportation costs). Therefore, it is primarily concentrated in the following areas:

Wood/furniture industry clusters

Regions rich in forestry resources (such as northern heating areas and biomass power plant clusters);

Cities with strict environmental protection policies and a high demand for solid waste recycling

Across these scenarios, the key is to achieve efficient conversion from wet sawdust to high-value pellets.

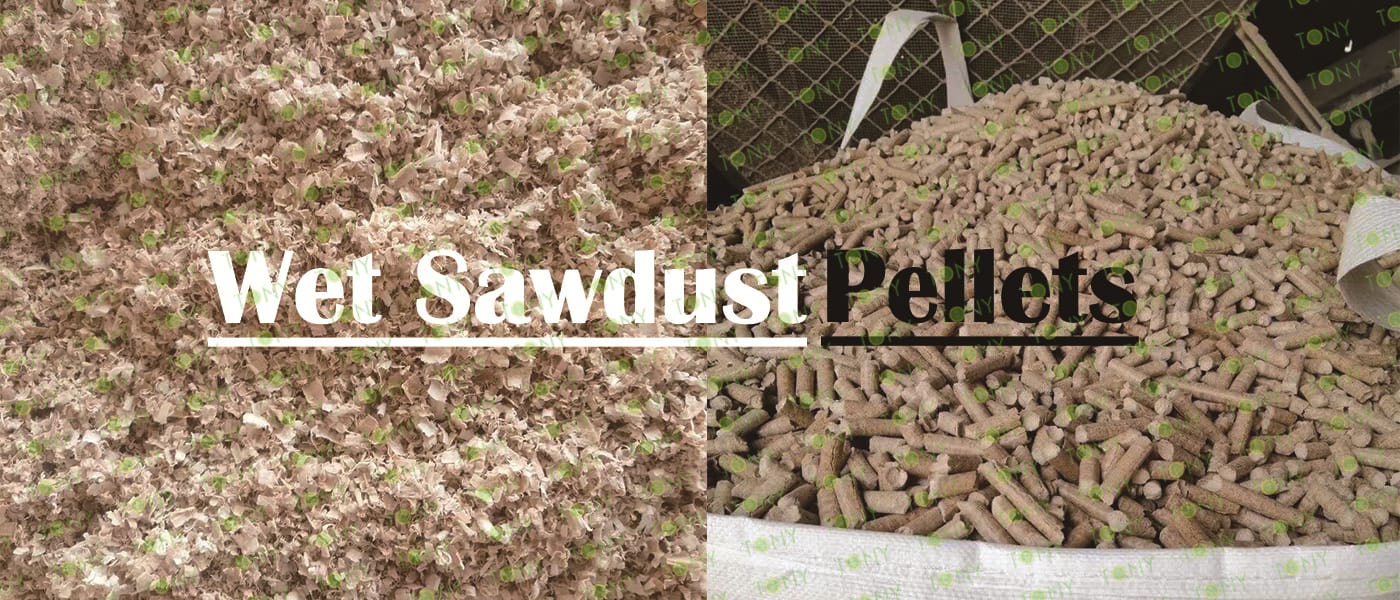

TONY Brand 28-35Ton/Hour Wet Sawdust Pellet Manufacturing Plant can take wet sawdust,wood chips, various types of wood - related biomass materials, such as wood pallets ,branches, wood logs, and wood shavings. After pretreatment and processing, wet sawdust is solidified into high - density wood pellet fuel. This fuel is an ideal substitute for coal and oil and plays a role in energy conservation and emission reduction.

1. Capacity: 28-35Ton/Hour

2. Raw materials: Wet sawdust

3. Moisture: Wet type, about 40%.

4. Application: All kinds of wood sawdust or more waste wood raw materials

Suitable customers:Wood processing plants, furniture manufacturing plants, construction sites, landscaping companies and other places with advantageous sawdust resources

5. Finished Pellets Markets: Large power plants ,domestic heating, industrial heating, combustion heat, heating systems, boiler rooms, school canteens, foundry heat sources.

1. Project Name: Wet Sawdust Pellet Production Line

2. Raw Material: All kinds of wet sawdust

3. Moisture Content of Raw Material: 40%

4. Capacity: 28-35 tons per hour

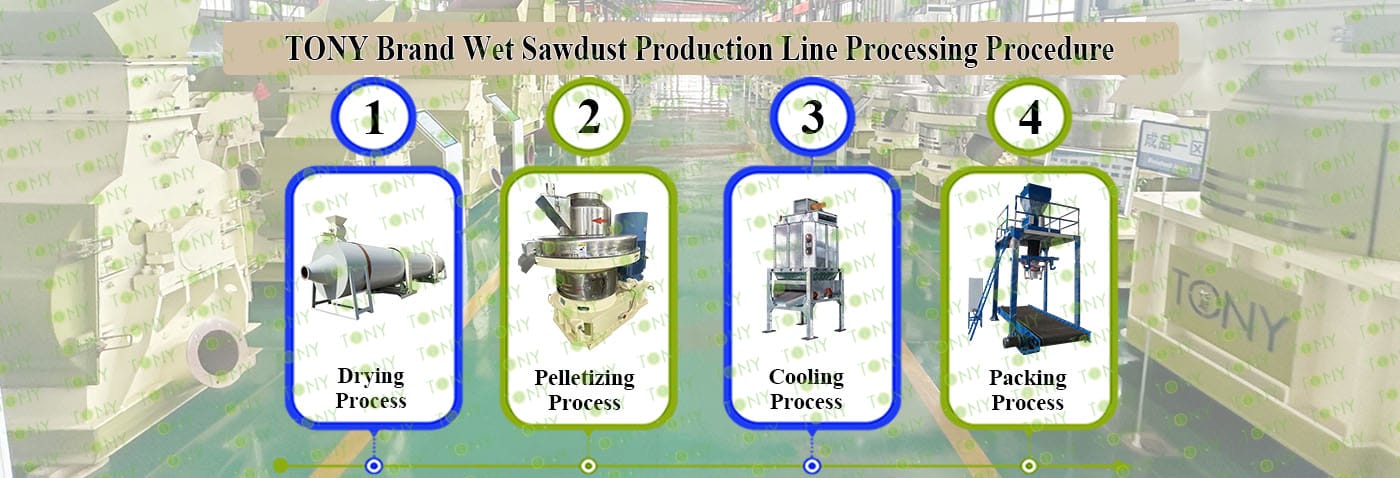

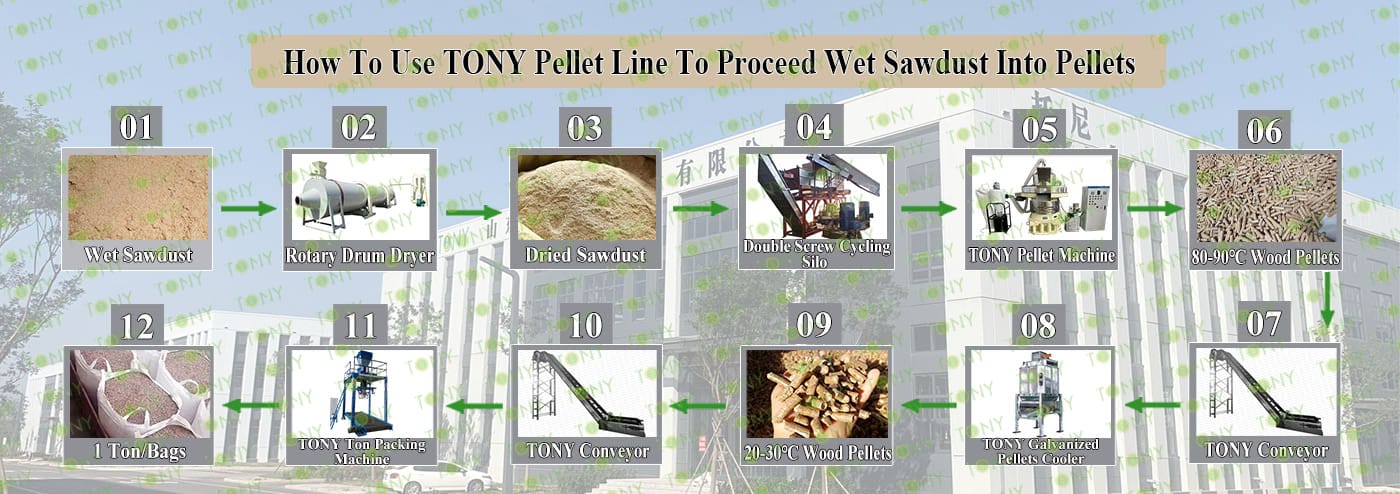

5. Process: Drying Process - Pelletizing Process - Cooling Process - Packing Process

6. Main Equipment: Rotary Drum Dryer-2.2*24m, TONY Pellet Machine TYJ860-Ⅲ-280KW, Galvanized Pellets Cooler, Ton Packing Machine and Belt Conveyors

|

How to use the TONY pellet production line to make pellets from wet sawdust? The process mainly includes the following steps and equipment: 1. Use TONY rotary drum dryer to dry the sawdust with a 40% moisture content down to a mois ure content of 10%-15%. 2. Use TONY vertical ring die pellet machine to produce pellets with a diameter of 6-8 mm. 3. Use TONY galvanized pellets cooler to cool the pellets from 80-90°C to 20-30°C. 4. Use TONY ton packing machine to pack the pellets into bags, each weighing 1 ton. For more detailed information and quotations, you can contact TONY. TONY can provide all the above - mentioned products at highly competitive prices and with excellent quality. |

|

||||||||||||||||||||||||||||||||||||||||

| Next, TONY Will Introduce To You All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some Machines Can Be Custom - Made By Customers According To Different Customers' Detailed Demands. Contact TONY For More Details, Including Quotation And Layout. | ||

|

|

|

| Rotary Drum Dryer | Double Screw Cycling Silo | Vertical Ring Die Pellet Machine |

| 1.To Dry The 40% Sawdust Into 10-15% Sawdust. 2.Model: THGD2.2*24*5sets 3.Capacity:5.5-7Ton/Hour/Set |

1.To Stroage Sawdust Before Pellet Machine; Adjust The Speed Of Sawdust Entering The Pellet Machine 2.Model: TLC-18*2sets 3.Capacity:14-18Ton/Hour/Set |

1.To Press Dry Sawdust Into 6-8mm Biomass Pellets 2.Model: TYJ860-III-280KW*7sets 3.Capacity:4-5Ton/Hour/Set 4.New 304SS Type |

|

|

|

| Galvanized Pellets Cooler | Ton Packing Machine | Belt Conveyor |

| 1.To Cool Pellets From 80-90℃ Into 20-30℃ 2.Model: TCN-10*2sets 3.Capacity:28-35Ton/Hour |

1.To Pack Pellets Into 1Ton/Bags. 2.Model: TBD*2sets 3.Capacity:28-35Ton/Hour |

1.To Transport Sawdust,Pellets. 2.Width: 80cm*18sets 3.Capacity:Designed With The Whole Line |

1.Sawdust Drying Process:

A.This process is mainly used to dry the sawdust from 40% to 10-15%.

B.Capacity:28-35Ton/Hour.

C.TONY use 5 sets of 2.2*24m rotary drum dryer for this process, TONY hot blast stove is made of firebrick pan, shell with H steel plate as the frame. There are 3 layers of fire blocking device inside, which can effectively prevent the fire from entering the tumble dryer.Customers can choose to use waste wood, biomass pellets, natural gas, etc. as fuel for the hot air furnace

TONY dryer use spiral tube material, and is not easy to deform.

Unlike other manufacturers with iron plate splicing welding, very easy to deformation.

Main Parts:

(1)TONY's Rotary Drum Dryer Main Body. (Reducers With Motors and Pips.)

(2)TONY's Hot Stove.

(3)Fan Blower+Cyclone With Airlock.

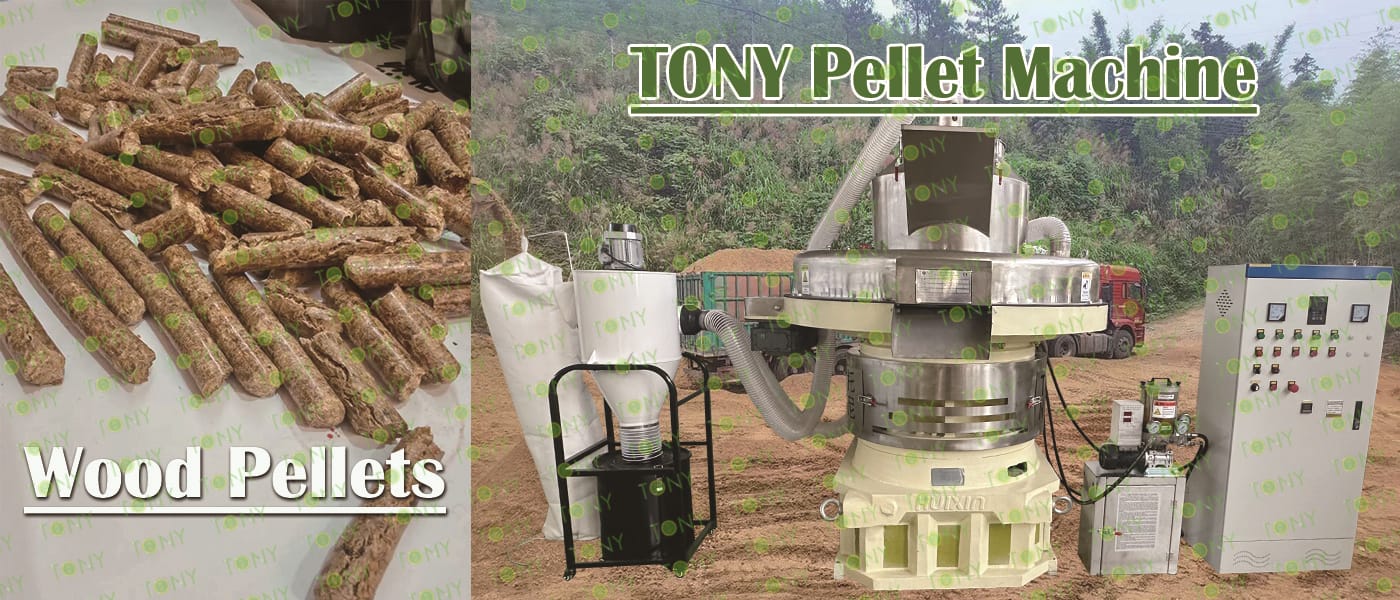

2.Pelletizing Process:

A.This process is mainly used to to product pellets into φ6-8mm.

B.Capacity:28-35Ton/Hour.

C.TONY brand vertical ring die pellet machine TYJ860-III-280KW*7sets

D.Double screw cycling silo is added above the pellet machine, which has the advantages of saving space, saving labor, intelligently controlling the feeding speed, not easy to block the material, and improving production efficiency.

Main Parts:

(1)TONY's New Vertical Ring Die Pellet Machine.

(2)Cyclone And Bags Dust Collectors.

(3)Automatic Lubrication System.

(4)Electrical Cabinets.

You can chose TONY new type SS304 pellet machine

3.Cooling Process:

A.This process is mainly used to cool pellets from 80-90℃ to 20-30℃

B.Capacity:28-35Ton/Hour.

C.TONY brand galvanized pellets cooler *2sets

Main Parts:

(1)TONY's Galvanized Pellets Cooler With Vibrating Screen.

(2)Cyclone And Bags Dust Collectors.

(3)Fan Blower.

(4)Connect Pipes.

4.Packing Process:

A.This process is mainly used to pack pellets into 1Ton/Bags.

B.Capacity:28-35Ton/Hour.

CTONY band ton packing machine*2sets

Main Parts:

(1)TONY Ton Packing Machine

(2)Electronic Platform Scale Metering System

(3)Automatic Tare, Zero, and Drop Correction Functions

(4)Feeding System Features Fast, Medium, and Slow Feeding Speeds to Ensure Measuring Accuracy

The sawdust biomass pellet project is an environmentally friendly investment with broad prospects.

1.Project Background:

Against the backdrop of the deepening implementation of the "Dual Carbon" strategy and the rising costs of traditional energy, the sawdust biomass pellet project has emerged. This project converts sawdust and other waste generated by wood processing plants and furniture factories into high-density biomass pellet fuel through high-pressure extrusion, achieving resource recycling and reuse, meeting environmental requirements, and generating significant economic benefits.

2.Project Investment:

The project investment scale varies depending on the production scale.

3.Equipment Selection:

Selecting efficient, intelligent, and stable sawdust pellet equipment is crucial to the project's success. High-quality equipment should feature core technologies such as high-precision roller die design, strong raw material adaptability, intelligent temperature and pressure control systems, and automatic lubrication and fault detection.

4.Market Demand and Application Scenarios

Stricter environmental protection policies are driving the phase-out of traditional coal-fired boilers. Biomass pellets, due to their cleanliness, high calorific value (comparable to coal), and stable combustion, have become an alternative energy source for industrial boilers, heating equipment, livestock farms, and food processing. Demand has surged, particularly under the "coal-to-biomass" policy.

The environmental advantages of sawdust biomass pellets are their core competitive advantage, primarily reflected in their "low carbon footprint throughout their lifecycle" and "low pollution during combustion":

1.Low carbon and renewable, aligning with the "double carbon" goal:

Sawdust, derived from wood processing waste, is a "biomass resource." The CO₂ absorbed during its growth is essentially balanced by the CO₂ released during combustion, achieving "carbon neutrality." Compared to coal (a fossil energy source whose combustion releases ancient carbon), it can reduce net carbon emissions by over 90%, making it an ideal alternative fuel for achieving both peak and neutral carbon emissions.

2.Low combustion pollutants, reducing the environmental burden:

Combustion is almost sulfur-free (sulfur content ≤ 0.05%) and nitrogen-free (nitrogen content ≤ 0.5%), and does not produce large amounts of SO₂ and NOₓ (the main pollutants from traditional coal combustion), which can significantly reduce the risk of acid rain and haze. The ash content is extremely low (only 2%-5%, far lower than the 10%-20% of coal). The small amount of ash remaining after combustion can be used as organic fertilizer or auxiliary building materials, eliminating the problem of "secondary pollution of solid waste."

3.Non-spontaneous combustion and safe storage:

Pellets have a low moisture content but a dense structure, resulting in a small contact area with air. They won't spontaneously combust at room temperature (they require a high-temperature open flame to ignite). In contrast, pulverized coal and loose sawdust, due to their large surface area, are susceptible to spontaneous combustion due to oxidation and heat generation. Pellets also contain no volatile flammable gases, preventing explosions from leaks like liquefied petroleum gas.

4.No toxic gases are produced during combustion, ensuring safe use:

Pellets do not produce toxic gases such as carbon monoxide (CO) and formaldehyde (assuming complete combustion and suitable combustion equipment). Incomplete combustion of coal can easily produce CO, while firewood can easily produce smoke and tar. Pellets are more health-friendly and are particularly suitable for applications involving direct human or product contact, such as residential heating and food processing (such as drying tea leaves and medicinal herbs).

2025 Tony Machinery - All Rights Reserved. Map